Abstract

The protein profile of four types of traditional rye breads formed on rye flours with the extraction rate of 100, 95, 85 and 70% and baked at 260 °C for 40 min was investigated as a nutritional quality indicator. A fractionation process was applied to discriminate high-molecular- (HMW >3 kDa) and low-molecular weight compounds (LMW <3 kDa) present in extracts of rye bread and its crumb and crust. The content of soluble proteins, available lysine, carbohydrates and total phenolic compounds was analysed before and after ultrafiltration in both retentates (HMW >3 kDa) and filtrates (LMW <3 kDa). The dependence between sensory quality of rye breads and composition on soluble proteins, available lysine, carbohydrates and total phenolic compounds was provided. Baking caused a decrease in rye bread protein content. The content of available lysine was the lowest in crusts and it was dependent on the rye flour extraction rate taken for rye bread making. The SDS-PAGE analysis showed that the primary structure of the rye bread proteins was modified in the highest extent in the crust’s bread of all types. The analyses of both retentates and filtrates after ultrafiltration demonstrated that the most of carbohydrates and phenolic compounds were incorporated into the HMW fraction suggesting their conjugation with proteins due to the Maillard reaction. Compounds able to react with Folin Ciocalteu reagent were also detected in filtrates of crust’s extracts (MW ≤3 kDa) from all breads indicating their distribution between LMW and HMW fractions. About 22.5, 27, 11.2 and 46.8% of the phenol compounds forming crusts of breads based on the flours with extraction rates of 100, 95, 85 and 70% were recovered in the corresponding LMW fractions.The sensory analysis of the four types of rye breads indicated for a high correlation between overall quality of breads and their content of carbohydrates. The highest correlation was noted for a rye bread formed on flour with extraction rate of 95%. This finding suggested that the content of carbohydrates as a substrate for Maillard reaction has had an influence on palatability by consumers of rye bread formed on flour with the extraction rate of 95% which had also the highest overall quality.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nowadays, consumers are drawing more attention on the quality and nutritional aspects of foods. Nutritionists worldwide recommend consumption of cereal-based products due to the nutritional health benefits, such as improvement in regulation of blood glucose levels and weight management, diminishing the risk of cardiovascular diseases and certain types of cancer [1–4]. Secondly to wheat, the most common cereal growing in Europe is rye (Secale cereale L.). According to FAO web page (http://www.faostat.fao.org), the production of this cereal is approximately 15.7 million tonnes in the world, and this account for almost 90% of its production in Europe. Increasing consumption of rye-based products has been noted due to the high nutritional quality regarded to amino acid composition of proteins which is inherently important [5]. The cereal proteins contribute to the nutritional value of the diet and they are integral and fundamental part of food components. Nutritionally, they are the good source of energy and its amino acids are essential for growth and maintenance. Functionally, they affect the physicochemical and sensory properties of various foods. Recently published data indicate that rye and rye-based products (including breads) are a good source of lignans, phytosterols and phenolic compounds that are biologically active and posses antioxidant properties (mainly they are good free-radical scavengers, reducing agents, potential complexers of prooxidant metals and quenchers of the singlet oxygen formation) [6, 7]. Rye-based products are also an excellent source of dietary fibre including fructans and β-glucans. Moreover, rye contains the highest amount of pentosans amongst cereals [8].

Baking process results in the formation of Maillard reaction products that influence the nutritional value of cereal-based products. Our previous study had shown that Maillard reaction took place during rye bread making and formation of newly formed compounds, overall antioxidant capacity and the final appearance and taste of breads were dependent on the flour extraction rates taken for dough formulation [9, 10]. The flavour of rye-based products is derived from raw material as well as processed-induced changes [11]. According to Heiniö et al. [12], the flavour of rye flour is mild and rather independent on rye cultivar; however, different milling fractions of rye possess different sensory perception that can be dependant on the phenolic compounds contents. It was highlighted that the outer layer of the rye grain had the strongest flavour and had an influence on processing of rye grain. Moreover, the rye-like flavour is strengthening during the sourdough fermentation process [13]. On the other hand, during the baking process, free amino acids and free sugars are the main substrates for flavour precursors of bakery products strictly related to Maillard and caramelisation reaction [14]. The free amino acids are also precursors of iso-alcohols [15] that contribute to sourdough fermented bread flavour and form pyrazines, pyrroles and furfurals during bread baking [16]. Liukkonen et al. [1] indicated that the profile and concentration of bioactive compounds in rye could be modulated by such factors like milling and fractionation of grain, sourdough fermentation and baking. The key priorities for consumers are healthy aspects of foods, nutritional quality and sensory quality. Scare information is available on the impact of rye bread making on the protein profile and no information exists in relation to the systemically study performed simultaneously in rye bread and its crumb and crust formulated on flour with different extraction rates.

