Abstract

An efficient ultrasonic microwave-assisted extraction (UMAE) coupled with macroporous resin chromatography technique was successfully used for the extraction and purification of antioxidant phenolics from jackfruit by-products (peels). After optimization by single factor experiments and response surface methodology, the optimum extraction conditions for UMAE were: ethanol concentration 63%, solvent-to-solid ratio 34 mL/g, microwave power 160 W and irradiation time 20 min. Under the optimal condition, the phenolics extraction yield was 8.14 mg GAE/g DW. After the purification by macroporous resin AB-8, the purity of antioxidant phenolics from UMAE extracts improved from 13.59 to 49.07%. Furthermore, ABTS radical scavenging activities were also significantly increased from 35.95 ± 2.21 to 162.36 ± 10.26 mg TE/g. HPLC analysis revealed that gallic acid, chlorogenic acid, and catechin were three dominant antioxidant phenolics in jackfruit peels. All of the results demonstrated that waste jackfruit peels could be utilized as a good source of phenolics with strong antioxidant activities in food and pharmaceutical industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Jackfruit (Artocarpus heterophyllus) is the largest fruit in the world, and mainly cultivated in and around tropical areas (Shyamalamma et al. 2008). Jackfruit is rich in vitamins and minerals, and offers numerous health benefits (de Faria et al. 2009; Swami et al. 2012). After processing, jackfruit residues, e.g. peel, is usually discarded as a waste and prone to microbial spoilage, which was not only a waste of resource, but also pollution to the environment. Virtually, jackfruit by-products are still rich in beneficial substances with high added value, which may find application as ingredients in the food, feed, cosmetics, and pharmaceutical industries. In recent years, many polyphenolic compounds have exhibited various biological activities, including antioxidant (Balasundram et al. 2006), anti-inflammatory (Hsu et al. 2013) and antimicrobial activities (Alves et al. 2013), and so forth. However, to the best of our knowledge, few information is available about the phenolics from jackfruit by-products (peels).

Extraction of phenolics is one of the most imperative steps for both application and further research and development. Various efficient and advanced extraction methods have been investigated, such as super critical fluid (CO2) extraction (SCFE), ultrasound-assisted extraction (UAE), and microwave-assisted extraction (MAE). However, these extraction techniques have drawbacks to some extent. For example, despite representing non-organic solvents residing as advantage, SCFE equipment is expensive with a high-energy consumption (Zhang and Liu 2008). Microwave-assisted extraction offers a rapid, clean, safe, and cost-effective method for heating that can cause a thermal effect by polarizing macromolecules, leading to alignment with electromagnetic field poles that may cause the breakage of hydrogen bonds, while its disadvantage is inhomogeneous heating (Lou et al. 2012; Liu et al. 2014). Ultrasound-assisted extraction relies on acoustic cavitation, which causes disruption of cell walls of plant materials, resulting in a more extensive release of internal cell compounds and a more homogeneous system (Pongmalai et al. 2015; Fan et al. 2015). Thus, ultrasonic microwave-assisted extraction (UMAE) may be an effective complementary technology for dramatically accelerating the extracting process, improving selectivity and simplifying manipulation (Xiao et al. 2012).

As for the separation and enrichment of phenolics, macroporous resins, with different physicochemical properties including specific surface area, pore diameter and polarity, have been successfully applied for the purification and enrichment of bioactive compounds from natural resources (Feng et al. 2015; Wang et al. 2013).

In the present study, UMAE technique was used as rapid and efficient extraction process for phenolics from jackfruit peels for high yields. Several processing parameters that could potentially influence the extraction efficiency were analyzed and optimized using RSM. Then, macroporous resin chromatography was employed to separate the crude extracts into six fractions with diverse phenolics contents and antioxidant activities. Finally, reverse phase high-performance liquid chromatography (RP-HPLC) method was established for qualitative identification and quantitative analysis of phenolics-enriched fractions.

Materials and methods

Samples

Fresh jackfruit fruits were purchased from local fruit center in Haikou City, Hainan Province of China. It was manually peeled and cut into small pieces (the moisture content for 84.5%), which were dried in a hot air oven at 60 °C for 48 h before being grinded and powdered (60 mesh).

