Abstract

The objective of this study was to compare the quality of legume cakes baked in microwave-infrared combination (MW-IR) oven with conventional oven. Legume cake formulations were developed by replacing 10 % wheat flour by lentil, chickpea and pea flour. As a control, wheat flour containing cakes were used. Weight loss, specific volume, texture, color, gelatinization degree, macro and micro-structure of cakes were investigated. MW-IR baked cakes had higher specific volume, weight loss and crust color change and lower hardness values than conventionally baked cakes. Larger pores were observed in MW-IR baked cakes according to scanning electron microscope (SEM) images. Pea flour giving the hardest structure, lowest specific volume and gelatinization degree was determined to be the least acceptable legume flour. On the other hand, lentil and chickpea flour containing cakes had the softest structure and highest specific volume showing that lentil and chickpea flour can be used to produce functional cakes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Legumes, in other words pulses, are the member of plant family named Leguminosae. They are consumed as meal by people for decades. The most common types that are used in the meals are beans, chickpeas, soybeans, lentils, peas and lupins. Legumes are one of the most nutritious foods in the world. They have high amount of amino acids, carbohydrates, dietary fiber, some minerals and vitamins (Iqbal et al. 2006). The most common amino acids that legumes contain are lysine, leucine, aspartic acid, glutamic acid and arginine (Minarro et al. 2012). Legumes also contain high amount of dietary fiber. Dietary fiber provides prevention of hypertension and regulates blood pressure (Lee et al. 2008). Dietary fibers are mainly classified as soluble fiber and insoluble fiber, according to their solubility in water (Dodevska et al. 2013). Insoluble fibers are mainly responsible for high water binding capacity and structure softening (Triniad et al. 2010). Legumes are also classified as low glycemic index food. Glycemic index represents how foods affect the blood glucose (Rizkalla et al. 2002). Legume flours are valuable source of nutrition for bakery products due to their high protein content (Gomez et al. 2008).

There are few studies in literature on legume containing bakery products. Hera et al. (2012) studied the effect of partial or total replacement of wheat flour by lentil flour on quality of cakes. Addition of lentil flour decreased cake volume but increased hardness. Similar results were obtained by Gomez et al. (2008), when chickpea flour was added to cake formulations.

Although microwave baking has the advantages of time and energy saving, quality problems occur in microwave baked cakes. Quality problems can be listed as unacceptable texture, lower volume, lack of browning and crust formation, high moisture loss and rapid staling (Sumnu 2001). The main reason for quality problems in microwave baking is short baking time. There are many studies in literature that focuses on reduction of quality problems in microwave baking (Icoz et al. 2004; Seyhun et al. 2003). MW-IR combination oven is one of the promising methods to solve the problems of microwave baked products. Besides, combination of microwave energy and IR heating provides the advantages of both microwave oven and conventional oven together. MW-IR baking combines time saving advantages of microwave and crisping and browning advantages of IR heating (Sumnu et al. 2005). It was found that the color and firmness values of cakes and gluten free rice cakes baked in MW-IR combination oven were comparable with the conventionally baked ones (Sumnu et al. 2005; Turabi et al. 2008). In addition conventional baking time was reduced by 75 %.

The studies on the effects of legume flour on quality of cakes baked in MW-IR combination oven in literature are limited. Sakyan (2015) showed that it was possible to develop soy cakes to be baked in MW-IR combination oven. Pea, lentil and chickpea flours have not been used in cakes baked in MW-IR combination oven so far. The main objective of the study was to develop legume cake formulations (lentil, pea and chickpea) to be baked in MW-IR combination oven and to compare the quality of legume cakes baked in MW-IR combination oven with those baked in conventional oven.

Materials and methods

Materials

Cake flour was obtained from Başak Flour Factory Inc. (Ankara, Turkey). Egg white powder was provided by ETI Food Industry Co. Inc. (Eskisehir, Turkey). Other ingredients such as sugar, non-fat dry milk (Bağdat Baharat, Ankara, Turkey), salt, fat (Becel, Unilever, Istanbul, Turkey) and baking powder (Dr. Oetker, Istanbul, Turkey) were bought from local markets in Ankara. Lentil flour with 22.2 % protein, 1.7 % fat, 8.9 % moisture, 3 % ash, chickpea flour with 20.9 % protein, 2.8 % fat, 7.9 % moisture, 3.1 % ash, and pea flour with 21.07 % protein, 1.3 % fat, 10.8 % moisture, 2.7 % ash was bought from Smart Chemical Trading Co. Inc. (Turkey).

