Abstract

The study was undertaken with the objective of formulating a fiber enriched functional bread by incorporating little millet flour (LMF). Wheat flour (WF) was replaced with LMF at various proportions (10, 30 and 50%) in the bread preparation. The developed breads were evaluated for physical, sensory and nutritional characteristics. The loaf volume, weight, height and specific volume were decreased significantly with increased levels of LMF. The wheat bread (control), 10 and 30 % percent incorporation of LMF did not show significance difference in the sensory scores. Control and bread with 30 % incorporation of LMF were evaluated further for nutritional characteristics. There was an increase in the percentage of micronutrients such as Iron (94%), Zinc (29%), Copper (70%), Phosphorus (28%) and also fiber (19%) which improved the nutritional value of the wheat bread when substituted with LMF. The incorporation of LMF at 30% level in bread can be considered as a functional and nutritional food choice for the management of diet related metabolic disorders.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Millets are small seeded grains used for food, feed and forage. They are widely cultivated in the tropics and consumed by all age groups in several forms after cooking as rice and roti. With respect to other cereals, millets are nutritionally comparable and even superior to some major cereals (Anonymous 2009; Gopalan et al. 2010; Balasubramanian et al. 2007). Millets are also rich sources of dietary fiber and phyto nutrients (Ushakumari and Malleshi 2007; Hadimani and Malleshi 1993, 2003; Geervani and Eggum, 1989). In India, Little millet (Panicum miliare) is one of the important staple cereal crops mainly grown in Karnataka and Tamil Nadu. Little millet has fat (4.7 g), crude fiber (7.7 g), iron (9.3 mg) and phosphorus (220 mg) per 100 g which is comparable to cereals and other millets (Gopalan et al. 2010). Dietary fiber content of little millet is the contributing factor for its low glycaemic index and a recent study conducted on little millet indicated that it exhibits hypoglycaemic effect due to its higher proportion of dietary fiber (Itagi et al. 2013). It has a significant role in providing significant amounts of antioxidants and phytochemicals in the diet (Ushakumari and Malleshi 2007; Pradeep and Guha 2011). Considering the growing awareness among the consumers regarding the health benefits of millet, there is a need to meet the diversified demands for millet based food products.

Bread is an important convenient staple food found around the world. A considerable amount of effort to develop composite bread with good sensory properties and nutritious health benefits have been reported by several workers (Sanchez et al. 2002; Edema et al. 2005; Olaoye et al. 2006; Mepba et al. 2007). The bakery sector is also focusing on the use of minor millets as a source of dietary fiber and bioactive compounds (Hugo et al. 2009; Singh et al. 2012; Ballolli et al. 2014; Bhol and John Don Bosco 2014). Finger millet and foxtail millet flour incorporated breads were nutritious with low glycemic index and were acceptable at 30 % level (Chhavi and Sarita 2012). The present study is undertaken to evaluate the possibility of increasing the nutritional quality of bread by substituting WF with LMF.

Materials and method

Little millet grains were obtained from the University of Agricultural Sciences, Dharwad, Karnataka, India. The grains were milled to fine flour (100 μm). Unbleached WF and traditional yeast were obtained from the local market of Montreal, Canada.

Bread making

Control wheat and millet breads were produced using the straight dough method (AACC 1995). The little millet breads were developed by replacing WF with10, 30 and 50% LMF. For 250 g of WF/LMF incorporated flour, 3 g of yeast, 15 g of sugar, 12.5 g of fat, 4 g of salt and 170 ± 10 ml water were used. Yeast was allowed to rise with some amount of sugar in warm water for ten minutes prior to incorporation into the flour. The flour was mixed thoroughly with all the other ingredients. A ‘Kitchen Aid’ brand kneading machine was used to mix the dough. The dough was kneaded until it naturally leaves the sides of the vessel. The dough was allowed to rest for the first proofing in an oil smeared vessel for 2 h at ambient temperature (25 ± 0.5 °C). The dough was then divided into equal sizes of 130 ± 3 g and kneaded to the cylindrical shape before keeping into the baking bread moulds (12 × 4.5 × 5.5 cm), where the dough was allowed to rest for an hour to proof for the second time. The breads were then baked at 400 °C for 10–12 min and allowed to cool. The bread loaves were analyzed for physical characteristics after cooling for 8 h.

Physical characteristics of breads

Loaf weight

Bread loaves were weighed after baking, using a laboratory scale balance. The readings were recorded in grams.

Loaf height, length and breadth

Loaf Height, length and breadth of the bread loaves were measured with a measuring meter and readings were recorded in centimeters.

