Abstract

Gamma irradiation (0.5–2.5 kGy) in combination with low temperature (4–15 °C) storage was attempted to increase shelf life of ready-to-cook shredded cabbage wrapped in cling films. A maximum extension in shelf life of 8 days, while retaining the microbial and sensory quality, was obtained with an irradiation dose of 2 kGy and storage at 10 °C. Gamma irradiation also inhibited browning of shredded cabbage at their cut edges resulting in enhanced visual appeal. An increase in total antioxidant activity was observed with respect to DPPH and hydroxyl radical scavenging ability while the nitric oxide radical scavenging activity and ferric reducing property remained unaffected with irradiation. Total phenolic, flavonoid and vitamin C content remained unchanged due to irradiation. No significant migration of additives from cling films into stimulant water was observed up to a radiation dose of 2 kGy thus demonstrating the feasibility of such films for above applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Consumption of minimally processed (MP) food products which includes ready-to-eat and ready-to-cook (RTC) food have increased considerably in the recent years. In Europe the market for MP fruits and vegetables is on the rise since 1990s. Similar scenario exists in USA where packaged salads are the second-fastest selling item in grocery stores followed by fresh-cut vegetables (FGN, http://fruitgrowersnews.com/index.php/magazine/article/Fresh-cut-RemainsFastest-Growing-Trend-in-Produce-Industry). In India a major share of all produce sold in the retail market is known to be accountable to fresh-cut produce (NIIR project consultancy services). Processing operations such as peeling, cutting etc. involved in the preparation of MP food causes tissue damage leading to browning, off-flavour generation and texture breakdown as a consequence of contact of enzymes with substrates. Further, an enhanced microbial population is also noted in the damaged product. Thus both biochemical changes and enhanced microbial load can reduce product quality and shelf-life. Widespread outbreak of food borne illness worldwide in recent years has been associated with the consumption of fresh leafy vegetables. This involves infection by pathogenic micro-organisms such as E. coli O157:H7, Campylobacter, Listeria, Toxoplasma, Trichinella and production of toxic substances like enterotoxin, mycotoxin and histamine by fungi. Thus, maintenance of overall sensory and nutritional quality as well as microbial safety of fresh cut produce remains a major challenge for production of MP food.

MP fruits and vegetables are preserved by several methods like refrigeration, chemical preservatives, mild heat treatments, reduction of water activity, ionizing radiation, disinfectants, ozone technology, hurdle technology etc. (Siddiqui et al. 2011). However, elimination of pathogenic microorganisms such as Listeria monocytogenes using such a treatment is difficult.

Use of γ-irradiation for eliminating pathogenic and spoilage microorganisms to ensure safety and extension of the shelf life of fresh fruits and vegetables has been extensively reported (Arvanitoyannis et al. 2009). Food and Drug Administration (http://www.fda.gov/ForConsumers/ConsumerUpdates/ucm093651.htm) USA, allows the use of ionizing radiation up to 4 kGy for microbial decontamination of iceberg lettuce and spinach. Radiation treatment along with other preservation techniques like low temperature or mild heat treatment can also act synergistically to increase the shelf life of the product.

Cabbage is an important member of Brassica family. It is known for its nutritional and phamacological value. Glucosinolates and phenolics are the major secondary metabolites in cabbage which impart significant anticancer and antioxidant properties respectively to the vegetable. Polyunsaturated fatty acids (PUFAs) have also been reported in this vegetable with beneficial effects in reducing the risk of incidence and progression of chronic diseases like type II diabetes and coronary heart disease (CHD) (Ortega et al. 2012; Harris 2008). Cabbage is also a good source of vitamins including carotenes, tocopherols, vitamin C, and folic acid.

Fresh leaves of cabbage are used for preparation of a wide variety of recipes including delicacies like sauerkraut and kimchi. It is also widely marketed as a MP product in the shredded form due to the associated convenience and fresh characteristics. Ahn et al. (2005) demonstrated the use of modified atmosphere packaging and γ-irradiation for preservation of cut salted chinese cabbage at 4 °C. Several countries recommend a temperature of 0 °C for storage of MP vegetables. However, during shipment and marketing temperatures normally reach 5–10 °C (Siddiqui et al. 2011) resulting in their lower acceptability. In India, MP vegetables are generally stored at 10 °C in supermarkets (IAEA 2005) that can result in substantial losses. About one third of the horticultural produce in developing countries is known to be lost due to poor cold storage facility (NIIR project consultancy services). Thus preservation methods that aid in safe storage at higher temperature is preferred.

Feasibility of storing radiation processed potatoes at higher temperature (15 °C) in contrast to the recommended post-harvest storage temperature of 4 °C for non-irradiated tuber has been demonstrated (Kodenchery and Nair 1972). Similar advantage of radiation processing in case of other vegetables like RTC ash gourd (Tripathi et al. 2013) has also been reported. However, majority of the work carried out on γ-irradiation of MP products involves storage at 0–4 °C. Potential use of γ-irradiation in enhancing shelf life of MP fruits and vegetables at higher temperature therefore needs to be further explored.

The objective of this study was to investigate the potential use of irradiation in combination with cling wrap packaging to extend the shelf life and maintain the quality of MP shredded cabbage when stored at higher temperatures.

