Abstract

The aim of this study was utilization of various seed flours on cake making and to investigate the effect on dough rheology. Apricot seed flour, sour cherry seed flour, pomegranate seed flour, and pumpkin seed flour were used at 5%, 10% and 15% substitution levels to wheat flour. Extensograph and Mixolab were used to determine the rheological and techno-functional attributes of wheat flour substituted with seed flours. Cake quality was investigated in terms of volume, baking loss, hardness, elasticity and sensorial properties. Apricot seed flour substitution highly affected the energy and maximum resistance. Pumpkin seed flour showed a higher effect on extensibility and Mixolab parameters than other seed flours did. Sensorial analysis showed that 5% substitution level was acceptable, however the substitution at 15% level caused a high negative impact on sensorial properties. It was shown that some Mixolab parameters could be used as indicators for the cake quality. The overall results indicated that rheological properties of wheat flour are affected based on the substitution level and it is possible to produce cakes with improved quality attributes with an adjustment of substitution level. The results could have important implications for the valorization of seed flours to produce functional baked products having high protein content.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recently, the studies on the valorization of fruit seeds have increased due to their high potential to be used as functional ingredients for the enrichment of food products. Fruit seeds are rich sources of protein and fibers [1,2,3,4,5] and may contain numerous compounds such as carotenoids [6], phenolic compounds [2, 3, 5], antioxidants [6,7,8,9], fatty acids [4, 8, 10, 11], vitamins [10,11,12] and minerals [6, 10, 11, 13] which makes them excellent source for the production of functional foods. As the cake and muffins are being highly consumed around the world, there have been several attempts to incorporate functional food ingredients into these products [6, 14,15,16,17,18,19,20,21,22]. Accordingly, studies are available where fruit seeds were used as functional ingredients in cake formulation [6, 13, 14, 22,23,24,25,26,27,28,29,30,31,32,33].

Fruit seed flour production is one of the method to valorize them in the food industry to meet the growing demand of consumers on functional foods and to decrease the by-product release, as well. In this study, it was aimed to evaluate the effects of various fruit seed flour substitutions on the rheological properties of wheat flour and on physical, textural and sensorial properties of cakes. Apricot seed flour (ASF), sour cherry seed flour (SCSF), pomegranate seed flour (POSF), and pumpkin seed flour (PUSF) were chosen for comparison as the fruits are widely consumed household and widely processed into juice, jams, syrup, and sauce or used in oil production in the food industry of Turkey. Extensograph and Mixolab were used to determine the rheological properties of substituted wheat flour. Mixolab was not used before to measure the effect of any seed flour substitution on wheat flour. The quality of cakes was measured in terms of volume, baking loss, textural properties and sensorial characteristics. To our knowledge, there is no comprehensive study in the literature on the incorporation of fruit seed flours into wheat flour and investigating the effect both in rheological properties by Extensograph—Mixolab and cake-making.

Material and methods

Materials

The SCSF, POSF, PUSF and ASF was supplied from a Turkish company—Hedef Herbal LLC Company. Wheat flour (WF) was also provided by a Turkish company—Intermil Flour. Modified starch, baking powder, egg and oil were obtained from local groceries. Emulsifier and potassium sorbate were obtained from a local company.

Proximate composition

Proximate compositional analysis was conducted on wheat flour and fruit seed flours (Table 1). Moisture content of samples were determined by using AOAC Official Method 925.40 [34]. Total nitrogen was determined by Kjeldahl method by AOAC Official Method 950.48 [35]. Nitrogen to protein conversion factor of 5.70 was used to calculate the total protein. AOAC Official Method 948.22 was used for lipid analysis [36]. Ash analysis was conducted according to AOAC Official Method 923.03 [37]. Total carbohydrate was calculated by difference.

Extensograph analysis

Extensograph test was conducted to assess the stretching behavior and extension of dough samples based on the AACC method [38, 39] using an Extensograph E (Brabender, Duisburg, Germany). Dough sample (150 g) which was previously prepared in Farinograph’s bowl was placed on the Extensograph to shape it into a cylinder. The cylinder dough was placed into the Extensograph dough cradle, secured with pins, and proved for 45 min at 30 °C. A hook was then drawn through the dough under constant displacement, stretching it downwards until it breaks. The Extensograph recorded a force–time curve as the test was run. The process was repeated on the same dough at every 45 min for 3 times to determine dough behavior at different proofing times.

Mixolab

The mixing and pasting behaviors of dough samples was studied on the Mixolab 6907 (Chopin Technologies, France) using 14% moisture basis. The method was adopted from the study of Dubat [40] where the protocol Chopin+ was followed. The dough weight was kept constant at 80 g and optimum water for reaching a torque of 1.11 Nm was used. After an initial mixing for 8 min at 30 °C, the dough was heated for 15 min at the rate of 4 °C/min till the temperature reached 90 °C. Dough was held at 90 °C for 7 min and then cooled to 50 °C at the rate of 4 °C/min and then mixed at 50 °C for 5 min. The mixing speed was kept constant at 80 rpm. Mixolab profiler consisted water absorption index, mixing index, gluten+ index, viscosity index, amylase activity and retrogradation index. The evaluated torque values from the curves were: C1—maximum torque during mixing, C2—protein weakening based on mechanical work and temperature increase, C3—maximum torque during the heating stage, expressing the rate of starch gelatinization, C4—minimum torque during the heating period, indicating the stability of the hot gel formed, C5—torque after cooling at 50 °C, representing starch retrogradation during the cooling stage.

