Abstract

In order to maintain the qualities at postharvest stages, Korean red leaf lettuces (Lactuca sativa L. cv. Tojong-mats) were packaged with different films or perforations such as perforated polypropylene with 1320 small-sized holes (PPP-1320-hole), perforated polypropylene with 4 large-sized holes (PPP-4-hole), non-perforated polypropylene (Non-PPP), non-perforated polypropylene with anti-fogging properties (Anti-Fog-PP) or without packaging (control) and stored at 10 °C up to 16 days. Minimum water loss was observed in both non-perforated films (< 3%) compared to 35% in control at the end of storage. Significant increase in CO2 and simultaneous decline in O2 concentration were recorded in both non-perforated films. A gradual decline in hue angle (h°) and SPAD (Soil–Plant Analyses Development) chlorophyll meter values was found in all samples during storage while the color difference (ΔE*) values showed opposite trend. However, Anti-Fog-PP treatment exhibited the least ΔE* values throughout the storage. The contents of chlorophyll a (Chl a), chlorophyll b (Chl b) and total chlorophyll (total Chl), decreased gradually in all cases with a comparatively higher declines in Non-PPP treatment on 6 days, in PPP-4-hole treatment both on 12 and 16 days. Anti-Fog-PP treatment exhibited the lowest chlorophyll degradation and least changes in anthocyanin content until the end of storage. Lettuces received scores for maintaining marketable limits up to 2, 4, 6, 12 and 16 days under control, PPP-1320-hole, PPP-4-hole, Non-PPP and Anti-Fog-PP packaging treatments, respectively. Results indicated that Anti-Fog-PP treatment could provide better postharvest qualities along with extended marketable life for about 2 weeks during storage at market display temperature.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Leafy vegetables are typically low in calories, packed with fiber and the source of many valuable bioactive components like vitamins, minerals and phytochemicals such as phenolic compounds that act as antioxidants (Kolton et al. 2014; Singh et al. 2016). Among leafy vegetables, lettuce is an important and one of the most popular vegetables that is mostly consumed fresh, especially in salads. There are many different lettuce cultivars that range in color from green to red as a result of varying concentrations of chlorophyll and anthocyanin contents in the leaves. Leaf lettuce is an essential component of salad and is preferred for wrapping foods such as rice or meat. Hence, it is much more popular than head lettuce in Korea. Especially, red leaf lettuce has a great impact in getting consumer preference as it is colorful and contributes to the color variety of mixed salad. Moreover, it contains higher amount of phenolics than green one that contribute to higher antioxidant capacity satisfying the demand for healthy foods (Liu et al. 2007). While green color, an obvious indicator of freshness and quality of leafy vegetable, is associated with chlorophyll content, anthocyanins constitute one of the primary phenols in red leaf lettuce (Llorach et al. 2008). However, leaf lettuces are highly perishable due to their higher water content, active and faster biological and physiological reactions, and being easy to be bruised after harvest. Despite its popularity and nutritional facts, consumers may reject or cancel buying decision of leaf lettuce when it losses quality or freshness besides their concern about the safety of the produces such as pesticide residues, especially when the commodities are consumed as fresh (Esturk et al. 2014). Unlike fruit vegetables, leaf lettuce quickly losses water and freshness after harvest which causes degradation of cell wall as well as quality attributes such as texture, color and other sensory and nutritional attributes. Moreover, physiological parameters are closely associated with sensory quality, which are essential requirements for the acceptance of the produces. Since leaf lettuce is consumed as raw, water loss and changes in color are the most important external quality traits used for buying decision by the consumers. Therefore, maintaining the freshness and quality characteristics of leaf lettuce are the main challenges for growers and suppliers in order to maintain continued supply of this delicate produce to the consumers.

Quality of fresh vegetables at postharvest stages could be maintained and deterioration rate could be inhibited by the application of some treatments. For instance, storage temperature, relative humidity, packaging materials, and packaging method are some important postharvest factors that determine the quality of leaf lettuce during storage (Lee et al. 2008). It has also been observed that leaf lettuce has poor storage potential after harvest due to high respiration rates (Lee et al. 2007). Although it is well established that low temperature reduces the respiration rate and senescence, as well as the growth of spoilage microorganisms (Roura et al. 2000), in practice lettuces are usually handled either at ambient temperature or at temperature that is higher than the recommended temperature of 0 °C along with more than 98% humidity (Saltveit 2016). Moreover, the usual market display (shelf) temperature, which is about 10 °C, is also higher than the household refrigeration temperature both in Korea and in many other countries (Nunes et al. 1999; Jeong et al. 2013; Mampholo et al. 2013). As a result, leaf lettuce loses both sensory and nutritional qualities in limited time during handling or postharvest operations after harvest. However, packaging of vegetables in polymeric films creates modified atmospheric conditions around the produce inside the package that allow lower degrees of exchange of gases and can actively influence the physiological processes of fresh commodities resulting in reduced rate of respiration, transpiration and other metabolic processes (Chitravathi et al. 2015; Soltani et al. 2016). Packaging is an inevitable component for assuring the safe handling and delivery of fresh produces from producer to the consumers (Opara and Mditshwa 2013). Several studies have shown that different types of polymeric film packaging can significantly inhibit the deterioration processes of fresh vegetables’ quality during storage such as reduction in shriveling of Bok Choy caused by water loss, minimize the color changes and weight loss of leaf lettuce (Lee et al. 2008; Lee 2008; Kolton et al. 2014), reduction in CO2 accumulation, off-odor and decay of fresh-cut salad savoy (Kim et al. 2004) as well as extension in storage life of Gynura bicolor D.C (Jiang et al. 2010). However, most polymeric films have lower water vapor transmission rates relative to transpiration rates of fresh produces; therefore, excessively high relative humidity may occur inside the packages causing moisture condensation, microbial growth and decay of the produces (Ben-Yohoshua 1985; Cameron et al. 1995).

