Abstract

Millet flours due to their high dietary fibre and therapeutic health benefits offer immense potential to enhance the nutritional quality of conventional durum wheat pasta. In the present study, physiochemical and functional properties of durum wheat semolina (DWS), sorghum flour (SF), finger millet flour (FMF) and multigrain flour (MF) prepared with a blend of DWS (51.60%), SF (31.96%) and FMF (13.04%), were examined for their pasta making potential. Developed multigrain pasta was characterized on the basis of antioxidant, anti-nutritional, in vitro protein and starch digestibility and microstructural properties. The rheological properties (water absorption, development time and departure time), pasting profile (peak and breakdown viscosity) and transition temperature (onset; To, mid; Tp and conclusion; Tc) of MF was higher (P ≤ 0.05) when compared with DWS. Significant improvement in total dietary fibre, antioxidant activity with reduced glycemic index was observed for uncooked multigrain pasta over the control sample (DWS). Multigrain uncooked pasta revealed limitation of higher anti-nutritional factors, reduced protein digestibility and structural strength as compared with control. The cooking of pasta increased protein and starch digestibility of the control and multigrain pasta as an effect of decreased anti-nutritional factors. Results suggest that both SF and FMF can become useful for manufacturing of pasta with improved nutritional value, antioxidant levels and reduced glycemic index.

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Conventional durum wheat pasta is a staple food, comprising 74–77% carbohydrates and 11–15% protein, but lacks minerals, vitamins, essential amino acids and phenolic compounds (Brennan et al. 2013). Nowadays, there has been a growing interest among the population for the consumption of nutritionally enriched low glycemic index (GI) foods, which can moderate/slow down the quantity of rapidly digestible starch and provide protection against risks of diabetes, cardiovascular and neurodegenerative problems (Desai et al. 2018). To offer the low GI and other health benefits, pasta can become an effective tool for the addition of different nutrients such as protein, bioactive ingredients (phenolic compounds), dietary fibre to the diet (Kamble et al. 2019a). Fortification of pasta with phenolic compounds may be helpful in providing protection against various diseases associated with oxidative damage like cancer, cardiovascular and neurological disorders, due to their high antioxidant activity (Sęczyk et al. 2016). Various studies have been conducted in recent years to fortify the pasta with different functional ingredients (Khetarpaul and Goyal 2007; Shukla and Srivastava 2014; Yadav et al. 2014; Gull et al. 2016; Chauhan et al. 2017; Rani et al. 2018). For the present study, sorghum and millet are selected because, to the best of our knowledge, hardly any equivalent research is conducted to investigate the combined effect of sorghum-millet integration on the quality attributes of pasta products.

Sorghum (Sorghum bicolor) is the 5th largest crop grown worldwide after wheat, rice, corn and barley, which plays an important role in ensuring food security in semi-arid regions due to its resilience to drought and high temperatures (Khan et al. 2013). Sorghum flour contains 9.20% moisture, 1.59% ash, 2.87% crude fat, 11.30% protein, 1.30% fibre on a dry weight basis (Kamble et al. 2019a). Sorghum has a high content of polyphenols viz., phenolic acids and flavonoids, which are associated with a positive impact on human health because of their antioxidant capacity, cholesterol-lowering properties and other possible health advantages. It has been found that sorghum has high levels of soluble (pectin, arabinoxylan and β glucans) and insoluble fibre (cellulose) which can reduce the blood serum cholesterol level and also has the beneficial effect on the gastrointestinal tract (Rani et al. 2019). Sorghum utilization offers the potential to decrease the glycemic index when added into wheat-based food formulations such as missi roti, dhokla and flat bread (Chauhan et al. 2017).

Finger millet (Eleusine coracana) is the fourth essential millet worldwide after sorghum, pearl millet and foxtail millet, which is mainly grown in South Asia and Africa under various agro-climatic conditions (Xiang et al. 2019). Finger millet is power house of health-promoting nutrients like calcium (0.34%), dietary fibre (18%), protein (6–13%) and minerals (2.5–3.5%). Finger millet consumption is linked with various health benefits including dietary intervention for Type 2 diabetes mellitus, anti-inflammatory, antitumorigenic, antimicrobial and antioxidant properties (Chandra et al. 2016). Earlier findings (Krishnan and Prabhasankar 2010; Shukla and Srivastava 2014; Gull et al. 2015; Chauhan et al. 2017) indicated that utilization of finger millet in food formulation can be a useful means of enhancing the nutritional, antioxidant level with the reduced glycemic index owing to its high dietary fibre content. Therefore, present study is designed to investigate the physiochemical, in vitro digestibility and microstructural properties of pasta manufactured from a blend of durum wheat semolina, sorghum and finger millet flour.