Methods

Cake batter preparation

Basic cake batter was prepared using 100 % cake flour, 100 % sugar, 12 % non-fat dry milk, 9 % egg white powder, 25 % fat, 5 % baking powder, 3 % salt and 90 % water (in flour basis) (Sakiyan et al. 2011). Wheat cakes containing no legume flours were used as control. Wheat flour was partially replaced by legume flour at concentration of 10 %.

While preparing cake batter all dry ingredients (sugar, egg white powder, non-fat dry milk, salt, baking powder and flour) were mixed with mixer (Kitchen Aid, 5K45SS, USA) for 1 min at low speed (85 rpm). Melted fat and water were then added. Then all ingredients were mixed for 1 min at low speed then 1 min at medium speed (140 rpm) and 2 min at low speed. Prepared cake batter samples (100 g each) were poured into glass cake cups with 8.7 cm diameter and 4.8 cm in height.

Baking in conventional oven

Electrical oven (Arçelik A.Ş., Istanbul, Turkey) was used for conventional baking. Oven was preheated to 175 °C. Four cake samples were baked at the same time. They were placed in oven and baked for 24 min at 175 °C..

Baking in microwave-infrared combination oven

MW-IR combination oven (Advantium oven™, General Electric Company, Louisville, KY, USA) was used. There are two halogen lamps, at the top and one at the bottom each having 1500 W power in the oven. Power level of halogen lamps was fixed (60 %). Microwave power was also kept constant at 50 % during baking. The microwave power of oven was found as 700 W according to IMPI 2 l test. In order to provide required humidity in the oven, two beakers having 400 ml water were placed at the corners of the oven. One cake sample was placed at the center of the rotary table and baked for 4 min.

Quality analysis of cakes

After baking, weight loss, specific volume, texture, color, gelatinization degree, macro and micro-structure of cakes were determined.

Weight loss

Percent weight loss of cake samples were calculated by measuring the cakes before and after baking.

Specific volume

Specific volumes of cakes were measured by rape seed displacement method (AACC 2000), after cakes were cooled to room temperature.

Color

Color of cake crust was measured by color reader (Minolta, CR10, Osaka, Japan). Values of L*, a* and b* were recorded (CIE coordinates). Five measurement of each value was recorded and mean value was calculated. ΔE* representing the color change was calculated as shown in the Eq. (1);

Where \( {\mathrm{L}}_0^{*} \),\( {\mathrm{a}}_0^{*} \) and \( {\mathrm{b}}_0^{*} \) values are the reference values obtained from barium sulphate which were 86.5, −2.63 and 7.0, respectively.

Texture

Texture analyzer (Lloyd Ins., England, UK) was used to measure crumb hardness value of the cubic cake samples (25 mm × 25 mm × 25 mm). Speed of the probe was 55 mm/min, diameter was 10 mm and the load was 50 N (AACC 2000). Forces required to compress the samples 25 % of initial height was recorded. Cake samples were cooled to room temperature for 1 h.

Gelatinization degree

The baked cakes samples were frozen immediately at −18 °C. The samples were freeze dried at −52 °C for 48 h (Christ, Alpha 1–2 LD plus, Osterode, Germany). The samples were ground and sieved via 200 μm mesh. The gelatinization degree of both cakes and batter was measured by differential scanning calorimetry (DSC) (Perkin Elmer DSC 4000, Ohio, USA). Water was added on to the samples placed in pans at ratio of 1:2 (dry sample: water). The pans were sealed hermetically and refrigerated for a night to equilibrate. Empty pan was used as reference and indium and zinc were used for calibration. Samples were heated from 30 to 120 °C at a heating rate of 10 °C/min. Pyris software (Version 11.0.0.0449) was used to calculate onset, peak and end temperatures and also gelatinization enthalpy. Gelatinization degrees of baked cake samples were calculated by the Eq. (2) (Ndife et al. 1998);

where ΔHc denotes enthalpy of baked cake samples (J/g) and ΔHb denotes enthalpy of cake batter (J/g).

Macro-structure

In order to analyze macrostructure of cakes, baked samples were divided vertically in half. Electrical knife was used to cut samples (Arzum AR 156 Colte, Ankara, Turkey). Then the samples were scanned by scanner with 300 dpi resolution. Images were converted to 8 bit scale (gray scale) and cropped into the possible largest rectangle (5.61 cm × 4.02 cm). Pixel was converted to centimeter using the scale in the image. Image J software was used to calculate the total pore numbers, pore size distribution and pore area fractions (Turabi et al. 2010).