Chemicals

ABTS [2,2′-azino-bis (3-ethylbenzthiazoline-6-sulfonic acid)] and Folin-Ciocalteu reagent were provided by Huadong Chemicals Co. (Hangzhou, China). Trolox, gallic acid, chlorogenic acid, catechin, rutin, quercetin, norartocarpetin and artocarpesin were obtained from Sigma Chemical Co. (St, Louis, MO, USA). Acetonitrile of HPLC grade was purchased from Merk (Darmstadt, Germany). The other chemical reagents were of analytical grade. Macroporous resins including HP20, D101, AB-8, NKA-II and S-8 were purchased from Nankai University Chemical Plant (Tianjin, China).

Ultrasonic and microwave assisted extraction

Phenolic compounds from powers of jackfruit (A. heterophyllus Lam.) peel were extracted using a domestic oven system (CW-2000, Shanghai Xin-tuo Microwave Instrument Co. Ltd., Shanghai, China). The apparatus was equipped with an open microwave with maximal power of 800 W at a frequency of 2450 MHz, and an ultrasonic transducer with a fixed power of 50 W at a frequency of 40 kHz. For each extraction, the pre-treated jackfruit peel powders (1 g) were weighed accurately and then transferred into the flask and proper volume (assigned according to the experimental design) of aqueous ethanol was added. Subsequently, the flask was transferred into the chamber of the apparatus connected with condensing tubes. Finally, the door of chamber was closed and the program of the parameters (microwave power and extraction time) according to the experiment planning was set for the extraction of phenolic compounds. When the extraction was accomplished, the flask was removed from apparatus and the resulting mixture was filtrated, then the volume of the filtrate and phenolic content in it were measured. Triplicate experiments were done for each design.

Response surface methodology (RSM)

Single-factor-test was employed to determination the preliminary range of the extraction variables including X1 (ethanol concentration, %), X2 (microwave power, W), X3 (irradiation time, min) and X4 (solvent-to-solid ratio, mL/g). Then, a three-level-four-factor Box–Behnken design (BBD) was conducted to determine the best combination of extraction variables for maximum recovery of total phenolic compounds (TPC) from jackfruit peels. Regression analysis was performed on the basis of the experimental data and fitted to a quadratic polynomial model presented in the following equitation:

where Y is the predicted response (the yield of TPC in mg gallic acid equivalents (GAE)/g dry weight (DW) basis); β0, βi, βii, βij are the regression coefficients for intercept, linearity, square and interaction, respectively; Xi and Xj are the independent variables.

Design Expert software (Trial Version 8.0.5, Stat-Ease Inc., Minneapolis, MN, USA) was used to estimate the response of each set of experimental design and optimized conditions. The adequacy of the generated quadratic polynomial model was evaluated by the regression coefficient R2 as well as the lack of fit using the F test. F value and p value were used to check the significances of the regression coefficient.

Determination of total phenolics

Total phenolics (TPs) content of the extract from jackfruit peels were determined using Folin–Ciocalteu reagent, according to a procedure described by Altemimi et al. (2015). Briefly, 1.5 mL of properly diluted extract solution were mixed with 2 mL of Folin–Ciocalteau reagent and shaken vigorously. After incubation for 5 min, 2 mL of sodium carbonate solution (10% w/v) was added into the mixture, following by topping up the mixture to 25 mL with distilled water. After standing for 40 min in the dark at room temperature, the absorbance was measured at 760 nm using a UV–Vis spectrophotometer against a reagent blank without the extract. A calibration curve (A = 0.0729 X + 0.0008, R2 = 0.9985) was established using standard solution of gallic acid (0–400 µg/mL). The results were expressed as mg of gallic acid equivalents (GAE) per gram of powder on dry weight basis.

Total antioxidant capacity assay

The total antioxidant capacity assay of the crude extract or fractions was determined with ABTS method, according to the procedure described by Mocan et al. (Mocan et al. 2014), with slight modifications. ABTS+·Bradical solution was generated by mixing 7 mM ABTS solution with 2.45 mM potassium persulfate solution and was kept at room temperature in dark for 12–16 h. Then, the ABTS+· radical solution was diluted with methanol to a final absorbance of 0.70 ± 0.02 at 734 nm to produce ABTS+· working solution. 5 µL of samples or blank (distilled water) was rapidly added in corresponding wells of 96-microplate, followed by addition of 200 μL of ABTS+· working solution to each well. After reaction for 5 min at 25 °C, the absorbance was measured at 734 nm by using the microplate reader. The percentage of ABTS consumption was converted to Trolox equivalents (TE) using a calibration curve with Trolox standard solutions of 10–400 mg/L. The higher the rate of ABTS consumption is, the stronger the antioxidant capacity.