Cake making

A standard white layer cake batter recipe was used [41]. Cake batter was prepared with wheat flour, fruit flours at the ratios of 5%, 10%, 15%, sugar, wheat starch, modified starch, baking powder, emulsifier, potassium sorbate, salt, milk, egg, water and oil and then blended with a mixer. The used ratios of fruit flours were determined based on the preliminary trials. The formulation of 100 g batter was demonstrated on Table 2. The prepared batter was then baked in a stone sole oven (Wiesheu, EBO 124-355, Germany) at 175 °C for 45 min. The samples were baked in sets and every sets composed of one control sample and samples substituted with one of the seed flours at different levels. The cakes cooled to room temperature and used for analyses.

Volume and baking loss

Volume of cake was determined by rapeseed displacement method, as described by AACC 10.05 [42]. Baking loss was measured by weighing the batter before and the cake after baking and keeping at room temperature for 2 h.

Texture analysis

The texture profile analysis (TPA) of cylindrical cake samples with a 3.5 cm diameter and 2 cm height were performed using a texture analyzer (TA-XT Plus, Stable Micro Systems Ltd., Surrey, UK) at a test speed of 1.0 mm s−1 during 60 s. The crust of cake samples was removed in cake texture determination. A double cycle was programmed and the texture profile was determined using Texture Expert 1.05 software (Stable Microsystems). The firmness and elasticity of cake samples were recorded.

Sensory analysis

The method of sensory evaluation was adopted from Dursun et al. [43]. Sensory evaluation was carried out on cake samples by a panel of 12 trained judges from Food Engineering Department. Samples were placed on white plates and identified with random 3-digit numbers. Panelists were requested to evaluate how much they liked or disliked each sample in relation to crumb color, crust color, taste, aroma, texture and overall acceptance on a 9-point hedonic scale (1 = extremely disliked, 5 = neither liked nor disliked, 9 = extremely liked). They were also asked to evaluate their intention to purchase the tested products, using a 5-point structured scale (1 = certainly will not buy, 5 = certainly will buy). Each panelist evaluated four cake samples in one session. At each session the consumers received a control cake sample and three cake samples having one of the fruit flours at three different concentrations.

Statistical analysis

All samples were prepared in duplicate. The averages and the standard deviations were calculated from three measurements of the duplicate samples using the Excel software (Microsoft Corporation, Redmond, WA, USA). A Tukey test with a confidence interval of 95 was used to evaluate the statistical differences (Minitab® 16 Statistical Software, Minitab Inc. State College, Pennsylvania, USA). Correlation analyses were performed using the Pearson’s correlation coefficient (r) which conducted using the Excel 2016 program (Microsoft, Troy, NY) [44].

Results and discussion

Proximate composition and physicochemical properties of flours

The compositional analysis of wheat flour and seed flours were determined (Table 1). All of seed flours had a lower moisture than wheat flour. Ash content of all fruit seed flours were higher than wheat flour which shows that fruit seeds are rich in mineral content. PUSF and ASF have higher ash content than other flours. It was observed that, SCSF had the highest lipid content where the other seed flours studied had approximate values for fat content. It was explained in the meeting with the producer company that a lipid removal process was applied in the production of PUSF and ASF [45]. Protein content was much higher in ASF, SCSF and PUSF than POSF. However, high protein content of ASF and PUSF could be due to the lipid removal process which applied only in these two fruit seed flour production. In addition, it should be noted that, SCSF had a high protein content although there is no such process. Carbohydrate content was much higher in POSF than the other seed flours tested. The reason for that could be the cellulosic structure of POSF [45]. Wheat flour had much lower ash, protein and fat content than all of the seed flours studied with a much higher carbohydrate content. There were some differences in values of proximate composition of seed flours with the results found in the literature. Based on the literature, ASF was found to have 2.31–2.76% ash content, 21.8–26.9% protein content, 40.2–52% lipid content, and 16.23–25.19% carbohydrate content [2, 10, 46,47,48]. As for POSF, proximate composition was 1.70–3.21% ash, 5.5–18.80% protein, 2,8–19.20% lipid, 73.1% carbohydrate [8, 22, 49, 50]. PUSF was found to have 3.62–8.78% ash, 15.41–55.02% lipids, 25.56–55.02% protein, 9.89–10.63% carbohydrate by various authors [5, 13, 51,52,53]. In case the proximate composition of SCSF, it was determined to have 32.21–42.07% protein, 9.00–34.75% lipid and 10.16–16.28% total carbohydrate by Çelik et al. [54]. There were some differences in values of proximate composition of seed flours with the results found in the literature. It could be due to the presence of a lipid removal process as mentioned earlier as well as the variety of fruits used.

Extensograph

Extensograph analysis gives information about the viscoelastic behavior of dough measuring the extensibility and resistance to extension. A combination of good resistance and good extensibility results in desirable dough properties [55]. The effects of fruit seed flour substitutions at different levels on Extensograph characteristics of dough samples throughout 135 min resting time was shown in Table 3.

It was determined that water absorption only decreased (p < 0.05) with 10% SCSF and 15% POSF substitution while there was no difference with the ASF and PUSF substitutions at all levels.

The addition of seed flour was effective in decreasing energy, resistance to extension and extensibility at 45 min resting time depending on the type and substitution level of seed flour. Energy and resistance to extension at 45 min resting time increased with 5% SCSF and 5% POSF substitution. PUSF substitution at increasing levels provided a decrease in the energy. Although the addition of 5% PUSF shows properties close to control flour in terms of energy and maximum resistance, it was found that PUSF substitution has significantly decreased the extensibility at increasing substitution levels. Extensibility also decreased with 10% and 15% SCSF and POSF substitutions. 5% ASF substitution did not cause any change in energy and extensibility, however, both parameters have decreased with substitution at increasing rates with a decrease in maximum resistance values.

