Abstract

Production of extracellular chitin deacetylase by Colletotrichum lindemuthianum ATCC 56676 under solid substrate fermentation was studied. The suitability of shrimp shell chitin waste (SSCW) and commercial wheat bran (CWB) was evaluated for maximal enzyme production. CWB medium (pH 6.4 ± 0.2) supplemented with chitosan favoured maximal chitin deacetylase yield of 460.4 ± 14.7 unit/g initial dry substrate (U/g IDS) at 96 h as compared to maximal yield of 392.0 ± 6.4 U/g IDS at 192 h in SSCW medium (pH 8.7 ± 0.2) at 25 °C incubation temperature and 60% (w/w) initial moisture content of medium. Along with chitin deacetylase, C. lindemuthianum ATCC 56676 produced maximum endo-chitinase (0.28 ± 0.03 U/g IDS at 144 h) and β-N-acetylhexosaminidase (0.79 ± 0.009 U/g IDS at 192 h) in CWB medium and 0.49 ± 0.05 U/g IDS of endo-chitinase at 264 h and 0.38 ± 0.04 U/g IDS of β-N-acetylhexosaminidase at 96 h of incubation in SSCW medium. SEM studies indicated the difference in the morphology of mycelia and hyphae of C. lindemuthianum ATCC 56676 when grown on different solid substrates. Production of chitin deacetylase by SSF is being reported for the first time.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Chitosan is a linear copolymer of β-(1→4) linked N-acetyl-D-glucosamine (GlcNAc) and glucosamine (GlcN) units. Chitosan has unique functional and biological properties favourable for a broad variety of biological and industrial applications (Synowiecki and Al-Khateeb 2003; Keisuke 2006). In spite of its several potent bio-functionalities, its application has been restricted because the lack of commercial availability of high quality chitosan (Tsigos et al. 2000). Currently, chitosan is produced by the thermochemical alkaline deacetylation of crustaceans chitin. Chitin, a linear homopolymer of β-(1→4) linked GlcNAc is the most abundant, easily available and renewable natural polymer second only to cellulose (Tsigos et al. 2000; Keisuke 2006). However, the production of chitosan from crustacean chitin is environmentally unsafe and not easily controlled, resulting in products with poor quality, inconsistent properties and exist considerable variation between different batches (Tsigos et al. 2000; Synowiecki and Al-Khateeb 2003). Chain length and degree of acetylation of chitosan are the most important factors influencing its functional value and biological activities (Synowiecki and Al-Khateeb 2003). An attractive alternative, controlled, non degradative and well defined processes to alkali deacetylation of chitin, is the enzymatic process that employs microbial chitin deacetylase that results in novel chitosan with consistent properties (Tsigos and Bouriotis 1995; Martinou et al. 1997; Tsigos et al. 2000; Synowiecki and Al-Khateeb 2003; Paul et al. 2007). However, at present there is no commercial process available for the production of chitin deacetylase and its use in chitosan production.

Chitin deacetylase (Chitin amidohydrolase, EC 3.5.1.41) catalyses the conversion of chitin to chitosan by the deacetylation of GlcNAc residues (Tsigos et al. 1999). Recently, chitin deacetylase has attracted increasing interest, owing to its possible applicability for preparation of specific novel chitosan oligomers and polymers from chitin oligomers or pretreated chitin (Kuk et al. 2005; Kim et al. 2008). Chitin deacetylase has been isolated, purified and characterized from several fungi such as Mucor rouxii (Araki and Ito 1975; Kafetzopoulos et al. 1993), Absidia coerulea (Gao et al. 1995), Aspergillus nidulance (Alfonso et al. 1995) [13], C. lindemuthianum (Tsigos and Bouriotis 1995; Tokuyasu et al. 1996), Metarhizium anisopliae (Nahar et al. 2004), Scopulariopsis brevicaulis (Cai et al. 2006) and Mortierella sp. (Kim et al. 2008) and also from some bacterial strains (Kadokura et al. 2006). Chitin deacetylase production is mostly intracellular, however, extracellular production is also reported (Tsigos and Bouriotis 1995; Tsigos et al. 2000). Extracellular chitin deacetylase has more potential for the bioconversion of chitin to chitosan in industry (Kim et al. 2008). Among the different chitin deacetylase produced by various fungi the enzyme from C. lindemuthianum is reported to exhibit extraordinary properties and could potentially be exploited for effective deacetylation of chitinous substrates (Tsigos and Bouriotis 1995). Production of higher level of extracellular chitin deacetylase by C. lindemuthianum (Tsigos and Bouriotis 1995; Tokuyasu et al. 1996) indicates the scope for the large-scale production by economically viable and feasible bioprocess.