Micro-structure

Freeze dried and ground cake samples were sputter coated with gold-palladium for microstructure analysis of cakes (Turabi et al. 2010). Scanning electron microscope (SEM) (JSM-6400, JEOL, Tokyo, Japan) was used to determine the microstructures of cake samples. Images obtained by 30× and 500× magnification were analyzed.

Statistical analysis

Analysis of variance (ANOVA) was used in order to identify significant differences between flour baking type by using 9.1 SAS software (SAS Institute Inc., NC, USA). If significant difference was found, Duncan’s Multiple Comparison Test was used to compare cake samples (p ≤ 0.05).

Results and discussion

Weight loss

Weight loss of cakes can be considered as an index of moisture loss during baking. The effects of the flour and baking type on the weight loss of cakes were shown in the Fig. 1. Relatively higher weight loss was observed in MW-IR combination oven cakes. Higher interior heating in MW-IR combination oven creates higher internal pressure. This pressure gradient causes greater amount of moisture to flow from inside to outside of the food. As a result, high moisture was lost in cakes baked in MW-IR combination oven. Similar results were found previously by several researchers (Sumnu et al. 2005; Turabi et al. 2008). Legume cakes lost less moisture than wheat cakes which could be explained by higher water holding capacity of legume flours. According to study conducted by Fenn et al. (2010), composite flours (legume-wheat flour blend) had higher water holding capacity than wheat flour. The high protein and fiber contents of legume flours were responsible for high water binding capacity. Sakiyan (2015) also reported that addition of soy flour to cakes enhanced the water holding capacity and decreased the moisture loss of soy-cakes.

Specific volume

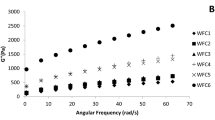

There was significant difference between specific volume of cakes baked in different ovens (Fig. 2). MW-IR baked cakes had higher specific volume than conventionally baked ones. Sumnu et al. (2005) also showed that using MW-IR baking increased volume of cakes. Larger amounts of interior heating in MW baking results in increased moisture vapor generation inside the food, which creates high pressure gradient. Higher pressure gradient occurring inside the cakes during MW heating as compared to conventional heating can cause more expansion and results in voluminous cakes (Turabi et al. 2010). There was no significant difference between volumes of wheat, lentil and chickpea cakes in terms of specific volume (p > 0.05). However, addition of pea flour resulted in significantly lower volumes probably due to lower foaming properties of pea protein. It has been shown that chickpea flour had higher foam expansion than pea flour (Boye et al. 2010), According to study conducted by Martinez et al. (2014) addition of insoluble pea fiber to gluten-free bread resulted in significant decrease in the volume of bread.

Hardness

Figure 3 shows the effect of baking types and legume flours on hardness of cakes. Control cakes which were baked in conventional oven were found to be harder than MW-IR baked cakes. As explained before, cakes baked in conventional oven had lower volumes than those baked in MW-IR cakes. It was shown by many researchers that volume and hardness of cakes were inversely correlated [Hera et al. 2012; Gularte et al. 2012). Therefore, it is not surprising to observe that cakes which had lower volume had harder texture. Hardness values of pea cakes were higher than wheat cakes due to their lower volume (Fig. 2). The results were in agreement with other studies in which pea flour gave the hardest structure to breads and cakes as compared to other legume flours (chickpea, lentil and bean) (Minarro et al. 2012; Gularte et al. 2012).

Color

Color is one of the most important quality parameters for bakery products. Color of foods directly affects the appearance, and thus acceptability of product. Crust color formation is provided by Maillard reactions (non-enzymatic browning) between amino acids and reducing sugars and by the caramelization of sugar (Purlis 2010).

Higher crust color change was observed in the MW-IR combination oven than conventional oven (Fig. 4). This was probably due to halogen lamp which is known as generating lower penetration depth and higher surface temperature. Higher temperatures at the surface of the cakes resulted in further browning and color change. Similar results were reported previously by Sumnu et al. (2005). On the other hand, legume cakes were observed to have significantly higher crust color change than wheat cakes. Sakiyan (2015) also showed that in the presence of soy flour higher crust color change values were obtained. This could be explained by the effect of original color of legume flour on crust color. It was also indicated in literature that addition of soy, yellow pea and chickpea protein to breads resulted in further crust browning (Fenn et al. 2010).