No difference was observed between 5% SCSF substitution and control flour at 90 min resting time. However, with an increase in substitution level, the energy, maximum resistance and extensibility decreased. The addition of POSF induced an increase in energy at the substitution levels of 5% and 10% while there was no statistically difference for the 15% POSF and control flour. When the maximum resistance and extensibility compared with the control, an increase was observed for maximum resistance while a decrease occurred for extensibility. The PUSF substitution induced a decrease in energy and extensibility. In terms of maximum resistance, an increase was observed with the substitution levels of 5% and 15%. In case of ASF substitution, a decrease in energy, maximum resistance and extensibility was observed at 90 min resting time.

Seed flours substitution had a large decreasing effect on energy at 135 min resting time. Extensibility was also decreased especially with PUSF substitution. Maximum resistance values showed different trends with the substitution by different seed flours at increasing levels. While it increased with PUSF and POSF substitution, the addition of SCSF and ASF caused a decrease in maximum resistance.

In general, the reduction in energy values was at higher level than that of wheat flour with increasing resting times. SCSF and POSF at 10% and PUSF at all substitution levels showed a similar variation over the resting period with wheat flour.

Extensibility of dough made by wheat flour showed a decrease as a result of extended resting times. Only a weak trend towards reduced extensibility was noted over the resting period with PUSF substitution at 5% level. However, larger doses did not cause any further change. POSF substitution induced a reduction at 135 min resting time at all levels. In contrast, there was no any significant change in extensibility with SCSF and ASF substitutions.

The effects of the substitutions over the resting period was more pronounced in the differentiation of dough resistance to extension. Wheat flour showed an increase at 90 min without further change at 135 min resting time. The extension of resting time from 45 to 90 min caused also a significant increase with SCSF and POSF substitution, however, then a decrease was observed at 135 min resting time. As for that PUSF and ASF substitutions, a gradual decrease was observed at extended resting times.

In summary, the highest change in energy and maximum resistance for increasing resting times and at increasing substitution levels was observed with ASF which is the seed flour having the highest protein and the lowest fat content studied. PUSF did not show a large variation in energy and extensibility during resting time and in maximum resistance at increasing substitution levels compared to wheat flour. POSF also did not cause a high level of change in energy and extensibility at different substitution concentration probably due to having the lowest protein and the highest carbohydrate content among studied flours. This composition enables it having a more similar composition to control flour among the studied flours.

It was observed that, all of the seed flours used for the substitution had an effect on dough rheology at a certain extent. The PUSF and POSF substitution caused an increase in maximum resistance while a decrease was observed with SCSF and ASF substitution. The substitution with all seed flours used induced a reduction in extensibility. Bangur et al. [56] indicated that Extensograph properties of dough are significantly affected by polymeric protein structure. Accordingly, the increase in maximum resistance with PUSF and POSF substitution could be attributed to interaction between proteins of seed flours and gluten of wheat flour.

There was limited study investigating the changes on Extensograph parameters with the seed flours substitutions used in this study. To our knowledge, the study of Shanshan [57] was the only study which determined the effect of PUSF on Extensograph parameters. They found similar results with this study at 5% and 10% levels of substitution for Extensograph characteristics. Indrani et al. [58] substituted wheat flour with fenugreek seed flour at the levels of 2.5, 5.0 and 7.5%. They found that resistance to extension showed an increasing trend up to 5% level while the extensibility decreased with increasing substitution level. Tulyathan et al. [59] found a poor extensibility and resistance to extensibility for doughs supplemented with jackfruit seed flour as compared to normal wheat dough. Ammar et al. [60] substituted wheat flour with alhydwan seed flour and determined that extensibility and energy value of the dough were highest in the absence of supplementation.

Mixolab

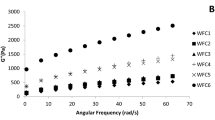

Mixing and pasting properties of wheat flour dough was studied by Mixolab, which is comparably a new tool capable of giving empirical rheological measurements of flour quality. The instrument allows analyzing the quality of the protein network and the starch behavior during heating and cooling [61,62,63]. The effect of seed flour substitution on Mixolab parameters was shown in Table 4. It was observed that all seed flours used had a significant effect on water absorption. There was a high correlation with water absorption values determined by Extensograph (r = 0.82). SCSF, ASF and POSF substitution caused a decrease at different levels while PUSF had an increasing effect on water absorption at a slight level. The reduction in water absorption is owing to lower content of starch and higher fat contents of seed flours used as stated by Khalifa et al. [64]. The higher water absorption observed with PUSF substitutions could be due to presence of a fiber structure having a large number of hydroxyl groups which enter into interactions with water via hydrogen bonds [65]. The high reduction in water absorption was also apparent in Mixolab profile while there was no change with PUSF substitution (Fig. 1).

Dough stability during mixing was positively affected by seed flours substitution. In the course of mixing step, hydration takes place and dough stability is determined by the interactions between polymeric compounds resulting from disulfide-linked proteins, hydrogen bonding aggregates and di-tyrosine bonds [55]. Murat Karaoğlu [66] indicated that use of oxidizing agents could increase the protein crosslinking through SS bond formation leading a stronger dough, whereas reducing agents cause a depolymerisation of gluten by cleaving the SS bonds. The reason of stability increase could be due to oxidizing agents in fat content of seed flours.