Loaf volume

The loaf volume was determined using millet seed displacement method. Little millet grains were loaded into an empty box with calibrated mark until it reached the marked level and unloaded back. The bread sample was put into the box and the measured little millet grains were loaded back again. The remaining little millet grains left outside the box was measured using measuring cylinder and recorded as loaf volume in cm3. Specific volume was calculated as volume to weight ratio (cm3/g) (Rosales-Juárez et al. 2008).

Texture profile analysis of bread crumb

Texture was analyzed using Instron Universal Testing Machine (model-4400). Textural analysis of wheat and millet breads was studied as the force required to compress 50 % of the original height of bread slices of 25-mm in thickness (Mochizuki 2001). The individual bread slices were tested under the compression mode using a 20 mm diameter compression probe. A crosshead speed of 12.5 mm/min was used to record the maximum force (N) expressed as the hardness of a bread slice of 25 mm thickness. All textural measurements were done in triplicate. Cohesiveness and adhesiveness were calculated using the texture profile analysis graph. Cohesiveness is defined as “the ratio of the positive force area during the second compression portion to that during the first compression (Area2/Areal), excluding the areas under the decompression portion in each cycle”. Adhesiveness (mJ) is defined as “the negative force area for the first bite, representing the work necessary to pull the plunger away from the food sample”.

Bread crust and crumb colour

Colour determinations were carried out on bread crumb and crust using a Minolta colorimeter (Minolta CR- 400, Konica Minolta Sensing, Inc., Osaka, Japan), and results were expressed in accordance with the Hunter Lab colour space. The parameters determined were L* (L = 0 [black] and L = 100 [white]), a* (−a = greenness and + a = redness), b* (−b = blueness and + b = yellowness).

Sensory evaluation of breads

Wheat and millet incorporated breads were subjected to sensory evaluation by a panel of 20 semi-trained judges using a 9-point Hedonic scale (where 9- like extremely and 1- dislike extremely) for appearance, crust and crumb color, aroma, taste and overall acceptability. Selected LMF incorporated and control breads were further evaluated for their nutritional qualities.

Nutritional composition of breads

Proximate composition

The moisture, protein, fat, crude fiber and ash contents were determined using AOAC (1980) procedures. The total carbohydrate content was determined by the method of difference

Dietary fiber

Soluble dietary fiber (SDF), insoluble dietary fiber (IDF) and total dietary fiber (TDF) were analyzed using AOAC (1995) procedures.

Micronutrient composition

The trace elements viz., iron, zinc, copper and manganese were estimated using Atomic Absorption Spectrophotometer (model: AAS GBC Avanta). Sodium and potassium were analyzed using flame photometry.

Statistical analysis

Statistical analysis was conducted using the software JMP version8.0, SAS institute Inc, Corg, NC, 27513, USA. The Tukey-Kramer test was used to assess the differences among the physical characteristics of breads made with and without millet flour.

Results and discussion

Physical characteristics of breads

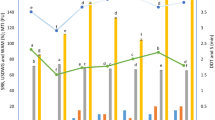

Physical characteristics of control and millet breads are presented in Table 1. In the present study, a significant decrease in the physical characteristics of the bread was observed with increased incorporation of millet flour (>10 %). It might be due to a decrease in the proportion of the gluten content which is an important protein responsible for maintaining the visco-elastic property of bread dough which ensures the increased volume of bread. However there was no significant difference (p ≥ 0.05) between control and 10% LMF incorporated bread for loaf weight, volume and specific volume (Fig 1 and 2). Rai et al. (2011) and Ballolli et al. (2014) also reported a decrease in loaf size with a progressive increase in the proportion of non gluten flour such as maize meal and rice flour and foxtail millet flour respectively. However, loaf weight is basically determined by the quantity of dough baked and the amount of moisture and carbon dioxide diffused out of the loaf during baking (Shittu et al. 2007). The control bread had a higher loaf volume whereas the 50% incorporated millet bread showed lower loaf volume. The decrease in volume of bread at maximum levels of incorporation was 39.04 %. Loaf volume is affected by the quantity and quality of protein in the flour (Ragaee and Abdel-Aal, 2006) as well as proofing time (Zghal et al. 2002). Wieser and Kieffer (2001) reported that bread volume was influenced by the total amount of gluten protein more than by the amount of protein in different groups or of different types and the correlation between bread volumes and the quantity of gluten proteins was higher, when dough was mixed optimally.