The aim of this work was to show how the protein profile of rye breads based on the flours with different extraction rate is modified during its making process and to gain insight in to the chemical events responsible for determining the overall quality of the food. Beside the analysis of the electrophoresis pattern of the proteins constituting flours, doughs, bread slices, crumbs and crusts, the content in protein, available lysine, carbohydrates and total phenolic compounds was investigated in whole samples and fractions obtained by ultrafiltration employing filtration devices with cut off of 3 kDa. Links between sensorial profiles and nutritional quality were searched.

Materials and methods

Chemicals

All the reagents were of analytical grade. Bicinchoninic acid (BCA) solution, bovine serum albumin (fraction V), sodium dodecyl sulphate (SDS), N-ε-acetyl-l-lysine, phenol reagent (90%), d-(+) glucose, cupric sulphate pentahydrate and ferulic acid were supplied by Sigma (Sigma Chemical Co., St. Louis, MO, USA). o-Phthaldialdehyde (OPA) was purchased from Fluka (Buchs, Switzerland). β-Mercaptoethanol and disodium hydrogen orthophosphate anhydrous were supplied by Merck KGaA (Darmstadt, Germany). Sulphuric acid (98%), Folin–Ciocalteu’s reagent, sodium carbonate and methanol were form POCh (Gliwice, Poland). Water was purified with a MilliQ system (Millipore, Bedford, MA, USA).

Materials

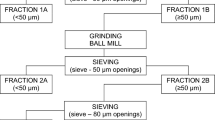

Four types of traditional rye bread formed on rye flours with the extraction rate of 100, 95, 85 and 70% were baked in a pilot scale bakery following the process shown in Fig. 1. Salt and baker’s yeast used in the formulation of bread dough were purchased from a local food manufacturer. For each type of bread, the sourdough starters were prepared from the respective type of flour. Four loafs of each type of bread were obtained. Baking process was performed in duplicate. Breads were cut into slices about 1-cm thick. Crust and crumb were separated by hand. Samples were freeze-dried, ground and sieved though a 60-mesh screen. Powdered samples were stored in polyethylene bags at −20 °C until analysis.

Sample preparation

Exactly 50 mg of rye flour with the extraction rate of 100 or 95, 85 and 70%, and respective dough and bread as well as its parts (crust and crumb) were solubilized with 1 mL of SDS buffer (0.5% SDS, 0.05 M Na2HPO4) for 1 h at room temperature followed by mixing on vortex for 60 s in each 15 min. Next, samples were centrifuged at 13,200g for 10 min in a Beckman GS-15 R centrifuge (Beckman Instruments, Inc., Palo Alto, CL, USA) at room temperature. The supernatants were collected for the determination of soluble protein contents and SDS-PAGE analysis. After that samples obtained as above described were fractioned for further chemical characterisation.

Soluble proteins (SP) assay

The content of soluble proteins in rye breads’ samples was determined using BCA protein assay according to Smith et al. [17]. Aliquots of 50 μL of blank, standard, or appropriate diluted sample were added to 1.4 mL of BCA solution (BCA: CuSO4 × 5H2O, 50:1, v/v). The mixture was incubated at 37 °C for 30 min. Then, the absorbance was read at λ = 562 nm. The data were expressed as mg protein/g d.m. employing calibration curve of bovine serum albumin within the range of 0.01–1 mg/mL. All measurements were performed in triplicate.

