Abstract

Microorganisms are the major cause of spoilage in most seafood products; however, only few microbes, called the specific spoilage organisms (SSOs), contribute to the offensive off-flavors associated with seafood spoilage. In food, microbial degradation manifests itself as spoilage, or changes in the sensory properties of a food product, rendering it unsuitable for human consumption. The use of antimicrobial substances can control the general microflora as well as specific microorganisms related to spoilage to provide products with higher safety and better quality. Many antimicrobial compounds have been evaluated in film structures for use in seafood, especially organic acids and their salts, enzymes, bacteriocins; some studies have considered inorganic compounds such as AgSiO2, zinc oxide, silver zeolite, and titanium oxide. The characteristics of some organic antimicrobial packaging systems for seafood and their antimicrobial efficiency in film structures are reviewed in this article.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Seafood can undergo rapid microbial contamination and growth if subjected to inadequate handling and storage. One-fourth of the world’s food supply and 30 % of landed fish (Amos 2007) are lost through microbial activity alone. Around 4–5 million tons of fish are lost every year because of enzymatic and microbial spoilage due to improper onsite storage. The specific spoilage microorganisms known to be involved in seafood spoilage are listed in Table 1, in descending order of spoilage activity (Ghaly et al. 2010). Some microorganisms cause spoilage to different degrees depending on the total microbial flora, fish quality, handling and packaging methods, and storage temperature. The traditional methods of fish preservation include thermal processing, drying, freezing, refrigeration, irradiation, modified atmosphere packaging, and addition of antimicrobial agents or salts. Unfortunately, some of these techniques cannot be applied to some fish products such as fresh meat and ready-to-eat products.

An antimicrobial agent is a chemical preservative that can be incorporated into a packaging material to induce antimicrobial activity. Various antimicrobial agents, which can generally be divided into three major groups, namely, chemical agents, natural spices, and probiotics, can be incorporated into conventional food packaging systems and materials to create new antimicrobial packaging systems (Han 2005). Antimicrobial packaging is a form of active packaging that interacts with the product or headspace between the package and food to obtain a desired outcome (Brody et al. 2001).

In particular, antimicrobial packaging is a promising form of active food packaging for fish products. Microbial contamination of these foods occurs primarily on the surface because of post-processing handling, attempts have been made to improve safety and to delay spoilage by using antibacterial sprays or dips. However, direct surface application of antibacterial substances onto foods has limited benefits because the active substances are often neutralized on contact or diffuse rapidly from the surface into the food mass (Quintavalla and Vicini 2002). On the other hand, incorporation of bactericidal or bacteriostatic agents into fish formulations may result in partial inactivation of the active substances by the product constituents and therefore, expected to exert only limited effects on the surface microflora. During the first stage of spoilage, fish emit a very bad odor that is undesirable to most consumers; therefore, antimicrobial agents that can reduce this odor are useful to control this problem while enhancing the shelf life of the fish at the same time (Ghaly et al. 2010). Traditionally, the antimicrobial agents are added directly to foods; however, many substances in the food itself inhibit antimicrobial activity, diminishing their effectiveness. In such cases, the use of antimicrobial films or coatings can be more efficient because they can selectively and gradually migrate from the package onto the food surface (Ouattara et al. 2001). Packaging films containing antimicrobial agents pose a potential solution to reduce the challenges of spoilage. The purpose of this paper is to provide an overview of the published data on the antibacterial activity of organic and inorganic components that can be considered suitable for application in seafood and to describe their possible modes of action.

Major microbial hazards

Seafood is associated with many microbial hazards. Temperature shifts during transportation, from low to high or high to low, can cause the formation or reproduction of heat-stable toxins. Salmonella species is the main cause of seafood-borne bacterial illness as well as the detention of imports at the border (Norhana et al. 2010). The growth factors associated with Salmonella species include the following: temperature range of 5.2–47 °C, pH range of 3.7–9.5; many Salmonella strains can survive freezing for up to 9 months (Kerry 2012). Listeria monocytogenes is not as widespread as Salmonella species but is commonly observed in seafood because of its presence as an environmental inhabitant in processing facilities. L. monocytogenes also grows in the temperature range of −0.4 to 45 °C; it grows rapidly and reaches higher numbers in shrimp and catfish (Shineman and Harrison 1994). Vibrio species is also associated with seafood-borne diseases and the most virulent species are Vibrio vulnificus. Schwarz (2000) found that the oysters harvested off the Texas coast subjected to rapid cooling showed 97.8 % reduction in the number of V. vulnificus, whereas conventionally cooled oysters took four days to reach the same numbers. The toxin produced by Clostridium botulinum, a spore-forming anaerobe, is a big concern because it is heat stable, highly toxic, and can grow at temperature exceeding 3.3 °C; the level of C. botulinum in seafood has been estimated at 1 to 2400 spores per kilogram of seafood (Dodds 1992). Aeromonas hydrophila is more commonly associated with or is exclusively found in seafood and in fresh-flowing, stagnant, and brackish water (Bremer et al. 2003). A study by Papadopoulou et al. (2007) showed that local seafood harvested within 24 h contained A. hydrophila as the predominant organism (freshwater fish, 38 %; shellfish, 73–86 %; and marine finfish, 93 %).

The packaging of seafood products has historically been passive, or used to protect from oxygen, desiccation, and microbial contamination. Tamper-evident packaging became the norm 30 years ago. Vacuum-packed cold-smoked salmon containing high levels (l07–108 CFU/g) of lactic acid bacteria remain good for several weeks before the product is rejected by sensory testing, which shows that the often used “total bacterial count” does not serve any purpose as a spoilage indicator for this type of product (Fig. 1) (Hansen et al. 1995).

Changes in total psychrotrophic count, lactic acid bacteria and Entevohactrriareac during storage of vacuum-packed cold-smoked salmon (4.6 %) w/w in water phase) at 5 °C. Source: Adapted and modified from Hansen et al. 1995

Antimicrobial packaging materials have potential as an alternative solution to prevent the growth of spoilage and pathogenic microorganisms.

Antimicrobial agents

Antimicrobial packaging have attracted the seafood industry because its potential in the hurdle technique used for minimally processed food. For application in food, seafood, pharmaceuticals, and cosmetic products, the antimicrobial agent industry must follow the guidelines and regulations of the country in which they are used, such as the FDA and/or the EPA in the United States. Thus, new antimicrobial packaging materials can be developed only by using agents that are approved by authorizing agencies such as the FDA as compounds notified-to-be-used within the concentration limits for enhancement or preservation of food safety. Various antimicrobial agents may be incorporated in the packaging system, including chemical antimicrobials, antioxidants, biotechnological products, antimicrobial polymers, and natural antimicrobials. Both organic and inorganic chemical antimicrobial agents are most commonly used in the industry.

Organic antimicrobials

Organic acids such as benzoic acids, parabens, sorbates, sorbic acid, propionic acid, acetic acid, lactic acid, medium-sized fatty acids, and/or their mixture possess strong antimicrobial activity and have been used as food preservatives, food contact substances, and food contact material sanitizers Han (2003). Coma et al. (2001) studied the moisture barrier and the antimicrobial properties of HPMC-fatty acid films (30–50-ìm-thick) containing nisin (105 IU/mL) as the AM agent and its efficacy against Listeria innocua and Staphylococcus aureus in food products.