The specific volume, which is the ratio of volume to weight, has been generally adopted in the literature as a more reliable measure of loaf size. Specific volume of little millet breads ranged from 2.51 to 4.05 cm3/g. The maximum specific volume was found for wheat bread and minimum was found for 50% LMF incorporated bread. According to the China Grain Products Research and Development Institute (CGPRDI) the specific volume of standard bread should be 6 cm3 /g and not less than 3.5 cm3 /g (Lin et al. 2009). In the present study, specific volume of millet breads ranged from 2.51 to 3.99 cm3/g limiting the incorporation of LMF to 10 to 30% can ensure that the standard specific volume mentioned above.

Bread crust and crumb colour

When comparing all breads, the control wheat bread had a whiter crumb. Millet breads were yellowish in colour. Bread crust and crumb colour varied with the proportion of millet present in the formulation (Table 2). “L*” values of crust and crumb ranged from 40.73 to 72.10 and 64.28 to 72.71 respectively. “a*” and “b*” values were found to be significantly different when compared to the control bread. The results of crust and crumb colour of millets incorporated breads revealed that the crust colour varied significantly (p > 0.05) with an increase in the millet proportion. The preferred bread crust colour is golden/caramel brown. In the present study “L*” (luminosity) value of crust decreased with increase in millet flour proportion up to 30%. At 50% incorporation the crust did not effectively turn brown. A similar trend was also observed with the ‘a*’ value and it varied significantly (p > 0.05) with increasing proportion of little millet. There was a significant difference (p > 0.05) between the wheat and millet breads for the ‘b*’ value which further depicts browning of the bread. ‘b*’ values for millet incorporated breads were lower than for wheat bread (Fig 3). Crumb colour varied significantly (p > 0.05), and the crumb's ‘a*’ value increased while its ‘b*’ value decreased (p > 0.05) with an increase in millet proportion (Fig 2). The results revealed that as the proportion of millet increased the colour contrast of bread decreased. Siddiq et al. (2009) observed that an addition of defatted maize germ flour to wheat bread decreased both the ‘L*’ and ‘b*’ values and increased ‘a*’ value with an increase in proportion.

Texture profile analysis of little millet incorporated breads

The texture profile analysis values of millet breads in comparison with the control bread are given in Table 3. An increase in the incorporation of millet flour increased the hardness value of the bread. On the other hand, there was no significant difference found in the cohesiveness and adhesiveness when compared to control bread. The millet breads were firm, as they had grainy texture. Among the bread-making cereals, both wheat and rye contain ‘gluten’, which makes them superior to other cereals for the production of aerated bakery products. During dough mixing the main function of gluten is to swell and hold water, forming cells with strong elastic walls that capture carbon dioxide formed during fermentation. Therefore, when substituting WF with other gluten-free flours, the amount of gluten is reduced. This thus reduces the available dough network which captures the carbon dioxide formed during yeast induced fermentation (Veluppillai et al. 2010). Hence breads formulated with gluten-free flour are denser and somewhat harder than that of control gluten containing flour. Rajiv et al.(2011) reported that the hardness of muffins increased, indicating a hardening texture, with the increase in the level of finger millet in a mixed flour. Texture of bread is significantly influenced by the amount of water retained in the dough, while different water retention capacities are expressed in wheat and other flours as the protein content changes. Ballolli et al. (2014) stated that incorporation of foxtail millet has increased the hardness and grainy texture of millet breads. Siddiq et al. (2009) also reported that the texture parameters were greatly affected by the addition of defatted maize germ (DMG) flour in breads. The hardness values increased with increasing levels of DMG flour, from 32.84 N recorded for the control bread to 61.58 N in 20 g/100 g DMG bread. In the present study similar trends were observed where the hardness value increased from 1.76 to 5.67 N. The addition of millet flour influenced the crumb structure by retaining moisture thus increasing the hardness values of the bread and also modifying the quantity and quality of protein in the wheat–millet flour bread system. Additionally, high levels of millet flour addition led to a lack of uniform crumb structure.