Material and methods

Material

Durum wheat semolina was purchased from Narmada Agro Industries, Indore (Madhya Pradesh, India). Finger millet was obtained from Arya Farm Products Pvt. Ltd. Bangalore, (Karnataka, India). Sorghum grains (Barshi Joot) were obtained from Vasantrao Naik Marathwada Agricultural University, Parbhani (Maharashtra, India). The grains were converted into the flour using domestic flour mill (Krishna Atta Chakki Machine, Hitesh Industries, Ahmedabad, India) and sieved through 250µ lower screen to obtain flour of fine size. The multigrain flour mix used in this study was designed using statistical software design expert version.10.0.2.0 (Stat-Ease, USA). A central composite design was used in which the proportion of sorghum flour, finger millet flour and gluten was at a level ranging between 20–35%, 10–25% and 3–5% (w/w of total mix), which gave 20 different combinations. The results of optimized formulation (Kamble et al. 2019a) contained durum wheat semolina (51.60%), sorghum flour (31.96%), finger millet flour (13.40%) and gluten (3.40%).

Proximate composition of durum wheat semolina (moisture; 10.26 ± 0.29, ash; 1.16 ± 0.05, fat; 1.81 ± 0.11, protein; 13.07 ± 0.12, fibre; 2.28 ± 0.05), sorghum four (moisture; 6.04 ± 0.14, ash; 1.29 ± 0.01; fat; 3.33 ± 0.03; protein; 9.05 ± 0.04, fibre; 2.49 ± 0.53), finger millet flour (moisture; 9.77 ± 0.34, ash; 1.82 ± 0.01; fat; 1.76 ± 0.02, protein; 6.64 ± 0.04, fibre; 3.45 ± 0.13) and multigrain flour (moisture; 8.64 ± 0.04; ash; 1.52 ± 0.08, fat; 2.00 ± 0.06; protein; 13.71 ± 1.00, fibre 2.98 ± 0.03) was analysed by the standard method (AACC 2000). All the additives, chemicals and reagents used were of analytical grade procured from Sigma Aldrich Research Laboratories Pvt. Ltd., Mumbai (Maharashtra, India).

Analysis of physical properties of semolina and flours

Physiochemical properties (water and oil absorption capacity, swelling power, solubility, bulk density) of durum wheat semolina (DWS), sorghum flour (SF), finger millet flour (FMF) and multigrain flour (MF) samples were determined as per the protocol suggested by Bashir and Aggarwal (2016). The color of flour samples was analysed using a hand held colorimeter (Model CR-400, Konica Minolta Co., Osaka, Japan).

High-speed mixing rheology

Rheological properties were determined with a Dough Lab (Model 2500, Perten, Australia) as described by Zaidul et al. (2007). Before starting the analysis, the thermostat of the dough lab was adjusted to maintain the temperature at 30 °C. The weight of the flour on 14% moisture basis (wb) was determined as per the equation given below;

Flour sample (300 g on 14% wb) was added to the mixing bowl of dough lab and the water was added until the curve leave off at the 500 BU (Barbender units). Parameters measured by the software included dough development time, stability time, arrival time, departure time and water absorption percentage.

Analysis of pasting and thermal profile of semolina and flour samples

Pasting behaviour of flours was measured with a Rheometer (MCR 52, Anton Paar, Graz, Austria) as described by Rani et al. (2019). The powdered samples (3.5 g) containing 25 ml distilled water were subjected to the automated heating–cooling cycle in which the software held the temperature at 50 °C for 1 min, heated at the rate of 6 °C/min from 50 to 95 °C, then kept for 5 min at 95 °C, then cooled to 50 °C at the rate of 6 °C/min and afterwards holding at 50 °C for 2 min. The pasting graph was analysed using Anton Paar software and characteristics such as peak, breakdown, final and setback viscosity were recorded.

The thermal attributes of samples were studied using the differential scanning calorimeter (DSC 200F3A01, Netzsch, China) as described by Rani et al. (2019). Flour samples (3.5 mg) were combined with distilled water in an aluminium crucible, stored for 1 h under room conditions in order to attain a equilibration between the sample and the water. DSC was first calibrated with indium and empty aluminum pan (reference material). The sample was heat treated from 20 to 110 °C at a rate of 10 °C/min. The resulting DSC curve was evaluated for the transitions temperature which was categorized according to the onset temperature (To), peak temperature (Tp), conclusion temperature (Tc) and gelatinization enthalpy (ΔH).

Pasta manufacture

Multigrain flour mixes contained DWS (51.60%), SF (31.96%), FMF (13.40%) and 3.40% gluten obtained using central composite design, were blended in an electric mixer (Planetary, B10F-1) for 4 min. The dough of composite flour (100 g) was made using 90 ml of water containing 0.2 g guar gum. The control pasta sample was prepared from durum wheat semolina. The prepared mixture was microwave for 1.5 min for improving processing and product qualities by enhancing starch gelatinization (Suhendro et al. 2000; Kamble et al. 2019a). The heated dough was extruded through the die of home scale pasta extruder (Atlas Regina, Italy) to get the macaroni type shape. This pasta was cut into the length of 5 cm and dried using two-stage methods (50 °C/30 min and 85 °C/60 min) in a laboratory tray dryer (Adity Associate, Mumbai, India). The prepared pasta samples were packed in low-density polyethylene (LDPE) bags and kept at room temperature (25 ± 2 °C) until further analysis.