The mechanism(s) by which organic acids inhibit microorganisms has been studied extensively. There is little evidence that organic acids influence cell wall synthesis in prokaryotes or that they significantly interfere with protein synthesis or genetic mechanisms. Instead, organic acids are more likely act at the cytoplasmic membrane level. The un-dissociated form of organic acids penetrates the cell membrane lipid bilayer, and once inside the cell, it dissociates because of the higher pH inside the cell. Because bacterial cells should be able to maintain the internal pH near neutral, the protons generated from the dissociation of organic acids must be transported to the exterior. Since the protons generated by the organic acids inside the cell must be extruded using energy in the form of ATP, a constant influx of these protons will eventually deplete cellular energy (Davidson et al. 2002).

The natural antimicrobials and essential oils found in seafood are very helpful against microbial growth and do not have any negative impact on the environment. Consumers demand premium quality seafood without any synthetic additives and there is greater demand by retail outlets for extended shelf life in case of fresh and processed seafood. These reasons have prompted the use of organic antimicrobial agents and there are many ongoing studies relating these agents and specific spoilage microorganisms (Irkin and Esmer 2015) (Table 2).

According to López-Malo et al. (2000), and Nychas and Tassou (2002), the active antimicrobial substances in many spices and essential oils interact with food components, and if used as the only preservative in foods, more than 1 % (w/w) of these spices and essential oils can be required to extend the shelf life of seafood. These high levels often extend a very strong flavor and are primarily useful in sauces and products that are mixed with other food ingredients. Mejlholm and Dalgaard (2002) found that 0.05 % (v/w) oregano oil yielded a distinctive but pleasant flavor to cod fillets, and the oil significantly extended the shelf life and delayed spoilage reactions. Oregano oil and many other essential oils are relatively cheap, and the addition of 0.05 % essential oil (v/w) constitutes approximately 1 % of the raw material cost in case of cod fillets. Majority of the studies focused on the use of essential oils to develop edible coating, encapsulation, or any other form, as we know that high fat content of the fish affects the function of the essential oil. For example, 0.5 μL/g oregano oil is more effective against P. phosphoreum on cod fillets than salmon, which is a fatty fish (Mejlholm and Dalgaard 2002). Alboofetileh et al. (2016) reported that alginate-clay films enriched with 1 % Marjoram essential oil significantly delayed the growth of L. monocytogenes during the 15-day storage with final counts reaching 6.23 log CFU/g. Alginate/carboxyl methylcellulose coating+clove essential oil 1.5 % showed lowest (p < 0.05) and acceptable biochemical, bacteriological and sensory characteristics attributes up to 16 days storage at 4 °C (Jalali et al. 2016).

Thymol, one of the key components of oregano oil, is mainly responsible for its antimicrobial activity. Mastromatteo et al. (2010) reported that a single coating did not affect microbial growth on ready-to-use peeled shrimps. A slight antimicrobial effect was obtained when the coating was loaded with thymol. Moreover, the active coating was effective at diminishing the loss in the sensory quality of the investigated product, which was particularly true at the lowest thymol concentration (Fig. 2). It is worth noting that for all MAP samples, the Pseudomonas count was always below the detection level until day 26 (Coat-thymol-MAP).

Evolution of mesophiles and hydrogen sulphide-producing bacteria (Log cfu/g) for Step II peeled shrimps. Source: Adapted and modified from Mastromatteo et al. 2010

Thymol and carvacrol are the most active constituents of thyme essential oil with a wide spectrum of antimicrobial and antioxidant properties (Burt 2004 and Lambert et al. 2001). Kykkidou et al. (2009) concluded that thyme oil and MAP were the most effective methods to inhibit pseudomonas and H2S-producing bacteria in swordfish. The shelf life of fresh refrigerated Mediterranean swordfish was 8 and 13 days under aerobic and MAP conditions, respectively. The addition of 0.1 % thyme essential oil extended the shelf life under aerobic conditions by 5 days, whereas the combination of MAP and thyme oil resulted in significant shelf life extension of the swordfish fillets by approximately 7 days. Galotto and Ulloa (2010) showed that flexible plastic films containing thymol as the antimicrobial agent for salmon packaging extended shelf life 18 days at 2 °C. Erkan (2012) concluded that hot smoked trout treated with thyme and garlic oil maintained a shelf life of 7 weeks in cold storage compared to 5 weeks for untreated hot smoked rainbow trout, based on sensory, chemical, and microbiological evaluation. Karakaya et al. (2015) carried out experiments on whey protein isolate coating enriched with thyme essential oil (3 %, 5 %, and 7 %, v/v) on whole trout under refrigerated storage at 4 ± 2 °C and concluded that increasing amount of thyme oil increased the storage stability of trout, in all aspects. Guran et al. (2014) investigated the effects of different concentrations of thyme, clove, and rosemary extracts on the microbiological, chemical, and sensory attributes of bonito fish patties and found that the addition of essential oils exerted a positive effect on the shelf life of this product; in particular, rosemary essential oil produced a remarkable effect. The mechanism of action of thymol is very similar to that of carvacrol, with both having the hydroxyl group at a different location on the phenolic ring. Both substances appear to make the cell membrane permeable (Lambert et al. 2001). Carvacrol and thymol are able to disintegrate the outer membrane of gram-negative bacteria, releasing lipopolysaccharides (LPS) and increasing the permeability of the cytoplasmic membrane to ATP. The presence of magnesium chloride has been shown to have no influence on this action, suggesting a mechanism other than chelation of cations in the outer membrane.

Chitosan is a nontoxic, biodegradable, and biocompatible natural polymer. It is a good choice for antimicrobial films because of its superior film-forming properties, ability to adsorb nutrients used by bacteria, and capacity to bind water and inhibit various bacterial enzyme systems (Darmadji and Izumimoto 1994). Chitosan, which is mainly obtained from crustacean shells, is the second most abundant natural polymer in nature after cellulose. Therefore, chitosan, which is commercially produced mostly from marine sources (e.g., crustacean shells), has been used to stabilize seafood-based products. Chitosan-based films and coatings have been used for a variety of fish species to reduce microbial flora and to improve overall fish quality and prolong storage life (Duan et al. 2010b). Cao et al. (2009) reported that 5 g/L chitosan extended the shelf life of oysters (Crassostrea gigas) from 8–9 days to 14–15 days. Preservative treatment was undertaken by immersing the oysters in 5.0 g/L chitosan solution for 10 min at a ratio of 1:2 (w/v). They explained that Pseudomonas and Shewanella species are the most prolific microorganisms during the cold storage of fish and shellfish. Günlü and Koyun (2013) found that the shelf life of chitosan film-wrapped and vacuum-packaged sea bass samples ended at 25–30 days, while that of vacuum-packaged sea bass sample alone ended within 5 days. Fernández-Saiz et al. (2013) demonstrated that the incorporation of chitosan acetate film before packaging led to a decrease in the final bacterial population by 1.6 and 3.8 log units in chitosan air-packaged and chitosan vacuum-packaged samples, respectively. Jasour et al. (2015) determined that trout fillets treated with chitosan and lactoperoxidase had significantly lower numbers of Shewanella putrefaciens, Pseudomonas fluorescens, and psychrotrophic and mesophilic bacteria and found that their shelf life was extended by at least 4 days, compared to the control samples. Speranza et al. (2013) built a polynomial model and highlighted that P. fluorescens was the most resistant microorganism in seafood. They also showed that P. fluorescens could be inhibited in fillets through an active solution containing 2 % chitosan and 6000 ppm thymol and grapefruit seed extract, combined with packaging under 5:95 O2/CO2, maintained fillets at the maximum level of microbiological quality for at least 8–10 days and the sensory attributes were at acceptable levels for about 20 days. The exact mechanism of the antimicrobial action of chitin, chitosan, and their derivatives is still unknown, but different mechanisms have been proposed. Interaction between positively charged chitosan molecules and negatively charged microbial cell membranes leads to the leakage of proteinaceous and other intracellular constituents. Chitosan acted mainly on the outer surface of the bacteria. At a lower concentration (<0.2 mg/mL), the polycationic chitosan does probably bind to the negatively charged bacterial surface to cause agglutination, whereas at higher concentrations, the larger number of positive charges may have imparted a net positive charge to the bacterial surface to keep them in suspension. Chitosan interacts with the cell membrane to alter cell permeability (Rabea et al. 2003).