Seed flour substitutions did not affect the C1 (behavior during mixing) which was expected due the variation in the amount of water added to obtain a consistency of 1.1 ± 0.05 Nm. The increase in dough strength was also clearly obtained at Mixolab Profiler (Fig. 1). Mixing index highly increased with SCSF, POSF and PUSF and slightly with ASF substitution. At the second stage, heating was applied in Mixolab reaching 52–57 °C where starch started to gelatinize, and the proteins underwent changes on their quaternary, tertiary, and secondary structures due to protein denaturation [67].

C2 was higher with POSF and PUSF substitutions indicating an increasing effect of the seed flours on protein network strength under increasing heating applied during second stage. However, ASF caused a slight decrease while no statistical change (p < 0.05) was observed with SCSF substitution. There was a high correlation between C2 and maximum resistance values obtained at 90 min and 135 min resting time with Extensograph (r = 0.78, r = 0.82). This was a predictable result as resistance of dough to the extension could increase with higher protein network strength. However, gluten+ index decreased with SCSF, POSF and PUSF while an increase observed with ASF substitution. It is an indication of stability to heating in Mixolab profile which is calculated using the drop between C1 and C2.

In the third step, heating is applied until reaching 70 °C while dough remained under constant mixing, stopping protein denaturation and starch gelatinization [67]. A slight reduction in C3 level has only observed at 10% and 15% SCSF, 15% ASF and 15% POSF while an increase was found with 5% PUSF without further change for increasing levels. It can be inferred that, SCSF, POSF and ASF substitution caused a retarding effect on gelatinization while PUSF accelerated it. During the step between C2 and C3, starch gelatinization tends to increase the dough viscosity, whereas amylase degradation shows the opposite effect. The viscosity index which summarizes the behavior between C2 and C3 showed a reduction with SCSF and POSF, a slight increase with PUSF substitution and remained same with ASF substitution. It was inferred that SCSF and POSF caused amylase degradation which was supported by the result of fourth stage. The fourth stage evaluated the enzymatic activity and heat stability of the starch gel, at temperatures above 80 °C [67].

Based on the C4 values, heat stability and amylase activity decreased only with SCSF and POSF substitutions at 15% substitution level while there was no significant change with ASF. A decrease in amylase activity was predictable due to the dilution of wheat flour by the addition of seed flours, leading to lower starch hydrolysis. In contrast, PUSF caused an increase in C4 indicating an increase in amylase activity and heat stability. According to Mixolab profile, a high reduction was only observed with POSF addition at 15% level indicating a lower resistance to shear thinning. In the last stage, dough was cooled to 58–60 °C.

C5 value demonstrates the impact of cooling on dough properties and is associated with starch retrogradation. It was found that, POSF could have a retarding effect on retrogradation at 15% substitution level as it causes a decrease in C5 value. ASF did not cause a large effect even at 15% substitution level. However, PUSF and SCSF caused an increase in C5 value which can be linked to the acceleration of retrogradation. It is also visible in Mixolab Profile (Fig. 1).

In summary, the largest variation in Mixolab parameters (stability, C1, C2, C3, C4 and C5) was observed with PUSF substitution. ASF which is the seed flour having the highest protein and the lowest fat content caused the lowest level of change in stability, C4 and C5. C1, C2 and C3 was affected less by SCSF having the highest fat and the lowest carbohydrate content among seed flours. Gluten+ index highly changed with ASF, whereas PUSF did not cause a large difference compared to other seed flours. Viscosity was not affected much by ASF compared to other seed flours while POSF and SCSF played an important role in viscosity. PUSF have the least and POSF gave the highest differentiation to amylase index which is the seed flour having the highest content of carbohydrate and the lowest protein.

The effect of seed flour on cake quality

Cake volume and baking loss

The volume of cakes is dependent on the capacity of the batter to retain the air (incorporated during mixing) during baking and on starch gelatinization temperature [68]. The effect of seed flour substitution on cake volume and baking loss was demonstrated in Fig. 2. There were no significant changes on volume with SCSF, POSF and ASF substitutions at all levels while PUSF caused a gradual decrease in cake volume at increasing substitution level. It was also found that, viscosity in Mixolab profiler only increased with PUSF substitution. PUSF caused the largest variation in volume and baking loss, it was also the seed flour having the highest effect on Mixolab parameters. The decrease in cake volume by PUSF substitution could be explained by increase in viscosity that obstructs air incorporation during mixing and not expand sufficiently during baking [68, 69]. This reduction could also be explained by the dilution of the wheat protein interfering with optimal gluten network formation during mixing [70, 71].

Cake volumes showed high negative correlation with some Mixolab parameters. Water absorption negatively affected cake volume with a high correlation (r = − 0.83). It was observed previously that cake volume decreased due to strong water binding properties [72, 73]. A high negative correlation was found between C3 which indicates starch gelatinization rate and cake volume (r = − 0.97). The high starch gelatinization rate probably does not allow the air bubbles to expand by the carbon dioxide gas and water vapor properly during the change of batter from a fluid to a solid structure resulting with a contraction of cake [69]. Moreover, cake volume increased with lower C4 which indicates physical breakdown of gelatinized starch granules with a high correlation factor (r = − 0.96), as well. The decreased rate of starch retrogradation—C5 also gave cakes with higher volume (p < 0.05, r = − 0.81). These results were in agreement with Kahraman et al. [41] and Khalifa et al. [64] who reported that, making a good cake flour should have low in C3, C4 and C5 values which indicate the importance of the starch phase of used flour in making of cake. It could be inferred that, these Mixolab parameters could be used to measure resulted cake quality which was also previously suggested by Kahraman et al. [41].