Analysis of the nutritional composition of pasta

Nutritional composition, i.e., moisture (AACC, method 44-15A), ash (AACC, method 08-01), fat (AACC, method 30-25), protein (AACC, method 46-13), dietary fibre (AACC, method 30-25) and carbohydrate (by difference) of the pasta samples was determined using the standard methods (AACC 2000). Energy values were calculated using the equation described by Kamble et al. (2019b) as below;

Analysis of total phenolic content and antioxidant activity of pasta

Total phenolic content (TPC) was calculated by the Folin–Ciocalteu assay (FC) as suggested by Rani et al. (2019). The antioxidant activity of pasta samples was studied using three different protocols viz., 1,1-diphenyl-2-picrylhydrazyl (DPPH) (Gull et al. 2016), ferric ion-reducing antioxidant power (FRAP) and 2,2-azino-bis-3-ethylbenzothiazoline-6-sulfonic acid (ABTS) assay (Kamble et al. 2019a).

Determination of tannin and phytate content

Tannin and phytate was determined as per the method suggested by Kamble et al. (2019a). For tannin estimation, about 0.1 ml of sample extract was transferred to a 100 ml volumetric flask containing 75 ml of distilled water. Folin–Denis reagent (5 ml) and sodium carbonate solution (10 ml) were then added and the volume was adjusted to 100 ml with distilled water. The resulting solution was incubated for 30 min and then the absorbance was recorded against an experimental blank at 760 nm. The data was expressed as milligram tannic acid equivalent/100 g dry basis of flour weight (mg TAE/100 g).

For the phytate test, the powder sample (0.15 g) was combined with 10 ml of HCl (2.4%) and the extraction was performed using a shaking incubator (1 h/25–27 °C). The resulting solution was centrifuged (3000 rpm/30 min) and filtered to obtain a pure phytate extract. Briefly, 1 ml of wade reagent (0.3% of sulfosalicyclic and 0.03% FeCl3.6H2O acid in water) was mixed with sample extract (3 ml) and vortexed for 5 s. The reading was immediately recorded at a wavelength of 500 nm and the results reported as mg/100 g dry basis of sample weight.

In vitro protein digestibility of the pasta samples

The in vitro protein digestibility (IVPD) of the pasta samples was estimated by means of an enzymatic digestion process as suggested by Rani et al. (2018). Approximately 1 g of the sample extract was combined with 15 ml of 0.1 M HCl containing 1.5 mg of pepsin and incubated for 3 h at 37 °C. The resulting mixture was added to 0.2 M NaOH (7.5 ml), followed by the addition of a pancreatin solution (4 mg in 7.5 ml of 0.2 M phosphate buffer, pH 8.0). Toluene (1 ml) was then added to prevent microbial growth, and the suspension was allowed to incubate at 37 °C for 24 h in a shaking incubator. Subsequently, the suspension was treated with 10 ml of TCA solution (10%) to separate undigested protein, as well as larger peptides. Finally, the solution was centrifuged (3000 rpm/20 min) and the protein content in the residue was determined using the Kjeldahl protocol (AACC 2000). The IVPD was calculated using the equation as below;

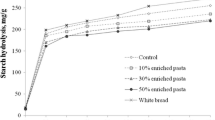

Evaluation of pasta for glycemic index

The glycemic index (GI) of pasta samples was measured in accordance with the protocol mentioned by Yousif et al. (2012). The powdered vacuum‐dried sample (500 mg) was taken in a centrifuge tube of 50 ml capacity, then artificial saliva (1 ml) consisting of porcine α‐amylase (Sigma A3176 Type VI‐B; 250 U/ml 0.2 M pH 7 carbonate buffer) was incorporated, after that 5 ml pepsin suspension (Sigma P‐6887; 1 ml/ml 0.02 M pH 2 HCl) was mixed. The resulting mixture was allowed to stand in a reticulating water bath (at 37 °C/30 min). The suspension obtained was neutralized with 0.02 M NaOH (5 ml) prior to the addition of 25 ml 0.2 M sodium acetate buffer (pH 6). After that, 5 ml pancreatin (Sigma P‐1750; 2 mg/ml 0.2 M pH 6 acetate buffer)/amyloglucosidase (Sigma A‐7420; 28 U/ml 0.2 M pH 6 acetate buffer) mixture was added and incubated at 37 °C using a water bath. Approximately 100 μl the sample was taken from the mixture at 0, 30, 60, 90, 120, 150 and 180 min intervals; then glucose was determined with 3, 5‐dinitrosalicylic acid (DNSA) assay. Then glucose was changed to starch with a conversion factor of 0.9. The hydrolysis index (HI) was determined by dividing the area under the curve (AUC) of pasta sample with the equivalent area of the reference product from white bread. The GI was determined according to the following equation;

Scanning electron microscopy of the pasta

The microstructure of the control and multigrain pasta (cooked and uncooked) was examined with a scanning electron microscope (Jeol JSM-6510LV, Joel Ltd, Tokyo, Japan). Instrumental support for SEM has been provided by Sophisticated Analytical Instruments Laboratories, Thapar University, Punjab, India. Strands of pasta samples were attached to a specific carbon film holder, coated with gold using a sputtering device (Jeol-JFC-1600, Jeol Resonance Corp.) and the images were taken at 1000 × magnification power (Gull et al. 2015).

