Abstract

Bread is one of the oldest functional foods which its health effects have been investigated in many studies. The current communication presents a review of published studies in recent years on the topic and looks at possible future trends in the improved nutritional and health qualities which have been applied in the bakery industry, directing it further to the formulation design and production of functional breads. The results show that many beneficial ingredients such as dietary fibers, phenolic antioxidants, marine ingredients, and n-3 fatty acids can be used in the bread industry to increase its functionality and result in healthy products, low in calories, cholesterol and celiac disease. Moreover, the use of psyllium seed, amaranth seed, chestnut flour and prebiotics in gluten-free bread (GFB) baking may be the promising frontier to improve overall appearance, quality, sensory properties, and shelf-life of GFB.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Functional foods can be used not only to solve consumer starvation and provide health needs by having the necessary nutrients, but also they can prevent nutrient shortages-related diseases (Abdul-Hamid and Luan 2000). Meanwhile, functional bakery products are becoming increasingly popular and are normally consumed with adjuncts in households, industrial canteens, restaurants, etc (Indrani et al. 2007). These products are less developed than dairy products. For example, in Germany, production of new functional products was began in 2001 by about 20–21 % relating to dairy products and confectionery and about 13 % to bakery industry (Siro et al. 2008). These differences are deeper in Spain, as in 2006, approximately 45 % of functional foods were dairy products and only 13 % were related to functional bakery products (Siro et al. 2008). In 2003, the first white functional bread called “Blue Band Goede” was produced by a British-Dutch company with bio-available essential ingredients including fiber, vitamins B1, B3, B6, iron, zinc and inulin (Siro et al. 2008).

Cereal grains and sprouts are good sources of different phytochemicals including phenolic acids, flavones, flavonoids, coumarins, and terpenes (HoltekjØlen et al. 2008). Cereal sprouts are considered as an excellent source of ferulic acid, glutathione and plant sterols. They also have vitamins E, B1, B2, B3, and minerals such as phosphorus, potassium, magnesium, calcium, zinc, and manganese. Due to the high content of nutrients, cereal sprouts have an essential role in enriched foods to produce functional products (Sidhu and Kabir 2007; Penella et al. 2008; Das et al. 2011). Currently, available cereals to produce bakery products are rye, corn, oat and rice. Also, grain-like seeds such as buckwheat, amaranth and quinoa can be used (Gawlik-Dziki et al. 2009).

Functional and nutritional values of these products can be improved by alternative dietary fibers and protein sources of cereals, tubers, corn gluten, corn germ and rice bran (Lima et al. 2002). Moreover, addition of marine foods (Kadam and Prabhasankar 2010), natural antioxidants (Ak and Gulçin 2008; Lim et al. 2011), plant extracts such as green tea (Wang et al. 2007; Bajerska et al. 2010), and grape seed extracts (Liang et al. 2004; Peng et al. 2010), and prebiotics (Harmsen et al. 2002; Korus et al. 2006) to bakery products due to existence of many potential neutraceuticals has been proposed to increase functionality of these products especially bread. Regarding bakery products, efforts are mainly directed toward their reformulation by modifying the gluten content, and/or by adding a series of functional ingredients (Brites et al. 2010; Elleuch et al. 2011). Therefore, the main objective of this study was to present recent researches in relation to functional ingredients and their beneficial effects to produce functional bread, as understood from recently published scientific articles.

Dietary fibers to produce functional bread

Dietary fibers as a group of compounds contains a mixture of oligosaccharides and polysaccharides such as resistant gums, inulin and hemicelluloses which may be associated with lignin and other non-carbohydrate components (Sabanis et al. 2009; Elleuch et al. 2011). Table 1 shows some of the various sources of dietary fibers for production of functional breads with their practical applications. Increase of water and oil holding capacities, modification of textural properties, reduction of syneresis (separation of liquid from a gel caused by contraction), prevention of lipid oxidation, emulsification and/or gel formation, stabilization of high fat food and emulsions, slowing down the retrogradation of starch, and improving shelf-life are some functional properties of dietary fibers, when incorporated into food products like bakery ones (Sanchez-Alonso et al. 2007; Sabanis et al. 2009; Elleuch et al. 2011).

Breads are considered as the main source of the dietary fiber (Penella et al. 2008). Moreover, important resources for improving fiber content of bread are cereals, chicory, gums, fruits and vegetables (Rosell et al. 2006; Penella et al. 2008). Whole wheat flour is a very cheap micronutrients and dietary fiber source for human. It is used to make some foods with lower glycemic index and calorie (Demir and Elgun 2011). High fiber breads have favorable physiological and metabolic effects and are considered as effective compounds in health to deal with cardiovascular diseases, digestive system, reduction of blood cholesterol levels, diabetes, and colon cancer (Penella et al. 2008; Elleuch et al. 2011). Also, it has been illustrated that higher intake of cereal fiber can improve insulin sensitivity and reduce risk of diabetes (Pereira et al. 2002).

The functionality increase of breads by replacing dietary fiber with a percentage of flour can lead to breaking of gluten-starch matrix, limiting the gas cells and the increase of dough plasticity (Rosell et al. 2006). Recent studies on production of mixtures of flour-hydrated fiber have shown that they could be a suitable viscoelastic profile for formulated bread doughs and final bread could have acceptable sensory properties and a favorable shelf life (Penella et al. 2008). Sangnark and Noomhorm (2004) indicated that fibers can modify bread loaf volume, bread crumb softness, bread springiness and the firmness of the loaf, but the extent of modification depends on the fiber source (Laurikainen et al. 1998). Sabanis et al. (2009) have shown that addition of dietary fiber from maize and oat into gluten free formulations gives bread a higher loaf volume and crumb softness compared with the control non fiber bread along with improving their acceptability. The quality of bread with additional dietary fiber can also be improved by different options such as enzymatic treatment of fibers, use of different milling fractions and alkaline hydrogen peroxide treatment of fibers (Laurikainen et al. 1998; Elleuch et al. 2011).