Static adsorption/desorption tests for screening of resins

In the static adsorption/desorption experiments, each of pretreated hydrated adsorbents (equal to 1 g of dry resins) was put into a conical flask (100 Ml) with stopper, followed by the addition of 40 mL of crude extract solutions to each flask. Then, the flasks were continually shaken (120 rpm) in a thermostatic oscillator (TOPT-1102, Xi’an Toption Instrument Co., Ltd., China) at 30 °C for 24 h. After adsorption equilibrium, the resins were washed with distilled water twice and then desorbed with 30 mL of 90% (v/v) ethanol solution. The total phenolics content of supernatants before and after desorption was determined.

The adsorption capacity, adsorption ratio and desorption ratio of different resins were calculated according to following equation:

where \( Q_{e} \) is the adsorption capacity (mg/g dry resin); \( C_{0} \) and \( C_{e} \) are the initial and equilibrium concentrations of phenolics in the solutions, respectively (mg/mL); \( V_{a} \) is the volume of phenolics solution (mL) and \( W \) is the weight of the dry resin used (g); \( E \) and \( D \) is the adsorption ratio (%) and desorption ratio (%), respectively; \( C_{d} \) is the concentration of phenolics in the desorption solution (mg/mL); \( V_{d} \) is the volume of the desorption solution (mL).

Purification of phenolics by resin column

Purification experiments were carried out on a glass column (300 mm × 25 mm i.d.) packed with the selected resin. The bed volume (BV) of the wet-packed resin was 120 mL. 1 g of jackfruit peels extract was dissolved in 20 mL of distilled water and carefully applied to the column. After adsorption equilibrium, the column was firstly washed with distilled water to remove water soluble impurities such as sugar, protein, pigment and other water-soluble molecules, and then sequentially eluted with 3 BV of 10%, 30%, 50%, 70% and 90% (v/v) ethanol solution at a constant flow rate of 2 mL/min. Each fraction was collected, evaporated in vacuum, and then freeze-dried. The fractions were weighed and stored at − 18 °C until the evaluation of their total phenolics content and antioxidant capacity was performed.

HPLC–DAD analysis

The HPLC analysis of the sample obtained under optimal conditions was performed on an Agilent 1260 Series HPLC System equipped with a quatermary pump, a diode array detector (DAD) and a autosampler (Agilent, Palo Alto, CA, USA). Chromatographic separation was accomplished with a AichromBond C18 analysis column (250 × 4.6 mm, 5 µm, Agilent, Palo Alto, CA, USA). The mobile phase was composed of acetonitrile (A) and 0.1% formic acid aqueous solution (B) with a detecting wavelength at 280 nm. The mobile phase gradient was programmed as follows: 0–5 min, 8% A; 5–15 min, 8–35% A; 15–20 min, 35–42% A; 20–25 min, 42–55% A; 25–35 min, 55–60% A; 35–40 min, 60–8% A. The flow rate was set to 1 mL/min and the injection volume was 5 µL. The phenolic compounds present in the samples were tentatively identified by comparing their retention times with those of the reference standards, while the quantitative determination was performed with the external standard method.

Results and discussion

Single factor experiment

Effect of ethanol concentration

In order to evaluate the effect of ethanol concentration on phenolics extraction yield, extraction process was carried out at various ethanol concentration (30–70%) and the results were shown in Fig. 1. The yield of phenolics increased first and then reduced with the further increase of ethanol concentration, and reached the maximum (6.68 mg GAE/g) at 60% ethanol aqueous solution. It was reported that water is acted as the plant swelling agent, while ethanol is believed to disrupt the bonding between the target components and plant matrices (Liu et al. 2013). Water and low ethanol concentration can easily pass through the cell membranes, but a high ethanol concentration can cause protein denaturation, preventing the dissolution of phenolics and then resulting in the decrease of mass transfer (Dahmoune et al. 2015). Hence, the ethanol concentration of 60% was suitable for the extraction of phenolics.