Sensory analysis

The mean sensory scores obtained for the millet incorporated wheat breads at different levels ranged between 6.31 and 7.84 (Table 4). The analysis of variance (ANOVA) showed that there was no significant difference (p > 0.05) between the control wheat breads and breads with 10 and 30% millet incorporation. Fifty per cent incorporated millet had slightly lower score when compared to other millet breads. This is supported by the quantitative analysis of the bread's characteristics through instrument measurements which also revealed lower acceptability of millet bread (50 %) for texture and colour. This is mainly because of increased hardness and lower browning of crust during baking. Since there was no significant difference for most of the sensory characteristics of bread with 10 and 30% millet incorporation, and with the potential health benefits of incorporation of little millet at higher proportion without affecting the consumer acceptability, the 30% incorporation was considered as the optimal level for enrichment of breads. Veluppillai et al. (2010) reported that WF substitution with 35% malted rice flour was the best according to the physical and sensory quality of the bread. Rai et al. (2011) reported that 25% replacement of WF by rice flour was found to be more acceptable than the control wheat bread. Hence millet flour substitution up to 30% in WF for baking bread can be considered for acceptable sensory attributes with little to no significant differences from wheat bread.

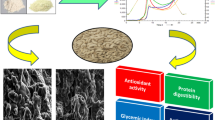

Nutritional composition of breads

The nutritional composition of little millet bread with 30% incorporation was compared to the control 100 % wheat bread and it is presented in Table 5. The comparison of the nutrient composition of 30% little millet incorporated bread and wheat bread showed that ash, crude fiber, dietary fiber contents increased significantly with the addition of millet (Table 5). The dietary fiber content increased by 19% compared to that of wheat bread for the little millet bread. This is explained by the contribution of the dietary fiber content which is present in the LMF (Anonymous 2009; Padulosi et al. 2009; Gopalan et al. 2010). Whereas the protein content of little millet incorporated bread was significantly lower (11.95 %) which is explained by the lower protein content in the little millet grain itself compared to wheat (Padulosi et al. 2009; Gopalan et al.2010). Similar results were also observed by Rajiv et al. (2011) where addition of finger millet flour increased the ash content and lowered protein content in muffins.

Micronutrient composition

Little millet bread with 30% incorporation showed higher values for iron, copper, manganese, zinc, potassium except sodium content compared to the control bread (Table 6). The per cent increase in iron, zinc, copper and phosphorus was 94, 29, 70, and 28 respectively. However consumption of 100 g millet bread provides more iron and zinc. The study demonstrated that incorporation of millet enhances the dietary fiber and micro nutrients which are considered beneficial in the management of diabetes and cardiovascular diseases.

Conclusion

Findings of the present study have shown that with the addition of LMF at 30%, there is potential for producing functional bread with acceptable quality. Along with its sensory properties, the little millet bread was acceptable in many nutritional aspects. It was found to show significantly more dietary fiber, copper, zinc, iron and phosphorus. As convenient novel foods, consumption of little millet bread could be more beneficial in terms of effective management of metabolic disorders.

References

AACC (1995) Approved methods of American Association of Cereal Chemists, AACC, 10th edn. St Paul, Minnesota

Anonymous (2009) Millet Network of India. Deccan Development Society, FIAN, India

AOAC (1980) Official Methods of Analysis, 13th edn. Association of Official Analytical Chemists, Washington DC

AOAC (1995) Official Methods of Analysis, 18th edn. Association of Official Analytical Chemists, Washington DC

Balasubramanian S, Vishwanathan R, Sharma R (2007) Post harvest processing of millets:An appraisal. Agriculture Engineering Today 31(2):18–23

Ballolli U, Malagi U, Yenagi N, Orsat V, Gariepy Y (2014) Development and quality evaluation of foxtail millet [Setariaitalica (L.)] incorporated breads. J Agric Sci 27(1):52–54

Bhol S, John Don Bosco S (2014) Influence of malted finger millet and red kidney bean flour on quality characteristics of developed bread. LWT Food Sci Technol 55(1):294–300

Chhavi A, Sarita S (2012) Evaluation of composite millet breads for sensory and Nutritional qualities and glycemic response. Mal J Nutr 18(1):89–101

Edema MO, Sanni LO, Sanni AI (2005) Evaluation of maize soybean flour blends for sour maize bread production in Nigeria. Afr J Biotechnol 4:911–918

Geervani P, Eggum BO (1989) Nutrient composition and protein quality of minor millets. Plant Foods Hum Nutr 29:201–208

Gopalan C, Ramasastri BV, Balaubramanian SC (2010) Nutritive value of Indian foods. National Institute of Nutrition, ICMR, Hyderabad

Hadimani NA, Malleshi NG (1993) Studies on milling, physico-chemical properties, nutrient composition and dietary fibre content of millets. J Food Sci Technol 30:45–52

Hugo LF, Rooney LW, Taylor JRN (2009) Bread making with malted and fermented sorghum.[2009–06-17]. http://www.afripro.org.uk/ papers/Paper19Hugo.pdf.