The process of baking loss can be defined as the damage occurred with gas escape during the baking process. It has an important role on structural transformation of cake and its shelf life [71, 74]. There were no significant changes on baking loss with seed flour substitutions indicating they did not cause any large structural transformations on cake production.

Texture analysis

Hardness is an undesirable characteristic of cake products. There were no significant differences between control cake and cakes prepared with SCSF, PUSF and ASF substitutions (Fig. 3). Cakes prepared with POSF substitution at 5% and 10% levels showed similar hardness values, however, substitution at 15% level gave softer cakes. It could be related to its low protein and high carbohydrate content compared to other seed flours. High positive correlation were found for the hardness values with water absorption values determined by Extensograph and Mixolab which are r = 0.75 and r = 0.79, respectively. This was confirmed by [75] who studies correlation between wheat quality and rheological properties.

Lower elasticity values were obtained with SCSF, PUSF and ASF substitutions at increasing levels, however, POSF substitution did not give different cakes in terms of elasticity. A negative correlation was found between elasticity and C5—starch retrogradation (r = − 0.71).

Sensory analysis

The purpose of this set of experiments was to investigate the impact of seed flour substitutions on sensorial properties and purchase intent of cake samples (Fig. 4).

According to sensorial results, 5% SCSF substitution had similar scores with the control cake in all criteria, while 10% SCSF substitution had lower scores compared to control in terms of texture, overall acceptance and purchase intent. In case of 15% SCSF substitution, cake samples had lower scores for all sensorial properties and purchase intent score was largely lower than control sample. However, it was the seed flour revealing the lowest variation in crumb color, crust color, texture and overall acceptance compared to wheat flour. It could be due the distinctive aroma of sour cherry seed oil. Yılmaz et al. [76] conducted a descriptive sensory analysis on sour cherry seed oil and found its unsuitability as it was resembled to cough syrup by panelists.

POSF substitution caused lower scores in terms of crust and crumb color. The substitution at 10% level also caused lower scores for taste, overall acceptance and purchase intent. Regarding the substitution at the level of 15%, panelists gave lower scores for texture, as well. Panelists commented that, the sample has non-uniform crunchy structures causing a lower score for texture. The highest level of substitution also caused very low purchase intent for cake samples. It was the seed flour causing the highest variation in crumb color, crust color, taste, overall acceptance and purchase intent, however panelists gave the highest aroma score to POSF substituted cakes compared the ones with other seed flours.

PUSF substitution at the level of 5% had similar scores compared to control sample except the texture. Overall acceptance and purchase intent scores decreased at 10% substitution level. However, lower scores were given in terms of all sensorial properties and purchase intent compared to control. In addition, some panelists commented that they perceive a rancid aroma at 15% PUSF substitution and it caused the highest degree of change in aroma according to sensorial results.

Regarding the ASF substitution, a gradual decrease was observed in texture and purchase intent scores at increasing substitution levels. It was the seed flour having the highest effect on texture probably due to having the highest protein content among seed flours. Substitution level at 10% also caused lower scores for taste, aroma and overall acceptance. Similar to other seed flour substitution, 15% level caused lower scores for all sensorial properties and purchase intent.

It was observed that has high correlation with energy (r = 0.84) and extensibility parameter (r = 0.90) measured by Extensograph.

Conclusion

In conclusion, variations with seed flour substitutions were determined on rheological properties to some extent. PUSF caused changes in most of the rheological parameters while SCSF substitution played a smaller role in rheological change compared to other seed flours. It was possible to produce cakes without large changes in sensorial properties and volume. It was also seen that softer cakes could be produced by POSF substitutions. Regarding the substitution level, it was observed that, SCSF substitution at 5% level could be used in functional cake production. POSF also caused changes in quality parameters especially in texture of cakes when it is used higher than 5% level. Based on the quality and sensorial parameters, ASF could be used at 10% substitution level. PUSF could also be used at the same level, especially because of the rancid taste occurred when it is used higher than 10% substitution level. As the seed flours have higher protein, fiber and oil content with anti-oxidative compounds, they might have important implications in the fabrication of novel baked products with enhanced health promoting effects.

References

P. Sharma, B. Tilakratne, A. Gupta, Utilization of wild apricot kernel press cake for extraction of protein isolate. J. Food Sci. Technol. 47(6), 682–685 (2010)

Ö. Özboy-Özbaş, I.T. Seker, I. Gökbulut, Effects of resistant starch, apricot kernel flour, and fiber-rich fruit powders on low-fat cookie quality. Food Sci. Biotechnol. 19(4), 979–986 (2010)

S.K. Devatkal, K. Narsaiah, A. Borah, Anti-oxidant effect of extracts of kinnow rind, pomegranate rind and seed powders in cooked goat meat patties. Meat Sci. 85(1), 155–159 (2010)

M. Kozhakhiyeva, S. Dragoev, Y. Uzakov, A. Nurgazezova, Improving of the oxidative stability and quality of new functional horse meat delicacy enriched with sea buckthorn (Hippophae rhamnoides) fruit powder extracts or seed kernel pumpkin (Cucurbita pero L.) flour. Comptes rendus de l’Academie bulgare des Scis 71(1), 132–140 (2018)

I. Nikolić, L. Dokić, V. Krstonošić, Z. Šereš, D. Šoronja-Simović, Possibility of the production of functional low-fat food spread of hull-less pumpkin seed flour from rheological and textural aspect. J. Texture Stud. 45(4), 324–333 (2014)