Statistical analysis

Experimental data of triplicate values were subjected to analysis of variance (ANOVA) followed by Duncan Multiple Range test to compare the means at 0.05% significance level by using the Statistical Package for the Social Sciences version 23.0 (SPSS, Inc, Chicago, 200 IL, USA).

Results and discussion

Physical analysis of flour

Physical characteristics including water and oil absorption capacity, swelling power, solubility, bulk density and color score of durum wheat semolina (DWS), sorghum flour (SF), finger millet flour (FMF) and multigrain flour (MF) are presented in Table 1. The data revealed a significant difference (P ≤ 0.05) among the water absorption capacity of flour samples. DWS, SF, FMF and MF were found to have water absorption capacity of 2.00 ± 0.01, 3.00 ± 0.10, 2.30 ± 0.21 and 2.56 ± 0.06 g/g, respectively. The higher water absorption capacity of MF (P ≤ 0.05) as compared to DWS could be because of its high fibre content owing to the presence of sorghum and finger millet flour (Rani et al. 2019). Water absorption capacity was observed to be a function of particle size and the average value of water absorption increased significantly with reduced particle size. Further, various other factor such as higher solubility, increased amylose leaching and loss of starch crystalline structure have always been characterized by the increased rate of water absorption (Kuntz 1971). Oil holding capacity of DWS, SF, FMF and MF were differed significantly (P ≤ 0.05) with a value being of 2.25 ± 0.36, 3.47 ± 0.04, 3.40 ± 0.31 and 3.10 ± 0.10 g/g, respectively. The highest oil absorption capacity of SF and FMF could be ascribed with the occurrence of non-polar side chains which bind to the hydrocarbon side chain of the oil among the flours. Further, MF also reported to have considerably higher oil absorption than the DWS and agreed with the outcomes of Chandra et al. (2015) where they reported higher oil absorption for composite flour used for biscuits preparation. The results of swelling power showed that all the flour samples had a restricted swelling pattern (< 16 g/g), which is important while formulating the noodles/pasta products having more resistance against shearing action during the cooking process (Khatkar et al. 2013). Among all the samples, FMF showed the lowest (P ≤ 0.05) swelling power of 0.07 ± 0.01 g/g and this tendency is possibly due to its lower amylopectin content or presence of non-carbohydrate substances especially high lipids content which form complexes with amylose and can have an inhibitory effect on the swelling behaviour (Rani et al. 2019). Solubility specifies the degree of amylose leaching after swelling of starch granules in the cooking water. Hence, the greater the solubility, the higher will be the leaching of amylose. A significant difference (P ≤ 0.05) was noticed among the solubility power of flour samples. Highest solubility of FMF (10.24 ± 0.44 g/100 g) as reported here, indicates its higher tendency to leach out the amylose during swelling process (Khatkar et al. 2013). The bulk density of different flours varied from 0.59 ± 0.04 g/ml to 0.74 ± 0.01 g/ml and DWS had a significantly higher value (P ≤ 0.05) among all the samples (Table 1). High bulk density of the flours will be advantages in food products formulations, while low bulk density recommends their suitability for complementary foods (Chandra et al. 2015). Among all the samples, FMF showed the lowest lightness L* score (80.54 ± 0.55), which was due to the darker-radish color imparted by higher tannin and polyphenol content (Kamble et al. 2019a). Negative a* value of DWS indicated the presence of green pigments while the highest positive value of FMF may be due to the brick red seed coat color of finger millet flour. Yellowness or b* value reported to be highest for DWS that might be the result of the presence of carotenoid pigment inside the flour. Similar findings were reported by Gull et al. (2015) where they observed decreased L* and b* score and increased a* value for millet enriched pasta samples.

Rheological characteristics

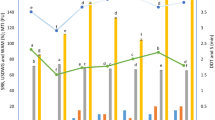

Table 1 and Fig. 1 displayed the rheological properties (development time, arrival time, departure time and stability time) of native and MF samples. The results indicated that SF, FMF and MF had significantly higher (P ≤ 0.05) water absorption as compared to DWS and this tendency is possibly due to the occurrence of the hydroxyl group in the dietary fibre and starch structure of these flours which permit more water absorption via hydrogen bonding (Li et al. 2015). An increased in water absorption has been reported in the literature for various multigrain enriched samples (Rani et al. 2019), where researchers correlated the increased water absorption with the higher water absorption capacity of composite flour, owing to the presence of high fibre. Arrival time specifies the rate of water absorption of flour when the top of the curve reaches the 500 BU line after the starting of the mixing process and addition of water. It was found that both FMF and MF had the highest arrival time and differences between their values are not significant. The highest dough development time of MF might be correlated with the higher water absorption capacity of the respective flour sample. Dough stability was reported minimum in case of FMF and this may be due to the absence of gluten protein responsible for providing the viscoelastic characteristics to the dough (Seleem and Omran 2014). Further, the lowest stability time of FMF suggested that the dough made with the respective flours cannot sustain long mechanical treatment (Sibanda et al. 2015). The highest departure time of MF suggested that dough made with the respective flour is stronger than those of DWS, SF and FMF and this could be due to the presence of gluten in the MF formulation which is added externally to improve the structural strength of dough.