Materials and method

Plant material

Fresh cabbage samples (Brassica oleracea) were purchased from a local market and healthy fresh-looking vegetables selected. Samples were cut with sterile stainless steel knives into 1 cm wide by 3.0–3.5-cm long strips. Cut samples were packed (40 g) into polystyrene trays (id: 9 × 9 × 2.5 cm). The trays were then over-wrapped all around with cling film.

Chemicals were purchased from various suppliers: plate count agar, potaoto dextrose agar from Himedia, India. Gallic acid, quercetin, ascorbic acid, Folin–Ciocalteu from Sigma–Aldrich (USA). All solvents were procured from Merck (India) and redistilled before use.

Irradiation and storage

Packaged samples was subjected to different radiation doses (0.5, 1.0, 1.5, 2.0 and 2.5 kGy) in a cobalt-60 irradiator (GC-5000, BRIT, Mumbai, India) having a dose rate of (3.34 kGy/h) and a DUR of 1.12. Irradiation was done at room temperature. Dosimetry in the present study was carried out using Fricke dosimeter according to standard procedure described in ASTM (Designation E2303-11 2011). Dosimeters were placed in the product box (33 × 33 × 22 cm) at three different layers (front, middle and rear) and at nine different positions of each layer for different time period to map the dose in gamma chamber. In total of 27 dosimeters were used for a single mapping. Absorbed dose at each point was estimated by the mean value of dose received by all the sets. The minimum dose was received at centre layer while maximum dose received at the outer layer. By calculating the Dmax and Dmin for all the sets, the DUR obtained was 1.12. Uncertainty of the doses was found to be within the limit of ±1 %. Irradiated samples were stored in the dark at 4 ± 1, 10 ± 1 and 15 °C. Non-irradiated samples served as controls. However, at 15 °C microbial and physiological spoilage was rapid resulting in a very short shelf life for both control and irradiated sample. Hence these samples were not used for further experiment. Three replicates were prepared for each dose and storage day.

Microbial analysis

Standard methods were used to enumerate microorganisms present in RTC cabbage at each sampling time and treatment for 21 days of storage. Mesophilic bacteria, yeast, and mold counts were carried out using described method (Saroj et al. 2006). Samples (25 g) were homogenized in 225 mL of sterile physiological saline. After appropriate serial dilutions, the samples were pour plated on plate count agar. The colonies were counted after 24 h of incubation at 37 °C. Total yeast and mold counts were performed with the pour plate method using potato dextrose agar supplemented with 0.1 % tartaric acid to maintain media pH at 3.5. Plates were incubated at 37 °C for 48 h. Microbial counts were expressed as log10 CFU g−1 of vegetable.

Determination of D10 value for pathogenic strains in MP cabbage

D values for 4 pathogenic strains in MP cabbage samples were determined using standard method used by Trigo et al. (2009) for fresh cut vegetables. Briefly, cabbage samples were sanitized using a 300 ppm sodium hypochloride solution for 3 min, rinsed under running distilled water and kept in flow chamber for 15 min to drain excess surface water. Pure cultures of E. coli (ATCC 35218), Salmonella typhimurium (MTCC 98), Bacillus subtilis and Staphylococcus aureus (coagulase-positive strain isolated from poultry meat) were obtained from ICT (Mumbai, India). Based on the protocol used by Khattak et al. (2005) the cultures were grown individually in tryptic soy broth for 20 h to a concentration of 9 log CFU/ml. The cultures were diluted and suspended in sterile 0.9 % saline. Samples (25 g) were submerged into the diluted cultures for 5 min to obtain 6 to 8 log CFU/g. The cut vegetables were kept in a laminar flow chamber for 10 min to remove excess surface water. Inoculated samples were irradiated at doses of 0.0, 0.2, 0.4, 0.6, 0.8, 1.0, 1.2 and 1.5 kGy. After irradiation, 25 g of each sample was homogenized with 225 ml of 0.9 % saline and after appropriate serial dilutions, the samples were pour plated on tryptic soy agar for Salmonella and E coli while Baird parker and Luria agar for Staphylococcus and Bacillus respectively. The D 10 value was determined by taking the negative reciprocal of the survivor curve slope.

Sensory analysis

Sensory analysis was carried out by a sensory panel of 15 members (7 women and 8 men). The panelists were chosen according to following criteria: people with no food allergies, nonsmokers, with age between 25 and 55 years, available for all sessions and interested in participating. All panelists had previous experience in carrying out sensory analysis of similar food products. Samples for sensory evaluation were prepared by boiling RTC cabbage in water for 5 min and immediately cooling it in chilled water. Boiling time was chosen in preliminary experiments by serving samples boiled for different duration (2, 5 and 10 min) to the panelist. Amongst these the samples boiled for 5 min was liked most. Cabbage samples (10 g) were served in white trays numbered randomly to the sensory panel. The replicates were assessed in three different sessions to avoid tiredness and saturation. The panelists had to consume the whole sample and rinse their mouths with water between them.

Hedonic test was carried out using a 9- point scale with 1, dislike extremely or not characteristic of the product and 9, like extremely or very characteristic of the product (Lopez-Rubira et al. 2005). Parameters evaluated were color, aroma, texture, taste and overall acceptability. To determine the acceptability of the samples at different storage points, all the parameters analyzed were compared with fresh control samples on each day. The scores given for all the attributes for each sample were tabulated. Next, the mean value was calculated for each attribute of a sample, representing the panel’s judgment about the sensory quality of the product and significant difference was found by analysis of variance (ANOVA).