Effect of solvent-to-solid ratio

The ratio of solvent to solid also played a potentially important parameter for efficient extractions. If the ratio of solvent to solid was too small, phenolics in plant tissue cannot be completely dissolved out and released into the extraction medium. Conversely, if the ratio of solvent to solid is too high, it will cause high process cost (Zou et al. 2011). In this study, the effect of ratio of solvent to solid on extraction yield of phenolics from jackfruit peels was investigated, and the results were listed in Fig. 1. It could be founded that the extraction yield of phenolics continued to increase evidently with the increase of ratio of solvent to solid, and reached to a maximum value at 30 mL/g. However, as the ratio exceeded 30 mL/g, the extraction yields were almost constant regardless of increase of ratio of solvent to solid. Considering the saving of solvent and easy operation, the ratio of 30 mL/g was used as the following optimized experiments.

Effect of microwave power

The effects of microwave power on the yield of phenolics from jackfruit peel were investigated at levels ranging from 50 to 200 W. As shown in Fig. 1, the yield of phenolics increased with the increase of microwave power at the beginning of extraction, and reached the maximum (7.30 mg GAE/g) at 150 W. It could be due to the fact that microwave absorption causes fast internal heating, thus generating significantly high internal pressures in plant material. This causes the cell walls to swell and burst, thus promoting the release and dissolution of target components into the solvent (Lu et al. 2011). However, an evident decrease in the extraction yield of phenolics was observed beyond 150 W. This might be attributed to the thermal degradation of the phytochemicals at higher microwave output power levels. The findings were similar with the research results reported by Ahmad and Langrish (2012). Therefore, microwave power level 150 W was selected for further RSM optimization.

Effect of irradiation time

Generally speaking, by increasing the irradiation time, the quantity of target compounds extracted is increased, although there a risk of degradation of extracted active compounds. In the present study, the yield of phenolics was investigated at various irradiation times (5–25 min). As shown in Fig. 1, the first increase of irradiation time within 5–15 min resulted in a significant increase of phenolics yield, and then the further increase of irradiation time led to the decrease of phenolics yield beyond 15 min. The findings indicated that prolonging irradiation time was not in favor of the yield of phenolics, possibly due to the chemical structural destruction and the decomposition of active compounds in longer exposure periods (Sun et al. 2011). As a result, 15 min was an appropriate irradiation time for further UMAE experiments.

Optimization of UMAE by RSM

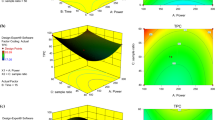

Statistical analysis and the model fitting

BBD with four factors and three levels were empolyed to optimize the mutual effect of four independent variables (ethanol concentration, solvent-to-solid ratio, microwave power and irradiation time) on the extraction yield of phenolics. Table 1 showed the design matrix and the extraction yields of phenolics. By applying multiple regression analysis on the experimental data, the response variable and the independent variables could be related using the following second-order equation:

Statistical testing of the developed model was performed in the form of analysis of variance (ANOVA) by software of Design-Expert 8.0.5. The ANOVA for the experiment results are listed in Table 2. High F value (F = 34.55) with a very low p value (p < 0.0001) suggested that the developed model was statistically significant, demonstrating that the extraction yield of TPs could be well predicated within the variable range employed with the model. Significance of the fitted model was also judged by lack-of-fit (Ji et al. 2012). As shown in Table 2, F value (F = 24.45) and p value (p = 0.0537) of the lack of fit implied that it was not significant relative to the pure error, which further confirmed that the fitted model adequately represented the experimental results under any combination of values of the variables during UMAE. The value of the determination coefficient (R2) evaluated from the second-order regression model was 0.9719, while the value of adjusted R-square (R 2adj ) was 0.9437, indicating a good degree of correlation between the actual and predicted values (Firatligil-Durmus and Evranuz 2010). At the same time, the relatively low value of coefficient of variation (C.V. = 4.76%) demonstrated a high degree of precision and good reliability of the experimental results. It is widely accepted that a model should be considered reasonably reproducible if the C.V. value is lower than 10% (Karabegović et al. 2013). All these results above suggested that the fitted model could work well for the prediction of TPC extract from jackfruit peels.

The F and p values are used as a tool to confirm the significance of each coefficient. The smaller the p value, the more significant the corresponding coefficient (Wu et al. 2015). According to the p and F values (Table 3), the linear coefficients (X1, X2 and X3), quadratic term coefficients (X 21 , X 22 and X 23 ) and cross product coefficients (X1X4) were significant, with very small p value (p < 0.05). Meanwhile, the ethanol concentration was the most significant factor affecting the extraction yield of phenolics.