Although different packaging films have shown beneficial effects in maintaining sensory, nutritional and microbial qualities in many fresh or fresh-cut produces, reports on the use of polypropylene films with different orientation of holes and the use of film with anti-fogging properties are scanty, especially in leaf lettuce at market display temperature. Hence, the objectives of this study were to investigate the effects of different polypropylene packaging films with or without different perforations/holes and a special type anti-fogging film on the shelf life of leaf lettuce during storage at 10 °C. Postharvest qualities such as changes in fresh weight, color, chlorophyll and anthocyanin contents as well as sensory qualities were measured and discussed.

Materials and methods

Plant material

Korean red leaf lettuce (Lactuca sativa L. cv. Tojong-mats) grown in plastic house was harvested from a commercial farm in Suwon, Gyeonggi province, Republic of Korea and was transported (within 2 h) to the postharvest laboratory. Samples were carefully sorted and over mature, uneven or abnormal as well as damaged or physically injured leaves were discarded. Then lettuce leaves (about 100 g) were packaged, sealed, weighed and evaluated for the loss of weight during storage.

Packaging materials and storage condition

Four different types of packaging treatments were used to pack the red leaf lettuces amongst the two were perforated (different perforations) and the others were non-perforated. All the bags were of 22 × 20 cm in size (after sealing) and the thicknesses were 0.03 mm. The commonly used polypropylene film was used for three packaging treatments that are perforated polypropylene with a piercing density of 1.5 holes/cm2 that resulted 1320 holes of 1 mm diameter (PPP-1320-hole), perforated polypropylene with 4 holes of 6.5 mm diameter (PPP-4-hole) and non-perforated polypropylene film (Non-PPP). The oxygen transmission rate of PP film (C & K Professional Package Co. Ltd., Republic of Korea) was 1981 cc.m−2 day−1 and water vapor transmission rate was 9.06 g.m−2 day−1 (without hole) at (23 ± 1) °C and (37.8 ± 1) °C, 100%RH, respectively. A non-perforated special type polypropylene film (Taebang Patec Co. Ltd., Republic of Korea) with anti-fogging properties (Anti-Fog-PP) was also used. The oxygen transmission rate and water vapor transmission rate of this film were 825 cc.m−2 day−1 (at 23 °C) and 3.5 g.m−2 day−1 (at 37.8 °C, 100%RH), respectively. Leaf lettuce without any packaging was used as control and placed in plastic tray. Each lettuce pouch was used as a replicate and four lettuce bags per treatment and evaluation day were prepared. The samples were then stored at 10 °C dark room until the end of shelf life. This temperature was chosen as a simulation of supermarket display shelf temperature, especially in Korea. Weight loss, gas composition and overall visual quality were measured in every 2 days interval while the color parameters, SPAD (Soil–Plant Analyses Development) values and contents of chlorophyll and anthocyanin were measured on 0, 6, 12 and 16 days of storage. For chlorophyll and anthocyanin determination, five gram fresh samples were collected from the upper portion and closer to the leaf apex, weighed separately in aluminum foil, immersed in liquid nitrogen and stored in − 72 °C refrigerator until needed for analyses. Except for harvest day, the amount of leaf tissues were adjusted based on water loss data on each sampling day in order to avoid the effects caused by water loss on the biochemical components.

Weight loss measurement

The individual lettuce bags were weighed on the day of harvest and considered as initial fresh weight. The percentage of relative fresh weight was calculated on each evaluation day using the formula:

Gas composition, color and SPAD

Using a gas analyzer (PBI Dansensor, CheckMate 9900, DK-4100 Ringsted, Denmark) headspace gas compositions (O2 and CO2) of packaged leaf lettuce were monitored at every 2 days interval until the end of storage. Gas samples were taken from the bag using a hypodermic needle, inserted through an adhesive septum previously fixed to the bag. The volume of gas sample taken from the package headspace was about 5 mL. In order to avoid modifications in the headspace gas composition due to gas sampling, each package was used only once. Four replicates were used for each treatment on every evaluation day.