Determination of color

As the minimum dose at which the microbial load was maintained below acceptable limit was 2 kGy, futher analyses were done at this dose. Color of the cabbage strips were measured by Minolta Chromameter (model CM-3600d Konica Minolta Sensing Inc., Japan) as described earlier (Tripathi et al. 2013).

Head space gas composition

O2 and CO2 content was analyzed at 2 kGy using a gas chromatograph (GC 2010, Shimadzu Corporation, Japan) as described earlier (Tripathi et al. 2013). Based on observed O2 and N2 concentrations in the package headspace, actual concentrations of O2 and CO2 (%O2 and %CO2) were calculated using following equations:

Texture analysis

The texture analysis for the sample was performed using a Texture Analyzer (TA. HD. Plus, Stable Micro Systems). Puncture strength of the strips (1 × 3 cm) were determined by 2 mm needle probe having test speed of 30 mm/min.

Preparation of methanolic extracts

Forty grams of cabbage were extracted twice with 150 mL of aqueous methanol. The extract was filtered (whatman filter 1) and the supernatant concentrated in a flash evaporator (Buchi Rotavapor R114) to make a 1 % solution that was used for subsequent assays.

DPPH radical scavenging activity

A DPPH radical scavenging assay was used to evaluate total antioxidant activity of cabbage (Tripathi et al. 2013). An aliquot of methanolic extract (100 μL) was added to 1 mL of DPPH solution (110 μM in 80 % aq methanol). After incubation under dark conditions for 20 min absorbance was measured at 516 nm. DPPH• scavenging activity was expressed as the μg gallic acid equivalent (GAE) / g of cabbage.

Ferric reducing power assay

The Fe3+ reducing power of the extract was assayed according to Meir et al. (1995). Briefly, 50 μl of methanolic extract was mixed with 950 μl of 0.2 M phosphate buffer (pH 6.6) and 1 % potassium ferricyanide (0.5 mL) and incubated for 20 min at 50 °C. TCA (0.5 mL, 10 %) was added to the mixture and centrifuged (12,000 rpm, 10 min). To 0.5 mL of supernatant an equal volume of distilled water and 0.1 mL of 0.1 % FeCl3 solution was added. The reaction mixture was left for 10 min at RT, and the absorbance measured at 700 nm. Reducing activity was expressed as μg ascorbic acid equivalent antioxidant capacity (AEAC) g−1 of cabbage.

Hydroxyl radical scavenging assay

The deoxyribose method for determining the scavenging effect of the methanolic extract on OH• was performed according to described procedure (Valentão et al. 2002). The reaction mixture contained deoxyribose (28 Mm), FeCl3 (20 Mm), EDTA (1 Mm), H2O2 (20 mM), ascorbate (1 Mm) and different concentration of methanolic extract. The reaction mixture was incubated for 1 h at 37 °C. 1 % TCA and 2.8 % TBA was added and incubated at 90 °C for 30 min. OD was measured at 532 nm. OH• scavenging activity was expressed as μg GAE g−1 of cabbage.

Nitric oxide scavenging assay

The NO• scavenging effects of methanolic extract was measured according to the method of Marcocci et al. (1994). Briefly, 100 μL of methanolic extract solution was added to 200 μL of 10 mM SNP solution and incubated at 25 °C for 150 min. To 100 μL of the above mixture 1 mL of Griess reagent was added. The absorbance immediately read at 546 nm. NO• radical scavenging activity was expressed as μg quercetin equivalent (QE) g−1 of cabbage.

Total phenolic content (TPC)

TPC was evaluated in accordance with the Folin–Ciocalteu procedure (Singleton and Rossi 1965). TPC in cabbage was expressed as mg GAE 100 g−1 fresh weight (FW) of cabbage.

Total flavonoid content

The AlCl3 method reported by Luximon-Ramma et al. (2002) was used for determination of total flavonoid content. Flavonoid content was expressed as μg QE g−1 of cabbage.

Ascorbic acid content

Total vitamin C content of cabbage was estimated in accordance with standard AOAC official titrimetric method (AOAC 1990). Cabbage (10 g) was extracted with 20 % metaphosphoric acid in an omnimixture. Reducing capacity of the supernatant was measured by titrating with 2,6 dichlorophenol indophenol. The end point of the reaction was detected by appearance of pink color by excess of the dye in the acidic solution. The same process was followed for standard ascorbic acid solutions of known concentration (0.1–0.0015 %). Ascorbic acid content was expressed as mg/100 g FW of cabbage of cabbage.

Statistical analysis

DSAASTAT ver. 1.101 by Andrea Onofri was used for statistical analysis of data. Data was analyzed by Analysis of variance (ANOVA) and multiple comparisons of means were carried out using Duncan’s multiple range test. Data are expressed as means ± SD of three independent analyses each carried out in triplicate. Means are expressed as significantly different or not at 5 % level of confidence.