M. Białek, J. Rutkowska, A. Adamska, E. Bajdalow, Partial replacement of wheat flour with pumpkin seed flour in muffins offered to children. CyTA-J. Food. 14(3), 391–398 (2016)

G. Durmaz, M. Alpaslan, Antioxidant properties of roasted apricot (Prunus armeniaca L.) kernel. Food Chem. 100(3), 1177–1181 (2007)

H. Bourekoua, R. Różyło, U. Gawlik-Dziki, L. Benatallah, M.N. Zidoune, D. Dziki, Pomegranate seed powder as a functional component of gluten-free bread (physical, sensorial and antioxidant evaluation). Int. J. Food Sci. Technol. 53(8), 1906–1913 (2018)

P. Jing, T. Ye, H. Shi, Y. Sheng, M. Slavin, B. Gao, L. Liu, L.L. Yu, Antioxidant properties and phytochemical composition of China-grown pomegranate seeds. Food Chem. 132(3), 1457–1464 (2012)

M.E. El-Demery, S. Elsanat, Influence of apricot kernel flour addition on sensory characteristics of spaghetti. Egypt. J. Food Sci. 38, 49–65 (2010)

M. Hayta, M. Alpaslan, Chapter 20—apricot kernel flour and its use in maintaining health, in Flour and breads and their fortification in health and disease prevention. ed. by V.R. Preedy, R.R. Watson, V.B. Patel (Academic Press, San Diego, 2011), pp. 213–221

J.S. Silva, T.R. Marques, A.A. Simão, A.D. Corrêa, A.C.M. Pinheiro, R.L. Silva, Development and chemical and sensory characterization of pumpkin seed flour-based cereal bars. Food Sci. Technol. 34(2), 346–352 (2014)

CMd.S. Gorgônio, M. Pumar, C.G. Mothé, Macrocospic and physiochemical characterization of a sugarless and gluten-free cake enriched with fibers made from pumpkin seed (Cucurbita maxima, L.) flour and cornstarch. Food Sci. Technol. 31(1), 109–118 (2011)

P. Ambigaipalan, F. Shahidi, Date seed flour and hydrolysates affect physicochemical properties of muffin. Food Biosci. 12, 54–60 (2015)

A. Arora, M.E. Camire, Performance of potato peels in muffins and cookies. Food Res. Int. 27(1), 15–22 (1994)

N.H.A. Hassan, N.A. Zulkifli, L.H. Ho, Physical and sensory evaluation of muffin incorporated with rubber seed (Hevea brasiliensis) flour, pumpkin (Cucurbita moschata) flour and cassava (Manihot esculenta crantz) flour. J. AgroBiotechnol. 10(1S), 1–12 (2019)

M.U. Rosales-Soto, J.R. Powers, J.R. Alldredge, Effect of mixing time, freeze-drying and baking on phenolics, anthocyanins and antioxidant capacity of raspberry juice during processing of muffins. J. Food Sci. Agric. 92(7), 1511–1518 (2012)

H.V. Rupasinghe, L. Wang, G.M. Huber, N.L. Pitts, Effect of baking on dietary fibre and phenolics of muffins incorporated with apple skin powder. Food Chem. 107(3), 1217–1224 (2008)

H. Vasantha Rupasinghe, L. Wang, N.L. Pitts, T. Astatkie, Baking and sensory characteristics of muffins incorporated with apple skin powder. J. Food Qual. 32(6), 685–694 (2009)

S.-Y. Joo, M.-H. Choi, H.-J. Chung, Studies on the quality characteristics of functional muffin prepared with different levels of grape seed extract. J. Korean Soc. Food Cult. 19(3), 267–272 (2004)

S.-M. Yang, M.-J. Kang, S.-H. Kim, J.-H. Shin, N.-J. Sung, Quality characteristics of functional muffins containing black garlic extract powder. Korean J. Food Cookery Sci. 26(6), 737–744 (2010)

Z. Saeidi, B. Nasehi, H. Jooyandeh, Optimization of gluten-free cake formulation enriched with pomegranate seed powder and transglutaminase enzyme. J. Food Sci. Technol. 55(8), 3110–3118 (2018)

S. Grasso, S. Liu, L. Methven, Quality of muffins enriched with upcycled defatted sunflower seed flour. LWT 119, 108893 (2020)

P.C. Das, M.J. Khan, M.S. Rahman, S. Majumder, M.N. Islam, Comparison of the physico-chemical and functional properties of mango kernel flour with wheat flour and development of mango kernel flour based composite cakes. NFS J. 17, 1–7 (2019)

S. Arpit, D. John, Effects of different levels of jackfruit seed flour on the quality characteristics of chocolate cake. Res. J. Agric. For. Sci. 2320, 6063 (2015)

A. Ayoubi, M. Balvardi, H.-R. Akhavan, R. Hajimohammadi-Farimani, Fortified cake with pomegranate seed powder as a functional product. J. Food Sci. Technol. 59(1), 308–316 (2022)

M. China, N. Deedam, P. Olumati, Effect of fluted pumpkin seeds flour on the proximate and sensory properties of cooking banana flour biscuits and queens cake for household consumption. Res. J. Food Sci. Nutr. 5(2), 30–34 (2020)

J. David, V. Parthasarathy, S. Kalaiselvan, S. Hemalatha, G.V. Swaroop, Y. Guo, N. Guo, J. Gao, Y. He, C. Chellaram, Antioxidant properties of fibre rich dietetic chocolate cake developed by jackfruit (Artocarpus heterophyllus L.) seed flour. Int. J. Food Eng. 2(2), 132–135 (2016)