Addition of buckwheat to bread

Buckwheat is an important functional food in some countries including China, Japan and Taiwan which is used in prepared noodles (Lin et al. 2009). This cereal which belongs to the polygonacea family can be a good alternative to rice or potato meal (Sensoy et al. 2006). The amino acid composition of buckwheat proteins is well balanced and of a high biological value. Buckwheat grains are an important source of microelements such as Zn, Cu, Mn and macro elements such as K, Na, Ca, Mg (Das et al. 2011). In general, there are two types of common buckwheat and Tartary buckwheat (grown in mountain areas). Carbohydrate content in buckwheat flour is lower than wheat flour, but the fiber composition is contrary because, buckwheat is rich in fiber (Jiang et al. 2007). Buckwheat contains flavonol glycosides with high antioxidant properties including rutin, quercetin, kaemferol-3-rutinoside and also small amounts of flavonol triglyceride (Lin et al. 2009). Tartary buckwheat has a bitter taste, small grain size, hard shell, but a higher rate of rutin (Jiang et al. 2007; Lin et al. 2009). Many studies have shown that buckwheat compared with most fruits, vegetables and grain products, have higher levels of rutin which can contribute to reduced risk of coronary heart disease, decrease of blood glucose levels and cancer types (Jiang et al. 2007; Lin et al. 2009). The amount of fiber in wheat flour is more than buckwheat flour. Lin et al. (2009) produced new bread by mixing high-gluten wheat flour, milk powder, sugar, salt, eggs, bread improver, shortening, and buckwheat flour with or without 15 % husk. Husky buckwheat has higher content of insoluble β-glucan, a polysaccharide stimulating immune system (Hozová et al. 2007). Therefore, husky buckwheat bread with high β-glucan has further functionality and health effects for consumers (Hozová et al. 2007; Lin et al. 2009).

Gawlik-Dziki et al. (2009) determined antioxidant activity of new functional bread enriched with 2.5 % and 5 % extract from the green parts of Tartary buckwheat plant. Their results showed that higher the buckwheat, lower the volume of obtained bread. Crust and crumb color of enriched bread was darker, while its taste and smell had less aromatic compounds. Maximum of the phenolic compounds and antiradical activity were observed in the breads fortified with 5 % buckwheat. However, the 2.5 % extract was the best level to achieve optimum taste, smell, elasticity and the appropriate volume of bread.

Influence of rice bran on bread properties

Rice bran is a by-product from the outer layers of rice grains and is considered as a rich source of protein, minerals, fatty acids and dietary fiber. It can be used for fortifying different food products particularly, breads (Mccaskill and Zhang 1999). Hu et al. (2009) found that insoluble part of rice bran has high amounts of dietary fiber (62.73 %) and protein (8.35 %), while B-type hemicellulose of rice bran has higher levels of dietary fiber (82.94 %) and lower protein amounts (2.69 %). Addition of different levels of rice bran flour (0–9 %) to two types of wheat flour (with 82 and 88 % extraction rate) revealed the effect of rice bran flour addition on dough rheological and textural properties of Barbary bread. Results showed that blending the rice bran flour (6 %) with the wheat flour (82 % extraction rate) received the best scores, in the aspect of sensory evaluation (khoshgozaran-Abras et al. 2012). The B-type hemicellulose of rice bran has important biological activities such as increasing faecal bulk, lowering blood cholesterol, and preventing colon cancer (Lima et al. 2002; Hu et al. 2009). Functional characteristics of rice bran have been applied to develop fortified breads with fiber (Hu et al. 2009). Some studies have revealed that B-type hemicellulose of rice bran compared with standard dietary fiber with commercial name of Fibrex had a higher ability to bind water and fat. The produced breads with high fiber content had a lower loaf volume and softer texture than control ones, thus on the market were comparable. However, the nutritional value of fiber in the final product was lower than expected, which could be hydrolyzed by the enzymatic activity of yeast or decomposed by baking at high temperatures (Hu et al. 2009; Elleuch et al. 2011). Sensory evaluations have shown that bread crumb color was darker and had lower acceptance when 10 % of each type of fiber was added. Taste and smell of these breads were significantly different than control breads as those with 10 % rice bran fiber showed a taste of rice which was clear to understand for most panelists. Further analysis also showed that the acceptable level of dietary fibers can remain in the range of bread products and have healthy-functional effects (Abdul-Hamid and Luan 2000; Hu et al. 2009).

Rye bread and improvement of intestine function

Rye is often consumed as a whole grain product and is a good source of dietary fiber, vitamins, minerals, and different biologically active compounds (Karppinen et al. 2003). Total arabinoxylan and soluble arabinoxylan of rye varies from 6.5 to 12 %, and 1.5 to 3 %, respectively (Vinkx and Delcour 1996). Other compounds are including β-glucan, cellulose, fructan, and lignin (Karppinen et al. 2003). By consumption of rye, the amounts of dietary fiber increases in intestinal microbial fermentation, which are converted further to phytochemicals such as lignin and finally to microbial metabolites (Grasten et al. 2000). Epidemiological tests have shown that the dietary fiber of cereals could have a protective role against colon cancer risk. Therefore, there is a reasonable relationship between dietary fiber absorption and decreased symptoms of colon cancer (McIntosh et al. 2003). Moreover, positive effects of rye on gut function and its microbial metabolic activity at several studies have been investigated (Grasten et al. 2000; McIntosh et al. 2003). It has been recognized that the rye bread and other products with increased stool weight, stool frequency rates, shorten the intestinal transit time, reduce the concentration of secondary bile acids and increase the concentrations of plasma enterolactone or lignin production by intestinal bacteria in women and men, improving bowel function (Grasten et al. 2000; McIntosh et al. 2003).

Major determinant of plasma enterolactone concentration is the amount of plant lignin in a food (Elleuch et al. 2011). Composition or activity of intestinal microbes is important in lignin metabolism. Enterolactones have a protective role against colon cancer although enterolactone plasma concentration is a biological marker of good nutritional health. Whole rye flour bread or other products containing rye increase fecal butyrate concentration in the average age of men, but women are not affected. Butyrate is an important compound in normal function of intestinal epithelial cells and provides protection against colon cancer (Grasten et al. 2007). Effects of cereal fibers on composition of human intestinal microbes are unknown, although rye caused an increased growth of Bifidobacterium longum. Therefore, arabinoxylan and fructan in rye can affect the human fecal microbes (Crittenden et al. 2002). Grasten et al. (2007) revealed that the whole grain rye bread improved bowel function and increased intestinal enterolactone concentrations in women and men, while other health effects such as increased butyrate and decreased enzyme activity of intestinal bacterial observed only in men. Absorption of total dietary fiber, soluble and insoluble fiber from rye bread was 36.4, 6 and 30.4 gram, respectively. The enterolactone plasma concentration during consumption of rye bread, increased from 27.1 to 53.6 nmol/L, but by consumption of wheat bread decreased from 32.8 to 22.7 nmol/L.