Gelatinization degree

As shown in the Table 1, oven type affected the gelatinization degree of all cakes. Baking in MW-IR oven resulted in less gelatinization. The reason may be higher moisture loss which limits available water for starch gelatinization and short baking time of MW-IR combination oven. Study conducted by Sakiyan et al. (2011) showed that gelatinization degree of cakes increased with increasing baking time of microwave, MW-IR combination and conventional oven. Short baking time failed to provide enough starch gelatinization in microwave cakes.

Addition of legume flour decreased gelatinization degrees of cakes baked in both ovens. This can be explaine by higher water binding capacities of legume flours due to their higher protein and fiber contents. In other words, protein and fiber present in the legume flours might have limited the available water amount necessary for starch swelling and gelatinization. Wang and Kim (1998) reported that the presence of protein and starch together resulted in lower gelatinization degree of corn flour. Another reason for the decrease in gelatinization degree can be the increase in gelatinization temperature due to addition of protein. It was shown that addition of protein to starch suspension shifted the onset gelatinization temperature to higher temperatures (Sumnu et al. 1999). Therefore, cakes with legume flours gelatinized less than wheat cakes due to the increase in gelatinization temperature. Specific volume results also supported the results of gelatinization degree of legume cakes. Pea cakes having the lowest specific volume (Fig. 2) had the highest gelatinization temperature and the lowest gelatinization degree (Table 1). Kraus et al. (2014) studied the relation between gelatinization degree and volume expansion of extrudates and concluded that volume of product was correlated with gelatinization degree.

Macro-structure

Table 2 shows the effect of legume flour and baking type on the total number of pores, pore size distribution and the pore area fraction. Baking type had an effect on pore area distribution. It was observed that higher number of pores were obtained for wheat and pea cakes in the MW-IR combination oven. Although pore numbers of lentil and chickpea cakes decreased in MW-IR oven, their pore area fractions increased since the number of larger pores increased in MW-IR oven for all flour types. The presence of larger pores could be explained by puffing effect of the MW-IR oven due to higher pressure gradient inside the cakes. Because of larger pores, pore area fraction and specific volumes of cakes baked in the MW-IR oven were also higher than conventionally baked cakes. It was previously stated that pore area fractions and pore numbers of gluten-free cakes increased in MW-IR combination oven (Turabi et al. 2010). The reason for this was the higher pressure gradient occurring inside the cakes during microwave heating as compared to conventional heating which caused looser and more porous structures in cakes. According to Table 2, addition of legume flour decreased the number of pores; however, increased the number of large pores. Similar results were found for lentil extrudates (Lazou and Krokida 2010). Among all legume flours, pea cakes had the smallest pore area fraction for both baking types. The results were in agreement with specific volume results. In other words, pea cakes which had the smallest specific volume values had the smallest pore area fraction.

Micro-structure

The Scanning Electron Microscopy (SEM) images of legume cakes baked in conventional and MW-IR combination oven at 30× magnification level were shown in the Fig. 5. It can easily be seen that pores of cakes which were baked in MW-IR combination oven were larger than those in conventional oven. Channel like structure due to coalescence of the pores were mainly caused by puffing effect of MW-IR combination oven. Specific volumes and pore area fractions of MW-IR baked cakes were also higher than conventionally baked cakes (Fig. 2 and Table 2). Similar results were obtained by Ozkoc et al. (2009) who studied microstructures of MW-IR baked cakes previously. On the other hand, images of pea cakes baked in both ovens were found to be less porous than other cakes. They were also found to have the lowest volume (Fig. 2).

SEM micrographs (30×) of cake samples baked in different ovens. a wheat cake baked in conventional oven, b wheat cake baked in MW-IR oven, c lentil cake baked in conventional oven, d lentil cake baked in MW-IR oven, e chickpea cake baked in conventional oven, f chickpea cake baked in MW-IR oven, g pea cake baked in conventional oven, h pea cake baked in MW-IR oven

SEM images of legume cakes baked in conventional and MW-IR combination oven at 500× magnification level were shown in the Fig. 6. It was observed that deformed starch structure was the majority in the wheat cakes that were baked in conventional oven (black arrows). However, deformed and granular starch structure can be seen together in the wheat cakes baked in MW-IR combination oven (white and black arrows). Incomplete deformation of starch granules was mainly due to lower gelatinization degrees of cakes that baked in MW-IR combination oven (Table 1). As can be seen in the figure, starch granules of conventional cakes were more deformed. Therefore, they lost their granular structure and created more uniform structure. These findings were in agreement with a previous study in which micro-structure of gluten-free rice cakes were studied (Turabi et al. 2010).