Results

Microbial analysis

Effect of irradiation (0.5–2.5 kGy) on microbial load is shown in Fig. 1. Irradiation was found to decrease the bacterial load at all doses studied. Increasing radiation dose resulted in a decrease in bacterial load. Maximum decrease in the microbial load was observed for 2.5 kGy followed by 2 kGy. A significant (p ≤ 0.05) increase in bacterial load during storage was observed in the non-irradiated samples. In control samples stored at 10 and 4 °C, the counts reached higher than 107 CFU/g on day 13 and 16 respectively which is beyond the acceptable limit prescribed for fresh cut vegetables and fruits (Fig. 1a and b). A similar trend was seen in samples irradiated at 0.5 kGy for both the temperatures. Between 1.0 and 1.5 kGy the above acceptable limit of bacterial population was reached within 16 and 21 days at 10 and 4 °C respectively. A radiation dose of 2 and 2.5 kGy was suitable to keep the mesophillic counts well below the acceptable limits up to 16 and 21 days when stored at 10 and 4 °C.

Total plate count (TPC) of RTC cabbage during storage at a. 10 °C, b. 4 °C; Total fungal count (TFC) count of RTC cabbage during storage at c. 10 °C; d. 4 °C. Values are expressed as mean ± SD (n = 9). Mean values for the same day bearing different superscripts are significantly different (p < 0.05). Samples stored at 10 and 4 °C were studied for 16 and 21 days respectively

The response of yeast and mould count for different radiation doses is shown in Fig. 1c and d. Control samples showed an increase in fungal count with storage. No fungi were detected in cabbage irradiated with 1.5 kGy up to 5 days of storage. In samples irradiated at doses ≥2 kGy no fungi were detected during the entire storage period of 16 and 21 days at 10 and 4 °C respectively.

Thus based on microbial analysis an optimum shelf life of 16 and 21 days could be achieved when shredded cabbage was radiation processed at doses ≥2 kGy and stored at 10 and 4 °C respectively.

Determination of D10 values

Table 1 shows D 10 values for the pathogenic strain onto MP cabbage samples. The D 10 values obtained in the current studies were comparable to those reported by earlier researchers for fresh cut vegetables (Khattak et al. 2005; Trigo et al. 2009). Bacillus subtilis and Staphylococcus aureus were found to have high D 10 values making it the more radioresistant species when compared to Escherichia coli and Salmonella typhimurium.

Sensory analysis

Sensory attributes of RTC cabbage based on hedonic analysis at different irradiation doses and storage time is given in Table 2 and 3. Sensory quality of control sample stored at 10 °C was found to deteriorate within 5 days due to browning of the cut edges. This increased to a high level on day 8. This was also the case with the control samples stored at 4 °C beyond 13 days of storage. Samples irradiated with doses from 0.5 to 1.5 kGy also showed significant blackening at the end of storage period at both the temperatures. However, 2 and 2.5 kGy appeared fresh throughout the storage period. The aroma quality of control and samples given a dose less than 2 kGy decreased with storage. Off odor was detected by the panel in the control, 0.5 and 1 kGy samples at the end of the storage period for both the temperatures. No off odor was detected in 2 and 2.5 kGy sample throughout the storage period. Also, an increase in cabbage like odor was noted in these samples that remained unaffected with storage. The 2 kGy sample showed a slight softening in texture immediately after irradiation. However, this did not affect the overall acceptability of the sample. The control and 0.5 to 1.5 kGy samples showed a decrease in firmness in later stages of storage but the 2 kGy sample maintained its texture throughout the storage period. The 2.5 kGy sample, however, showed a considerable softening in texture at all storage intervals which reduced its overall acceptability. No difference in taste was found between control and irradiated sample immediately after irradiation. At the end of storage period control and samples given a dose of less than 2 kGy were extensively spoiled due to microbial load and hence could not be assessed by the sensory panel for taste at later stages of storage. The 2 and 2.5 kGy samples showed a slight decrease in taste score at the end of storage period but it was found to be within the acceptable limit.

Thus based on microbial and sensory analysis at the optimum conditions of irradiation (2 kGy) and storage (10 and 4 °C) an extension in shelf life by 8 and 5 days respectively was achieved compared to the non-irradiated controls.

Color

As 2 kGy was found to be the optimum dose from sensory and microbial analysis, further analyses were done at this dose. Figure 2a and b represents the effect of irradiation and storage on L values of RTC cabbage strips. A continuous decrease in L values during storage, with a substantial decrease beyond day 5 at 10 °C and 13 days at 4 °C was seen in control sample. Interestingly, luminosity (L) of the cabbage strips irradiated at 2 kGy remained unchanged during storage and the visual quality was acceptable at the end of storage.

Effect of radiation treatment (2 kGy) and storage on L values of RTC cabbage at a. 10 °C and b. 4 °C. Values are expressed as mean ± SD (n = 9). Mean values for the same day bearing different superscripts are significantly different (p < 0.05). Samples stored at 10 and 4 °C were studied for 16 and 21 days respectively

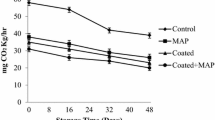

Headspace gas composition

Significant (p ≤ 0.05) effect of irradiation and storage time on the head space composition of both the gases was observed during storage (Fig. 3a and b). Similar trend was seen for both gases for samples stored at 4 and 10 °C. O2 and CO2 concentration remained constant in control samples throughout the storage period. A significant decrease in O2 content and an increase in CO2 content were noted immediately after irradiation. On further storage the O2 content gradually increased and CO2 content decreased reaching the level in the control on day 5 that further remained constant.