Barley and soybean flours

Barley has a high acceptance in human nutrition, when its new functional and nutritional properties are recognized. Barley is used as flour, semolina and as whole-dehulled grain. Barley flour has a high concentration of total β-D-glucans (especially soluble β-glucan). β-glucan rich fractions from barley may result in increased loaf volumes when used at certain concentrations in wheat flour, probably by increasing the viscosity of the dough (Delcour et al. 1991; Das et al. 2011). It is considered that β-glucans may play a role in the improvement of bread crumb structure by stabilizing air cells in the dough and preventing their coalescence (Wang et al. 1998). Also, the antioxidant properties and sensory profiles of breads with 40 % of barley flour instead of wheat flour have been studied (HoltekjØlen et al. 2008). The results of chemical and sensory evaluations showed that incorporation of barley flour increased the bread antioxidant properties, while sensory attributes were differed depending on the barley variety. Also, the sensory evaluation corresponded well with the content of phenolics.

Soybean flour is more commonly used in the bakery products because of its functional properties. It has high protein (38–40 %), fat (18–20 %) and lysine (5–6 %) contents, which have great potentials in overcoming protein-calorie malnutrition. Dhingra and Jood (2001) found that soy flour (full fat and defatted) and barley flour could be added to bread flour up to levels of 10 and 15 %, respectively, separately and in combinations without any significant changes in organoleptic characteristics. Moreover, the breads containing barley and defatted soy flours (up to 15 % level) were considered as most acceptable, organoleptically and nutritionally as they contained an appreciable amount of protein, total lysine, dietary fiber, β-glucan and minerals.

Addition of natural antioxidants to bread

Phenolic components are found frequently in food products such as fruits, vegetables and grains. Natural antioxidants are phenolic compounds that have different biological activities including anti-allergic, anti-viral, anti-inflammatory, anti-mutation and anti-cancer properties (Yao et al. 2004). Nanditha and Prabhasankar (2008) reported that antioxidants are used as food additives with the aim of prevention oxidative deterioration of fats and oils in processed foods. However, due to limitation on the use of synthetic antioxidants and enhanced public awareness of health issues, there is an increasing need to use health-promoting natural antioxidants in foods like bakery products. There are several plant sources which have important antioxidants capable of scavenging free radical (Table 2) and they are preferred over synthetic and toxic antioxidants such as butylated hydroxy toluene (BHT) and butylated hydroxyl anisole (BHA) (Lean and Mohamed 1999). For example, antioxidant property and quality of breads containing Auricularia auricular polysaccharide (AAP) flour was evaluated by Fan et al. (2007). The results showed that with addition of AAP to bread, the antioxidant activity considerably increased. The following sections discuss the production of functional breads by supplementing some natural antioxidant sources.

Application of turmeric in bread

Turmeric (Curcuma longa L.), a member of the Zingiberaceae family, is one of the most popular spices having natural antioxidants. Curcuminoids are the major biologically active components of turmeric which contain curcumin, bis-demethoxy curcumin, and demethoxy curcumin. Curcumin or phenolic pigment is an effective antioxidant that can absorb free radicals and its use as an antioxidative and antimycotic agent in butter cakes has been reported (Lean and Mohamed 1999; Hirun et al. 2012). Ak and Gulçin (2008) reported that it had other medicinal properties such as anti-protozoal, anti-tumour, anti-inflammatory and anti-venom activities.

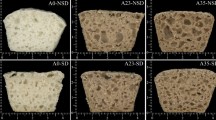

Lim et al. (2011) used turmeric powder to substitute 0 %, 2 %, 4 %, 6 % and 8 % of wheat flour for making breads. The results showed that up to 4 % turmeric powder could be accepted in a bread formulation without any significant hindrance in sensory acceptability of bread. Total phenolic contents and antioxidant activities of bread increased with turmeric powder (Fig. 1a). The crumb hardness and color values of breads also increased with turmeric powder as an additive but bread specific volume decreased (Fig. 1b). The level of 4 % turmeric powder showed good potentials for antioxidant and sensory properties in comparison with wheat bread. Therefore, breads with turmeric powder can be developed as healthy functional bread.

Increase of antioxidant activities of breads containing the different concentration of turmeric powder (TB) in comparison with control bread. Cross-sections of the breads prepared with turmeric powder replacement for wheat flour. Control, TB2, TB4, TB6 and TB8 are breads prepared with 0 %, 2 %, 4 %, 6 % and 8 % replacement of wheat flour with turmeric powder, respectively (Lim et al. 2011)

Addition of grape seed extract to bread

Grape seed extract is a rich source of catechins and proanthocyanidins with a strong antioxidant and free radicals scavenging activities (Liang et al. 2004). Other activities are noted such as anti-inflammatory activity, anti-ulcer activity and prevention of blood platelets accumulation (Peng et al. 2010). Also, the ability of important phenolic compounds such as catechin and proanthocyanidin to scavenge reactive carbonyl species (such as glyoxal, methylglyoxal) in non-enzymatic browning reaction has been proved (Lo et al. 2006; Peng et al. 2008). In a study, grape seed extract was mixed with other ingredients of to the bread formulation, and its antioxidant properties after the thermal process in comparison with standard solutions of grape seed extract was evaluated (Peng et al. 2010). The effect of extract on the formation of N-carboxymethyl lysine in bread (CML) was also studied. CML is one of the final products of Millard reaction and its content in crust was reported to be much higher than in crumb. Recently, it is considered as a toxic substance in foods and a biological marker associated with oxidative stress, diabetes and atherosclerosis in humans (Sebekova and Somoza 2007). The results showed that the antioxidant activity of bread increased by adding different levels of the extracts. The thermal process of bread production may reduce extract antioxidant capacity. This phenomenon could be related to thermophilic reactions of extract proanthocyanidins with food ingredients such as proteins or starches to form larger molecules. Heat process can also cause decomposition of extract proanthocyanidins leading to reduced antioxidant capacity of bread. Sensory evaluation of bread did not show certain differences compared with control bread. Despite color changing of bread, 70 % of panelist reported a better color for bread containing extracts than control one. Moreover, with addition of two levels of 600 and 1,000 mg extract to bread, carboxymethyl lysine in bread crust decreased to 30 % and 50 % levels, respectively (Peng et al. 2010).

Addition of green tea extract to bread

Tea and its products contain polyphenols, mainly catechins which are considered as natural antioxidants (Bajerska et al. 2010). In recent years, the health effects of tea especially green tea have attracted much attention. Green tea contains a number of biologically active compounds including epicatechin (EC), epigallatocatechin (EGC), epicatechin gallate (ECG) and epigallatocatechin gallate (EGCG) (Wang and Zhou 2004). Wu and Wei (2002) reported green tea had cathecin polyphenols around 35 % of its dry weight. These compounds exhibit considerable anti-oxidative, anti-cancer and anti-microbial properties (Wiseman et al. 1997). Moreover, the human intake of green tea decreases total cholesterol, increases the high-density lipoprotein (HDL) fraction, and decreases lipoprotein oxidation (Ferrari and Torres 2003).