Ahmad et al. (2012) concluded in their study that films incorporated with lemongrass oil exhibited more antibacterial activity than bergamot-treated films against Escherichia coli, L. monocytogenes, Pseudomonas aeruginosa, S. aureus, and S. typhimurium. Shakila et al. (2015) showed that vacuum-packed fish steaks coated with chitosan and clove films extended the shelf life from 4 to 8 days at 4 °C. Norhana et al. (2012) determined that fresh shrimp in 3 % potassium sorbate (PS), sodium benzoate (SB), sodium diacetate (SD), and combined nisin–EDTA–PS, −SB or –SD solutions resulted in marginal reduction in the number of inoculated L. monocytogenes at day 0 and 3 at 4 °C. However, the same treatments failed to reduce the number of Salmonella spp. on the shrimp surface. Neetoo and Mahomoodally (2014) found that cellulose-based coatings incorporating nisin, potassium sorbate, or sodium benzoate reduced the population of L. monocytogenes in cold-smoked salmon by a maximum of 4.2, 4.8, and 4.9 log CFU/cm2, respectively, after 4 weeks of refrigerated storage. Behnam et al. (2015) found that treatment of the vacuum packaged rainbow trout with nisin resulted in improvement of quality and extension of shelf life of the fish from 12 to 16 days at 4 °C. The cytoplasmic membrane of vegetative cells is the primary site of action of nisin. Nisin is believed to induce pore formation in the cytoplasmic membrane, which results in the depletion of proton-motive force and loss of cellular ions, amino acids, and ATP.

Ramírez-Suárez et al. (2015) determined that vacuum-packed frankfurters made from jumbo squid (Dosidicus gigas) muscle with the antimicrobial agent Pronat (0.1 %) were physico-chemically stable and in good microbiological condition up to 21 days. Pang et al. (2013) demonstrated that allyl isothiocyanate (18 and 36 μg/L) present in the vapor phase was an effective antimicrobial agent to inhibit the growth of P. aeruginosa because it provided a 3-fold longer shelf life of fresh catfish fillets relative to the controls. Higher gaseous AIT concentrations showed an increased antimicrobial effect on P. aeruginosa. Karakaya et al. (2015) used potassium sorbate and sodium lactate either separately or in combination with 3 % (w/v) brine for pre-smoking or by spraying post-smoking on rainbow trout (Oncorhynchus mykiss) fillets and determined that potassium sorbate in brine used at the pre-smoking stage was most efficient, which could maintain trout fillets within the range of consumable limits, for 4 weeks at 6 ± 1 °C. Pre-smoking reduced the total aerobic mesophilic bacteria (TAMB). Ozogul et al. (2014) determined that vacuum-packed European eel had a 16- and 20-day shelf life with laurel and myrtle treatment, respectively. Natural extracts from myrtle and laurel can be used in the food industry to extend the shelf life of seafood because they exhibit promising antioxidant and antimicrobial effects. García-Soto et al. (2015) found that megrim (Lepidorhombus whiffiagonis) wrapped with polylactic acid film containing 8 % alga and 1 % sorbic acid was acceptable after day 11, while control fish specimens that were maintained under polyethylene film alone were rejected at that time. The mechanism by which sorbic acid inhibits microbial growth may partially be attributed to its effect on enzymes. Melnick et al. (1954) postulated that sorbic acid inhibited the dehydrogenases involved in fatty acid oxidation. Addition of sorbic acid resulted in the accumulation of β-unsaturated fatty acids that are intermediate products of fatty acid oxidation by fungi. This prevented the function of dehydrogenases and inhibited metabolism and growth.

Lee et al. (2015) developed a mathematical model to predict the antimicrobial film-coating requirements for obtaining protection against L. monocytogenes in smoked salmon by using a defatted mustard meal-based antimicrobial edible film (DMM film). They found that the film with 0.41 mg/g thiocyanate was predicted to provide 19.7 h of protection in smoked salmon against continuous-post-contamination by L. monocytogenes at 4.0 log CFU/g, during which time thiocyanate remained above the inhibitory concentration of 0.28 mg/g. For 24-h inhibition, the initial concentration of thiocyanate required was estimated as 0.43 mg/g in a 0.14-mm-thick film for optimal antimicrobial effects. Fernández-Pan et al. (2015) studied the kinetics of carvacrol release rate toward different food-simulating solvents, and recommend the use of edible films obtained from chitosan with a low molecular weight to preserve medium and high fat content fishes such as sardines, salmon, and tuna. The films showed antimicrobial effectiveness against the gram-negative bacteria Pseudomonas fragi, S. putrefaciens, and A. hydrophila, common spoilers of fish and seafood products. El-Sayed et al. (2015) controlled the growth of Bacillus cereus/thuringiensis and Citrobacter freundii in fresh chilled Atlantic salmon (Salmo salar) by using rosemary plant extracts (Rosmarinus officinalis) and showed strong antibacterial activity against C. freundii, FIM-SH, and B. cereus/thuringiensis, with zone of inhibitions with a mean diameter of 16 and 29 mm, respectively. Patel (2015) also showed that essential oils from many floras could be recommended as safe biopreservatives for fish. Hasani et al. (2015) showed that silver carp (Hypophthalmichthys molitrix) fillets treated with grape pomace extract (0 %, 2 %, and 4 %) during chilled storage has lower TVB-N (24.2 and 21.2 mg N/100 g, respectively), TVC (7.33 and 7.09 log CFU/g, respectively), and PTC (7.26 and 7.03 log CFU/g, respectively) at the end of the storage period.

Inorganic antimicrobials

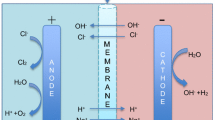

Antimicrobial packaging with inorganic nanoparticles has recently been gaining popularity because of the excellent ability of these materials to withstand harsh process conditions such as high pressure or temperature during the plastic fabrication process, which is of particular importance for seafood due to the difficulties encountered during processing, packaging, and transport. Organic antimicrobial agents are limited in their activity during these processing conditions. Although organic antimicrobial agents (essential oils) are used in very small quantity, most consumers do not prefer the odor of essential oils in seafood packaging. Organic antimicrobial agents are often complex toxic bactericides that can leach from the polymer, causing health concerns. Organic antibiotic agents are also often heat-labile and readily degraded by humidity and mechanical processing, making organic antibiotic agents difficult to incorporate into the standard resin processing systems. Microbial antimicrobial resistance continues to be a concern with seafood packaging. Therefore, the use of inorganic antimicrobial agents is a wide area of research for seafood packaging. ChronoFlex antimicrobial polymers containing silver ions (Ag+) exhibit a wide spectrum of antimicrobial activity, safety, and heat stability (Guggenbichler et al. 1999) (Garey and Reed 2010). As inorganic antimicrobial agents have a broad spectrum against several pathogens, they are increasingly incorporated into food packaging. The most extensively studied inorganic nanoparticles for antimicrobial packaging include titanium dioxide (TiO2), zinc oxide (ZnO), magnesium oxide (MgO), and silver zeolite.