Variation of O2 & CO2 content in headspace of packets during storage at a. 10 °C and b. 4 °C; Puncture strength (N) of RTC cabbage during storage at c. 10 °C and d. 4 °C. Values are expressed as mean ± SD (n = 9). Mean values for the same day bearing different superscripts are significantly different (p < 0.05). Samples stored at 10 and 4 °C were studied for 16 and 21 days respectively

Texture analysis

Firmness of cabbage strips was measured by determining puncture strength on a texterometer. Figure 3c and d provides the puncture strength of both the control and irradiated (2 kGy) samples stored for different days at two different temperatures (10 and 4 °C). A slight decrease in puncture strength immediately after irradiation with no further decrease in firmness thereafter until the end of the storage period was noted. In contrast, in the control samples, the firmness remained unaffected up to a storage period of 13 days beyond which this parameter decreased significantly. These changes were similar for both the samples at the two storage temperatures. The data obtained are in agreement with the scores on texture obtained from the sensory panel.

Antioxidant activity

DPPH• and OH• activity increased significantly in response to radiation treatment at all stages of storage (Fig. 4a and c). Storage beyond 8 days resulted in a decrease in DPPH scavenging activity. This decrease was, however, comparable for both the control and irradiated samples. Irradiation and storage was found to show no effect on nitric oxide radical scavenging activity and ferric reducing power of the sample (Fig. 4d and b). No difference was seen in antioxidant activity due to storage temperature.

Effect of radiation processing (2 kGy) and storage on a. DPPH radical scavenging activity; b. Ferric reducing property; c. Hydroxyl radical scavenging activity; d. Nitric oxide radical scavenging activity. e. Total phenolic content; f. Total flavonoid content; g. Vitamin C content. Values are expressed as mean ± SD (n = 9). Mean values for the same day bearing different superscripts for a particular temperature are significantly different (p < 0.05). Samples stored at 10 and 4 °C were studied for 16 and 21 days respectively

Total phenolic and flavonoid content

TPC was found to be comparable to that reported earlier (Jaiswal et al. 2011) for cabbage. Beyond 10 days of storage a decrease in TPC was noted in both the control and irradiated samples (Fig. 4e). No significant effect on the TPC was, however, noted as a result of irradiation. Irradiation was also found to have no effect on the flavonoid content of cabbage during the entire storage period (Fig. 4f). No difference was also observed as a result of variation in storage temperature. The content of flavonoid estimated in the present study is comparable with the values reported in literature (Jaiswal et al. 2011).

Ascorbic acid content

Variation in the vitamin C content among different cabbage cultivars ranging from 5.7 to 23.5 mg/100 g has been reported by Singh et al. (2007). The amount estimated in present study is in agreement with the previous reports available. No significant change (p ≤0.5) in the vitamin C content was observed during storage in both the control and radiation processed cabbage in the present study for both the temperatures studied (Fig. 4g).

Discussion

γ-irradiation is known to be an effective tool for microbial decontamination of food. It has been proven to be an effective method to reduce both bacterial and fungal population. In the present study a dose dependent decrease in bacterial and fungal population was noted. A dose of 2 and 2.5 kGy dose was found to substantially reduce microbial population throughout the storage period. Interestingly no fungal colonies were detected at this dose. Similar results have been reported for irradiated lettuce (Prakash et al. 2000). Khattak et al. (2005) found that fungal colonies were eliminated on carrot and cabbage when treated with doses higher than 2 kGy. Results obtained in the present study are in agreement with that reported previously by other researchers. Thus, 2 kGy was found to be the optimum dose required for maintenance of microbial safety during storage of RTC cabbage.

Pathogenic bacteria present in fresh cut vegetables commonly include Escherichia coli, Salmonella, Listeria monocytogenes etc. Estimation of D10 values is a commonly used method for determination of effectiveness of radiation processing against a particular pathogen inoculated on food sample. A reduction by 4–5 log cycles in the population of Listeria monocytogenes has been extensively documented in various radiation processed vegetables. Similar results were obtained for the pathogenic strains studied in the present study (Saroj et al. 2006; Goularte et al. 2004). While a radiation dose of less than 1 kGy was found to be sufficient to reduce the bacterial count by 5 log cycle for Escherichia coli and Salmonella typhimurium a dose of 2 kGy was required for Staphylococcus aureus and Bacillus subtilis. For a sanitizing process to be effective it is necessary to kill 99.999 % of a certain microorganism population, when using γ-radiation a 5 log reduction is desired. Thus, 2 kGy was found to be the optimum dose where a reduction by minimum 5 log is achieved for all the pathogenic strains studied.

Sensory quality of control and samples irradiated at various doses were analyzed by hedonic scores. 2 kGy samples were found to have highest acceptability throughout the storage period. No difference was found in appearance immediately after irradiation compared to the control. However, the control sample developed browning at edges after 5 days unlike the irradiated sample that appeared fresh throughout the storage period. The aroma quality of control samples deteriorated with storage. On the other hand, irradiated samples demonstrated better aroma scores than control samples throughout the storage period. In fact, irradiated samples had a higher cabbage like smell immediately after irradiation. Allyl isothiocyanate (AITC) has been reported to be the major volatile compound responsible for the characteristic odor of cabbage. This compound is known to be derived by the hydrolytic cleavage of the glucosinolate, sinigrin, Our recent studies (Banerjee et al. 2014) on the effect of radiation processing of cabbage have demonstrated an enhanced formation of sinigrin and a consequent increased liberation of AITC. Thus the enhanced cabbage odor observed here could be explained. Significantly higher aroma scores for irradiated carrots, cilantro, green onions, parsley and red lettuce after 14 days of storage has been earlier reported (Fan and Sokorai 2008).