Pasting properties

Table 2 and Fig. 2 showed a significant difference (P ≤ 0.05) among the pasting parameters of semolina and flours. Among all the samples, FMF had the highest peak viscosity, which could be due to its smaller granule size, which promotes greater degree of swelling and subsequently increased peak viscosity (Aprianita et al. 2009). Further, incorporation of sorghum and finger millet also increased the peak viscosity of MF, which indicates that this flour had a greater tendency to leach their content in the surrounding liquid during the cooking process (Krishnan and Prabhashankar 2010). This was also confirmed by the cooking evaluation of multigrain pasta which showed the maximum cooking loss in boiling water compared to durum wheat semolina pasta. The highest breakdown viscosity of FMF may be the results of its highest peak viscosity which is characterized by a greater degree of starch swelling during the heating process (Rani et al. 2019). It has been believed that sample with greater breakdown viscosity usually has a less tendency to tolerate the high temperature and shear stress, during the cooking process (Krishnan and Prabhashankar 2010). The lowest final viscosity of MF reported in the present study specifies its reduced strength and ability to form a viscous paste during cooking (Khatkar et al. 2013).

The observed higher setback viscosity of SF may negatively affect the food quality because of its higher tendency towards retro-gradation and syneresis (Zaidul et al. 2007). Pasting temperature is the minimum temperature necessary to cook or gelatinize a given food product. This highest value of pasting temperature in FMF can be ascribed with its high amylose content as reported by Nishani et al. (2014) where a positive relationship was observed between amylose and pasting temperature of finger millet flour.

Thermal properties

The gelatinization temperature (onset; To, mid; Tp and end; Tc) and enthalpy (∆H) of native and MF samples are shown in Table 2. A significant difference (P ≤ 0.05) was observed among the thermal properties of all the flour samples. The SF had the highest gelatinization temperature (70.16 ± 0.06 for To, 70.83 ± 0.06 for TP and 71.43 ± 0.05 for Tc) among all the flour samples. This difference in the gelatinization behaviour of the flour samples could be ascribed to a difference in their starch structure and protein content (Rani et al. 2019). However, the low gelatinization temperature of DWS is most likely due to the short amylopectin branch-chains, since a positive relationship had been reported earlier between thermal properties and amylopectin branch chain length (Jane et al. 1999). Enthalpy of gelatinization (∆H) represents the amount of energy necessary for facilitating the gelatinization process and variation in ∆H could specify the difference in bonding forces within the double helices that form the amylopectin crystallites, which caused different alignment of hydrogen bonds inside the starch molecules (Khatkar et al. 2013). The observed higher enthalpy value of MF indicated higher order of crystallinity in the respective flour sample (Bashir and Aggarwal 2016). The higher melting point of SF and MF determines the presence of strong molecular interactions that cause a slow postprandial glucose and insulin response, which is helpful in the treatment of various human diseases such as type 2 diabetes, hyperlipidemia, obesity and cardiovascular diseases.

Nutritional analysis of control and multigrain pasta

The results of the nutritional analysis showed that the control (durum wheat semolina) and multigrain pasta had a moisture content of 5.54 ± 0.10% and 6.34 ± 0.77%, which is within the acceptable limit (< 14%) prescribed for higher shelf life of the products. Ash (1.07 ± 0.03%), fat (0.92 ± 0.01%) and fibre (2.51 ± 0.05%) content of developed multigrain pasta were significantly (P ≤ 0.05) higher than control sample (0.90 ± 0.01%, 0.50 ± 0.30% and 1.56 ± 0.04%, respectively) that can be explained by the higher proportion of these components in the sorghum and finger millet flour (Gull et al. 2016; Rani et al. 2018). Reduced energy score of multigrain pasta (364.77 ± 0.38 kcal/100 g) as compared with durum wheat pasta (370.47 ± 0.27 kcal/100 g), likely because of its lower carbohydrate content (76.38 ± 0. 62%) than the control pasta (78.67 ± 0.26) as reported earlier for pasta made with combination of multigrain flour (Krishnan and Prabhasankar 2010; Khetarpaul and Goyal 2007; Chauhan et al. 2017).

Total phenolic content (TPC) and antioxidant activity of uncooked and cooked pasta samples

Significant differences (P ≤ 0.05) were reported between TPC and antioxidant activity of control and multigrain pasta samples (Table 3). As compared to control pasta, developed multigrain pasta revealed higher TPC and antioxidant activity expressed as DPPH, FRAP and ABTS assay that could be because of addition of sorghum and finger millet, as these are well known for their high source of bioactive compounds like gallic acid, p-hydroxybenzoic, protocatechuic, vanillic, ferulic, catechin, epicatechin and quercetin, etc. (Gull et al. 2016). However, both the pasta samples reported having significantly lower antioxidant level after cooking in boiling water, likely due to leaching of these components into cooking water as well as their thermal disruption due to the heat treatment (Hirawan et al. 2010). The reduced contents of bioactive compounds in cooked pasta than uncooked formulations have also reported in various investigations (Khan et al. 2013; Gull et al. 2016).