After a green tea extract was added to the bread dough by the levels of 50, 100, and 150 mg/100 g flour, varied stability was detected among the individual phenolics and 83 % to 91 % of the total phenolics were retained (Wang and Zhou 2004). Considering how much the green tea catechins can be associated with sensory characteristics of bread quality, a study by Wang et al. (2007) on quality of the fortified bread with green tea extract was carried out at different levels of 1.5 and 5 g/kg of flour. The results indicated that bread lightness declined with increasing level of extract. Green tea extract was a water-soluble powder and brown in appearance. Therefore, it could be expected that color of bread with extract was different from control bread. At the same time, bread density increased and volume decreased by adding the extract to bread. The results also showed that the formation of gas cells in dough can be affected by adding the extract in mixing stage at two different levels. Application of 5 g/kg level of extract reduced sweet flavor of bread and the most astringency established. Tea catechins are responsible for creating astringent taste of tea, especially EGCG are very involved. Based on texture analysis, firmness of bread increased at higher extract concentration. Also, by the addition of extract, the viscosity increased while dough with 1.5 g per kg of extract was similar to control bread. Total amount of tea catechins were 533 and 1,775 μg/g dough on 1.5 and 5 g/kg of extract, respectively. Therefore, it is likely to have lower yeast activity in bread dough partially by green tea extract in an effective level of about 1.5 g/kg flour, followed by reduced gas ability and the produced bread had less volume. The enriched bread by green tea extracts can be used as a functional food and health effects are considered (Wang et al. 2007).

Bajerska et al. (2010) studied the effect of green tea extract at three levels of 0.5, 0.8 and 1.1 % on catechin stability, antioxidant properties and sensory evaluation in rye breads. They developed a novel formulation as a source of polyphenols. The results showed that antioxidant properties increased with addition of higher levels of the extract. However, due to changes in sensory properties, the level of green tea extract introduced to rye bread should be limited to 0.8 %.

Gluten free bread

Celiac disease is a genetic disease that sick persons have a long intolerance to wheat gliadin components; rye prolamin, barley hordein and oat avidin, and nearly 1 % of the world’s population are involved (Kiskini et al. 2007). Gluten digested by sick people leads to inflammation of small intestine and lack of important nutrients like iron, folic acid, calcium and fat-soluble vitamins. Disease-related symptoms are including diarrhea, anemia, and nausea, mouth sore and psychological symptoms such as headache, nervous depression and osteoporosis (Niewinski 2008). The only effective process on celiac disease is preparation of food without gluten. Global average of patient people is estimated to increase 10-fold factor and has caused a growing in the market of bakery products without gluten (Siro et al. 2008). In Canada, gluten free products have less than 20 mg gluten/kg according to standard, while in other countries this value is 200 mg/kg. Recently, many studies have been conducted to assess the nutritional adequacy of gluten-free diets including gluten-free bread (GFB). In general, there are two types of new and old compounds to produce breads without gluten. Old ingredients include rice, corn, soy, beans, peas, and other hydrocolloids, while new compounds are divided into two categories including grains without gluten such as sorghum and teff and pseudo cereals like amaranth, quinoa and buckwheat fibers (Table 2) (Gallagher et al. 2004). There are many available products (for example pasta, noodles and biscuits) containing pseudo cereals as composites with wheat flour (Gallagher et al. 2003, 2004). New compounds have many benefits such as high amount of protein and amino acids and better digestibility than cereals. Also, they have bioactive compounds such as fructooligosaccharides, antioxidants, resistant starch, fibers and mineral resources and other nutrients (Gallagher et al. 2003). Alvarez-Jubete et al. (2009) studied viability of the pseudo cereals (amaranth, quinoa and buckwheat) as ingredients in gluten free baking with regard to improvement of nutritional value of GFBs. The results showed that nutritional aspects of pseudo cereal grains and breads are applicable to the general population and not especially limited to celiac disease patients. However, the bread formulation without gluten will cause bakery problems and creates unstable dough. The resulting bread has a firm texture, unsuitable color and other quality defects (Gallagher et al. 2003).

Production of gluten free bread with psyllium

Psyllium (Plantago ovata Forsk) seed shell contains functional hydrocolloids which is a rich source of natural soluble fibers, almost eight times higher than soluble fiber found in oat bran (Guo et al. 2009). In addition, psyllium hydrocolloid as an emulsifier or thickener has considerable benefits including reduction of cholesterol, reduced risk of cardiovascular diseases and diabetes, laxative properties, treating colds, coughs, and other respiratory problems (Fischer et al. 2004; Guo et al. 2009). The shell of psyllium seed can be a valuable source of minerals to balance other minerals in foods (Fischer et al. 2004). The psyllium fiber due to its stability at different temperatures and pH levels is similar to gluten, and can be considered as a good alternative in bakery products (Zandonadi et al. 2009). Similar approaches to produce physical structures like gluten in the dough is application of dietary fiber with complex carbohydrates, lignin, and resistant starch (Gallagher et al. 2004). Zandonadi et al. (2009) evaluated the effect of replacing gluten with psyllium on sensory, chemical, nutritional and technological properties of the modified bread. The sensory evaluation of bread revealed that resulted bread had an overall acceptability similar to white bread. The modified bread dough achieved a 93.0 % acceptance rate for individuals with celiac disease and up to 97.0 % for individuals without celiac disease. Chemical analysis showed that levels of energy and fat in bread dough reduced to 32.1 % and 42.3 %, respectively. Overall results showed that psyllium can be a suitable alternative to gluten in bread dough (Zandonadi et al. 2009).