Five leaves were randomly chosen from each lettuce bag and used for color measurement by using a chromameter (Minolta CR-400, Minolta, Osaka, Japan). Three readings from left, middle and right part of the upper region and closer to the tip of the adaxial surface of leaf were taken and therefore, the average of 15 readings were used for a single replication. Before measuring the color readings from leaf samples, the chromameter was calibrated using the standard white plate (Y 93.5, × 0.3155, y 0.3320) provided by the manufacturer. Color changes were quantified in the L*, a*, b* color space. L* refers to the lightness and ranging from L* = 0 (black) to L* = 100 (white). A negative and positive values of a* indicates green and red color, respectively while positive and negative b* indicate yellow and blue color, respectively. The color values of a* and b* were further converted into hue angle {hue = 180° + tan−1 (b*/a*)}. The total color difference (ΔE*) was also calculated using the formula ΔE* = {(L 0 * − L*) 2 + (a0* − a*)2 + (b0* − b*)2}1/2. L 0 *, a0*, b0* represent the values at harvest and L*, a*, b* indicate the reading at any evaluation day (Manolopoulou and Varzakas 2016). SPAD values were also collected from lettuce leaf following the similar ways as of color measurement using SPAD-502 Chlorophyll meter (Konica-Minolta, Osaka, Japan). The average of 15 readings from a replicate was directly used as SPAD value.

Chlorophyll and anthocyanin

Chlorophyll contents were determined in terms of chlorophyll a (Chl a) chlorophyll b (Chl b) and total chlorophyll (total Chl) following the method of Jaime and Saltveit (2002) with some modifications. Five gram frozen tissues of lettuce sample were homogenized in 20 mL of 80% acetone (acetone and water were mixed in 80:20 ratio, v/v) with an Ultra-Turrax tissue homogenizer (T 25 B, Ika Works Sdn. Bhd, Malaysia) at a moderate speed (about 13,000 rpm) for about 1 min. The homogenate was filtered through four layers of cotton cloth, centrifuged at 4 °C, 15,000×g for 20 min. The supernatant was carefully transferred to a volumetric flask and the volume made up to 50 mL with 80% acetone. Then the supernatant was used for measuring Chl a and Chl b at 663 and 645 nm with an UV–VIS recording spectrophotometer (DU 650, Beckman Coulter™, USA). Chl a, Chl b and total Chl contents were calculated according to the formula given by Arnon (1949).

Total anthocyanins were estimated using a spectrophotometric pH-differential method following the procedure of Ferrante et al. (2008) with some modifications. Five gram frozen leaf tissues were homogenized in 20 mL methanol containing 1% HCl with an Ultra-Turrax tissue homogenizer (T 25 B, Ika Works Sdn. Bhd, Malaysia) at a moderate speed for about 1 min. The homogenate was incubated overnight at 4 °C in darkness, centrifuged at 4 °C, 12,000×g for 20 min. The supernatant was carefully transferred to a volumetric flask and the volume made up to 50 mL with the same methanolic HCl (1%). An aliquot of 2 mL was diluted with 18 mL potassium chloride buffer (pH 1.0) and another 2 mL aliquot was diluted separately with 18 mL sodium acetate buffer (pH 4.5). Absorbance of these solutions was measured at 510 and 700 nm using an UV–VIS recording spectrophotometer (DU 650, Beckman Coulter™, USA). Concentration of anthocyanins was calculated by the following equation as described by Giusti and Wrolstad (2001):

where absorbance was calculated as A = (A510 − A700)pH1.0 − (A510 − A700)pH4.5 with molar absorptivity (ε) of cyanidin-3-glucoside (26,900 L·cm−1·mol−1); MW = molecular weight of cyanidin-3-glucoside (449.2); DF = dilution factor of this experiment; 1 = assumed path length of cuvette in cm. Anthocyanin content (mg/L) was then converted to mg/100 g fresh sample. All the chemicals used for biochemical assay were purchased from Sigma Aldrich Co. Ltd. unless otherwise stated.

Sensory analysis

The sensory analyses of leaf lettuce samples were carried out following the procedure of Banerjee et al. (2016) in which an 8-member panelists aged between 28 and 52 years (5 men and 3 women) were selected from the postharvest technology division of National Institute of Horticultural and Herbal Science. The members of the panel were trained to recognize and score off-odor and overall visual quality (OVQ) of lettuce prior to the test. Off-odor was evaluated immediately after opening the packages and scored on a five-point scale where 0 = none, 1 = slight, 2 = moderate, 3 = strong, and 4 = extremely strong; a score of 3 was considered non-acceptable. OVQ was evaluated by using 9-point scale (9 = excellent, 7 = good, 5 = fair, 3 = poor and 1 = unusable) which was adopted from Chandra et al. (2015). A score of 6 was considered as the limit of marketability. These sensory qualities were evaluated on the processing day and at every 2 days interval until the end of shelf life during storage at 10 °C.

Statistical analysis

The experiments were conducted with four replications per treatment per evaluation period. The data were statistically analyzed using SAS software (SAS Institute, Cary, NC, USA). The level of significance was calculated from the F value of ANOVA. Duncan’s multiple range tests were applied for mean comparison among the treatments and storage durations. Before conducting the final experiment, two preliminary experiments were done with limited replications that yielded similar trend.