Appearance of the product plays an important role in consumer acceptance. Beyond 5 days at 10 °C and 13 days at 4 °C, the control samples showed visual browning that increased with further storage. Ke and Saltveit (1989) have reported similar observations in fresh-cut vegetables. The irradiated sample, however, showed no visual browning throughout the storage period. Polyphenoloxidase (PPO), that catalyses the oxidation of phenolic compounds to colored melanins, is the major enzyme responsible for browning in fruits and vegetables. We have earlier demonstrated a five-fold increase in alpha resorcylic acid, an inhibitor of PPO, in irradiated MP cut ash gourd cubes resulting in a possible prevention of browning in this product. Lowering in PPO activity as a consequence of conformational changes in the active site on exposure to radiation and a resulting browning inhibition in irradiated mushroom has also been reported. Prathapan et al. (2009) have demonstrated that a decrease in PPO activity due to heating in fresh turmeric rhizome led to a decrease in browning. Changes in PAL activity under stress and a consequent variation in content of various benzoic and cinnamic acid derivatives that are known to be either substrates or inhibitors of PPO have also been reported. The mechanism of browning inhibition in cabbage by γ-irradiation in the light of the above observations needs further investigation.

Headspace gas composition forms an important aspect in the storage of MP vegetables. A very high O2 content often leads to greater unfavorable reactions like browning while a lower O2 level leads to growth of anaerobic bacteria. Hence, maintenance of optimum balance between O2 and CO2 level is very crucial. O2 level less than 2 % is known to favor growth of anaerobic bacteria like Clostridium botulinum and microaerophilic bacteria like Listeria spp. and lactic acid bacteria. In the present work, the lowest O2 content observed was 15.8 % immediately after irradiation. This may be because of rapid increase in respiration rate due to rise in cellular activity after irradiation. Aerobic condition was thus maintained throughout the storage period. On further storage, the O2 content gradually increased and CO2 content decreased reaching the level in the control on day 5 and then remained constant throughout the storage period. A similar observation in irradiated mushroom resulting from reduction in metabolic activity during storage has been demonstrated. Elevated CO2 levels have been shown to extend lag phase and thus slow the propagation of bacteria (Zagory 1999). The enhanced CO2 levels during the initial storage period in the irradiated samples may thus aid in slowing down microbial growth and thus improving shelf life compared to the control samples. The maintenance of constant O2 and CO2 level beyond storage of period of 5 days may be due to attainment of equilibrium condition between package headspace and atmosphere with time. A similar observation was also noted by us in irradiated MP ash gourd (Tripathi et al. 2013). The headspace gas composition was therefore found to be suitable for storage of RTC cabbage.

Loss in firmness of vegetable often affects consumer acceptability. Therefore texture of RTC cabbage was analyzed by a texture analyzer. A slight decrease in puncture strength was noted immediately after irradiation. This may be due to radiation induced depolymerization of pectin and other cell wall components such as cellulose and hemicelluloses leading to softening (Prakash et al. 2000). However, this did not affect the overall acceptability of the sample. The irradiated sample (2 kGy) retained its texture throughout the storage period. This may be due to lower transpiration rate in irradiated sample than control. The decrease in puncture strength after 16 days of storage in control sample could be due to its decay. A loss of firmness when stored in air after 12 days of storage resulting from a possible increased proliferation of pectolytic pseudomonas has also been reported by Amanatidou et al. (2000). Fan and Sokorai (2008) on the other hand reported that irradiation had no effect on the firmness of MP iceberg lettuce. No significant effect of radiation processing on firmness was also noted by Khattak et al. (2005) in MP cabbage and cucumber when stored at refrigeration temperatures (5 °C). In the present study, 2 kGy sample was thus found to be well acceptable from the view point of texture.

The 2 kGy dose was thus found to be optimum for shelf life extension of cabbage both at 10 and 4 °C. The nutritional quality of the vegetable with respect to radical scavenging activity, total phenolics, total flavonoid and vitamin C content was therefore evaluated at this dose.

Fresh fruits and vegetables are known to possess significant antioxidant activity. Many authors has demonstrated significant radical scavenging activity in fruits and vegeatbles like Aegle marmelos (Prathapan et al. 2012) and Boerhaavia diffusa (Prathapan et al. 2010). However, processing and storage may deteriorate the inherent antioxidant activity of the product. Hence assessment of effect of processing and storage on antioxidant activity forms an important parameter for development of RTC vegetables from nutritional point of view. However, a single antioxidant assay does not reflect the total antioxidant capacity of the compounds present in the product. So a number of antioxidant assays involving different principles were studied in RTC cabbage.

The DPPH• test is usually used to provide basic information on the ability of extracts to scavenge free radicals. γ-irradiation was found to enhance DPPH• scavenging activity of RTC cabbage. It is known that irradiation generates free radicals that may act as stress signals and trigger stress responses in vegetables, resulting in increased antioxidant synthesis. A similar phenomenon in present case could account for the increased antioxidant activities observed in the irradiated vegetable. However, beyond 10 days, the activity declined in both control and irradiated samples which might be due to degradation of antioxidants as a result of oxidation on prolonged storage. Similar trend in antioxidant activity was also noted at both the storage temperatures studied.