SEM micrographs (500×) of cake samples baked in different ovens. a wheat cake baked in conventional oven, b wheat cake baked in MW-IR oven, c lentil cake baked in conventional oven, d lentil cake baked in MW-IR oven, e chickpea cake baked in conventional oven, f chickpea cake baked in MW-IR oven, g pea cake baked in conventional oven, h pea cake baked in MW-IR oven (Black arrows represent deformed starches, white arrows represent granular starches)

On the other hand, although gelatinization degrees of legume cakes were lower than the wheat cakes, more uniform sheet of deformed starch was observed in the images of legume cakes (Fig. 6c, e and g). The reason might be that protein in the legume flours covered the surface of starch structure and formed veil-like structure on the starch granules. When legume cakes were compared, it was observed that lentil cakes had more uniform starch structure and it was in a good agreement with gelatinization degrees of legume cakes (Table 1). Veil like structure was also protein and fiber present in the legume flours limited the available water amount, and thus starch swelling and gelatinization reported by other researches (Ozkoc et al. 2009; Barcenas and Rosell 2005).

Conclusions

Weight loss and specific volumes of MW-IR baked cakes were found to be higher but their hardness values were lower than conventionally baked cakes. The gelatinization degree of MW-IR baked cakes was less than conventionally baked cakes. Moreover, pore area fractions of MW-IR baked cakes were higher than conventionally baked cakes. Although total number of pores was lower in cakes baked in the MW-IR combination oven, the number of large pores was more. Channel like pores were observed in the MW-IR cakes and MW-IR cakes were found to be more porous according to SEM images. On the other hand, both deformed and granular starches were observed in the MW-IR cakes while deformed starch was the majority of conventionally baked cakes.

Pea cakes were observed to have the lowest specific volume among other flour types. There was no significant difference between wheat, lentil and chickpea cakes in terms of specific volume, and hardness. On the other hand, crust of wheat cakes had lower ΔE* values than legume cakes in both ovens. Usage of legume flour retarded starch gelatinization in all cakes.

As a result, it can be concluded that MW-IR combination oven significantly enhanced the quality parameters of cakes and can be recommended for baking. Pea flour was found to be least acceptable legume flour. On the other hand, it was concluded that wheat flour replacement by lentil and chickpea flour can be recommended to be used in cakes.

References

AACC (2000) Approved methods of the AACC. American Association of Cereal Chemists, St Paul

Barcenas ME, Rosell CM (2005) Effect of HPMC addition on the microstructure, quality and aging of wheat bread. Food Hydrocoll 19:1037–1043

Boye JI, Aksay S, Roufik S, Ribereau S, Mondor M, Farnwoth E, Rajamohamed SH (2010) Comparison of the functional properties of pea, chickpea and lentil protein concentrates processed using ultrafiltration and isoelectric precipitation techniques. Food Res Int 43:537–546

Dodevska MS, Djordjevic BI, Sobajic SS, Miletic ID, Djordjevic PB, Dimitrijevic-Sreckovic VS (2013) Characterisation of dietary fibre components in cereals and legumes used in Serbian diet. Food Chem 141:1624–1629

Fenn D, Lukow OM, Humphreys G, Fields PG, Boye JI (2010) Wheat- legume composite flour quality. Int J Food Prop 13:381–393

Gomez M, Oliete B, Rosel CM, Pando V, Fernandez E (2008) Studies on cake quality made of wheat-chickpea flour blends. Food Sci Technol LWT 41:1701–1709

Gularte MA, Gomez M, Rosell CM (2012) Impact of legume flours on quality and in vitro digestibility of starch and protein from gluten-free cakes. Food Bioprocess Technol 5:3142–3150

Hera E, Ruiz-Paris E, Oliete B, Gomez M (2012) Studies of the quality of cakes made with wheat-lentil composite flours. Food Sci Technol 49:48–54

Icoz D, Sumnu G, Sahin S (2004) Color and texture development during microwave and conventional baking of breads. Int J Food Prop 7:201–213

Iqbal A, Khalil IA, Ateeq N, Khan MS (2006) Nutritional quality of important food legumes. Food Chem 97:331–335