Optimization of extracting parameters and validation of the model

According to regression model, the optimum conditons were ethanol concentration 62.93%, solvent-to-solid ratio 34.39 mL/g, microwave power 160.49 W and irradiation time 20 min. Under above conditions, the model predicted a maximum response of 8.21 mg GAE/g DW. Considering the actual operability, the optimized condition was modified as following: ethanol concentration 63%, solvent-to-solid ratio of 34 mL/g, microwave power of 160 W and irradiation time 20 min. To validate the suitability of the model equation, a verification experiment was carried out. In the verification experiment, the average yield of phenolics was 8.14 mg GAE/g DW (n = 3), which was no significant difference from the predicted value within the 95% confidence interval. This good correlation confirmed that the response model was adequate for reflecting the expected optimization.

Selection of macroporous adsorption resin

Static adsorption and desorption tests were investigated in order to select appropriate macroporous resins. The macroporous adsorption resins exhibit higher adsorption capacity not only because of their similar polarity with the target compounds, but also because of their higher surface area and larger average pore diameter (Lin et al. 2012). Furthermore, phenolics possessing hydrogen groups and benzene rings, could be adsorbed by weak-polar or polar resins with appropriate surface area and average pore diameter. Therefore, five sorts of commonly used commercial macroporous resins, varying from non-polarity to polarity, were tested to acquire the most suitable resin for adsorbing and separating phenolics from jackfruit peels. The adsorption capacities and desorption ratios of the resins are depicted in Table 3. Results demonstrated that among five resins, AB-8 and S-8 exhibited considerably high adsorption capacities (41.67 and 44.37 mg TP g−1 resin, respectively) and asorption ratios (54.90% and 58.68%, respectively). But as far as desorption ratio, it was very low for S-8 (37.66%) which was likely attributed to its strong polarity and adsorbability, which inevitably leaded to difficult desorption of phenolics, while it was comparatively high for AB-8 (94.20%). The polarity differences between AB-8 and S-8 is due to the result of different polar groups on their structural surfaces, which results in their distinctly different desorption abilities (He and Xia 2008). AB-8 exhibited moderate polarity compared with S-8. As a result, AB-8 resin possessed a relatively higher adsorption selectivity for phenolics in the complex extract solution as well as higher desorption ratio. Thus, AB-8 resin was selected as an appropriate macroporous resin for the enrichment and separation of phenolics.

Purification of phenolics by resin column

The purification of phenolics was performed by the adsorption of resin and desorption of aqueous ethanol. As shown in Table 4, the majority of the phenolics absorbed by AB-8 resin were obtained when desorption agents of 30% and 50% ethanol solution were used. The total phenolics accounted for over 40.51% and 57.22% in the 30% and 50% ethanol fractions, respectively. In addition, the substances with excellent antioxidant ability were also found in the 30% and 50% ethanol fractions obtained from AB-8 resin column, especially in 50% ethanol fraction. The ABTS+· radical scavenging capacity of the 30% and 50% ethanol fractions were 3.06–4.52 times higher than that of original crude extract. The results demonstrated that the total phenolics content in jackfruit peels extract had a significant correlation with its antioxidant capacity. Consequently, AB-8 could be used as effective macroporous resin for the purification of antioxidant phenolics from waste jackfruit peels. The phenolic-enriched fractions, namely 30% and 50% ethanol fractions, were combined, concentrated and freeze-dried for further HPLC–DAD analysis.

HPLC–DAD analysis

Due to the fact that phenolics usually exist in complex plant matrices together with a large variety of other phytochemicals, the direct analysis of phenolics from complex extracts is a challenging task. Thus, the macroporous resin chromatography, with high adsorption capacity, good stability and easy regeneration, was used for purification of phenolics from original crude extracts of jackfruit peels. As shown in Fig. 2, Gallic acid, chlorogenic acid, catechin were identified in the extract of jackfruit peels by comparing the rentention times with authentic standers. The amount of individual phenolics (expressed as mg g−1 of dried plant) were as follows: 0.68 ± 0.01 Gallic acid, 2.53 ± 0.04 chlorogenic acid, 0.56 ± 0.01 catechin in jackfruit peels. The results revealed that chlorogenic acid was the dominant phenolic compound in jackfruit peels. Chlorogenic acid has been documented to effectively scavenge free radicals and improve antioxidant defenses in humans and animals (Sun et al. 2015), and might be mainly responsible for the antioxidant activity of enriched phenolic extract from jackfruit peels.