SDS-PAGE analysis

Sample preparation was optimised to achieve a maximum solubilisation of the protein fraction using SDS buffer (0.5% SDS, 0.05 M Na2HPO4, pH 6.9) [18]. For SDS-PAGE analyses, rye bread samples were diluted with sample buffer and aliquots of 32.5 μL were mixed with 5 μL of DTT (0.5 M) and 12 μL of NuPAGE® LDS sample buffer (4×) (Invitrogen, Barcelona, Spain) and heated at 100 °C for 10 min. Samples were loaded (20 μL) on a 4–12% linear gradient polyacrylamide NuPAGE® Novex Bis–Tris pre-cast gel. A continuous buffer system (NuPAGE® MES SDS running buffer, Invitrogen) was used. Gels were run for 50 min at initial current of 120 mA per gel at a constant voltage of 200 V and stained using Colloidal Blue Staining Kit (Invitrogen). Marker proteins were trypsin inhibitor (21.5 kDa), carbonic anhydrase (31 kDa), lactate dehydrogenase (36.5 kDa), glutamic dehydrogenase (55.4 kDa), bovine serum albumin (66.3 kDa) and phosphorylase B (97.4 kDa), β-galactosidase (116.3 kDa) and myosin (200 kDa). After proteins separation, the gels were stained using the SilverQuest™ Silver Staining Kit following the manufacturer’s instructions.

Fractionation procedure

Supernatants (500 μL) obtained after extraction with SDS buffer (see sample preparation section) were subjected to ultrafiltration employing filter devices with membranes of 3 kDa cut off (Microcon, Ym-3, Millipore) and centrifugation at room temperature, 14,000g for 30 min. Fractions constituted by compounds with molecular mass higher than 3 kDa were retained (retentate) whilst fractions possessing compounds with mass below 3 kDa were filtered (filtrate). Next, both the retentates and filtrates were dissolved with SDS buffer up to 1 mL in volumetric flasks and the protein content of each fraction was determined according to the BCA protein microassay [17]. The protein content of whole and fractionated samples is presented in Table 1. Filtrates and retentates were subjected to analysis of the available lysine, carbohydrates and total phenolic compounds.

Available lysine assay

The content of available lysine was measured through the reaction of OPA with free amino groups as was described by Goodno et al. [19] and modified by Ramirez-Jimenez et al. [20]. The OPA reagent was prepared by dissolving 16.4 mg OPA in 2.5 mL of methanol followed by the addition of 25 mL 0.1 M borate buffer (pH 9.5), 400 μL of 10% (v/v) β-mercaptoethanol and 5 mL of 20% aqueous SDS solution. The OPA reagent was made up to 100 mL with deionised water. Samples were dissolved to obtain 0.01 mg of protein per millilitre. Protein amino groups were determined by reacting 0.25–50 μg of protein sample with 3 mL of OPA reagent, incubated at 25 °C for 2 min. Subsequently, the fluorescence was read at 340 and 455 excitation and emission wavelengths, respectively. N-ε-acetyl-l-lysine was used as a standard and a calibration curve was prepared with concentration ranged from 10 to 250 μM. All measurements were carried out in triplicate and the data were expressed as g of N-ε-acetyl-l-lysine/g protein.

Determination of carbohydrates content

Carbohydrates content was determined in filtrates and retentates by means of phenol–sulphuric assay described by Dubois et al. [21] with some modifications. Briefly, 500 μL of sample was added to 500 μL of phenol solution (5%, v/v) and mixed, then, 2.5 mL of sulphuric acid was added and stirred for 30 s. The mixture was left for 10 min at room temperature followed by incubation in water bath at 30 °C for 20 min. After vortexing, the absorbance was read at 490 nm (Shimadzu, UV-160 1PC, Japan). A calibration curve of glucose in concentration ranging from 0.10 to 1.38 mM was prepared. All measurements were done in triplicate and expressed as mg glucose/g d.m.

Determination of total phenols content

Content of total phenolic compounds (TPC) in filtrates and retentates was determined according to Shahidi and Naczk [22]. Exactly 0.25 mL aliquot of blank, standard, or sample was mixed with 0.25 mL Folin–Ciocalteu reagent aqueous solution (1:1, v/v) and 0.5 mL of saturated sodium carbonate (Na2CO3) solution and 4 mL of water. The mixture was allowed to stand at room temperature for 25 min and then it was centrifuged at 4 °C, 2,000g for 10 min. Absorbance of clear supernatants was measured at 725 nm using a spectrophotometer (UV-160 1PC, Shimadzu, Japan). The calibration curve of ferulic acid (0.03–0.5 mg/mL) in SDS buffer was constructed and data were expressed as mg ferulic acid equivalents/g protein.