Results and discussion

Weight loss and gas composition

Changes in relative fresh weight of leaf lettuce packaged in different films and/or perforations during storage at 10 °C are presented in Fig. 1. Significant variations were found among the packaging treatments in terms of relative fresh weight during the storage of lettuce. Since the control sample was unpacked, it lost water rapidly from the beginning of storage. Consequently, the sample became unmarketable (discussed later) after two days of storage. Moreover, the highest amount (about 35%) of water loss was recorded in this sample before ending the storage duration at 6 days presumably due to severe moisture loss that damaged the sample. On the other hand, all packaged samples showed higher relative fresh weight compared to control sample exhibiting the highest and nearly similar values in samples packaged in Non-PPP and Anti-Fog-PP films (Fig. 1). However, sample packaged in PPP-1320-hole film showed higher water loss among only the packaging treatments and therefore, the sample was unusable after 12 days of storage. Many researches have demonstrated that film packaging can protect water loss and can maintain the quality of perishable commodities (Lee et al. 2007; Lee 2008; Lee et al. 2008). In this study, anti-fogging film and non-perforated polypropylene film had no hole, therefore, protected the usual evaporation of water from the sample while the other two packaging treatments showed significant evaporation of water and the higher evaporation was occurred when the higher number/area of holes were used in the packages. At the end of 16 days storage period, total weight loss for Non-PPP and Anti-Fog-PP were 2.7 and 2.2%, respectively while this value was 16.2% for PPP-4 hole packaging treatment. In accordance with our result, Rizzo and Muratore (2009) also found less than 3% total weight loss after 31 days of storage in celery by using non-perforated polyolefin anti-fogging film. Films with anti-fogging properties showed not only the reduction in water loss of fresh vegetables but also it maintained other qualities including visual quality. Maintaining the water content of fresh samples especially of leafy vegetables is one of the main characteristics that determine the freshness and overall quality of the produces. Similar with many other studies (Lee et al. 2007; Lee 2008; Lee et al. 2008), our results also depicted that packaging of leaf lettuce with appropriate film is beneficial for retaining its freshness by reducing the evaporation of water during storage and transportation before reaching to the consumers.

Changes in relative fresh weight (%) of leaf lettuce packaged with or without different films/methods during storage at 10 °C for up to 16 days. Each point represents the mean of four replications. Vertical bars indicate SE, which, when absent is concealed by the graph symbols. Legend: Control = unpacked lettuce placed in tray, PPP-1320-hole = packaging in perforated polypropylene film with 1320 holes, PPP-4-hole = packaging in perforated polypropylene film with 4 holes, Non-PPP = packaging in non-perforated polypropylene film and Anti-Fog-PP = packaging in non-perforated polypropylene film with anti-fogging properties

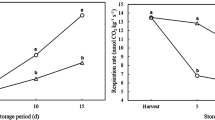

Figure 2 shows the head space gas composition (O2 and CO2) of leaf lettuce packaged with or without different films or perforations during storage at 10 °C. As control sample was unpacked, its gas composition was same with air. Likewise, lettuce sample packaged in perforated polypropylene (PPP) films showed 20.52–21.42% O2 and 0–0.16% CO2, which were also similar with outside air, indicating no modification was occurred to the packages atmosphere. On the other hand, decreases in O2 and increases in CO2 levels were observed in Non-PPP and anti-fogging film (Fig. 2). At 2 days of storage, the O2 concentration declined to about 15% and CO2 concentration increased to about 4.5% in both films. After that the degrees of decline of O2 and rises of CO2 concentration were higher in the Anti-Fog-PP packages compared to that of Non-PPP film throughout the 16 days storage period. At the end of the storage, O2 concentration reached to 1.7% and CO2 increased to 6.5% in Non-PPP films while those concentrations were 0.15 and 8.9%, respectively in Anti-Fog-PP treatment. These results clearly indicate that both the films were able to modify the inside atmosphere of leaf lettuce pouches being the greater degrees observed in Anti-Fog-PP packages.

Changes in headspace gas composition (O2 and CO2) of leaf lettuce packaged with or without different films/methods during storage at 10 °C. Data are the mean of four replications. Vertical bars indicate SE, which, when absent is concealed by the graph symbols. Legend: same as shown in Fig. 1

It has long been observed that the modified atmosphere leads to the reduction of respiration rate of fresh commodities. The influence of CO2 in retarding the enzyme activities that plays pivotal roles in glycolysis and the Kreb’s cycle has also been discussed (Peppelenbos and van’t Leven 1996). Moreover, higher concentration of CO2 (5–10%) and lower O2 (1–3%) were recommended as suitable environment for the storage of a number of green vegetables as these conditions effectively inhibit the loss of quality (Saltveit 1997). Although the O2 and CO2 concentration of the lettuce pouches in this study were not exactly in the same range of recommended concentration, we found that the modification occurred by the packaging films were beneficial for maintaining the overall quality of leaf lettuce (discussed later) when comparing with control or samples packed in perforated film. Several studies have demonstrated that different packaging films can significantly modify the package atmosphere that render beneficial effect in maintaining the quality of fresh vegetables such as in leaf lettuce (Lee et al. 2007, 2008) or in Chinese cabbage (Mampholo et al. 2013).