Singh et al. (2015) found that silver zeolite, AgSiO2, has good antimicrobial activity for P. aeruginosa, S. putrefaciens, L. monocytogenes, except for Clostridium perfringens. ZnAg has also shown good antimicrobial properties against P. aeruginosa, S. putrefaciens, and L. monocytogenes except Clostridium perfringen. Only ZnAg is capable to reduce the count of C. perfringens compared to silver zeolite and AgSiO2. Two mechanisms are proposed for the bactericidal action of silver zeolite. One is the action of silver ion itself released from zeolite and the other is that of reactive oxygen species generated from silver in the matrix. While oxygen has been reported to be necessary for the bactericidal activity of silver zeolite by some researchers, silver zeolite has also been reported to be effective on oral bacteria under anaerobic conditions by Matsumura et al. (2003).

TiO2 is non-toxic and approved by the FDA for use in foods, drugs, and food contact materials. Recently, Bodaghi et al. (2013) developed a TiO2-LDPE film using a blown film extruder, which was tested on Pseudomonas spp. using a modified in-vitro test method. we found that the number of Pseudomonas spp. decreased significantly by 4 and 1.35 log CFU/mL after 3 h of ultraviolet A illumination on TiO2 film and blank film, respectively. Hamilton-Brehm (2009) demonstrated that Roussin’s black salt [Fe4S3(NO)7] at a concentration of only 2 μM, compared to 0.5 μM, inhibited the growth of C. perfringens vegetative cells, 3 μM for L. monocytogenes, and 1.3 μM for Clostridium sporogenes (5). Lysis of Pyrococcus furiosus cells by Roussin's black salt occurs both near the optimum growth temperature, that is, 98 °C, as well as at 4 °C, where the metabolic and enzymatic activities are effectively zero.

Arfat et al. (2015) researched the antimicrobial effect of fish protein isolate (FPI)/fish skin gelatin (FSG) films incorporated with 3 % ZnO nanoparticles (ZnONP, w/w, based on protein content) and 100 % basil leaf essential oil (BEO) and observed that the shelf life of sea bass with the FPI/FSG-ZnONP-BEO film extended the shelf life of sea bass slices up to 12 days at refrigerated temperatures (Fig. 3), which was 8 days longer than the control. In ZnO nanoparticles, the primary cause of antibacterial function might be the disruption of cell membrane activity. ZnO nanoparticles exerted a bactericidal, not bacteriostatic, effect on Campylobacter jejuni by showing no recovery of the treated cells on drug-free MH plates as well as by rapid killing of 108 CFU/mL of freshly grown cells of three different C. jejuni strains (Xie et al. 2011).

Pseudomonas counts from sea bass slices wrapped without and with films (PP film, FPI/FSG film, FPI/FSGZnONP film, FPI/FSG-BEO film, and FPI/FSG-ZnONP-BEO film) during storage at 4 °C for 12 days. Source: Adapted and modified from Arfat et al. 2015

Effect of antimicrobial agent on peroxide value and acid value

Peroxide value (PV) and acid value (AV) were chosen as useful indices to control food safety and quality in seafood, and the standard values of PV and AV were set at no more than 30 mequiv/kg and 3, respectively. These values were chosen because they indicate the initial stage of fat deterioration in fish and seafood. During the storage of seafood, PV increases very rapidly. Overview of studies testing organic antimicrobial and components in the Chemical Quality Indices of seafood are given in Table 3. Pezeshk et al. (2011), who showed that shallot and turmeric extracts were effective in retarding the production of primary lipid oxidation products in rainbow trout fillets stored at 4 ± 1 °C, found that sodium acetate, sodium lactate, and sodium citrate worked well in refrigerated sliced salmon. Lipid oxidation, expressed by PV and thiobarbituric acid (TBA) value, was delayed in samples treated with sodium acetate and sodium citrate. The TBARS value is considered as an index for malondialdehyde (MDA) content, the most predominant products of secondary lipid oxidation; therefore, it is considered a good chemical indicator for quality assurance. According to Gomes et al. (2003), the maximum level of TBARS indicating good quality of fish is 1–2 mg MDA equivalents/kg of tissue. In this study, TBARS for the control, shallot (1.5 %), shallot (3.0 %), ajwain (1.5 %), and ajwain (3.0 %) treatment groups were lower than the proposed limits until days 6, 9, 12, 9, and 15, respectively (Sallam 2007). A solution of tea polyphenol (0.2 %, w/v) and rosemary (0.2 %, w/v) was used for dip pretreatment, and chitosan (1.5 %, w/v) was used for the coating. The results showed that chitosan coating was effective in retarding PV in large yellow croaker during the refrigerated storage (Li et al. 2012).

Effect of freezing techniques, high pressure, and electron beam on antimicrobial efficiency

Freezing, frozen storage, and thawing effect the quality and shelf stability of fish and seafood. If kept under appropriate condition, fish and seafood can be stored in the frozen state for several months without appreciable changes in quality. Application of the hurdle technology concept has been proposed as an approach to increase the microbicide effect of lower pressure processes. The combination of freezing, high pressure processing, and electron beam improves the effect of antimicrobial components. Burt (2004) concluded in a review that physical conditions that improve the action of EOs are low pH, low temperature, and low oxygen levels. Thymol and carvacrol exert a synergistic effect with high hydrostatic pressure (HHP). The viable numbers of mid-exponential phase L. monocytogenes cells were reduced more by combined treatment with 300 MPa HHP and 3 mmol/L thymol or carvacrol than by separate treatments. Gao and Ju (2008) studied the combined effects of pressure (300.0–700.0 MPa), temperature (30–70 °C), and the presence of nisin (0–333 IU/mL) on the inactivation of Clostridium botulinum 33A spores at various pressure-holding times (7.5–17.5 min). Günlü et al. (2014) observed that the shelf life of rainbow trout fillets was 4 days in the HHP group, 8 days in the chitosan-based film (CFW) group, and 24 days in the HHP + CFW group, when compared to the control group. In conclusion, it was determined that treatment with high pressure and wrapping with CFW had protective effect, both chemically and microbiologically, and that the most effective protection was obtained when both methods were used together. Ouattara et al. (2001) found that gamma irradiation combined with edible antimicrobial coatings showed significant potential for inhibiting aerobic bacteria, including Pseudomonas putida, and as a result, the microbial shelf life of shrimp was extended by 5 days with gamma irradiation, and by more than 11 days with gamma irradiation combined with a protein-based coating containing thyme oil and trans-cinnamaldehyde. Das et al. (2015) concluded that a combination of high pressure and potassium sorbate dip treatment (at acidic pH) was very useful in inactivating L. monocytogenes in Indian white prawns. Potassium sorbate (0.1 %) dip for 15 min coupled with treatment with 250 and 350 MPa pressure reduced the level of L. monocytogenes by 2.345 and 5.908 log CFU/g, respectively.