D.J.M. de Abreu, I.A. de Moraes, E.R. Asquieri, C. Damiani, Red (Spondias purpurea L.) mombin seed flour as a functional component in chocolate brownies. J. Food Sci. Technol. 58(2), 612–620 (2021)

M. Kaur, S. Sharma, Development and nutritional evaluation of cake supplemented with pumpkin seed flour. Asian J. Dairy Food Res. 37(3), 232–236 (2018)

S. Khan, M. Saqib, M. Alim, Evaluation of quality characteristics of composite cake prepared from mixed jackfruit seed flour and wheat flour. J. Bangladesh Agric. Univ. 14(2), 219–227 (2016)

C. Lalchhandami, C. Nganthoibi, N.R. Marak, Acceptability of incorporation of jackfruit seed flour in cakes. Food Sci. Res. J. 9(2), 245–249 (2018)

M.A. Marufa, P.C. Das, A. Iqbal, Utilization of jamun seed powder in composite cake formulation. J. Bangladesh Agric. Univ. 17(4), 599–605 (2019)

W. Horwitz, Moisture in Nuts and Nut Products (AOAC Official Method 925.40). Officials Methods of Analysis of AOAC International, 17th edn. (AOAC International, Gaithersburg, 2000)

W. Horwitz, Protein (Crude) in Nuts and Nut Products. Improved Kjeldahl Method (AOAC Official Method 950.48). Officials Methods of Analysis of AOAC International, 17th edn. (AOAC International, Gaithersburg, 2000)

A. International, Method 948.22, lipid and oil, ch. 40, p. 1; method 950.49, ash. Ch. 40, p. 2; method 990.03, crude protein, ch. 4. Official Methods of Analysis of AOAC International. pp. 26–27 (2000)

AOAC., Ash of flour. Method 923.03. Association of Official Analytical Chemists International Washington, DC (1997)

American Association of Cereal Chemists, A.R., Method 54-10.01. Physical dough test procedure, 11th edn. (AACC International, Minnesotta, 2010a)

American Association of Cereal Chemists, A.R., Method 54-21.02. Constant weight flour procedure, 11th edn. (AACC International, Minnesotta, 2010b)

A. Dubat, A new AACC international approved method to measure rheological properties of a dough sample. Cereal Foods World (CFW) 55(3), 150 (2010)

K. Kahraman, O. Sakıyan, S. Ozturk, H. Koksel, G. Sumnu, A. Dubat, Utilization of mixolab® to predict the suitability of flours in terms of cake quality. Eur. Food Res. Technol. 227(2), 565–570 (2008)

Americal Association of Cereals Chemists, A.R., Method 10-05. Guidelines for measurement of volume by rapeseed displacement. (AACC International, Minnesotta, 2000)

S. Dursun, A. Yapar, İ Çelik, Kadife balığı (tinca tinca l., 1758) etiyle zenginleştirmenin hamurun reolojik özellikleri ve ekmeğin duyusal özellikleri üzerine etkisi. Gıda Teknolojileri Elektronik Dergisi. 4(3), 44–58 (2009)

H.E.T. Aĝirbaş, M. Yavuz-Düzgün, B. Özçelik, The effect of fruit seed flours on farinograph characteristics of composite dough and shelf life of cake products. J. Food Meas. Charact. 15(5), 3973–3984 (2021)

D. Dalimov, G. Dalimova, M. Bhatt, Chemical composition and lignins of tomato and pomegranate seeds. Chem. Nat. Comp. 39(1), 37–40 (2003)

N. Dhen, I.B. Rejeb, M.M. Martínez, L. Román, M. Gómez, M. Gargouri, Effect of apricot kernels flour on pasting properties, pastes rheology and gels texture of enriched wheat flour. Eur. Food Res. Technol. 243(3), 419–428 (2017)

F.S. El-Safy, R.H. Salem, M. Abd El-Ghany, Chemical and nutritional evaluation of different seed flours as novel sources of protein. World J. Dairy Food Sci. 7(1), 59–65 (2012)

E. Eyidemir, M. Hayta, The effect of apricot kernel flour incorporation on the physicochemical and sensory properties of noodle. Afr. J. Biotechnol. 8, 1 (2009)

H. Gül, H. Şen, Effects of pomegranate seed flour on dough rheology and bread quality. CyTA J. Food 15(4), 622–628 (2017)

I. Koca, B. Tekguler, V.A. Yilmaz, I. Hasbay, A.F. Koca, The use of grape, pomegranate and rosehip seed flours in Turkish noodle (erişte) production. J. Food Proc. Preserv. 2(1), e13343 (2018)

L. Costa, P. Tomé, F. Jardim, V. Silva, E. Castilho, K. Damasceno, P. Campagnol, Physicochemical and rheological characterization of pan bread made with pumpkin seed flour. Int. Food Res. J. 25(4), 1489–1496 (2018)

R. Navarro-Cortez, B. Hernández-Santos, C. Gómez-Aldapa, J. Castro-Rosas, E. Herman-Lara, C. Martínez-Sánchez, J. Juárez-Barrientos, C. Antonio-Cisneros, J. Rodríguez-Miranda, Development of extruded ready-to-eat snacks using pumpkin seed (Cucurbita pepo) and nixtamalized maize (Zea mays) flour blends. Revista Mexicana de Ingeniería Química 15(2), 409–422 (2016)

G. Sharma, S. Lakhawat, Development, quality evaluation and acceptability of pumpkin seed flour incorporated in gravy. J. Nutr. Food Sci. 7, 4 (2017)