Anti-nutritional content of pasta samples

Anti-nutritional factors viz., tannins and phytate can interfere with the bioavailability of several essential minerals through their chelation in the gastrointestinal tract (Adewusi and Falade 1996). Table 3 revealed a significant difference (P ≤ 0.05) between phytate and tannin content of control and multigrain pasta samples. The multigrain pasta showed a significantly increased proportion of phytate (1106 ± 6.71 mg/100 g) and tannin (151.12 ± 0.55 mg TAE/100 g) than the control sample (247.07 ± 4.07 mg/100 g and 142.70 ± 0.75 mg TAE/100 g). These values are in agreement with results of Khetarpaul and Goyal (2007) who reported a significant increase in anti-nutrient content for noodles fortified with sorghum flour. Compared to the uncooked formulation, both the cooked control and optimized pasta had a significantly lower percentage of tannin and phytate. Adewusi and Falade (1996) showed similar trends where 11–84% of total tannin and 13–22% of phytate reduction were observed for cooked cowpeas seeds. The reduction in total anti-nutritional content of pasta upon cooking might reveal their leaching in the cooking water along with concomitant thermal degradation.

In vitro protein digestibility (IVPD)

Variances in the protein digestibility of different foods may arise due to the inherent differences in the nature of food protein (amino acid bonding, protein configuration), the existence of non-protein components that modify digestion (dietary fibre) and the presence of anti-nutritional factors (occurring naturally or formed during processing) that can alter the protein digestibility and the bioavailability of amino acids. Naturally occurring anti-nutrients (phytates and tannins) and also those generated during alkali/heat processing (methionine sulfoxide, methionine sulfone, cysteic acid, lysinoalanine and lanthionine) all reported to have an adverse effect on amino acid availability and protein digestibility (Gilani et al. 2005). Table 3 shows that multigrain pasta (76.10 ± 0.33%) had significantly (P ≤ 0.05) lower IVPD than the control pasta (89.69 ± 0.21%). These findings are in covenant with the observations made by Khetarpaul and Goyal (2007) who found a lower IVPD of sorghum incorporated noodles (68.16 ± 0.54%), compared with the refined wheat noodles (71.49 ± 0.54%). According to Annor et al. (2017), lower digestibility of millets might come from various factors viz., prevention of digestive enzymes activity by protease inhibitors or tannins, lesser protein solubility, protein organization into protein bodies and poorer enzyme accessibility owing to rigid cell walls and seed coats. Protein digestibility of food products also depends on phenolic components and polysaccharides. The phenolic compounds may interact with protein and may modify the protein digestibility. It has been observed that oxidized phenolic compounds might react with proteins and form insoluble complexes, inhibiting the activity of proteolytic enzymes and interfering with the utilization of proteins (Desai et al. 2018). However, the IVPD were increased significantly after cooking up to 91.48 ± 0.12% and 84.78 ± 0.32% respectively, for control and multigrain pasta. Annor et al. (2017) similarly reported that protein digestibility increased from 72.3 to 85.5% for finger millet upon cooking, possibly due to the heating effect on anti-proteinase factors and protein denaturation and/or decreasing the resistance of protein to enzyme attack. The reduction in the tannin and phytate content during cooking also improves the nutritional quality of the product by enhancing the protein and mineral digestion (Adewusi and Falade 1996).

Total dietary fibre of uncooked and cooked pasta samples

As shown in Table 3, total dietary fibre in multigrain pasta (4.60 ± 0.04%) was significantly higher than that of control durum wheat pasta (2.38 ± 0.04%) in both the uncooked and cooked forms. It has been reported that sorghum and finger millet flour are a rich source of dietary fibre which might be the reason of high dietary fibre content of respective pasta sample (Chauhan et al. 2017). Results obtained in the present study are in conformity with those reported in earlier studies (Khan et al. 2013; Chandra et al. 2016). The soluble and insoluble dietary fibre of uncooked pasta samples was also reported to be higher in multigrain pasta than those made from durum wheat semolina. The increased proportion of soluble and insoluble fibre can be ascribed with the presence of higher proportion of soluble (arabinoxylans) and insoluble dietary fractions (cellulose) in sorghum and finger millet. Soluble fibre has been reported to be associated with hypoglycemic and hypocholesterolemic effect, whereas insoluble fibre is useful in enhancing the bowel functions (Rani et al. 2019). From the results of total dietary fibre composition, it is clear that the incorporation of sorghum and finger millet flour could improve the total dietary fibre content of the pasta which has potential to offer various health benefits along with reduced GI score.

Glycemic index of uncooked and cooked pasta samples

The glycemic index (GI) of the control and multigrain pasta samples determined using in vitro enzymatic digestion assay is shown in Table 3. Results revealed that both pasta samples can be grouped as low GI foods (≤ 55) and are in agreement with the values of Trinidad et al. (2010) who observed similar trends for different types of noodles viz., Canton, Bihon Miki and Misua. Further, significantly lower value of GI of multigrain pasta in both cooked and uncooked form as compared to control sample could be the results of lower digestibility effect of sorghum and finger millet flour due to their high anti-nutritional and dietary fibre content (Yousif et al. 2012). This hypoglycemic property of millets enriched pasta samples also reported to be associated with various other factors, such proteins and lipids, which interact with starch to reduce the rate at which glucose is released by α-glucosidases and pancreatic α amylase (Annor et al. 2017). Further, various factors such as the reduced proportion of rapidly digestible starch and increase in slowly digestible starch as well as resistant starch content of fibre-enriched food products also accountable for their reduced GI score (Kumar and Prabhasankar 2015). Compared to the equivalent uncooked formulation, all cooked pasta had significantly increased total GI which may be due to the leaching of resistant starch from the pasta surface during cooking (Vernaza et al. 2012). Further, this increased GI in cooked pasta formulations could also results from the destruction of polyphenols, phytic acid and tannin after cooking which are well known for their inhibitory effect on in vitro starch digestion and lowering the GI (Khan et al. 2013).