Color parameters and SPAD value

Changes in color parameter such as hue angle (h°) and color difference (ΔE*) of lettuce leaves are presented in Table 1. A gradual decline in hue angle was found in all samples during storage with higher degrees in control and PPP-1320-hole packaged sample. Although similar values of hue angle were calculated for the remaining 3 types of packaging treatments on 6 days, sample in Non-PPP lost h° with a higher rate afterwards compared to the others though the differences were statistically insignificant (P > 0.05) considering the variation among the treatments on a specific day of storage. Due to the poor state of the samples, we did not continue storage of control and PPP-1320-hole packed samples after 6 days and 12 days, respectively. At the end of storage (16 days), the decline in h° values for both the PPP-4-hole and Anti-Fog-PP packaged samples were about 11% to their initial value, while it was 14% for Non-PPP. Decline in h° in green or nearly green vegetables such as green or red leaf lettuce is a common phenomenon as the lower h° value indicates an increase in leaf yellowing which is associated with the degradation of chlorophyll content (Toivonen and Brummell 2008; Mampholo et al. 2013). Increases in color differences (ΔE*) were found from the sixth day onwards of storage in all samples, the lowest was in PPP-4-hole and the highest in Non-PPP packed samples on 6-day evaluation (Table 1). However, we calculated almost similar values (P > 0.05) of ΔE* for all samples on 12 days of storage except control as the storage time of control sample was ended on 6 days of storage. Among the 3 samples which were stored for up to 16 days, Anti-Fog-PP packed sample exhibited the lowest ΔE* value at the end of storage followed by sample packed in Non-PPP. Our color parameters’ results were in accordance with the results of Manolopoulou and Varzakas (2016) in lettuce where they described hue angle as an indication of degreening associated with aging. The higher the decline in hue angle value along with increased values of color difference (ΔE*) indicate degradation in color quality of fresh green vegetables. The comparatively lower reduction in hue value as well as lower increase of ΔE* of Anti-Fog-PP packed sample suggest the potential of this film in packaging leaf lettuce for commercial marketing.

Table 1 also shows the mean SPAD values of red leaf lettuce at harvest and successive storage with or without different packaging materials and perforations. Overall, gradual declines in SPAD values were recorded throughout the storage in all cases. However, the noticeable decline in SPAD values was found in the control sample on 6 days of storage. While the lowest value (12.53) was observed in PPP-1320-hole treatment (P ≤ 0.05) on 12 days of storage, Non-PPP treatment showed the lowest value (12.70) at the end of 16 days storage period. Corresponding with our results of hue angle, we found similar trend of changes in SPAD value in all treatments. Cretescu et al. (2014) also reported significant decline in SPAD values as an equivalent of chlorophyll content in different types of lettuce during storage at 4 °C. Although SPAD chlorophyll meter, a portable device, was initially developed for diagnosing foliar nitrogen (N) status and determining N fertilizer requirements of rice (Chubachi et al. 1986; Richardson et al. 2002), it has been found useful in measuring leaf greenness or estimating chlorophyll content in many crops including fruits and vegetables (Ma et al. 1995; Peryea and Kammereck 1997; Leon et al. 2007) even in postharvest stages (Lee et al. 2007, 2008; Cretescu et al. 2014). Highly positive correlations between the SPAD values as well as overall visual quality and/or chlorophyll content have been reported in many previous studies (Ma et al. 1995; Richardson et al. 2002; Wang et al. 2005; Cretescu et al. 2014)). Hence, the measurement of SPAD value became one of the easiest ways for assuming the visual acceptance as an outcome of total chlorophyll content in plant samples especially in leafy green fresh commodities.

Chlorophyll and anthocyanin content

Red leaf lettuce used in this study contained 0.59, 0.14 and 0.73 mg g−1fresh weight of chlorophyll a (Chl a), chlorophyll b (Chl b) and total chlorophyll (total Chl), respectively on the harvesting day (Table 2). During storage, the contents of Chl a, Chl b and total Chl decreased (P ≤ 0.05) gradually throughout the storage regardless of different packaging treatments, except for a slight fluctuation in Non-PPP packaging treatment on 12 days of storage. Comparatively higher decline (P > 0.05) in Chl a (22%), Chl b (21%) and total Chl (23%) in regards to their initial levels were observed in Non-PPP packaging treatment among the samples on 6 days of storage. However, sample of PPP-4-hole packaging treatment exhibited the highest decline (P ≤ 0.05) in chlorophyll contents (49, 35 and 46% of initial Chl a, Chl b and total Chl contents, respectively) on 12 days which reached 57, 35 and 52% decreases, respectively on 16 days of storage. On the other hand, Anti-Fog-PP packed sample showed the highest inhibition of chlorophyll degradation among the packaging treatments (P ≤ 0.05) until the end of storage. Moreover, this treatment maintained its level of Chl a and total Chl after initial decline on 6 days as well as Chl b level to its initial value (P > 0.05) until the end of storage. At the end of storage, about 23, 14 and 20% decreases of Chl a, Chl b and total Chl, respectively in respect to their initial levels were determined in Anti-Fog-PP treatment whereas these losses were about 37, 21 and 34%, respectively in Non-PPP packed sample. Although we found almost similar trend in relative fresh weight, gas composition and color parameters in both of Non-PPP and Anti-Fog-PP packaging treatments, Non-PPP treatment showed higher decline in SPAD value and likewise the greater losses of chlorophyll contents (P ≤ 0.05) compared to that of Anti-Fog-PP packaging treatment. This result clearly indicates the superiority of Anti-Fog-PP packaging in terms of maintaining quality traits of leaf lettuce during storage over the control or other packaging treatments.