Evaluation of sensory quality

For evaluation of differences in sensory characteristics of four kinds of rye breads, the quantitative description analysis (QDA) was performed [23, 24]. According to the standardized procedure ISO/DIS 13299 [25], sensory panel developed the vocabularies of the sensory attributes in the round-table session. For determination of sensory characteristic, slices of appropriate rye bread were presented to the panelists in three-digit coded plastic containers covered by lids in random order. The panelists evaluated the intensity perceived for each single attribute on unstructured 10-cm line scale verbally anchored to each end. Simultaneously, the overall quality of rye breads was assessed using the same scale where unstructured graphical scale was anchored on both the ends: 0 referred to ‘dislike’ and 10 referred to ‘like’. The results from the linear scale were converted to numerical values (from 0 to 10 units) using computerized system (Analsens System, IRZiBZ PAN, Olsztyn, Poland). The sensory analysis of all samples was done in duplicate preceded by an introductory session. Each panelist was provided with spring water to cleanse their plate between tasting. The assessments were conducted in the sensory laboratory room fulfilled the requirements of the international ISO standards [26].

Statistical analysis

Data were subjected to one-way analysis of variance (ANOVA) to test statistical differences in sensory data as well as content of soluble proteins, available lysine, carbohydrates and total phenolic compounds in four kinds of rye bread and their respective crust and crumbs. Treatment means were compared using Fisher’s least significant difference test. Principal component analysis (PCA) was performed to describe the variance amongst all sensory data obtained. A multiple regression analysis was used to determine the relation between sensory quality (overall quality) and content of proteins, available lysine, carbohydrates and total phenolic compounds. Statistical analyses were performed using software package STATISTICA (statSoft Inc., v. 7.1, Tulsa, OK, USA) for Windows using PC-Pentium with the level of significance set at 95%.

Results and discussion

Soluble proteins (SP) content

Table 1 shows the protein content of flours, doughs, slices, crumbs and crusts. No statistically significant differences amongst the protein values of flours (P > 0.05) with extraction rates of 100, 95 and 85% were found while the value detected for the flour with 70% extraction rate significantly differed form the rest of the samples. For all analysed rye doughs, a significant increase (P < 0.05) in protein content was observed after sourdough fermentation process. The data are in agreement with the results obtained by Tukkanen et al. [27]. This behaviour could be due to the activity of endogenous cereal enzymes during fermentation. Simultaneously, the yeast addition might also alter the total content of proteins of the dough. Moreover, statistically significant differences in protein values (P < 0.05) amongst dough samples were found. The protein content of the rye dough based on a flour with extraction rate 95% was statistically the highest (P < 0.05) amongst the samples. Following the baking process, the protein content of the whole bread decreased about twofold. A similar finding was found by baking of wheat bread by Singh [18]. Values detected in crumbs were of the same order of magnitude amongst the samples (P > 0.05).

The decrease in protein content during baking may be ascribed to Maillard and cross-linking reactions; and also, diminished content of proteins after baking was dependent on the composition of the flour used for bread making, and a direct reflection on what happened in the dough, because fermentation step may be the key point for protein solubilisation and because of that baking process of rye bread decreases the availability of soluble proteins. Moreover, higher values were recorded for crusts and this could be due to the formation of complexes with functional groups able to react with alkaline copper II to produce copper I which easily react with BCA solution. It is worth to mention that no difference in content of soluble proteins in all analysed crusts was noted. In addition, aggregation process induced by dehydration on the surface of the food exposed to high temperatures may occur. Further investigation was performed to confirm this hypothesis and to gain insight in to the chemical events responsible for the changes in protein values caused by bread making process.

SDS-PAGE analysis

Figure 2 shows SDS-PAGE migration patterns corresponding to flour, dough, slice, crust and crumb of rye breads based on the flour extraction rate 100% (A), 95% (B), 85% (C) and 70% (D). The major proteins in rye kernel are secalins that could be divided into four groups: high-molecular weight secalins with molecular weight 100 kDa, sulphur-poor ω-secalins with molecular weight 50 kDa and sulphur-rich γ-secalins with molecular weight 40 or 75 kDa [28]. Bands having these molecular weights can be observed in the flour samples. The molecular mass distribution of flours’ protein was with the agreement with data reported by Hartmann and Koehler [29].