The reducing power of a compound may serve as a significant indicator of its potential antioxidant activity. Hence, effect of irradiation and storage on the Fe3+-reducing powers of methanolic extract was investigated. No difference was seen in reducing power values for control and irradiated sample with storage time and temperature.

Reactive oxygen metabolites, including free radicals such as NO• and OH• radicals are toxic and play an important role in tissue injury. OH• is the most reactive radical known, it can attack and damage living cells. In the present study an increase in OH• scavenging activity was found with irradiation. AITC, the major volatile compound of cabbage is known to possess significant OH• scavenging activity (Manesh and Kuttan 2003). An increase in AITC due to γ-irradiation has been reported by us earlier (Banerjee et al. 2014). This may account for the enhancement in OH• scavenging activity in irradiated sample. Reactive nitrogen species like NO• is associated with several types of cellular damage like lipid peroxidation, protein oxidation and nitration, enzyme inactivation, and DNA damage. No significant effect was noted as a result of irradiation, storage or variation in temperature on NO• scavenging activity.

Phenolics, flavonoids and vitamin C form important nutritional constituents of vegetables. Preserving these compounds in the vegetable is therefore essential for maintaining quality. Radiation induced increase in phenolic content has been previously demonstrated in vegetables like carrot and kale juice (Arvanitoyannis et al. 2009), fresh-cut iceberg lettuce (Fan and Sokorai 2008) and ash gourd (Tripathi et al. 2013). Villavicencio et al. (2000) on the other hand reported a radiation induced reduction in phenolic content at 10 kGy in Macacar bean. Reduction in phenolic content in Chinese cabbage beyond a dose of 1 kGy has also been reported (Ahn et al. 2005). In the present study, however, no changes in phenolic content were noted as a result of irradiation. No difference was found in flavonoid content due to irradiation. Temperature also had no effect on the total phenolic content and flavonoids. Vitamin C is the most sensitive vitamin being degraded quickly on exposure to heat, light and oxygen. It acts as an antioxidant in the body and is also a cofactor in several key enzymatic reactions. The content of ascorbic acid was found to be unaffected by radiation processing and storage in the present study. A similar observation was observed by us in irradiated ash gourd. Thus the nutritional quality of RTC cabbage with respect to antioxidant activity, phenolic and flavonoid content and vitamin C status was maintained upon irradiation.

Conclusions

The present study has demonstrated that radiation processing at a dose of 2 kGy can extend shelf life of RTC cabbage at 10 °C thereby improving the feasibility of storage of such products at higher temperature. The product was found to be microbiologically safe and had acceptable sensory and nutritional quality. Thus radiation processing can aid in enhancing shelf life of MP vegetables when stored at higher temperatures in supermarkets thereby saving on both energy and cost besides increasing its marketability.

References

Ahn H, Kim J, Kim J, Kim D, Yook H, Byun M (2005) Combined effects of irradiation and modified atmosphere packaging on minimally processed Chinese cabbage (Brassica rapa L.). Food Chem 89:589–597

Amanatidou A, Slump RA, Gorris LGM, Smid EJ (2000) High oxygen and high carbon dioxide modified atmospheres for shelf-life extension of minimally processed carrots. J Food Sci 65:61–66

AOAC (1990) Official methods of analysis, 15th edn. Association of Official Analytical Chemists, Arlington

Arvanitoyannis IS, Stratakos AC, Tsarouhas P (2009) Irradiation applications in vegetables and fruits: a review. Crit Rev Food Sci Nutr 49:427–462

Banerjee A, Variyar PS, Chatterjee S, Sharma A (2014) Effect of post harvest radiation processing and storage on the volatile oil composition and glucosinolate profile of cabbage. Food Chem 151:22–30

Fan X, Sokorai KGB (2008) Retention of quality and nutritional value of 13 freshcut vegetables treated with low dose radiation. J Food Sci 73:367–372

Goularte LL, Martins CG, Morales-Aizpurúa IC, Destro MT, Franco BDGM, Vizeu DM, Hutzler BW, Landgraf M (2004) Combination of minimal processing and irradiation to improve the microbiological safety of lettuce (Lactuca sativa, L.). Radiat Phys Chem 71:157–161

Harris WS (2008) Linoleic acid and coronary heart disease. Prostaglandins Leukot Essent Fat Acids 79:169–171

IAEA (2005) Use of irradiation to ensure hygienic quality of fresh, pre-cut fruits and vegetables and other minimally processed food of plant origin. Proceedings of a final research coordination meeting organized by the Joint FAO/IAEA Programme of Nuclear Techniques in Food and Agriculture and held in Islamabad, Pakistan

Jaiswal AK, Rajauria G, Abu-Ghannam N, Gupta S (2011) Phenolic composition, antioxidant capacity and antibacterial activity of selected irish brassica vegetables. Nat Prod Commun 6:1–6

Ke D, Saltveit ME (1989) Wound-induced ethylene production, phenolic metabolism and susceptibility to russet spotting in iceberg lettuce. Phys Plant 76:412–418