Controlled release packaging (CRP)

This is a new generation of packaging materials that can release active compounds at different controlled rates and enhance the quality and safety of many food items during extended storage. The basic concept is to use the package as a delivery system for active compounds such as antimicrobials, antioxidants, enzymes, flavors, and nutraceuticals. Controlled release of antimicrobial agents from films is a very important parameter to study the efficiency and effectiveness of antimicrobial films and coatings in seafood packaging. Rossi‐Márquez et al. (2009) found that the release of antimicrobial agents from packaging films depends on many factors such as electrostatic interaction between the antimicrobial agent and polymer chains, ionic osmosis, and structural changes induced by the presence of the antimicrobial agent and the environmental condition. Diffusion of the antimicrobial agent is also affected by the type of food, hydrophilic characteristics, and storage conditions. A natural antimicrobial known as lysozyme that inhibits lactic acid bacteria is incorporated in polyvinyl alcohol (PVOH) films. The degree of crosslinking of PVOH films helps maintain the release rate of the antimicrobial agent, in order to exert effective inhibition (Buonocore et al. 2003). Antimicrobial packaging materials were obtained by incorporating lysozyme into cellulose acetate (CA) films. In order to achieve controlled release of lysozyme, the structure of the films was changed from highly asymmetric and porous to dense by modulating the composition of the initial casting solution. The highest release rate, soluble lysozyme activity, and antimicrobial activity were obtained with the film prepared from 5 % CA solution, including 1.5 % lysozyme (Gemili et al. 2009). The application of antimicrobial films allows the migration of the antimicrobial agent to the film surface and provides continuous antimicrobial cover to the seafood during the extended transportation time.

Applications

Antimicrobial packaging for seafood is a rapidly emerging technology. The need to package seafood in a versatile manner for transportation and storage, along with the increasing consumer demand for fresh, convenient, and safe seafood products predicts a bright future for antimicrobial packaging. The shelf life of fresh seafood is short and this poses a substantial problem in product distribution (Ashie et al. 1996). The purpose of the antimicrobial agents is to extend the shelf life of the food and to ensure safety by reducing the rate of growth of specific microorganisms by direct contact of the package with the surface of solid foods (e.g., meat, seafood, cheese, etc.) or with the bulk of liquids (e.g., milk or meat exudates). In addition, antimicrobial packaging materials should be self-sterilizing or sanitizing. Such antimicrobial packaging materials greatly reduce the potential for recontamination of processed products and simplify the treatment of materials in order to eliminate product contamination (Han 2003). The application of antimicrobial films might allow the migration of the antimicrobial agent to the film surface, enabling continued antimicrobial effect on the food surface during extended exposure. Direct addition of antimicrobials to seafood will result in immediate reduction of the bacterial population, but this technique may not account for the recovery of injured cells or the growth of cells that were not destroyed by this direct addition (Quintavalla and Vicini 2002). The direct addition of antimicrobial agents to seafood may also change the organoleptic properties.

The use of antimicrobial packaging materials in seafood packaging can minimize the microbial contamination of seafood product surfaces during storage, transportation, and handling. The main action of these films is based on the release of antimicrobial substances into the seafood products. Some of these agents can pose a safety risk to consumers if the release is not tightly controlled by some mechanism within the packaging material itself. An interesting innovation would be the use of polymers with surfaces that have been modified by electron irradiation or plasma treatment to generate antimicrobial activity without any transfer or migration of the substances to the food (Buonocore et al. 2003).

As the growth and death rates of bacteria will vary for each growth medium, it is necessary to determine how antimicrobial films will perform for every food product.

Effectiveness testing

To evaluate if the antimicrobial packaging has an effect on the microorganisms present in seafood, agar plate method, minimum inhibitory concentration (MIC) determination, and dynamic shake flask test have been used; these methods are similar to those used to evaluate antimicrobials alone . In Japan, a method referred to as the “Film Contact Method” is used as the standard to assess the ability of products containing antimicrobial agents to impart antimicrobial properties to the products (SIAA 1998). The method was developed for inorganic antimicrobials such as silver-substituted zeolite. It is appropriate for films and sheets and involves inoculation of bacteria on the test specimen, followed by incubation and enumeration of the cells under specified conditions. The intent is to determine the resistance of the plastic to microbial growth, but it may also serve to determine if polymers are “self-sterilizing.” As shown in Table 4, standard methods have been used for testing antimicrobial efficiency. MICs can indicate the antimicrobial strength of the polymer and allow the comparison of polymer antimicrobial activity to that of the antimicrobial alone (Velazquez 2015). The MIC is the lowest concentration of an antimicrobial in a polymer resulting in complete growth inhibition of a test microorganism.

In the agar plate test, antimicrobial films are placed on a solid agar medium containing the test microorganism, which is then incubated until visible growth is attained. A clear zone surrounding the film indicates antimicrobial diffusion from the film and subsequent growth inhibition (Fig. 4). The agar plate test method simulates the wrapping of food items and indicates the possibilities when antimicrobial films are exposed to the contaminated surfaces and the antimicrobial agent migrates from the film to the food (Appendini and Hotchkiss 2002).

Challenges using organic and inorganic antimicrobial agents

Many of the antimicrobial compounds studied are not permitted for food application, as they need to migrate into the food to be effective. Technical challenges exist in incorporating appropriate antimicrobial agents into packaging systems. Most studies cited in this review article have been carried out at a laboratory scale; very few studies have been conducted in a pilot plant and none was conducted at an industrial scale to ascertain the commercial value and scaling-up difficulties involved in this method.

Some of the antimicrobial agents like chitosan are still not permitted in the European countries; the major disadvantage of chitosan is that it is highly sensitive to humidity, and therefore, it is not suitable for seafood packaging. However, some researchers tried to solve this problem by designing water-resistant chitosan-based films. Current trends suggest that packaging will generally incorporate antimicrobial agents and that the sealing systems will continue to improve. The direct use of organic-based antimicrobial agents can have disadvantage based on their sensitivity to processing conditions. Many factors affect the application of antimicrobial agents on a commercial basis:

-

1.

Synthesis of antimicrobial agents per their stability, simplicity, and cost effectiveness

-

2.

The choice of an antimicrobial compound may be limited by not only its compatibility to the type of packaging material used, but also the heat resistance of the component during extrusion

-

3.

Diffusion rate of the antimicrobial agents through the film

-

4.

Physical properties of the packaging film, as affected by adding antimicrobial agents

-

5.

Mode of action to inhibit bacterial growth

-

6.

Interaction of antimicrobial agents within the food matrix

-

7.

Resistance mechanisms

-

8.

Toxicity release by antimicrobial agents

Researchers have primarily focused on developing new approaches and testing new methods on model systems, but not quite as much on real food products. Antimicrobial packaging technology must focus on the technical feasibility, consumer acceptance, and food safety aspects of antimicrobial agents, in addition to their chemical, microbiological, and physiological effects. The final goal of antimicrobial seafood packaging to create a packaging film that does not harm human health and does not change the sensory or chemical properties of seafood and stable antimicrobial properties.