Use of amaranth to produce gluten free bread

Lysine is one of the essential amino acids which is low in cereals, but legumes have high levels of this amino acid (Iqbal et al. 2006). In addition to soy proteins, pea proteins can be successfully used in bakery products and improve the nutritional value of these products (Tömsközi et al. 2001; Mohammed et al. 2012). Another ingredient applied in the production of GFB is amaranth flour which has 11.7–18.4 % protein, higher than wheat protein and has acceptable levels of essential amino acids, especially lysine, tryptophan and methionine (Tömsközi et al. 2001; Avanza et al. 2005; Iqbal et al. 2006; Sudha and Leelavathi 2011). Structural properties of these proteins affect their functional characteristics. Amaranth fat content is also considered which has high levels of unsaturated fatty acids, with large percentage of linoleic acid (Avanza et al. 2005). Mariotti et al. (2009) prepared the gluten-free dough with different levels of corn starch, amaranth flour (increased nutritional value), pea isolate (to increase protein) and psyllium flour (as thickener and fiber source) and evaluated their rheological properties. Two levels of amaranth flour (0 or 40 %), pea protein isolate (1 % or 6 %) and psyllium fiber (0 % or 2 %) were used while corn starch levels based on values of other compounds were variable. Overall results showed that addition of protein and fiber source (pea isolate and amaranth) improved physical, rheological and nutritional properties of gluten free dough. Presence of psyllium fiber increased physical properties of dough due to formation of a network structures like films. Also, experimenting more complex formulations (with starch, corn flour and pea isolate, amaranth flour and psyllium fiber) showed that these ingredients can improve technological and nutritional qualities of final bread compared with commercially mixtures available in the market (Mariotti et al. 2009).

Chestnut flour in gluten-free bread

Turkey is an important producer of chestnut with its production around 49,000 tons per year. Chestnut flour includes high quality proteins with essential amino acids, adequate amount of sugar (13.9–32.6 %), starch, dietary fiber (4–10 %), low amount of fat, vitamins E and B group and essential elements such as potassium, phosphorous and magnesium (Chenlo et al. 2007). This flour can be used in GFBs leading to good nutritional quality and health benefits. However, it creates several defects including low volume and unacceptable dark color. Therefore, blending chestnut flour with other types of flours seems to be a better method. Rice (Oryza sativa) is one the most important crops in the world in addition to wheat and maize. Among the chemical components of rice grains, amylase and protein contents are very important factors influencing the eating quality of rice (Rai et al. 2011). Demirkesen et al. (2010) developed GFB formulations using chestnut and rice flours at different ratios (0/100, 10/90, 20/80, 30/70, 40/60, 50/50 and 100/0). Moreover, the effects of different hydrocolloids such as xanthan-locust bean gum, xanthan-guar gum blends and emulsifier on the rheological properties of dough formulations and quality of bread were determined.

Due to rigid and compact structure of chestnut fibrous, the bread formulated only with chestnut flour had the hardest structure and the lowest volume. The loaf volume decreased when the chestnut flour content increased. This may be due to the fact that high sugar content of chestnut flour led to reduced starch gelatinization and result in low specific volume and hardness of breads. Moreover, delay of starch gelatinization by reducing the water activity with incorporation of sugar in formulation was reported by Sumnu et al. (1999). Therefore, an optimum flour ratio between chestnut and rice flour was needed to gain desired quality parameters. The best ratio in terms of color, hardness, texture and flavor attributes was chestnut/rice flour at 30/70 with addition of the blends of xanthan-guar and emulsifier. When higher ratios was used, undesirable dark color of breads was observed due to increasing Millard and caramelization reactions with increasing sugar content. However, increased levels of chestnut flour caused to some deteriorations in quality parameters (low volume, harder texture and darker color) regardless of gum blend and emulsifier addition (Demirkesen et al. 2010).

Effect of prebiotics on quality of gluten free bread

Prebiotics are defined as non-digestible food ingredients that beneficially affect the host by stimulating the growth and/or activity of one or a limited number of bacteria such as probiotic bacteria in the colon, thus increasing host health (O’Riordan et al. 2001; Siro et al. 2008). These compounds include fructooligosaccharides, isomalto-oligosaccharides, inulin, resistant starch, polyols (lactitol, mannitol, sorbitol, xylitol), and modified dextrins (Siro et al. 2008). The effect of prebiotic additives on GFB quality and their loss during the production of bread has been investigated by Korus et al. (2006). In this study, three prebiotic substances including Frutafit standard inulin (inulin produced by a Dutch company), bitter-free chicory flour and oligofructose syrup in three addition levels of 3, 5 and 8 % were used. The results showed that the lowest dose of inulin decreased bread volume about 10 %, but the volume increased about 4 and 9 %, respectively, by adding 5 and 8 % of inulin in comparison with control bread. The oligofructose syrup changed bread volume ranging from 5 % to 9 %. Adding the lowest dose of chicory flour to formulation caused an increase of bread volume about 10 % but it reduced to 4 % in higher doses. The best yield of bread was observed when inulin was added, chicory flour and syrup set in secondary grade. This could be due to the linkage of water to probiotic additives, which was indicated by values of total baking loss, inversely related to the bread yield. Bread with 8 % of oligofructose syrup as second-quality bread was classified because of non-uniform and large holes. Also, addition of 8 % inulin to bread led to produce bread as secondary due to crust shrinkage. Crust color of all bread was darker than control bread. According to quality evaluation, most favorable additives were chicory flour and inulin. Among the practical level, the most beneficial effect on quality of bread depended on about 5 % of inulin intake (increased bread volume, reduced hardening rate and positive evaluation) (Korus et al. 2006).

Harmsen et al. (2002) reported intake of 9 g inulin/day after two weeks caused an increase of 2.3 fold in Bifidobacteria amount and reduction of 1.4 fold in E.rectale and E. coccoides fecal microorganisms in small intestine. Moreover, the inulin led to a certain increase in calcium absorption in the gastrointestinal tract and digested to ionized form during colon. This performance especially for celiac disease is important due to greater sensitivity to osteoporosis (Korus et al. 2006).

Marine foods as novel healthy food ingredients in bread

Marine foods are excellent sources of many healthy food ingredients and biological components as fish oils, bioactive peptides and microalgae. These foods contain omega-3 fatty acids, chitin and chitosan, algal ingredients, antioxidants, minerals and vitamins like calcium, carotenoids and bioactive compounds. Bread is an excellent product in which incorporation of marine functional ingredients especially omega-3 fatty acids is attempted (Kadam and Prabhasankar 2010). Encapsulation approach could help to incorporate better omega-3 fatty acids into bread and the stability enhancement of omega-3 lipids (Liu et al. 2001). Liu et al. (2001) showed that hyperlipidemic patients had a significant increase in plasma omega-3 fatty acids and in HDL-cholesterol as they fed with bread containing fish oil (Table 2). Yep et al. (2002) also demonstrated that bread enriched with microencapsulated tuna oil increases DHA fatty acid. The enrichment of white bread with omega-3 fatty acids in the form of fish oil was previously studied by Neilsen (1992). Moreover, supplementation of several marine hydrocolloids to the bread making process in several experiments has been studied and physical properties such as hardness, moisture and volume and sensory evaluation of bread loaf have been assessed (Table 2). These hydrocolloids were able to reduce the moisture loss during the storage or had an anti-staling effect on bread (Guarda et al. 2004).