Itagi S, Naik R, Yenagi N (2013) Versatile little millet therapeutic mix for diabetic and non diabetics. Asian Journal of Food Science and Technology 4(10):33–35

Rajiv J, Soumya C, Indrani D, Venkateswararao G (2011) Effect of replacement of wheat flour with finger millet flour (Eleusinecoracana) on the batter microscopy, rheology and quality characteristics of muffins. J Texture Stud 42:478–489

Lin L, Liu H, Yu Y, Lin S, Mau J (2009) Quality and antioxidant property of buckwheat enhanced wheat bread. Food Chem 37:461–467

Mepba H, Eboh L, Nwaojigwa SU (2007) Chemical composition, functional and baking properties of wheat-plantain composite flours. Afr J Food Agric Nutr Dev 7:1–22

Mochizuki Y (2001) Compressive measurement of solids and semi-solids. Current Protocols in Food Analytical Chemistry H2(3):1–H2.3.7

Olaoye OA, Onilude AA, Idowu OA (2006) Quality characteristics of bread produced from composite flours of wheat, plantain and soybeans. Afr J Biotechnol 5:1102–1106

Padulosi S, Mal B, BalRavi S, Gowda J, Gowda KTK, Shantkumar G, Yenagi N, Dutta M (2009) Food security and climate Change: Role of plant genetics resources of minor millets. Indian Journal of Plant Genetics and Resource 22:1–16

Pradeep SR, Guha M (2011) Effect of processing methods on the nutraceutical and antioxidant properties of little millet (Panicum sumatrense) extracts. Food Chem 126:1643–1647

Ragaee S, Abdel-Aal EM (2006) Pasting properties of starch and protein in selected cereals and quality of their products. Food Chem 95:9–18

Rai S, Amarjeet K, Singh B, Minhas KS (2011) Quality characteristics of bread produced from wheat, rice and maize flours. J Food Sci 49:786–789

Rosales-Juárez M, González-Mendoza B, López-Guel EC, Lozano-Bautista F, Chanona-Pérez J, Gutiérrez-López G, Farrera-Rebollo R, Georgina C-D (2008) changes on dough rheological characteristics and bread quality as a result of the addition of germinated and non-germinated soybean flour. Food Bioproce Technol 1:152–160

Sanchez HD, Osella CA, Torre MADL (2002) Optimization of gluten-free bread prepared from cornstarch, rice flour, and cassava starch. J Food Sci 67:416–419

Shittu TA, Raji AO, Sanni LO (2007) Bread from composite cassava-wheat flour: I. Effect of baking time and temperature on some physical properties of bread loaf. Food Res Int 40:280–290

Siddiq M, Nasir M, Ravi R, Butt MS, Dolan KD, Harte JB (2009) Effect of defatted maize germ flour addition on the physical and sensory quality of wheat bread. LWT Food Sci Technol 42:464–470

Singh KP, Mishra A, Mishra HN (2012) Fuzzy analysis of sensory attributes of bread prepared from millet-based composite flours. LWT-Food Sci Technolcs 48(2):276–282

Ushakumari SR, Malleshi NG (2007) Small millets: Nutritional and technological advantages. Food uses of small millets and avenues for further processing and value addition, Ed. Krishnegowda, K. and Seetharam, All India Coordinated Small Millets Improvement Project, ICAR, UAS, Bangalore, In

Veluppillai S, Nithyanantharajah K, Vasantharuba S, Balakumar S, Arasaratnam V (2010) Optimization of bread preparation from wheat flour and malted rice flour. Rice Sci 17:51–59

Wieser H, Kieffer R (2001) Correlations of the amount of gluten protein types to the technological properties of wheat flours determined on a micro-scale. J Cereal Sci 34(1):19–27

Zghal MC, Scanlon MG, Sapirstein HD (2002) Cellular structure of bread crumb and its influence on mechanical properties. J Cereal Chem 36:167–176

Acknowledgment

We sincerely acknowledge International Development Research Centre, Ottawa, Canada for the financial support provided through the Canadian International Development Agency (CIDA) Grant No. 106314–001. We sincerely acknowledge Prof. Valerie Orsat, Department of Bioresource Engineering, McGill University Montreal, Canada for providing laboratory facilities for conducting this study. We thank Yvan Gariepy for helping in designing experiment and statistical analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mannuramath, M., Yenagi, N. & Orsat, V. Quality evaluation of little millet (Panicum miliare) incorporated functional bread. J Food Sci Technol 52, 8357–8363 (2015). https://doi.org/10.1007/s13197-015-1932-y

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-1932-y