To the best of our knowledge, no previous studies on protein profile by SDS-PAGE analysis of rye breads, crumbs and crusts have been published and so they are of interest. The composition on individual proteins of the flours was greatly modified during both fermentation and baking processes. The number of protein bands with molecular weights lower than 40 kDa increased after fermentation while some of the bands having molecular weights of around 66 kDa decreased after fermentation. Data supported the occurrence of proteolysis during fermentation. In contrast, a low number of protein bands were observed in bread samples when compared with those found in the corresponding flours. Few and fainted bands of proteins were detected in bread crusts. Data seem to indicate that during thermal processing of the dough alterations in protein structure due to the Maillard and protein cross-linking reactions might take place. This could be due to the formation of aggregates or protein cross-linking connected with the formation of disulphide bonds resulting in the formation of high-molecular weight insoluble material [18, 31]. The formation of high-molecular weight molecules by both pathways have been previously documented [18, 30, 31]. Molecules possessing molecular weights higher than 200 kDa cannot enter into the gel and hence may not be detected under SDS-PAGE conditions assayed in the present paper. Samples were fractionated and submitted to further chemical analyses to gain insight into the protein structure modification resulted during the bread making process.

Fractionation results

Available lysine content

Figure 3 shows data on the available lysine of those fractions containing compounds possessing molecular weight of ≥3 kDa (retentates). The content of available lysine found in retentates of the four rye flours ranged from 0.35 to 0.38 g N-ε-acetyl-l-lysine/g protein. No statistically significant differences (P > 0.05) in available lysine content amongst the analysed rye flours were noted. However, Mustafa et al. [32] showed that the highest content of lysine determined by EZ:faast™ method was noted for rye bran and the milling process caused decrease in content of this essential amino acid. Next, dough making process caused the release of available lysine. Statistically significant increase in available lysine of 80.1, 82.7, 52.4 and 36.3% was found for dough obtained from flours with the extraction rates of 100, 95, 85 and 70%, respectively, and that was strongly dependent on the flour extraction rate employed for bread formulation. The highest increase was noted for dark flours (100 and 95%) as this may be due to a higher ash content that results in more minerals and micronutrients necessary for lactic acid bacteria growth [33], which multiply the concentration of amino acids [34]. Mustafa et al. [32] highlighted the fact that after bread making, the content of lysine increased when compared with the respective flour which was in agreement with our results. Nevertheless, in crust the availability of lysine was drastically limited. In comparison to slices, the available lysine content decreased 6.2-, 20.7-, 19.7- and 31.3-fold in 100, 95, 85 and 70% crusts, respectively.

Content in available lysine in fractions containing compounds with molecular weights equal or higher than 3 kDa. Bars represent mean values (n = 3) expressed as g of N-ε-acetyl-l-lysine/g protein while the error bars represent the standard deviation of the measurements. Bars with the same letter are not significantly different (P > 0.05)

Data supported the occurrence, fundamentally in bread crusts, of chemical events compromising lysine availability such as cross-linking of protein and Maillard reaction [35]. Moreover, flours with different extraction rates used for baking influenced the availability of lysine in crusts which was 3.7-, 3.6- and 6 times higher for whole meal bread crust when compared with 95, 85 and 70% bread crusts, respectively.

Content of carbohydrates

Figure 4 shows the content on carbohydrates incorporated to the fractions containing compounds with molecular weight higher than 3 kDa. The content of carbohydrates was dependent on the composition of the rye flour used for bread making. The results showed that dough making process did not cause statistically significant changes in carbohydrate content, whereas baking process did. As can be observed baking process induced incorporation of carbohydrates to the fractions containing compounds with molecular weight higher than 3 kDa. The content of carbohydrates in the high-molecular weight (HMW) fraction increased 3.72-, 3.65-, 4.3- and 3.8 times for 100, 95, 85 and 70%, respectively, after baking process. The analysis of the fractions demonstrated that the most of the sugars was incorporated to the high-molecular fraction suggesting their covalent binding to the protein by Maillard reaction. This finding was supported by other authors who have pointed out the same hypothesis investigating different biological activities of high and LMW isolate Maillard reaction products [36].