M. Çelik, M. Güzel, M. Yildirim, Effect of ph on protein extraction from sour cherry kernels and functional properties of resulting protein concentrate. J. Food Sci. Technol. 56(6), 3023–3032 (2019)

C.M. Rosell, E. Santos, C. Collar, Physical characterization of fiber-enriched bread doughs by dual mixing and temperature constraint using the mixolab®. Eur. Food Res. Technol. 231(4), 535–544 (2010)

R. Bangur, I. Batey, E. McKenzie, F. MacRitchie, Dependence of extensograph parameters on wheat protein composition measured by SE-HPLC. J. Cereal Sci. 25(3), 237–241 (1997)

N. Shanshan, Effect of natural additions from marjoram and pumpkin seeds on the rheological and sensory properties of wheat flour bread. Damietta Univ. Pub. 1, 2 (2014)

D. Indrani, J. Rajiv, G.V. Rao, Influence of fenugreek seed powder on the dough rheology, microstructure and quality of parotta—an Indian flat bread. J. Texture Stud. 41(2), 208–223 (2010)

V. Tulyathan, K. Tananuwong, P. Songjinda, N. Jaiboon, Some physicochemical properties of jackfruit (Artocarpus heterophyllus lam) seed flour and starch. Sci. Asia 28(1), 37–41 (2002)

A.F. Ammar, H. Zhang, A. Siddeeg, M. Chamba, B. Kimani, H. Hassanin, M. Obadi, N. Alhejj, Effect of the addition of alhydwan seed flour on the dough rheology, bread quality, texture profile and microstructure of wheat bread. J. Texture Stud. 47(6), 484–495 (2016)

M.A.S. Abdel-Samie, J. Wan, W. Huang, O.K. Chung, B. Xu, Effects of cumin and ginger as antioxidants on dough mixing properties and cookie quality. Cereal Chem. 87(5), 454–460 (2010)

W. Huang, L. Li, F. Wang, J. Wan, M. Tilley, C. Ren, S. Wu, Effects of transglutaminase on the rheological and mixolab thermomechanical characteristics of oat dough. Food Chem. 121(4), 934–939 (2010)

C.M. Rosell, A. Foegeding, Interaction of hydroxypropylmethylcellulose with gluten proteins: small deformation properties during thermal treatment. Food Hydrocol. 21(7), 1092–1100 (2007)

I. Khalifa, H. Barakat, H. El-Mansy, S. Soliman, Influencing of guava processing residues incorporation on cupcake characterization. J. Nutr. Food Sci. 6(513), 2 (2016)

C.M. Rosell, J.A. Rojas, C. Benedito de Barber, Influence of hydrocolloids on dough rheology and bread quality. Food Hydrocol. 15(1), 75–81 (2001)

M. Murat Karaoğlu, Cephalaria syriaca addition to wheat flour dough and effect on rheological properties. Int. J. Food Sci. Technol. 41, 37–46 (2006)

M. Schmiele, M.H. Ferrari Felisberto, M.T. Pedrosa Silva Clerici, Y.K. Chang, Mixolab™ for rheological evaluation of wheat flour partially replaced by soy protein hydrolysate and fructooligosaccharides for bread production. LWT 76, 259–269 (2017)

D.M. Lebesi, C. Tzia, Use of endoxylanase treated cereal brans for development of dietary fiber enriched cakes. Innov. Food Sci Emerg. Technol. 13, 207–214 (2012)

M. Gómez, F. Ronda, P.A. Caballero, C.A. Blanco, C.M. Rosell, Functionality of different hydrocolloids on the quality and shelf-life of yellow layer cakes. Food Hydrocol. 21(2), 167–173 (2007)

Y. Pomeranz, M. Shogren, K. Finney, D. Bechtel, Fiber in breadmaking—effects on functional properties. Cereal Chem. 50(6), 51 (1977)

J.H. Kim, H.J. Lee, H.-S. Lee, E.-J. Lim, J.-Y. Imm, H.J. Suh, Physical and sensory characteristics of fibre-enriched sponge cakes made with Opuntia humifusa. LWT 47(2), 478–484 (2012)

H. Chen, G.L. Rubenthaler, H.K. Leung, J.D. Baranowski, Chemical, physical, and baking properties of apple fiber compared with wheat and oat bran. Cereal Chem. 65(3), 244–247 (1988)

M.L. Sudha, V. Baskaran, K. Leelavathi, Apple pomace as a source of dietary fiber and polyphenols and its effect on the rheological characteristics and cake making. Food Chem. 104(2), 686–692 (2007)

G.-Y. Choi, J.-H. Bae, G.-J. Han, The quality characteristics of sponge cake containing a functional and natural product (1. Mulberry leaf powder). J. East Asian Soc. Diet. Life 17(5), 703–709 (2007)

C.-H. Yin, Y.-P. Wang, H.-L. Lu, J.-P. Hu, X.-L. Qin, T. Jia, Correlation analysis of wheat quality index and dough rheological property index. J. Henan Univ. Tech (Nat. Sci. Ed.) 33(4), 41–44 (2012)

E. Yılmaz, O. Keskin, S. Ok, Valorization of sour cherry and cherry seeds: cold press oil production and characterization. J. Agroaliment. Proc. Technol. 26(3), 228–240 (2020)

Acknowledgements

We thank Polen Food Inc. for their technical and financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tuna Ağirbaş, H.E., Yavuz-Düzgün, M. & Özçelik, B. Valorization of fruit seed flours: rheological characteristics of composite dough and cake quality. Food Measure 16, 3117–3129 (2022). https://doi.org/10.1007/s11694-022-01423-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01423-0