Khattak AB, Bibi N, Chaudry MA, Khan M, Khan M, Qureshi MJ (2005) Shelf life extension of minimally processed cabbage and cucumber through gamma irradiation. J Food Prot 68:105–110

Kodenchery UK, Nair MP (1972) Metabolic changes induced by sprout inhibiting dose of y-irradiation in potatoes. J Agric Food Chem 20:282–285

Lopez-Rubira V, Conesa A, Allende A, Artes F (2005) Shelf life and overall quality of minimally processed pomegranate arils modified atmosphere packaged and treated with UV C. Postharvest Biol Technol 37:174–185

Luximon-Ramma A, Bahorun T, Soobrattee MA, Aruoma OI (2002) Antioxidant activities of phenolic, proanthocyanidin, and flavonoid components in extracts of Cassia fistula. J Agric Food Chem 50:5042–5047

Manesh C, Kuttan G (2003) Anti-tumour and anti-oxidant activity of naturally occurring isothiocyanates. J Exp Clin Cancer Res 22:193–199

Marcocci L, Packer L, Droy-Lefaix MT et al (1994) Antioxidant action of Ginkgo biloba extracts EGB 761. Methods Enzymol 234:462–475

Meir S, Kanner J, Akiri B, Philosoph-Hadas S (1995) Determination and involvement of aqueous reducing compounds in oxidative defense systems of various senescing leaves. J Agric Food Chem 43:1813–1819

NIIR consultancy services. Cold storage, food & fruits storage, refrigerated warehousing, industrial cold rooms. http://www.niir.org/profiles/profiles/cold-storage-food-amp-fruitsstorage-refrigerated-warehousing-industrial-cold-rooms/z,,7f,0,a/index.html

Ortega A, Varela LM, Bermudez B, Lopez S, Abia R, Muriana FJ (2012) Dietary fatty acids linking postprandial metabolic response and chronic diseases. Food Funct 3:22–27

Prakash A, Guner AR, Caporaso F, Foley DM (2000) Effects of low-dose gamma irradiation on the shelf life and quality characteristics of cut Romaine lettuce packaged under modified atmosphere. J Food Sci 65:549–553

Prathapan A, Lukhman M, Arumughan C, Sundaresan A, Raghu KG (2009) Effect of heat treatment on curcuminoid, colour value and total polyphenols of fresh turmeric rhizome. Int J Food Sci Technol 44:1438–1444

Prathapan A, Singh MK, Anusree SS, Kumar S, Sundaresan, Raghu KG (2010) Antiperoxidative, free radical scavenging and metal chelating activities of Boerhaavia diffusa L. J Food Biochem 35:1548–1554

Prathapan A, Krishna MS, Nisha VM, Sundaresan A, Raghu KG (2012) Polyphenol rich fruit pulp of Aegle marmelos (L.) Correa exhibits nutraceutical properties to down regulate diabetic complications—An in vitro study. Food Res Int 48:690–695

Saroj SD, Shashidhar R, Pandey M, Dhokane V, Hajare S, Sharma A, Bandekar JR (2006) Effectiveness of radiation processing in elimination of Salmonella typhimurium and Listeria monocytogenes from Sprouts. J Food Prot 69:1858–1864

Siddiqui MW, Chakraborty I, Ayala-Zavala JF, Dhua RS (2011) Advances in minimal processing of fruits and vegetables: a review. J Sci Ind Res 70:823–834

Singh J, Upadhyay AK, Prasad K, Bahadur A, Rai M (2007) Variability of carotenes, vitamin C, E and phenolics in Brassica vegetables. J Food Compos Anal 20:106–112

Singleton VL, Rossi JA Jr (1965) Colorimetry of total phenolics with phosphomolybdic phosphotungstic acid reagents. Am J Enol Vitic 16:144–158

Trigo MJ, Sousa MB, Sapata MM, Ferreira A, Curado T, Andrada L, Botelho ML, Veloso MG (2009) Radiation processing of minimally processed vegetables and aromatic plants. Radiat Phys Chem 78:659–663

Tripathi J, Chatterjee S, Vaishnav J, Variyar PS, Sharma A (2013) Gamma irradiation increases storability and shelf life of minimally processed ready-to-cook (RTC) ash gourd (Benincasa hispida) cubes. Postharvest Biol Technol 76:17–25

Valentão P, Fernandes E, Carvalho F, Andrade PB, Seabra RM, Bastos ML (2002) Antioxidative properties of cardoon (Cynara cardunculus L.) infusion against superoxide radical, hydroxyl radical, and hypochlorous acid. J Agric Food Chem 50:4989–4993

Villavicencio ALCH, Mancini-Filho J, Delincee H, Greiner R (2000) Effect of irradiation on anti-nutrients (total phenolics, tannins and phytate) in Brazilian beans. Radiat Phys Chem 57:289–293

Zagory D (1999) Effects of post-processing handling and packaging on microbial populations. Postharvest Biol Technol 15:313–321

Author information

Authors and Affiliations

Corresponding author

Additional information

Aparajita Banerjee and Suchandra Chatterjee contributed equally to this work.

Rights and permissions

About this article

Cite this article

Banerjee, A., Chatterjee, S., Variyar, P.S. et al. Shelf life extension of minimally processed ready-to-cook (RTC) cabbage by gamma irradiation. J Food Sci Technol 53, 233–244 (2016). https://doi.org/10.1007/s13197-015-2025-7

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-2025-7