The loss of chlorophyll pigment is a commonly occurred biochemical changes during storage of leafy vegetable which is characterized by the activity of Chlorophyllase enzyme (Yamauchi and Watada 1991). Therefore, maintaining the chlorophyll level is vital in retaining the quality of fresh produces, especially in leafy green vegetables. Results of this study clearly depict that red leaf lettuce packed in Anti-Fog-PP had the least changes in the measured relative fresh weight, color parameters, SPAD values and chlorophyll content when comparing with other packaging treatments or control sample. The possible reason of maintaining those quality traits could be the consequences of accumulated CO2 and depleted O2 concentration of the inside atmosphere of the packages (Fig. 2). It was reported that the elevated CO2 and lower concentration of O2 can retard the yellowing, chlorophyll and protein degradation which improve the overall acceptance of leafy vegetables (Lers et al. 1998; Mampholo et al. 2013). Despite the accumulated level of CO2 and lower O2 level in Non-PPP film pouches, sample showed comparatively higher degradation of chlorophyll that resulted changes in color and overall quality. This observation might be attributed to the accelerated ethylene level of Non-PPP treatment that enhances Chlorophyllase activity rendering the chlorophyll destruction (Shimokawa et al. 1978). In agreement with our results, similar chlorophyll degradation trends have been reported in other studies such as in Romana lettuce (Manolopoulou and Varzakas 2016), in curly lettuce and arugula (Cretescu et al. 2014) as well as in lamb’s lettuces (Ferrante and Maggiore 2007; Kolton et al. 2014).

In general, anthocyanin content also declined in all packaging treatments along with control sample though some fluctuations were found in some treatments (Table 2). The initial level of total anthocyanin was 1.6 mg. (100 g)−1 fresh weight which was almost maintained in all packaged samples until 6 days of storage while a greater decline (P ≤ 0.05) of 23% of its initial level was observed in control sample in that period. Although we found the declining trend of anthocyanin on 12 days of storage, the levels were again increased in all cases of packaged samples at the end of 16 days storage period. Similar to chlorophyll content, sample packed in anti-fogging film (Anti-Fog-PP) showed the least changes of anthocyanin content among the treatments used in this study. Variable patterns of changes in anthocyanin content during storage of leafy vegetable have also been reported previously (Ferrante and Maggiore 2007; Ferrante et al. 2008, 2004) which support our results of this study. The reason for the irregular patterns of changes of anthocyanin content could be due to the occurrence of inter-conversions among the many groups of phenolic compounds (Ferrante and Maggiore 2007). It was also explained that different species of vegetables may have different behavior of changes in qualities during postharvest storage (Ferrante et al. 2008). Since substantial decline in anthocyanin was observed in control sample, packaging could inhibit the loss of anthocyanin contents thereby ensure better nutritional properties of leaf lettuce during storage.

Sensory quality

Apart from instrumental measurement of qualities, sensory tests were conducted by the panelists in order to judge the overall quality of lettuce in terms of consumers’ view point. Overall visual quality (OVQ) scores of lettuce samples decreased gradually when storage time elapsed regardless of packaging treatments (Fig. 3). However, no off odor was detected in any sample until the end of storage except for a slight and negligible off odor that was detected only in Non-PPP treatment on 12 days onwards during storage (data not shown). As the OVQ was evaluated based on the freshness, color (leaf yellowing) and decay qualities of samples, unpacked control sample lost OVQ in maintaining the marketable limit which was set at 6 in a 9-point scale just after 2 days of storage. The main reason for rapid visual quality deterioration of this sample was characterized by the reduction in freshness as a consequence of severe water loss (Fig. 1). Although all packaged samples showed higher OVQ compared to control, the OVQ scores of lettuce packaged in perforated films did not sustain for retaining marketable limit at the later stages of storage. Lettuces packed in PPP-1320-hole film received OVQ scores with marketable limit only until 4 days of storage while it was until 6 days in PPP-4-hole treatment. It revealed that loss of relative fresh weight largely contributed to the OVQ scores that affected the decision of marketability. Non-perforated film packed samples reflected significantly higher (P ≤ 0.05) OVQ scores compared to other samples where the continued highest OVQ scores were received in Anti-Fog-PP treatment. Numerous studies have shown the effectiveness of different polymeric films for extending the storage life of fresh vegetables including lettuce (Lee et al. 2007; Lee 2008; Lee et al. 2008; Mampholo et al. 2013). Until 10 days of storage, both the samples packed in non-perforated film received higher OVQ scores (Fig. 3). For instance, these scores were 7.2 and 8.1 for Non- PPP and Anti-Fog-PP treatments, respectively on 10 days of storage and then both the scores were felt down and Non-PPP packed sample received just 6.0 OVQ score on 12 days when its marketable limit was ended while this score was 6.6 for Anti-Fog-PP treatment on that evaluation day. Although we noticed a gradual water condensation inside the packages of Non-PPP treatment from the beginning of storage, it did not affect much in maintaining the acceptable OVQ scores until 12 days. However, severe water condensation was occurred afterward in this sample and probably, as a consequence, sample started to decay which yielded a lower OVQ and ultimately made the sample unusable. Similar to other measured parameters, Anti-Fog-PP treatment demonstrated the best result in receiving the OVQ score as the sample was still remained marketable on 16 days.