Future scope

Antimicrobial packaging is a novel development in the field of seafood safety; it plays a significant role in the future of “protection and preservation.” Organic-based antimicrobial agents are restricted in their activity because of harsh processing conditions during mixing with plastic. Seafood microorganisms easily develop resistance to organic antimicrobial agents; therefore, the continuous use of organic antimicrobial agents for seafood packaging is problematic. Future work will focus on the use of inorganic derived antimicrobial compounds (e.g., Ag+, Cu++, Zn++) that have a wide spectrum of activity and low toxicity. ChronoFlex antimicrobial polymers contain Ag+ ions, which are preferred as they possess a wide spectrum of antimicrobial activity, are safe for human consumption, and are heat stable (Guggenbichler et al. 1999). ChronoFlex Antimicrobial Polymers can be processed by conventional extrusion and injection molding techniques while maintaining the desired antimicrobial properties. The silver-containing additive used in these Polymers is uniquely incorporated into the polymer structure during the polymerization sequence, thus ensuring uniform dispersion throughout the resulting polymer. The active silver ions incorporated in ChronoFlex Antimicrobial Polymers are stabilized by their association with carriers such as phosphates (in particular, zirconium phosphate), water-soluble silicate powder, zeolite, and ion exchange resin. It is possible that the development of “intelligent” or “smart” antimicrobial packages will follow. These materials will be able to sense the presence of microorganisms in the seafood, triggering an antimicrobial response in a controlled manner.

Antimicrobial packaging can play a significant role in reducing the risk of pathogen contamination, as well as extending the shelf life of seafood; however, it can never substitute for high-quality raw materials, properly processed foods, and good manufacturing practices. Antimicrobial packaging should be considered as a hurdle technology that, in addition to other non-thermal processes such as pulsed light, high pressure, and irradiation, can reduce the risk of pathogen contamination and extend the shelf life of perishable seafood products. Participation and collaboration of research institutions, industry, and government regulatory agencies will be imperative for the success of antimicrobial packaging technology for seafood applications.

References

Ahmad M, Benjakul S, Prodpran T, Agustini TW (2012) Physico-mechanical and antimicrobial properties of gelatin film from the skin of unicorn leatherjacket incorporated with essential oils. Food Hydrocoll 28:189–199

Alboofetileh M, Rezaei M, Hosseini H, Abdollahi M (2016) Efficacy of activated alginate-based nanocomposite films to control Listeria monocytogenes and spoilage flora in rainbow trout slice. J Food Sci Technol 53(1):521–530

Amos B (2007) Analysis of quality deterioration at critical steps/points in fish handling in Uganda and Iceland and suggestions for improvement. United Nations University, Uganda. http://www.unuftp.is/static/fellows/document/amos06prf.pdf

Appendini P, Hotchkiss JH (2002) Review of antimicrobial food packaging. Innovative Food Sci Emerg 3:113–126

Arfat YA, Benjakul S, Vongkamjan K, Sumpavapol P, Yarnpakdee S (2015) Shelf-life extension of refrigerated sea bass slices wrapped with fish protein isolate/fish skin gelatin-ZnO nanocomposite film incorporated with basil leaf essential oil. J Food Sci Technol 52(10):6182–6193

Ashie IN, Smith JP, Simpson BK, Haard NF (1996) Spoilage and shelf‐life extension of fresh fish and shellfish. CRC Crit Rev Food Sci 36:87–121

Behnam S, Anvari M, Rezaei M, Soltanian S, Safari R (2015) Effect of nisin as a biopreservative agent on quality and shelf life of vacuum packaged rainbow trout (Oncorhynchus mykiss) stored at 4° C. J Food Sci Technol 52:2184–2192

Bodaghi H, Mostofi Y, Oromiehie A (2013) Evaluation of the photocatalytic antimicrobial effects of a TiO 2 nanocomposite food packaging film by in vitro and in vivo tests. LWT - Food Sci Technol 50:702–706

Bremer PJ, Fletcher GC, Osborne C (2003) Aeromonas spp. in seafood. New Zealand Institute for Crop & Food Research, Christchurch, pp 1–6

Brody A, Strupinsky E, Kline L (2001) Active packaging for food applications. Technomic Publishing Co., Lancaster

Buonocore GG, Del Nobile MA, Panizza A, Corbo MR, Nicolais L (2003) A general approach to describe the antimicrobial agent release from highly swellable films intended for food packaging applications. J Control Release 90:97–107

Burt S (2004) Essential oils: their antibacterial properties and potential applications in foods—a review. Int J Food Microbiol 94:223–253

Cai L, Cao A, Li T, Wu X, Xu Y, Li J (2015) Effect of the fumigating with essential oils on the microbiological characteristics and quality changes of refrigerated turbot (Scophthalmus maximus) fillets. Food Bioprocess Technol 8:844–853

Cao R, Xue C-H, Liu Q (2009) Changes in microbial flora of Pacific oysters (Crassostrea gigas) during refrigerated storage and its shelf-life extension by chitosan. Int J Food Microbiol 131:272–276

Coma V, Sebti I, Pardon P, Deschamps A, Pichavant FH (2001) Antimicrobial edible packaging based on cellulose ethers, fatty acids, and nisin incorporation to inhibit Listeria innocua and Staphylococcus aureus. J Food Prot 64:470–475

Darmadji P, Izumimoto M (1994) Effect of chitosan in meat preservation. Meat Sci 38:243–254

Das S, Lalith KV, Joseph G, Kamalakanth CK, Bindu J (2015) High pressure destruction kinetics along with combined effect of potassium sorbate and high pressure against Listeria monocytogenes in Indian white prawn muscle. Ann Microbiol 66:245–251

Davidson PM, Juneja VK, Branen JK (2002) Antimicrobial agents. Food Sci Technol -New York-Marcel Dekker, p 563–620

Dodds KL (1992) Clostridium botulinum in foods. In: Hauschild AW, Dodds K (eds) Clostridium botulinum, ecology and control in foods. M. Dekker, New York, pp 53–58

Dorman HJ, Deans SG (2000) Antimicrobial agents from plants: antibacterial activity of plant volatile oils. J Appl Microbiol 88:308–316

Duan J, Jiang Y, Cherian G, Zhao Y (2010) Effect of combined chitosan-krill oil coating and modified atmosphere packaging on the storability of cold-stored lingcod (Ophiodon elongates) fillets. Food Chem 122:1035–1042

El-Sayed MH, El-aziz ZKA, Elbadawy HH (2015) Evaluation of the microbial spoilage of Atlantic salmon (Salmo salar) fillets during the packaging processes and its control by preservatives. IJSRSET 1:134–141

Erkan N (2012) The effect of thyme and garlic oil on the preservation of vacuum-packaged hot smoked rainbow trout (Oncorhynchus mykiss). Food Bioprocess Technol 5:1246–1254

Fernández-Pan I, Maté JI, Gardrat C, Coma V (2015) Effect of chitosan molecular weight on the antimicrobial activity and release rate of carvacrol-enriched films. Food Hydrocoll 51:60–68

Fernández-Saiz P, Sánchez G, Soler C, Lagaron JM, Ocio MJ (2013) Chitosan films for the microbiological preservation of refrigerated sole and hake fillets. Food Control 34:61–68

Galotto M, Ulloa P (2010) Effect of high‐pressure food processing on the mass transfer properties of selected packaging materials. Packag Technol Sci 23:253–266

Gao YL, Ju XR (2008) Exploiting the combined effects of high pressure and moderate heat with nisin on inactivation of Clostridium botulinum spores. J Microbiol Methods 72:20–28