Carbohydrate content in fractions containing compounds with molecular weight equal or higher than 3 KDa. Bars represent mean values (n = 3) expressed as mg glucose/g d.m. while the error bars indicate the standard deviation of the measurements. Bars with the same letter are not significantly different (P > 0.05)

Total phenolics content

The content of total phenolic compounds forming the fractions with molecular weight ≥3 kDa is shown in Fig. 5. The highest content of phenolic compounds were noted for flours with the extraction rate of 100 and 95% which was in accordance with Andreasen et al. [37] where 86% of ferulic acid were found in rye bran in comparison to different milling fractions. The data demonstrated the benefits of the fermentation stage during rye bread making since TPC content in dough based on flour extraction rate 100, 95, 85 and 70% was higher about 16.3, 11.1, 58.7 and 15.5%, respectively. Moreover, the content of total phenolic compounds in slices was strongly dependent on flour extraction rate used for baking. Similar observation was noted for crumbs. Baking process caused big alterations in TPC mainly in crust, where the content of compounds able to react with Folin–Ciocalteu reagent increased 1.7-, 2.1-, 1.7- and 3.8 times when compared with the respective slices. This may be due to the formation of Maillard reaction products able to perform this reaction or binding of polyphenols to the protein backbones; and also, a high correlation (r = 0.86) between content of TPC present in flours used for bread preparation and crusts were observed. Thus, flour used for rye bread making determined the content of total phenolics in crusts. Further characterisation of total phenolic compounds present in rye breads showed that after fractionation 22.5, 27, 11.2 and 46.8% of rye crust 100, 95, 85 and 70%, respectively, belongs to compounds with low-molecular weight fraction (MW <3 kDa) (Fig. 6). It can be concluded that fractions, those formed by free phenol and phenol–protein conjugates, may contribute to the overall antioxidant capacity of the rye breads.

Phenolic compounds incorporated to the fraction containing compounds with molecular weight higher than 3 kDa. Bars represent mean values (n = 3) expressed as mg FAE/g protein, while the error bars represent the standard deviation of the measurements. Bars with the same letter are not significantly different (P > 0.05)

Sensory evaluation

Quantitative descriptive analysis is commonly used for evaluating sensory quality of cereal products [12, 38]. For four types of rye breads based on rye flour with extraction rate of 100, 95, 85 and 70%, the QDA procedure elicited attributes which have influence on overall sensory characteristic of rye breads. In this study, 18 attributes related to the appearance (2 attributes), odour (4 attributes), taste (6 attributes) and texture (6 attributes) of rye breads were selected and thoroughly defined for profiling (Table 2). The mean sensory ratings for each rye bread samples and ANOVA are presented in Table 3. The thorough analysis of rye bread sensory attributes indicated that statistically significant differences in colour of four types of rye breads were noted and correspond to different flours used for baking. Further analysis of sensory attributes showed statistically significant differences between breads based on flour with the extraction rate of 100 and 70% in relation to cereal, rye bread and acidic odour. However for sweet odour as well as for sweet and salty taste, no differences between four breads were noted. In case of texture, statistically important were springiness, adhesiveness and moisture which were correlated with the pentosans content in flours with extraction rate 100–85% as these compounds are mainly present in the outer layer of rye kernel [39]. The average overall quality of scores for rye breads based on flour extraction rates 100, 95, 85 and 70% are also presented in Table 3. Data indicated that bread based on flour with the extraction rate 95% is more palatable for consumers.

Chemical composition versus preference of rye breads

To find a link between chemical composition and sensory profile of rye breads for evaluation of which group of compounds could be responsible for the preference of rye breads, the regression equation (Eq. 1) was made.

where y refers to overall quality, x 1 refers to available lysine content, x 2 refers to carbohydrate content and x 3 refers to total phenolic compounds content.