Effect of flaxseed and quinoa flours on bread functionality

Flaxseed (Linum usitatissimum L.) or linseed is a dark brown seed which is used in the food industry as a supplement in the bread preparation or/and other bakery products. This seed is a healthy ingredient with appropriate levels of polyunsaturated fatty acids (PUFAs). PUFA have an important role on the prevention and regulation of cardiovascular diseases and cancer types (Hall et al. 2005).

Quinoa is a pseudo cereal with high quality protein and without gluten. This cereal is used as an alternative ingredient in oil production due to high levels of fatty acid and having good oxidative stability (Ng et al. 2007). It is currently used as a substitute for wheat flour in gluten free bread.

Calderelli et al. (2010) studied the characteristics of two new types of bread containing these seeds based on the potential of quinoa and flaxseed as functional ingredients. These breads showed significant differences for the majority of parameters. Flaxseed bread indicated a higher content of lipids and also had a greater caloric value. There were higher levels of saturated, monounsaturated, polyunsaturated, omega-3 and 6 fatty acids in flaxseed bread. The ratio of omega-6 to omega-3 depending on a country is variable but some studies have recommended that better ratio should be a maximum of 4 with regard to cardiac diseases. The flaxseed bread followed the above-mentioned limit but the quinoa bread did not. The quinoa bread was well accepted and the results showed the possibility of development of a nutritional product with sensory acceptance. Flaxseed and quinoa breads could be regarded as standard breads with a well acceptance by customers (Calderelli et al. 2010).

Concluding remarks

In this study, different types of nutritional ingredients for production of functional bread are investigated. The results showed that the addition of functional ingredients including fiber-rich compounds and phenolic antioxidants to breads not only had physiological effects on the blood cholesterol levels and preventing cardiovascular diseases, cancers and inflammation, but also had a positive effect on the sensory properties of breads. The functional compounds such as shell of psyllium seeds and prebiotics are consumed in GFB and have a good effect on their quality, safety and acceptability. Also, recent studies have shown that marine foods, flaxseeds and quinoa seeds can be used as a rich source of omega-3 fatty acids and can be incorporated in bakery products, especially breads without much intervention in sensory quality. Further research is needed to understand interactions of functional ingredients with breads constituents and thus to improve their safety in potential industrial applications.

References

Abdul-Hamid A, Luan YS (2000) Functional properties of dietary fibre prepared from defatted rice bran. Food Chem 68(1):15–19

Ak T, Gulçin I (2008) Antioxidant and radical scavenging properties of curcumin. J Chem Biol Interact 174(1):27–37

Alvarez-Jubete L, Arendt EK, Gallagher E (2009) Nutritive value and chemical composition of pseudocereals as gluten-free ingredients. Int J Food Sci Nutr 60(S4):240–257

Angioloni A, Collar C (2011) Physicochemical and nutritional properties of reduced-caloric density high-fibre breads. LWT-Food Sci Technol 44(3):747–758

Avanza MV, Puppo MC, Añón MC (2005) Rheological characterization of amaranth protein gels. Food Hydrocolloids 19(5):889–898

Bajerska J, Mildner-szkudlarz S, Jeszka J, Szwengiel A (2010) Catechin stability, antioxidant properties and sensory profiles of rye breads fortified with green tea extracts. J Food Nutr Res 49(2):104–111

Brites C, Trigo MJ, Santos C, Collar C, Rosell CM (2010) Maize based Gluten-free bread: Influence of processing parameters on sensory and instrumental quality. Food Bioprocess Technol 3(5):707–715

Calderelli VAS, Benassi DT, Visentainer JV, Matioli G (2010) Quinoa and flaxseed: potential ingredients in the production of bread with functional quality. Braz Arch Biol Technol 53(4):981–986

Chenlo F, Moreira R, Pereira G, Silva CC (2007) Evaluation of the rheological behaviour of chestnut (Castanea sativa Mill) flour pastes as function of water content and temperature. Elect J Environ Agric Food Chem 6(2):1794–1802

Crittenden R, Karppinen S, Ojanen S, Tenkanen M, Fagerström R, Mättö J, Saarela M, Mattila-Sandholm T, Poutanen K (2002) In vitro fermentation of cereal dietary fiber carbohydrates by probiotic and intestinal bacteria. J Sci Food Agric 82(8):781–789

Das A, Raychaudhuri U, Chakraborty R (2011) Cereal based functional food of Indian subcontinent: a review. J Food Sci Technol. doi:10.1007/s13197-011-0474-1

Delcour JA, Vanhamel S, Hoseney RC (1991) Physicochemical and functional properties of rye nonstarch polysaccharides. II. Impact of a fraction containing water-soluble pentosans and proteins on gluten starch loaf volumes. Cereal Chem 68(1):72–76

Demir MK, Elgun A (2011) Comprarison of autoclave, microwave, IR and UV-C stabilization of whole wheat flour branny fractions upon the nutritional properties of whole wheat bread. J Food Sci Technol. doi:10.1007/s13197-011-0475-0

Demirkesen I, Mert B, Sumnu G, Sahin S (2010) Utilization of chestnut flour in gluten-free bread formulations. J Food Eng 101(3):329–336

Dhingra S, Jood S (2001) Organoleptic and nutritional evaluation of wheat breads supplemented with soybean and barley flour. Food Chem 77(4):479–488

Elleuch M, Bedigian D, Roiseux O, Besbes S, Blecker C, Attia H (2011) Dietary fibre and fibre-rich by products of food processing: characterisation, technological functionality and commercial applications: a review. Food Chem 124(2):411–412

Fan L, Zhang S, Yu L, Ma L (2007) Evaluation of antioxidant property and quality of breads containing Auricularia auricula polysaccharide flour. Food Chem 101(3):1158–1163

Ferrari CKB, Torres EAFS (2003) Biochemical pharmacology of functional foods and prevention of chronic diseases of aging. Biomed Pharmacother 57(5–6):251–260

Fischer MH, Yu N, Gray GR (2004) The gel-forming polysaccharide of psyllium husk (Plantago ovata Forsk). Carbohydr Res 339(11):2009–2017

Gallagher E, Gormley TR, Arendt EK (2003) Crust and crumb characteristics of gluten-free breads. J Food Eng 56(2–3):153–161