Conclusion

An efficient extraction and purification technique based on ultrasonic microwave-assisted extraction method combining macroporous resin chromatography was established to obtain phenolics-rich fraction from jackfruit by-products. The final results demonstrated that the optimum extraction conditions for UMAE were: ethanol concentration 63%, solvent-to-solid ratio of 34 mL/g, microwave power of 160 W and irradiation time 20 min. Under the optimal extraction conditions, the phenolics extraction yield was 8.14 mg GAE/g DW. The best macroporous resin for the purification of phenolics was AB-8 resin. After the purification by macroporous resin chromatography, the purity of phenolics in the crude extracts improved from 13.59 to 49.07%. HPLC–DAD analysis revealed that chlorogenic acid was the dominant phenolic compound in jackfruit peels. Furthermore, total phenolics content showed good correlations with antioxidant activities, indicating that waste jackfruit peels could be utilized as a good source of phenolics with strong antioxidant activities for food and pharmaceutical industry. The study provides a new way for utilization of waste jackfruit peels. These results could be helpful in the development of large-scale batch adsorption–desorption system for use in the production of antioxidant phenolics from jackfruit peels.

References

Ahmad J, Langrish T (2012) Optimisation of total phenolic acids extraction from mandarin peels using microwave energy: the importance of the Maillard reaction. J Food Eng 109:162–174

Altemimi A, Choudhary R, Watson DG, Lightfoot DA (2015) Effects of ultrasonic treatments on the polyphenol and antioxidant content of spinach extracts. Ultrason Sonochem 24:247–255

Alves MJ, Ferreira ICFR, Froufe HJC, Abreu RMV, Martins A, Pintado M (2013) Antimicrobial activity of phenolic compounds identified in wild mushrooms, SAR analysis and docking studies. J Appl Microbiol 115:346–357

Balasundram N, Sundram K, Samman S (2006) Phenolic compounds in plants and agri-industrial by-products: antioxidant activity, occurrence, and potential uses. Food Chem 99:191–203

Dahmoune F, Nayak B, Moussi K, Remini H, Madani K (2015) Optimization of microwave-assited extraction of phenolics from Myrtuscommunis L. leaves. Food Chem 166:585–595

de Faria AF, de Rosso VV, Mercadante AZ (2009) Carotenoid composition of jackfruit (Artocarpus heterophyllus), determined by HPLC − PDA − MS/MS. Plant Foods Hum Nutr 64:108–115

Fan T, Hu J, Fu L, Zhang LJ (2015) Optimization of enzymolysis-ultrasonic assisted extraction of polysaccharides from Momordica charabtia L. by response surface methodology. Carbohydr Polym 115:701–706

Feng S, Luo Z, Tao B, Chen C (2015) Ultrasonic-assisted extraction and purification of phenolic compounds from sugarcane (Saccharum officinarum L.) rinds. LWT Food Sci Technol 60:970–976

Firatligil-Durmus E, Evranuz O (2010) Response surface methodology for protein extraction optimization of red pepper seed (Capsicum frutescens). LWT Food Sci Technol 43:226–231

He ZY, Xia WS (2008) Preparative separation and purification of phenolic compounds from Canarium album L. by macroporous resins. J Sci Food Agric 88:493–498

Hsu CL, Fang SC, Yen GC (2013) Anti-inflammatory effects of phenolic compounds isolated from the flowers of Nymphaea mexicana Zucc. Food Funct 4:1216–1222

Ji YB, Dong F, Ma DB, Miao J, Jin LN, Liu ZF, Zhang LW (2012) Optimizing the extraction of anti-tumor polysaccharides from the fruit of Capparis spionosa L. by response surface methodology. Moolecules 17:7323–7335

Karabegović IT, Stojičević SS, Veličković DT, Nikolić NČ, Lazić ML (2013) Optimization of microwave-assisted extraction and characterization of phenolic compounds in cherry laurel (Prunus laurocerasus) leaves. Sep Purif Technol 120:429–436

Lin LZ, Zhao HF, Dong Y, Yang B, Zhao MM (2012) Macroporous resin purification behavior of phenolics and rosmarinic acid from Rabdosia serra (MAXIM.) HARA leaf. Food Chem 130:417–424