Statistical analysis indicated a high correlation between sensory quality of rye breads with contents of these compounds, which could be confirmed by high coefficient of regression (R 2 = 89.29). Moreover, the results were subjected to student’s t test which showed that the highest influence on overall quality had the content of carbohydrates (P = 0.028). The data suggested that the flavour compounds produced during the baking process are possibly the most essential for the flavour of rye bread, and they are mainly formed during the heat treatments as a result of the Maillard reaction and caramelisation progress. Moreover, recently our group showed also a link between sensory profile of rye breads and their antioxidant properties which were dependent on the type of flour taken for bread making [10]. Nevertheless, the perceived sensory flavour of rye products depends on the combined effects of the volatile compounds as well as their relative proportions, and it is dependent on applied processing technique [16]. The data obtained from QDA method (18 attributes and 4 products) were subjected to PCA. Two principal components were extracted (PC1 and PC2) and together explained 98.33% of the total variance (Fig. 7). PC1 explained the majority of the variations comprising 95.41%, while 2.92% was for PC2. The attributes responsible for colour, odour (cereal, rye bread, acidic, sweet), taste (‘cereal’, acidic, sweet, ‘rye bread’ and aftertaste) and texture (springiness, flexibility, adhesiveness and moistness) had a high loading (>0.9) in PC1. Thus, these attributes had a profound effect on the variation in the sensory quality of rye bread samples.

Conclusion

The data demonstrate that baking process of rye bread according to traditional recipe greatly affects its nutritional aspects. The protein quantity and quality is modified during baking by Maillard reaction and interaction with phenolic compounds modifying the protein nutritional quality within other protein properties. The content of available lysine, carbohydrates and total phenolic compounds is affected by the thermal processing. Loss of available lysine seems to be the main alteration affecting the protein fraction of all analysed breads. The nutritive value of bread crust was markedly lower than that of crumb or whole bread which was in agreement with Friedman [40] and which could be due to the differences in the rate of temperature changes as well as moisture content in the different parts of bread. Moreover, the formation of newly formed compounds able to react with Folin–Ciocalteu reagent was strongest in crust and dependent on flour extraction rate used for bread making. A relationship between sensory overall quality and content of carbohydrates has been noted suggesting the influence of formed compounds during Maillard reaction and sensory perception of rye breads.

According to our data, rye flour with extraction rate of 95% may be used for producing a high quality rye bread. Nutritional and sensorial quality of the rye breads are fundamentally determined by the occurrence of the interaction between free amino groups forming the polypeptide chains of rye proteins with both carbohydrates and phenolic compounds during bread making process. Therefore, the overall quality of the food can be optimised by an effective control of the technological process including, milling, fermentation and baking being the later the most critical step of the process.

References

Liukkonen KH, Katina K, Wilhelmsson A, Myllymaki O, Lampi AM, Kariluoto S, Piironen V, Heinonen SM, Nurmi T, Adlercreutz H, Peltoketo A, Pihlava JM, Hietaniemi V, Poutanen K (2003) Proc Nutr Soc 62:117–122

Jacobs DR, Gallagher DD (2004) Curr Atherosclerosis Rep 6:415–423

Edge MS, Jones JM, Marquart L (2005) J Am Diet Assoc 105(12):1856–1860

Larsson SC, Giovannucci E, Bergkvist L, Wolk A (2005) Br J Cancer 92:1803–1807

Narvhus JA, Søraung T (2006) In: Hui YH (ed) Food biochemistry and food processing. Blackwell, Oxford, pp 615–639

Zieliński H (2002) Pol J Food Nutr Sci 11(52):3–9

Michalska A, Ceglińska A, Amarowicz R, Piskula MK, Szawara-Nowak D, Zieliński H (2007) J Agric Food Chem 55:734–740

Nowotna A, Gambuś H, Liebhard P, Praznik W, Ziobro R, Berski W, Krawontka J (2006) Acta Sci Polon 5(1):87–96

Michalska A, Amigo-Benavent M, Zieliński H, del Castillo MD (2008) J Cereal Sci 48:123–132

Zieliński H, Michalska A, Ceglińska A, Lamparski G (2008) Eur Food Res Technol 226:671–680

Heinio RL, Liukkonen KH, Myllymaki O, Pihlava JM, Adlercreutz H, Heinonen SM, Poutanen K (2008) J Cereal Sci 47:566–575

Heinio RL, Liukkonen KH, Katina K, Myllymaki O, Poutanen K (2003) Lebensm-Wiss u-Technol 36:577–583