Kraus S, Enke N, Gaukel V, Schuchmann HP (2014) Influence of degree of gelatinization on expansion of extruded, starch-based pellets during microwave vacuum processing. J Food Process Eng. doi:10.1111/jfpe.12077

Lazou A, Krokida M (2010) Structural and textural characterization of corn–lentil extruded snacks. J Food Eng 100:392–408

Lee YP, Puddey IB, Hodgson JM (2008) Protein, fibre and blood pressure: potantial benefit of legumes. Clin Exp Pharmacol Physiol 35:473–476

Martinez MM, Diaz A, Gomez M (2014) Effect of different microstructural features of soluble and insoluble fibres on gluten-free dough rheology and bread-making. J Food Eng 142:49–56

Minarro B, Albanell E, Aguilar N, Guamis B, Capellas M (2012) Effect of legume flours on baking characteristics of gluten-free bread. J Cereal Sci 56:476–481

Ndife M, Sumnu G, Bayındırlı L (1998) Differential scanning calorimetry determination of gelatinization rates in different starches due to microwave heating. Food Sci Technol LWT 31:484–488

Ozkoc SE, Sumnu G, Sahin S (2009) The effects of gums on macro and micro-structure of breads baked in different ovens. Food Hydrocoll 23:2182–2189

Purlis E (2010) Browning development in bakery products – a review. J Food Eng 99:239–249

Rizkalla SW, Bellisle F, Slama G (2002) Health benefits of low glycaemic index foods, such as pulses, in diabetic patients and healthy individuals. Br J Nutr 3:255–262

Sakiyan O, Sumnu G, Sahin S, Meda V, Koksel H, Chang PA (2011) Study on degree of starch gelatinization in cakes baked in three different ovens. Food Bioprocess Technol 4:1237–1244

Sakiyan O (2015) Optimization of formulation of soy-cakes baked in infrared-microwave combination oven by response surface methodology. J Food Sci Technol-Mys 52:2910–2917. doi:10.1007/s13197-014-1342-6

Seyhun N, Sumnu G, Sahin S (2003) Effects of different emulsifier types, fat contents, and gum types on retardation of staling of microwave-baked cakes. Nahrung-Food 47:248–251

Sumnu G (2001) A review on microwave baking of foods. Int J Food Sci Technol 36:117–127

Sumnu G, Ndife MK, Bayındırlı L (1999) Effects of sugar, protein and water content on wheat starch gelatinization due to microwave heating. Eur Food Res Technol 209:68–71

Sumnu G, Sahin S, Sevimli M (2005) Microwave, infrared and infrared-microwave combination baking of cakes. J Food Eng 71:150–155

Triniad TP, Mallillin AC, Loyola AS, Sagum RS, Encabo RR (2010) The potential health benefits of legumes as a good source of dietary fibre. Br J Nutr 103:569–574

Turabi E, Sumnu G, Sahin S (2008) Optimization of baking of rice cakes in infrared–microwave combination oven by response surface methodology. Food Bioprocess Technol 1:64–73

Turabi E, Sumnu G, Sahin S (2010) Quantitative analysis of macro and micro-structure of gluten-free rice cakes containing different types of gums baked in different ovens. Food Hydrocoll 24:755–762

Wang SS, Kim Y (1998) The effect of protein and fiber on the kinetics of starch gelatinization and melting in waxy corn flour. Food Sci Technol LWT 50:419–423

Acknowledgments

We would like to thank ETI Food Industry Co. Inc. (Eskisehir, Turkey). for supplying egg white powder.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ozkahraman, B.C., Sumnu, G. & Sahin, S. Effect of different flours on quality of legume cakes to be baked in microwave-infrared combination oven and conventional oven. J Food Sci Technol 53, 1567–1575 (2016). https://doi.org/10.1007/s13197-015-2101-z

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-2101-z

): wheat flour, (□): lentil flour, (■): chickpea flour, (

): wheat flour, (□): lentil flour, (■): chickpea flour, ( ): pea flour

): pea flour

): wheat flour, (□): lentil flour, (■): chickpea flour, (

): wheat flour, (□): lentil flour, (■): chickpea flour, ( ): pea flour

): pea flour

): wheat flour, (□): lentil flour, (■): chickpea flour, (

): wheat flour, (□): lentil flour, (■): chickpea flour, ( ): pea flour

): pea flour

): wheat flour, (□): lentil flour, (■): chickpea flour, (

): wheat flour, (□): lentil flour, (■): chickpea flour, ( ): pea flour

): pea flour