Gallagher E, Gormley TR, Arendt EK (2004) Recent advances in the formulation of gluten-free cereal-based products. Trends Food Sci Technol 15(3–4):143–152

Gawlik-Dziki U, Dziki D, Baraniak B (2009) The effect of simulated digestion in vitro on bioactivity of wheat bread with Tartary buckwheat flavones addition. LWT-Food Sci Technol 42(1):137–143

Grasten SM, Juntunen KS, Poutanen KS (2000) Rye bread improves bowel function and decreases the concentrations of some compounds that are putative colon cancer risk markers in middle-aged women and men. J Nutr 130(9):2215–2221

Grasten SM, Juntunen KS, Matto J (2007) High fiber rye bread improves bowel function in postmenopausal women but does not cause other putatively positive changes in the metabolic activity of intestinal microbiota. Nutr Res 27(8):454–461

Guarda A, Rosell CM, Benedito C, Galotto MJ (2004) Different hydrocolloids as bread improvers and antistaling agents. Food Hydrocolloids 18(2):241–247

Guo Q, Cui SW, Wang Q, Goff DH, Smith A (2009) Microstructure and rheological properties of psyllium polysaccharide gel. Food Hydrocolloids 23(6):1542–1547

Hall CA, Manthey FA, Lee RE, Niehaus M (2005) Stability of α-linolenic acid and secoisolariciresinol diglucoside in flaxseed-fortified macaroni. J Food Sci Technol 70(8):483–489

Harmsen HJM, Raangs GC, Franks AH (2002) The effect of the prebiotic inulin and the probiotic Bifidobacterium longum on the fecal microlfora of healthy volunteers measured by Fish and DGGE. Microbial Ecol Health Dis 14(4):211–219

Hirun S, Utama-ang N, Roach PD (2012) Turmeric (Curcuma longa L.) drying: an optimization approach using microwave-vacuum drying. J Food Sci Technol. doi:10.1007/s13197-012-0709-9

HoltekjØlen AK, Bævre AB, RØdbotten M, Berg H, Knutsen SH (2008) Antioxidant properties and sensory profiles of breads containing barley flour. Food Chem 110(2):414–421

Horszwald A, Troszynska A, Del Castillo MD, Zielinski H (2009) Protein profile and sensorial properties of rye breads. Eur Food Res Technol 229(6):875–886

Hozová B, Kuniak L, Moravcikova P, Gajdošova A (2007) Determination of water-insoluble β-D-glucan in the whole-grain cereals and pseudocereals. Czech J Food Sci 25(6):316–324

Hu G, Huang SH, Cao SH (2009) Effect of enrichment with hemicellulose from rice bran on chemical and functional properties of bread. Food Chem 115(3):839–842

Indrani D, Prabhasankar P, Rajiv J, Rao GV (2007) Influence of whey protein concentrate on the rheological characteristics of dough, microstructure and quality of unleavened flat bread (parotta). Food Res Int 40(10):1254–1260

Iqbal A, Khalil IA, Ateeq N, Khan MS (2006) Nutritional quality of important food legumes. Food Chem 97(2):331–335

Jiang P, Burczynski F, Campbell C, Pierce G, Austria JA, Briggs CJ (2007) Rutin and flavonoid contents in three buckwheat species Fagopyrum esculentum, F. tataricum, and F. homotropicum and their protective effects against lipid peroxidation. Food Res Int 40(3):356–364

Kadam SU, Prabhasankar P (2010) Marine foods as functional ingredients in bakery and pasta products. Food Res Int 43(8):1975–1980

Karppinen S, Myllymäki O, Forssell P, Poutanen K (2003) Fructan content of rye and rye products. Cereal Chem 80(2):168–171

Khoshgozaran-Abras S, Azizi MH, Bagheripoor-Fallah N, Khodamoradi A (2012) Effect of brown rice flour fortification on the quality of wheat-base dough and flat bread. J Food Sci Technol. doi:10.1007/s13197-012-0716-x

Kiskini A, Argiri K, Kalogeropoulos M, Komaitis M, Kostaropoulos A, Mandala I, Kapsokefalou M (2007) Sensory characteristics and iron dialyzability of gluten-free bread fortified with iron. Food Chem 102(1):309–316

Korus J, Grzelak K, Achremowicz K (2006) Influence of prebiotic additions on the quality of gluten-free bread and on the content of inulin and fructooligosaccharides. Food Sci Technol Int 12(6):489–495

Laurikainen T, Harkonen H, Autio K, Poutanen K (1998) Effects of enzymes in fiber-enriched baking. J Sci Food Agric 76(2):239–249

Lean LP, Mohamed S (1999) Antioxidative and antimycotic effects of turmeric, lemon-grass, betel leaves, clove, black pepper leaves and Garcinia atriviridis on butter cakes. J Sci Food Agric 79(13):1817–1822

Liang CP, Wang M, Simon JE, Ho CT (2004) Antioxidant activity of plant extracts on the inhibition of citral off-odor formation. Mol Nutr Food Res 48(4):308–317

Lim HS, Park SH, Ghafoor K, Hwang SY, Park J (2011) Quality and antioxidant properties of bread containing turmeric (Curcuma longa L.) cultivated in South Korea. Food Chem 124(4):1577–1582

Lima I, Guraya H, Champagne E (2002) The functional effectiveness of reprocessed rice bran as an ingredient in bakery products. Nahrung 46(2):112–117

Lin LY, Liu HM, Yu YW (2009) Quality and antioxidant property of buckwheat enhanced wheat bread. Food Chem 112(4):987–991

Liu M, Wallin R, Saldeen T (2001) Effect of bread containing fish oil on plasma phospholipid fatty acids, triglycerides, HDL-cholesterol, and malondialdehyde in subjects with hyperlipidemia. Nutr Res 21(11):1403–1410

Lo CY, Li S, Tan D, Pan MH, Sang S, Ho CT (2006) Trapping reactions of reactive carbonyl species with tea polyphenols in simulated physiological conditions. Mol Nutr Food Res 50(12):1118–1128

Mariotti M, Lucisano M, Pagani MA, Ng PKW (2009) The role of corn starch, amaranth flour, pea isolate and psyllium flour on the rheological properties and the ultrastructure of gluten-free doughs. Food Res Int 42(8):963–975

Mashayekh M, Mahmoodi MR, Entezari MH (2008) Effect of fortification of defatted soy flour on sensory and rheological properties of wheat bread. Int J Food Sci Technol 43(9):1693–1698

Mccaskill D, Zhang F (1999) Use of rice bran oil in foods. Food Technol 53(2):50–51