García-Soto B, Miranda JM, Rodríguez-Bernaldo de Quirós A (2015) Effect of biodegradable film (lyophilised alga Fucus spiralis and sorbic acid) on quality properties of refrigerated megrim (Lepidorhombus whiffiagonis). Int J Food Sci Technol 50:1891–1900

Garey HE, Reed AM, inventors, Advansource Biomaterials Corporation, assignee (2010) excellent mechanical and biocompatibility properties; medical devices; silver incorporated during polymerization; glass powder; polycarabonateurethane. United States patent US 7,772,296

Gemili S, Yemenicioğlu A, Altınkaya SA (2009) Development of cellulose acetate based antimicrobial food packaging materials for controlled release of lysozyme. J Food Eng 90:453–462

Ghaly AE, Dave D, Budge S, Brooks MS (2010) Fish spoilage mechanisms and preservation techniques: review. Am J Appl Sci 7:859–877

Gomes HDA, Silva END, Nascimento MRLD, Fukuma HT (2003) Evaluation of the 2-thiobarbituric acid method for the measurement of lipid oxidation in mechanically deboned gamma irradiated chicken meat. Food Chem 80:433–437

Guggenbichler JP, Boswald M, Lugauer S, Krall T (1999) A new technology of microdispersed silver in polyurethane induces antimicrobial activity in central venous catheters. Infection 27:S16–S23

Günlü A, Koyun E (2013) Effects of vacuum packaging and wrapping with chitosan-based edible film on the extension of the shelf life of sea bass (Dicentrarchus labrax) fillets in cold storage (4 °C). Food Bioprocess Technol 6:1713–1719

Günlü A, Sipahioğlu S, Alpas H (2014) The effect of chitosan-based edible film and high hydrostatic pressure process on the microbiological and chemical quality of rainbow trout (Oncorhynchus mykiss Walbaum) fillets during cold storage (4 ± 1 C). High Pressure Res 34:110–121

Guran HS, Oksuztepe G, Coban OE, Incili GK (2014) Influence of different essential oils on refrigerated fish patties produced from bonito fish (Sarda sarda Bloch, 1793). Czech J Food Sci 33:37–44

Hamilton-Brehm SD, Schut GJ, Adams MW (2009) Antimicrobial activity of the iron-sulfur nitroso compound Roussin's black salt [Fe4S3 (NO) 7] on the Hyperthermophilic Archaeon Pyrococcus furiosus. Appl Environ Microbiol 75:1820–1825

Han JH (2003) Antimicrobial food packaging. In: Ahvenainen R (ed) Novel food packaging techniques. Woodhead Publishing limites, Cambridge, pp 50–70

Han JH (2005) Antimicrobial packaging systems. In: Jung HH (ed) Innovations in Food Packaging. Academic, London, ISBN: 0123116325

Hansen LT, Gill T, Hussa HH (1995) Effects of salt and storage temperature on chemical, microbiological and sensory changes in cold-smoked salmon. Food Res Int 28:123–130

Hasani S, Alizadeh E, Elahi MY (2015) Effects of grape pomace extract on the quality and shelf life of silver carp (Hypophthalmicthys molitrix) fillets during chill storage. Int J Aquat Biol 3:108–113

Heydari R, Bavandi S, Javadian SR (2015) Effect of sodium alginate coating enriched with horsemint (Mentha longifolia) essential oil on the quality of bighead carp fillets during storage at 4° C. Food Sci Nutr 3:188–194

Irkin R, Esmer OK (2015) Novel food packaging systems with natural antimicrobial agents. J Food Sci Technol 52:6095–6111

Jalali N, Ariiai P, Fattahi E (2016) Effect of alginate/carboxyl methyl cellulose composite coating incorporated with clove essential oil on the quality of silver carp fillet and Escherichia coli O157:H7 inhibition during refrigerated storage. J Food Sci Technol 53:757–765

Jasour MS, Ehsani A, Mehryar L, Naghibi SS (2015) Chitosan coating incorporated with the lactoperoxidase system: an active edible coating for fish preservation. J Sci Food Agric 95:1373–1378

Karakaya TB, Sert F, Aksun ET, Özoğul F (2015) The effect of whey protein isolate coating enriched with thyme essential oils on trout quality at refrigerated storage (4 ± 2°C). J Aquat Food Prod Technol. doi:10.1080/10498850.2014.896063

Kerry JP (ed) (2012) Advances in meat, poultry and seafood packaging. Elsevier, ISBN: 9780857095718

Kim YM, Paik HD, Lee DS (2002) Shelf-life characteristics of fresh oysters and ground beef as affected by bacteriocin-coated plastic packaging film. J Sci Food Agric 82:998–1002

Kykkidou S, Giatrakou V, Papavergou A, Kontominas MG, Savvaidis IN (2009) Effect of thyme essential oil and packaging treatments on fresh Mediterranean swordfish fillets during storage at 4 °C. Food Chem 115:169–175

Lambert RJW, Skandamis PN, Coote PJ, Nychas GJE (2001) A study of the minimum inhibitory concentration and mode of action of oregano essential oil, thymol and carvacrol. J Appl Microbiol 91:453–462

Lee H-B, Oh YA, Min SC (2015) Prediction of the coating requirements for smoked salmon protection against Listeria monocytogenes using a defatted mustard meal-based antimicrobial edible film containing thiocyanates. LWT - Food Sci Technol 61:231–237

Li T, Hu W, Li J, Zhang X, Zhu J, Li X (2012) Coating effects of tea polyphenol and rosemary extract combined with chitosan on the storage quality of large yellow croaker (Pseudosciaena crocea). Food Control 25:101–106

Limjaroen P, Ryser E, Lockhart H, Harte B (2003) Development of a food packaging coating material with antimicrobial properties. J Plast Film Sheeting 19:95–109

López P, Sánchez C, Batlle R, Nerín C (2007) Development of flexible antimicrobial films using essential oils as active agents. J Agric Food Chem 55:8814–8824

López-Malo A, Alzamora SM, Palou E (2005) Naturally Occurring Compounds: Plant Sources. In: Davidson PM, Sofos JN, Branen AL (eds) Antimicrobials in Food, 3rd edn. CRC Press, New York, p 429–251

Mastromatteo M, Danza A, Conte A, Muratore G, Del Nobile MA (2010) Shelf life of ready to use peeled shrimps as affected by thymol essential oil and modified atmosphere packaging. Int J Food Microbiol 144:250–256

Matsumura Y, Yoshikata K, Kunisaki SI, Tsuchido T (2003) Mode of bactericidal action of silver zeolite and its comparison with that of silver nitrate. Appl Environ Microbiol 69:4278–4281

Mejlholm O, Dalgaard P (2002) Antimicrobial effect of essential oils on the seafood spoilage micro-organism Photobacterium phosphoreum in liquid media and fish products. Lett Appl Microbiol 34:27–31

Melnick D, Luckmann FH, Gooding CM (1954) Sorbic acid as a fungistatic agent for foods. VI. Metabolic degradation of sorbic acid in cheese by molds and the mechanism of mold inhibition. Food Res 19:44

Mexis SF, Chouliara E, Kontominas MG (2009) Combined effect of an oxygen absorber and oregano essential oil on shelf life extension of rainbow trout fillets stored at 4 C. Food Microbiol 26:598–605