Overall visual quality (OVQ) score of leaf lettuce packaged with or without different films/methods during storage at 10 °C for 16 days. Data are the mean of four replicates. Vertical bars indicate SE, which, when absent is concealed by the graph symbols. Legend: same as shown in Fig. 1

Conclusion

Packaging leaf lettuce in non-perforated film contributed in maintaining the quality parameters along with extension of shelf-life. Although both the Non-PPP and Anti-Fog-PP packaging materials were able to modify the gas composition of lettuce pouches that contributed in maintaining better quality, Anti-Fog-PP packaging material had more beneficial effects on shelf life parameters. Results obtained from this study provide the evidence for the better ability of Anti-Fog-PP packaging material out of different films and orientations of perforation used through minimizing water loss, least changes in color difference values and anthocyanin content as well as the lowest degradation in chlorophyll a, chlorophyll b and total chlorophyll contents. Application of non-perforated polypropylene anti-fogging film (Anti-Fog-PP) might ensure maintaining overall visual quality for about 2 weeks at market display temperature and therefore, could be suggested for commercial use.

References

Arnon DI (1949) Copper enzymes in isolated chloroplasts Polyphenoloxidase in Beta vulgaris. Plant Physiol 24:1–15

Banerjee A, Chatterjee S, Variyar PS, Sharma A (2016) Shelf life extension of minimally processed ready-to-cook (RTC) cabbage by gamma irradiation. J Food Sci Technol 53:233–244

Ben-Yohoshua S (1985) Individual seal packaging of fruits and vegetables in plastic films. A postharvest technique. Hort Sci 20:32–37

Cameron AC, Talasila PC, Joles DJ (1995) Predicting the film permeability needs for modified-atmosphere packaging of lightly processed fruits and vegetables. Hort Sci 30:25–34

Chandra D, Choi AJ, Kim YP, Kim JG (2015) Physicochemical, microbial and sensory quality of fresh-cut red beetroots in relation to sanitization method and storage duration. Ital J Food Sci 27:208–222

Chitravathi K, Chauhan OP, Raju PS (2015) Influence of modified atmospheric packaging on shelf life of green chillies. Food Packag Shelf Life 4:1–9

Chubachi T, Asano I, Oikawa T (1986) The diagnosis of nitrogen nutrition of rice plants (sasanishiki) using chlorophyll meter. Soil Sci Plant Nutri 57:190–193

Cretescu I, Caprita R, Velicevici G, Dorin C, Sirbu C, Buzamat G, Ropciuc S (2014) Researches regarding the influence of cold storage on the chlorophyll content in lettuce. Sci Pap Anim Sci Biotechnol 47:162–166

Esturk O, Yakar Y, Ayhan Z (2014) Pesticide residue analysis in parsley, lettuce and spinach by LC-MS/MS. J Food Sci Technol 51:458–466

Ferrante A, Maggiore T (2007) Chlorophyll a fluorescence measurements to evaluate storage time and temperature of Valeriana leafy vegetables. Postharvest Biol Technol 45:73–80

Ferrante A, Incrocci L, Maggini R, Serra G, Tognoni F (2004) Colour changes of fresh-cut leafy vegetables during storage. J Food Agric Env 2:40–44

Ferrante A, Incrocci L, Serra G (2008) Quality changes during storage of fresh-cut or intact Swiss chard leafy vegetables. J Food Agric Environ 6:60–62

Giusti MM, Wrolstad RE (2001) Characterization and measurement of anthocyanins by uv-visible spectroscopy. Curr Protoc Food Anal Chem F1.2.1-F1.2.13. https://doi.org/10.1002/0471142913.faf0102s00

Jaime P, Saltveit ME (2002) Postharvest changes in broccoli and lettuce during storage in argon, helium, and nitrogen atmospheres containing 2% oxygen. Postharvest Biol Technol 26:113–116

Jeong M, An DS, Ahn GH, Lee DS (2013) Master packaging system for sweet persimmon applicable to produce supply chains. Postharvest Biol Technol 86:141–146

Jiang L, Hou TY, Yuan XY, Jiang J, Yu ZF (2010) Effect of storage temperature and packaging method on the decay and physiology of fresh leaves of Gynura bicolor D.C. J Food Process Preserv 34:858–871

Kim JG, Luo Y, Gross KC (2004) Effect of packaging film on the quality of fresh-cut salad savoy. Postharvest Biol Technol 32:99–107

Kolton A, Wojciechowska R, Długosz-Grochowska O, Grzesiak W (2014) The storage ability of lamb’s lettuce cultivated in the greenhouse under LED or HPS lamps. J Hort Res 22:159–165

Lee JH (2008) Extending shelf-life of leaf lettuce using active packaging. J Food Tech 6:14–19

Lee JS, Chung DS, Lee JU, Lim BS, Lee Y, Chun C (2007) Effects of cultivars and storage temperatures on shelf-life of leaf lettuces. Korean J Food Preserv 14:345–350 (in Korean with English abstract)