McIntosh GH, Noakes M, Royle PJ, Foster PR (2003) Whole-grain rye and wheat foods and markers of bowel health in overweight middle-aged men. Am J Clin Nutr 77(4):967–974

Mohammed I, Ahmed AR, Senge B (2012) Effects of chickpea flour on wheat pasting properties and bread making quality. J Food Sci Technol. doi:10.1007/s13197-012-0733-9

Nanditha B, Prabhasankar P (2008) Antioxidants in bakery products: a review. Cr Rev Food Sci Nutr 49(1):1–27

Ndife J, Abdulraheem LO, Zakari UM (2011) Evaluation of the nutritional and sensory quality of functional breads produced from whole wheat and soya bean flour blends. Afr J Food Sci 5(8):466–472

Neilsen H (1992) n-3 polyunsaturated fish fatty acids in a fish-oil-supplemented bread. J Sci Food Agri 59(4):559–562

Ng SC, Anderson A, Coker J, Ondrus M (2007) Characterization of lipid oxidation products in quinoa (Chenopodium quinoa). Food Chem 101(1):185–192

Niewinski MM (2008) Advances in celiac disease and gluten-free diet. J Am Diet Assoc 108(4):661–672

O’Riordan K, Andrews D, Buckle K, Conway P (2001) Evaluation of microencapsulation of a bifidobacterium strain with starch as an approach to prolonging viability during storage. J Appl Microbiol 91(6):1059–1066

Penella JM, Collar C, Haros M (2008) Effect of wheat bran and enzyme addition on dough functional performance and phytic acid levels in bread. J Cereal Sci 48(3):715–721

Peng X, Cheng KW, Ma J, Chen B, Ho CT, Lo C, Chen F, Wang M (2008) Cinnamon bark proanthocyanidins as reactive carbonyl scavengers to prevent the formation of advanced glycation endproducts. J Agric Food Chem 56(6):1907–1911

Peng X, Ma J, Cheng K (2010) The effect of grape seed extract fortification on the antioxidant activity and quality attributes of bread. Food Chem 119(1):49–53

Pereira MA, Jacobs DR, Pins JJ, Raatz SK, Gross MD, Slavin JL, Seaquist ER (2002) Effect of whole grains on insulin sensitivity in overweight hyperinsulinemic adults. Am J Clin Nutr 75(5):848–855

Rai S, Kaur A, Singh B, Minhas KS (2011) Quality characteristics of bread produced from wheat, rice and maize flours. J Food Sci Technol. doi:10.1007/s13197-011-0548-0

Rosell CM, Santos E, Collar C (2006) Mixing properties of fibre-enriched wheat bread doughs: a response surface methodology study. Eur Food Res Tech 223(3):333–340

Sabanis D, Lebesi D, Tzia C (2009) Effect of dietary fibre enrichment on selected properties of gluten-free bread. LWT-Food Sci Technol 42(8):1380–1389

Sanchez-Alonso I, Jimenez-Escrig A, Saura-Calixto F, Borderias AJ (2007) Effect of grape antioxidant dietary fibre on the prevention of lipid oxidation in minced fish: evaluation by different methodologies. Food Chem 101(1):372–378

Sangnark A, Noomhorm A (2004) Chemical, physical and baking properties of dietary fiber prepared from rice straw. Food Res Int 37(1):66–74

Sebekova K, Somoza V (2007) Dietary advanced glycation endproducts (AGEs) and their health effects-PRO. Mol Nutr Food Res 51(9):1079–1084

Sensoy I, Rosen RT, Ho CT, Karwe MV (2006) Effect of processing on buckwheat phenolics and antioxidant activity. Food Chem 99(2):388–393

Sidhu JS, Kabir Y (2007) Functional food from cereal grains. Int J Food Prop 10(2):231–244

Siro I, Kapolna E, Kapolna B (2008) Functional food, product development, marketing and consumer acceptance—a review. Appetite 51(3):456–467

Sudha ML, Leelavathi K (2011) Effect of blends of dehydrated green pea flour and amaranth seed flour on the rheological, microstructure and pasta making quality. J Food Sci Technol. doi:10.1007/s13197-010-0213-z

Sumnu GS, Ndife MK, Bayındırlı L (1999) Effects of sugar, protein and water content on wheat starch gelatinization due to microwave heating. Eur Food Res Technol 209(1):68–71

Tariqul Islam AFM, Chowdhury MGF, Islam MN, Islam MS (2007) Standardization of bread preparation from soy flour. Int J Sustain Crop Prod 2(16):15–20

Tömsközi S, Lásztity R, Haraszi R, Baticz O (2001) Isolation and study of the functional properties of pea proteins. Nahrung 45(6):399–401

Vinkx CJA, Delcour JA (1996) Rye (Secale cereale L.) arabinoxylans: a critical review. J Cereal Sci 24(1):1–14

Wang R, Zhou W (2004) Stability of tea catechins in breadmaking process. J Agric Food Chem 52(26):8224–8229

Wang L, Miller RA, Hoseney RC (1998) Effects of (1-3) (1-4)-β-Dglucans of wheat flour on breadmaking. Cereal Chem 75(5):629–633

Wang R, Zhou W, Isabelle M (2007) Comparison study of the effect of green tea extract on the quality of bread by instrumental analysis and sensory evaluation. Food Res Int 40(4):470–479

Wiseman SA, Balentine DA, Frei B (1997) Antioxidants in tea. Cr Rev Food Sci 37(8):705–718

Wu CD, Wei GX (2002) Tea as a functional food for oral health. Nutrition 18(5):443–444

Yao LH, Jiang YM, Shi J, Tomas-Barberan FA, Datta N, Singanusong R, Chen SS (2004) Flavonoids in food and their health benefits. Plant Food Hum Nutr 59(3):113–122

Yep Y, Li D, Mann N, Bode O, Sinclair A (2002) Bread enriched with microencapsulated tuna oil increases plasma docosahexaenoic acid and total omega-3 fatty acids in humans. Asia Pac J Clin Nutr 11(4):285–291

Zandonadi RP, Botelho RB, Araujo WM (2009) Psyllium as a substitute for gluten in bread. J Am Diet Assoc 109(10):1781–1784

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rahaie, S., Gharibzahedi, S.M.T., Razavi, S.H. et al. Recent developments on new formulations based on nutrient-dense ingredients for the production of healthy-functional bread: a review. J Food Sci Technol 51, 2896–2906 (2014). https://doi.org/10.1007/s13197-012-0833-6

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-012-0833-6