Liu Y, Wei SL, Liao MC (2013) Optimization of ultrasonic extraction of phenolic compounds from Euryale ferox seed shells using response surface methodology. Ind Crops Prod 49:837–843

Liu X, Hu Y, Wei DF (2014) Optimization of enzyme-based ultrasonic/microwave-assisted extraction and evaluation of antioxidant activity of orcinol glucoside from the rhizomes of Curculigo orchioides Gaertn. Med Chem Res 23:2360–2367

Lou ZX, Wang HX, Zhu S, Chen SW, Zhang M, Wang ZP (2012) Ionic liquids based simultaneous ultrasonic and microwave assisted extraction of phenolic compounds from burdock leaves. Anal Chim Acta 716:28–33

Lu CX, Wang HX, Lv WP, Ma CY, Xu P, Zhu J, Xie J, Liu B, Zhou QL (2011) Ionic liquid-based ultrasonic/microwave-assisted extraction combined with UPLC for the determination of anthraquinones in Rhubarb. Chromatographia 74:139–144

Mocan A, Vlase L, Vodnar DC, Bischin C, Hanganu D, Gheldiu AM, Oprean R, Silaghi-Dumitrescu R, Crisan G (2014) Polyphenolic content, antioxidant and antimicrobial activities of Lycium barbarum L. and Lycium chinense Mill. Leaves. Molecules 19:10056–10073

Pongmalai P, Devahastin S, Chiewchan N, Soponronnarit S (2015) Enhancement of microwave-assisted extraction of bioactive compounds from cabbage outer leaves via the application of ultrasonic pretreatment. Sep Purif Technol 144:37–45

Shyamalamma S, Chandra SBC, Hegde M, Naryanswamy P (2008) Evaluation of genetic diversity in jackfruit (Artocarpus heterophyllus Lam.) based on amplified fragment length polymorphism markers. Genet Mol Res 7:645–656

Sun Y, Xu W, Zhang W, Hu Q, Zeng X (2011) Optimizing the extraction of phenolic antioxidants from kudingcha made from Ilex Kudingcha C. J. Tseng by using response surface methodology. Sep Purif Technol 78:311–320

Sun PC, Liu Y, Yi YT, Li HJ, Fan P, Xia CH (2015) Preliminary enrichment and separation of chlorogenic acid from Helianthus tuberosus L. leaves extract by macroporous resins. Food Chem 168:55–62

Swami SB, Thakor NJ, Haldankar PM, Kalse SB (2012) Jackfruit and its many functional components as related to human health: a review. Compr Rev Food Sci Food Saf 11:565–576

Wang C, Shi L, Fan L, Ding Y, Zhao S, Liu Y, Ma C (2013) Optimization of extraction and enrichment of phenolics from pomegranate (Punica granatum L.) leaves. Ind Crops Prod 42:587–594

Wu DM, Gao TT, Yang HS, Du YZ, Li C, Wei LX, Zhou TY, Lu JM, Bi HT (2015) Simultaneous microwave/ultrasonic-assisted enzymatic extraction of antioxidant ingredients from Nitraria tangutorun Bobr. juice by-products. Ind Crops Prod 66:229–238

Xiao XH, Si XX, Tong X, Li GK (2012) Ultrasonic microwave-assisted extraction coupled with high-speed counter-current chromatography for the preparation of nigakinones from Picrasma quassioides (D. Don) Benn. Phytochem Anal 23:540–546

Zhang LF, Liu ZL (2008) Optimization and comparison of ultrasound/microwave assisted extraction (UMAE) and ultrasonic assisted extraction (UAE) of lycopene from tomatoes. Ultrason Sonochem 15:731–737

Zou YF, Chen XF, Yang WY, Liu S (2011) Response surface methodology for optimization of the ultrasonic extraction of polysaccharides from Codonopsis pilosula Nannf. Var. modesta L. T. Shen. Carbohydr Polym 84:503–508

Acknowledgements

The work was supported by Natural Science Foundation of Hainan Province of China (318MS013), and Scientific Research Project of Hainan Provincial Universities of China (Hnky2015ZD-3).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiang, Z., Shi, R., Chen, H. et al. Ultrasonic microwave-assisted extraction coupled with macroporous resin chromatography for the purification of antioxidant phenolics from waste jackfruit (Artocarpus heterophyllus Lam.) peels. J Food Sci Technol 56, 3877–3886 (2019). https://doi.org/10.1007/s13197-019-03858-8

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-019-03858-8