Microstructural evaluation using scanning electron microscopy

Scanning electron microscopy (SEM) has been used extensively for examining the size, shape and arrangement of the particles which can be correlated with final cooking, textural and digestibility attributes of the product (Kumar and Prabhasankar, 2015). SEM analysis carried out for uncooked and cooked pasta samples is presented in Fig. 3. Microstructural results displayed the presence of few starch granules of varied sizes, free from holes and cracks, on the surface of uncooked control pasta sample. However, in case of multigrain pasta, a large number of starch granules with numerous small holes and cracks were visible on the outer surface, which would facilitate rapid water penetration during cooking (Krishnan and Prabhasankar 2010). This reduction in the structural strength of optimized pasta has been correlated with the disruption of the protein-starch network as an impact of the high fibre content of sorghum and finger millet (Rani et al. 2019). This structural weakness of multigrain pasta is well supported by the results of water absorption and cooking loss, where optimized multigrain pasta had significantly higher water absorption than the control sample. Compared to the equivalent uncooked pasta formulation, both the cooked pasta samples presented a smooth outer surface in which starch granules are completely embedded in a protein matrix. This may be due to the expansion of the volume of the pasta strand during cooking, causing great pressure on the surrounding protein film; thus the surface of the pasta sample becomes smooth (Gull et al., 2016). The starch granules in the cooked multigrain pasta seems to be less swollen, irregular in shape and size, which probably indicates the lower degree of gelatinization after cooking (Tudorica et al. 2002).

Conclusion

This study demonstrated that substitution of durum wheat semolina with 31.7% sorghum and 13.0% finger millet flour significantly affected the thermo-physical, rheological and pasting properties of multigrain flour due to the difference in gluten, fibre and starch levels. Developed multigrain paste is an effective way to improve the nutritional value, TPC and antioxidant activity of traditional durum wheat pasta. Pasta cooking has increased the digestibility of protein and starch by reducing the anti-nutritional factors. Reduced levels of GI, high antioxidants and fibre content in multigrain paste suggest their potential as functional foods. However, further research is still needed to assess in vivo antioxidant potential, protein digestibility, and GI in these cereal-millet-based pasta formulations. The results of the current study can be helpful in improving the nutritional quality of pasta and the efficient use of millet flour in various types of food, which additionally offers the benefits of reducing the burden on traditional crops, inspiring agricultural production and lowering the cost of end product.

References

AACC (2000) American Association of Cereal Chemists approved methods of the AACC, 10th edn. American Association of Cereal Chemists, St. Paul

Adewusi SRA, Falade OS (1996) The effects of cooking on extractable tannin, phytate, sugars and mineral solubility in some improved Nigerian legume seeds. Food Sci Technol Int 2:231–239

Annor GA, Tyl C, Marcone M et al (2017) Why do millets have slower starch and protein digestibility than other cereals? Trends Food Sci Technol 66:73–83

Aprianita A, Purwandari U, Watson B et al (2009) Physico-chemical properties of flours and starches from selected commercial tubers available in Australia. Int Food Res J 16:507–520

Bashir K, Aggarwal M (2016) Effects of gamma irradiation on the physicochemical, thermal and functional properties of chickpea flour. LWT Food Sci Technol 69:614–622

Brennan MA, Derbyshire E, Tiwari BK et al (2013) Ready-to-eat snack products: the role of extrusion technology in developing consumer acceptable and nutritious snacks. Int J Food Sci Technol 48:893–902

Chandra S, Singh S, Kumari D (2015) Evaluation of functional properties of composite flours and sensorial attributes of composite flour biscuits. J Food Sci Technol 52:3681–3688

Chandra D, Chandra S, Sharma AK (2016) Review of finger millet (Eleusine coracana (L.) Gaertn): a power house of health benefiting nutrients. Food Sci Hum Well 5:149–155

Chauhan S, Sonawane SK, Arya SS (2017) Nutritional evaluation of multigrain khakra. Food Biosci 19:80–84

Desai A, Brennan M, Brennan C (2018) Effect of fortification with fish (Pseudophycis bachus) powder on nutritional quality of durum wheat pasta. Foods 7(62):1–12

Gilani GS, Cockell KA, Sepehr E (2005) Effects of antinutritional factors on protein digestibility and amino acid availability in foods. J AOAC Int 88:967–987

Gull A, Prasad K, Kumar P (2015) Evaluation of functional, antinutritional, pasting and microstructural properties of millet flours. J Food Meas Charact 10:96–102

Gull A, Prasad K, Kumar P (2016) Nutritional, antioxidant, microstructural and pasting properties of functional pasta. J Saudi Soc Agric Sci 17:147–153