Hansen A (1995) In: Poutanen K, Autio K (eds) Proceedings of VTT symposium, international rye symposium: technology and products, Helsinki, 7–8 Dec, Espoo, pp 194–200

Rehman S, Paterson A, Piggott JR (2006) LWT Food Sci Technol 17:557–566

Hansen A, Schieberle P (2005) Trends Food Sci Technol 16:85–94

Heiniö RL, Katina K, Wilhelmson A, Myllymäki O, Rajamäki T, Latva-Kala K, Liukkonen KH, Poutanen K (2003) Lebensm-Wiss u-Technol 36:533–545

Smith PK, Krohn RI, Hermanson GT, Macia AK, Gartner FH, Provenzano MD, Fujimoto EK, Goeke NM, Olson BJ, Klenk DC (1985) Anal Biochem 150:76–85

Singh H (2005) Food Chem 90:247–250

Goodno CC, Swaisgood HE, Catignani GL (1981) Anal Biochem 115:203–211

Ramirez-Jimenez A, Guerra-Hernandez EJ, Garcia-Villanova B (2004) Food Control 15:351–354

Dubois M, Gilles A, Hamilton JK, Rebers PA, Smith F (1956) Anal Chem 28(3):350–356

Shahidi F, Naczk M (1995) In: Shahidi F, Naczk M (eds) Food phenolics: sources, chemistry, effects and applications. Technomic Publishing Company, Lancastewr/Pensylvania, pp 287–293

Stone H, Sidel JL (1993) Sensory evaluation practices, 2nd edn. Academic press, San Diego

Lawless HT, Heymann H (1999) In: Lawless HT, Heymann H (eds) Sensory evaluation of food: principles and practices. Kluwer Academic/Plenum Publishers, New York, p 341

ISO/DIS (1998) Sensory analysis—methodology—general guidance for establishing a sensory profile. International Organization for Standardization, Geneva, Switzerland, 13299

ISO 8589 (1998) Sensory analysis—general guidance for the design of test rooms. International Organization for Standardization, Geneva, Switzerland

Tukkannen K, Loponen J, Mikola M, Sontag-Sthorm T, Salovaara H (2005) Cereal Chem 82(6):677–681

Shewry PR, Bechtel DB (2001) In: Boshruk W (ed) Rye: production, chemistry and technology, 2nd edn. AACC International, St. Paul, pp 69–127

Hartmann S, Koehler P (2008) J Cereal Sci 47:576–586

Camire ME, Camire A, Krumhar K (1990) Crit Rev Food Sci Nutr 29:35–57

Miller AG, Gerrard A (2005) Prog Food Biopolymer Res 1:69–86

Mustafa A, Aman P, Andersson R, Kamal-Eldin A (2007) Food Chem 105:137–324

Decock P, Cappelle S (2005) Trends Food Sci Technol 16:113–120

De Angelis M, Coda R, Silano M, Minervini F, Rizzello CG, De Cagno R, Vicentini O, De Vincenzi M, Gobbetti M (2006) J Cereal Sci 43:301–314

Delgado-Andrade C, Rufián-Henares JA, Morales FJ (2007) Food Chem 100:725–731

Delgado-Andrade C, Morales FJ (2005) J Agric Food Chem 53:1403–1407

Andreasen MF, Christensen LP, Meyer AS, Hansen A (2000) J Cereal Sci 31:303–307

Heenan SP, Dufour JP, Hamid N, Harvey W, Delahunty CM (2008) Food Res Int 41:989–997

Härkönen H, Pessa E, Suortti T, Poutanen K (1997) J Cereal Sci 26:95–104

Friedman M (1996) J Agric Food Chem 44(3):631–653

Acknowledgment

This research was supported by the COST Action 927 “Thermally Processed Foods: possible health implications” and project CSIC-Polish Academy of Sciences (2008PL0025). The present work has been partially funded by the CONSOLIDER INGENIO 2010 Program; FUN-C-FOOD CSD2007-063’ and the project AGL2008-2541/ALI. This article is a part of the Ph.D. thesis of A. Horszwald.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Horszwald, A., Troszyńska, A., del Castillo, M.D. et al. Protein profile and sensorial properties of rye breads. Eur Food Res Technol 229, 875–886 (2009). https://doi.org/10.1007/s00217-009-1129-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-009-1129-6