Lee JS, Lee HE, Lee YS, Chun C (2008) Effect of packaging methods on the quality of leaf lettuce. Korean J Food Preserv 15:630–634 (in Korean with English abstract)

Leon AP, Vina SZ, Frezza D, Chaves A, Chiesa A (2007) Estimation of chlorophyll contents by correlations between SPAD-502 meter and chromameter in butterhead lettuce. Commun Soil Sci Plant Analy 38:2877–2885

Lers A, Jiang WB, Lomaniec E, Aharoni N (1998) Gibberellic acid and CO2 additive effect in retarding postharvest senescence of parsley. J Food Sci 63:66–68

Liu X, Ardo S, Bunning M, Parry J, Zhou K, Stushnoff C, Stoniker F, Yu L, Kendall P (2007) Total phenolic content and DPPH radical scavenging activity of lettuce (Lactuca sativa L.) grown in Colorado. LWT Food Sci Technol 40:552–557

Llorach R, Martínez-Sánchez A, Tomás-Barberán FA, Gil MI, Ferreres F (2008) Characterisation of polyphenols and antioxidant properties of five lettuce varieties and escarole. Food Chem 108:1028–1038

Ma BL, Morrison MJ, Voldeng HD (1995) Leaf greenness and photosynthetic rates in soybean. Crop Sci 35:1411–1414

Mampholo BM, Sivakumar D, Beukes M, van Rensburg WJ (2013) Effect of modified atmosphere packaging on the quality and bioactive compounds of Chinese cabbage (Brasicca rapa L. ssp. chinensis). J Sci Food Agric 93:2008–2015

Manolopoulou E, Varzakas T (2016) Effect of temperature in color changes of green vegetables. Curr Res Nutri Food Sci 4(SI. 2): 10-17 Web. http://dx.doi.org/10.12944/CRNFSJ.4.Special-Issue-October.02

Nunes MCN, Villeneuve S, Emond JP (1999) Retail display conditions affects quality of broccoli florets. Paper no. 277 Proceedings of the 20th International Congress of Refrigeration IIR/IIF Sydney

Opara UL, Mditshwa A (2013) A review on the role of packaging in securing food system: adding value to food products and reducing losses and waste. Afr J Agric Res 8:2621–2630

Peppelenbos HW, van’t Leven J (1996) Evaluation of four types of inhibition for modeling the influence of carbon dioxide on oxygen consumption of fruits and vegetables. Postharvest Biol Technol 7:27–40

Peryea FJ, Kammereck R (1997) Use of Minolta SPAD-502 chlorophyll meter to quantify the effectiveness of mid-summer trunk injection of iron on chlorotic pear trees. J Plant Nutri 20:1457–1463

Richardson AD, Duigan SP, Berlyn GP (2002) An evaluation of noninvasive methods to estimate foliar chlorophyll content. New Phytol 153:185–194

Rizzo V, Muratore G (2009) Effects of packaging on shelf life of fresh celery. J Food Eng 90:124–128

Roura SI, Davidovich LA, Valle CE (2000) Quality loss in minimally processed Swiss chard related to amount of damaged area. LWT Food Sci Technol 33:53–59

Saltveit ME (1997) A summary of CA and MA requirements and recommendations for harvested vegetables. In: Salviet ME (ed) Proceedings of the 7th International controlled atmosphere research conference Vol. 4. Vegetables and ornamentals, University of California, Davis, pp 98–117

Saltveit ME (2016) Lettuce. In: Gross KC, Chien YW, Saltveit M (eds) The Commercial Storage of Fruits, Vegetables, and Florist and Nursery Stocks. Agriculture Handbook 66, U.S. Department of Agriculture, Agricultural Research Service, Washington, DC, pp 386-389

Shimokawa K, Shimada S, Yaeo K (1978) Ethylene-enhanced chlorophyllase activity during degreening of Citrus unshiu Marc. Sci Hort 8:129–135

Singh JP, Kaur A, Shevkani K, Singh N (2016) Composition, bioactive compounds and antioxidant activity of common Indian fruits and vegetables. J Food Sci Technol 53:4056–4066

Soltani M, Alimardani R, Mobli H, Mohtasebi SS (2016) Modified atmospheric packaging: a progressive technology for shelf life extension of fruits and vegetables. J Appl Packag Res 8:33–59

Toivonen PMA, Brummell DA (2008) Biochemical bases of appearance and texture changes in fresh-cut and vegetables. Postharvest Biol Technol 48:1–14

Wang Q, Chen J, Stamps RH, Li Y (2005) Correlation of visual quality grading and SPAD reading of green-leaved foliage plants. J Plant Nutri 28:1215–1225

Yamauchi N, Watada AE (1991) Regulated chlorophyll degradation in spinach leaves during Storage. J Am Soc Hort Sci 116:58–62

Acknowledgements

The second author gratefully acknowledges the financial support from the National Institute of Horticultural and Herbal Science (NIHHS), Rural Development Administration (RDA), Republic of Korea received through the Postdoctoral Fellowship Program for foreign researcher.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, JS., Chandra, D. Effects of different packaging materials and methods on the physical, biochemical and sensory qualities of lettuce. J Food Sci Technol 55, 1685–1694 (2018). https://doi.org/10.1007/s13197-018-3081-6

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-018-3081-6