Hirawan R, Ser WY, Arntfield SD et al (2010) Antioxidant properties of commercial, regular- and whole-wheat spaghetti. Food Chem 119:258–264

Jane JL, Chen YY, Lee LF et al (1999) Effects of amylopectin branch chain length and amylose content on the gelatinization and pasting properties of starch. Cereal Chem 76:629–637

Kamble DB, Singh R, Rani S et al (2019a) Physicochemical properties, in vitro digestibility and structural attributes of okara-enriched functional pasta. J Food Process Preserv 43:1–9

Kamble DB, Singh R, Rani S et al (2019b) Optimization and characterization of antioxidant potential, in vitro protein digestion and structural attributes of microwave processed multigrain pasta. J Food Process Preserv 43:1–11

Khan I, Yousif A, Johnson SK et al (2013) Effect of sorghum flour addition on resistant starch content, phenolic profile and antioxidant capacity of durum wheat pasta. Food Res Int 54:578–586

Khatkar BS, Behal R, Yadav BS (2013) Physicochemical, functional, thermal and pasting properties of starches isolated from pearl millet cultivars. Int Food Res J 20:1555–1561

Khetarpaul N, Goyal R (2007) Effect of supplementation of soy, sorghum, maize, and rice on the quality of cooked noodles. Ecol Food Nutri 46:61–76

Krishnan M, Prabhasankar P (2010) Studies on pasting, microstructure, sensory, and nutritional profile of pasta influenced by sprouted finger millet (Eleucina coracana) and green banana (Musa paradisiaca) flours. J Texture Stud 41:825–841

Kumar SB, Prabhasankar P (2015) A study on noodle dough rheology and product quality characteristics of fresh and dried noodles as influenced by low glycemic index ingredient. J Food Sci Technol 52:1404–1413

Kuntz ID Jr (1971) Hydration of macromolecules. III. Hydration of polypeptides. J Am Chem Soc 93:514–516

Li PH, Lu WC, Hsieh CW et al (2015) Rheological properties of dough and quality of salted noodles supplemented with djulis (Chenopodium formosanum Koidz.) flour. J Agric Sci 7:84–92

Nishani SS, Rudra SG, Datta SC et al (2014) Phenolics, antioxidant and pasting properties of various pearl millet and finger millet varieties varying in amylose content. Vegetos 27:36–50

Rani S, Singh R, Kaur BP (2018) Optimization and evaluation of multigrain gluten-enriched instant noodles. Appl Biol Chem 61:531–541

Rani S, Singh R, Kamble DB et al (2019) Structural and quality evaluation of soy enriched functional noodles. Food Biosci 32:100465

Sęczyk Ł, Świeca M, Gawlik-Dziki U (2016) Effect of carob (Ceratonia siliqua L.) flour on the antioxidant potential, nutritional quality, and sensory characteristics of fortified durum wheat pasta. Food Chem 194:637–642

Seleem HA, Omran AA (2014) Evaluation quality of one layer flat bread supplemented with beans and sorghum baked on hot metal surface. Food Nutr Sci 5:2246–2256

Shukla K, Srivastava S (2014) Evaluation of finger millet incorporated noodle for nutritive value and glycemic index. J Food Sci Technol 51:527–534

Sibanda T, Ncube T, Ngoromani N (2015) Rheological properties and bread making quality of white grain sorghum-wheat flour composites. Int Food Sci Nutr Eng 5:176–182

Suhendro EL, Kunetz CF, McDonough CM, Rooney LW, Waniska RD (2000) Cooking characteristics and quality of noodles from food sorghum. Cereal Chem 77:96–100

Trinidad TP, Mallillin AC, Sagum RS et al (2010) Glycemic index of commonly consumed carbohydrate foods in the Philippines. J Funct Foods 2:271–274

Tudorica CM, Kuri V, Brennan CS (2002) Nutritional and physicochemical characteristics of dietary fiber enriched pasta. J Agric Food Chem 50:347–356

Vernaza MG, Biasutti E, Schmiele M et al (2012) Effect of supplementation of wheat flour with resistant starch and monoglycerides in pasta dried at high temperatures. Int J Food Sci Technol 47:1302–1312

Xiang J, Apea-Bah FB, Ndolo VU et al (2019) Profile of phenolic compounds and antioxidant activity of finger millet varieties. Food Chem 275:361–368

Yadav DN, Sharma M, Chikara N et al (2014) Quality characteristics of vegetable-blended wheat-pearl millet composite pasta. Agric Res 3:263–270

Yousif A, Nhepera D, Johnson S (2012) Influence of sorghum flour addition on flat bread in vitro starch digestibility, antioxidant capacity and consumer acceptability. Food Chem 134:880–887

Zaidul ISM, Norulaini NN, Omar AM et al (2007) RVA analysis of mixtures of wheat flour and potato, sweet potato, yam, and cassava starches. Carbohydr Polym 69:784–791

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors do not have any conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kamble, D.B., Singh, R., Rani, S. et al. Evaluation of structural, chemical and digestibility properties of multigrain pasta. J Food Sci Technol 58, 1014–1026 (2021). https://doi.org/10.1007/s13197-020-04616-x

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04616-x