Neetoo H, Mahomoodally F (2014) Use of antimicrobial films and edible coatings incorporating chemical and biological preservatives to control growth of Listeria monocytogenes on cold smoked salmon. Biomed Res Int 2014:1–10. doi:10.1155/2014/534915

Norhana MW, Poole SE, Deeth HC, Dykes GA (2010) Prevalence, persistence and control of Salmonella and Listeria in shrimp and shrimp products: a review. Food Control 21:343–361

Norhana MW, Poole SE, Deeth HC, Dykes GA (2012) Effects of nisin, EDTA and salts of organic acids on Listeria monocytogenes, Salmonella and native microflora on fresh vacuum packaged shrimps stored at 4 C. Food Microbiol 31:43–50

Nychas GE, Tassou CC (2002) Traditional preservatives—oils and spices. Encycl Food Microbiol Encycl Food Microbiol 1:1717–1722

Ouattara B, Sabato SF, Lacroix M (2001) Combined effect of antimicrobial coating and gamma irradiation on shelf life extension of pre-cooked shrimp (Penaeus spp.). Int J Food Microbiol 68:1–9

Ozogul İ, Polat A, Özogul Y, Boga EK, Ozogul F, Ayas D (2014) Effects of laurel and myrtle extracts on the sensory, chemical and microbiological properties of vacuum-packed and refrigerated European eel (Anguilla anguilla) fillets. Int J Food Sci Technol 49:847–853

Pang YH, Sheen S, Zhou S, Liu L, Yam KL (2013) Antimicrobial effects of allyl isothiocyanate and modified atmosphere on Pseduomonas aeruginosa in fresh catfish fillet under abuse temperatures. J Food Sci 78:M555–M559

Papadopoulou C, Economou E, Zakas G, Salamoura C, Dontorou C, Apostolou J (2007) Microbiological and pathogenic contaminants of seafood in Greece. J Food Qual 30:28–42

Patel S (2015) Plant essential oils and allied volatile fractions as multifunctional additives in meat and fish-based food products: a review. Food Addit Contam Part A 32:1049–1064

Pezeshk S, Rezaei M, Hosseini H (2011) Antibacterial and antioxidant activities of shallot extract (Allium ascalonicum) on rainbow trout (Oncorhynchus mykiss) during chilled (4 ± 1 °C) storage. Iran J Nutr Sci Food Technol 6:11–19

Qiu X, Chen S, Liu G, Lin H (2015) Inhibition of lipid oxidation in frozen farmed ovate pompano (Trachinotus ovatus Linnaeus) fillets stored at −18 °C by chitosan coating incorporated with citric acid or licorice extract. J Sci Food Agric. doi:10.1002/jsfa.7517

Quintavalla S, Vicini L (2002) Antimicrobial food packaging in meat industry. Meat Sci 62:373–380

Rabea EI, Badawy MET, Stevens CV, Smagghe G, Steurbaut W (2003) Chitosan as antimicrobial agent: applications and mode of action. Biomacromolecules 4:1457–1465

Raeisi S, Quek SY, Ojagh SM, Alishahi AR (2015) Effects of cumin (Cuminum cyminum L.) seed and wild mint (Mentha longifolia L.) leaf extracts on the shelf life and quality of rainbow trout (Oncorhynchus mykiss) fillets stored at 4C ± 1. J Food Saf. doi:10.1111/jfs.12240

Ramírez-Suárez JC, Pacheco-Aguilar R, Scheuren-Acevedo SM (2015) Microbiological and physicochemical quality changes in frankfurters made from jumbo squid (D osidicus gigas) mantle muscle in the presence and absence of a natural antimicrobial agent. J Food Saf 35(4):473–481. doi:10.1111/jfs.12197

Rossi‐Márquez G, Han JH, García AB, Castaño TE, Regalado GC (2009) Effect of temperature, pH and film thickness on nisin release from antimicrobial whey protein isolate edible films. J Sci Food Agric 89:2492–2497

Sallam KI (2007) Antimicrobial and antioxidant effects of sodium acetate, sodium lactate, and sodium citrate in refrigerated sliced salmon. Food Control 18:566–575

Schwarz JR (2000) Rapid chilling of oyster shellstock: a postharvest process to reduce Vibrio. In: Proceedings of the 25th Annual Meeting of the Seafood Science & Technology Society of the Americas, Longboat, Fla (9)

Seaberg AC, Labbe RG, Shetty K (2003) Inhibition of Listeria monocytogenes by elite clonal extracts of oregano (Origanum vulgare). Food Biotechnol 17:129–149

Shakila RJ, Jeevithan E, Varatharajakumar A, Jeyasekaran G (2015) Suitability of antimicrobial grouper bone gelatin films as edible coatings for vacuum packaged fish steaks. J Aquat Food Prod Technol. doi:10.1080/10498850.2014.921658

Shineman TL, Harrison MA (1994) Growth of Listeria monocytogenes on different muscle tissues. J Food Prot 57:1057–1062

SIAA (1998) Test methods for assessing the antimicrobial strength of products processed with antimicrobial agents. Society of Industrial Technology for Antimicrobial Articles, Japan

Singh S, Park IS, Shin Y, Lee YS (2015) Comparative study on antimicrobial efficiency of AgSiO2, ZnAg, and Ag-Zeolite for the application of fishery plastic container. J Mater Sci Eng 4:2169–0022

Speranza B, Bevilacqua A, Conte A, Del Nobile MA, Sinigaglia M, Corbo MR (2013) Use of desirability approach to predict the inhibition of Pseudomonas fluorescens, Shewanella putrefaciens and Photobacterium phosphoreum in fish fillets through natural antimicrobials and modified atmosphere packaging. Food Bioprocess Technol 6:2319–2330

Tassou CC, Drosinos EH, Nychas GJ (1996) Inhibition of resident microbial flora and pathogen inocula on cold fresh fish fillets in olive oil, oregano, and lemon juice under modified atmosphere or air. J Food Prot 59:31–34

Tsigarida E, Skandamis P, Nychas GJE (2000) Behavior of Listeria monocytogenes and autochthonous flora on meat stored under aerobic, vacuum and modified atmosphere packaging conditions with or without the presence of oregano essential oil at 5 °C. J Appl Microbiol 89:901–909

Velazquez BJ (2015) Antimicrobial Food Packaging. Academic press Elsevier, ISBN: 9780128007235

Xie Y, He Y, Irwin PL, Jin T, Shi X (2011) Antibacterial activity and mechanism of action of zinc oxide nanoparticles against Campylobacter jejuni. Appl Environ Microbiol 77:2325–2331

Ye M, Neetoo H, Chen H (2008) Control of Listeria monocytogenes on ham steaks by antimicrobials incorporated into chitosan-coated plastic films. Food Microbiol 25(2):260–268

Zhuang RY, Huang YW, Beuchat LR (1996) Quality changes during refrigerated storage of packaged shrimp and catfish fillets treated with sodium acetate or propyl gallate. J Food Sci 61, 241e244, 261

Acknowledgments

The authors would like to thank the Ministry of Oceans and Fisheries, South Korea. This research study is part of the project titled “Development of eco-friendly fish box and logistics system” (Project Number: 20140294).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, S., ho Lee, M., Park, l. et al. Antimicrobial seafood packaging: a review. J Food Sci Technol 53, 2505–2518 (2016). https://doi.org/10.1007/s13197-016-2216-x

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-016-2216-x