Solid state (substrate) fermentation (SSF) has been known for centuries and exploited successfully for the production of microbial extracellular enzymes due to economic advantages over conventional submerged fermentation (SmF) (Suresh and Chandrasekaran 1999). The type of microorganisms and the nature of the solid substrates is an important parameter that influences the product yield and consequently affects the success of SSF process (Pandey et al. 1999). Among various solid substrates reported, commercial wheat bran (CWB) is the most widely exploited solid substrate for the production of fungal enzymes (Suresh and Chandrasekaran 1999). Seafood processing solid shrimp shell chitin waste (SSCW) is another potential inexpensive solid substrate for SSF production of microbial chitinases (Suresh and Chandrasekaran 1998; Nopakarn et al. 2002) and β-N-acetylhexosaminidases (Yoyi et al. 2004). Annually India produces more than 100,000 tonnes of shrimp processing waste (Mathew and Nair 2006), of which only an insignificant amount is utilized for the extraction of chitin and the rest is discarded. Effective utilization of such a waste has an important bearing both from the point of clean environment and also increasing the economic value of this marine bio-waste (Suresh and Chandrasekaran 1998; Chang et al. 2007).

C. lindemuthianum ATTCC 56676, a phytopathogenic fungus is well known for extracellular chitin deacetylase production (Tsigos and Bouriotis 1995; Tokuyasu et al. 1996). However, its potential to produce chitin deacetylase by employing SSF remains unexploited. The aim of the present study is to evaluate the potential of C. lindemuthianum ATTCC 56676 to produce chitin deacetylase by SSF using different food processing by product as substrates for the economic production of this enzyme.

Materials and methods

SSCW and chemicals

Fresh shrimp (Penaeus indicus) processing SSCW containing head and abdominal shells were obtained from a local fish market and transported to the laboratory under chill condition. It was dried in a drying oven at 55 ± 2 °C to constant moisture content (~10%, w/w) and stored at room temperature (28 ± 2 °C). CWB was procured from a local market. ρ-nitrophenyl-N-acetyl-β-D-glucosaminide (ρ-NPGlcNAc) and glycol chitosan were purchased form Sigma Chemical Co., USA. Potato dextrose agar (PDA) was purchased form Himedia, Mumbai, India. All other chemicals and reagents were of the analytical grade. C. lindemuthianum ATCC 56676 was procured from American Type Culture Collection, Manassas, USA.

Preparation of pure chitin

Pure chitin was prepared according to Shimahara and Takiguchi (1988) with slight modifications. The fresh shrimp abdominal shells waste was minced in a wearing blender into about 1 cm2 size and washed repeatedly with tap water. One kilogram of wet shrimp shell residue was immersed in 20 l of 2N HCl. The mixture was kept for 24 h at room temperature with occasional stirring with glass road and decanted. The process was repeated once again. After 2 days the demineralized shell residue was washed with deionized water until the wash water became neutral. The demineralized shrimp shell residue was immersed in 10 l of 1N NaOH. The mixture was boiled with occasional stirring for 1 h and decanted. The process was repeated twice. After decanting the supernatant, the shell residue was immersed in 20 l of 1N NaOH and kept for 24 h at 55 ± 2 °C with intermittent stirring with glass road. The NaOH solution was replaced twice. After 2 days, the deproteinised shell residue was collected and washed with deionized water until the wash water became neutral. Finally, demineralized and deproteinized shrimp shell residue was immersed in five volume of absolute ethanol at room temperature and slowly stirred using a mechanical stirrer for 1 h to decolorize the chitin. This process was repeated once again. The decolorized chitin was collected and dried at 45 ± 2 °C for overnight. The dried chitin was powdered to a particle size of <22 mesh and stored at room temperature in air tight container. The purity of chitin prepared was analyzed according to Spinelli et al. (1974).

Preparation of colloidal chitin

The colloidal chitin was prepared, according to the procedure of Shimahara and Takiguchi (1988) with some modifications. Ten grams of chitin powder (<22 mesh) prepared as described above was added in to 400 ml of ice chilled concentrated HCl with mechanical stirring. The mixture was heated slowly up to 37 ± 2 °C. After 45 min of stirring, the mixture was filtered through glass wool to remove the insoluble fraction and the clear filtrate was poured into 4 l of ice chilled deionized water with mechanical stirring for 30 min in order to precipitate the chitin. The suspension was kept overnight at 4 °C. The supernatant was decanted and the remaining mixture was centrifuged at 5,000 rpm for 20 min at room temperature. The residue was resuspended in deionized water and centrifuged. This process was repeated until the wash water became neutral. The prepared colloidal chitin was autoclaved at 15 psi for 15 min and stored at 4 °C. The chitin content was determined by drying a sample at 55 ± 2 °C for overnight.

Preparation of SSCW and CWB substrates for enzyme production by SSF

The dried SSCW were ground into 1 cm2 size with an electric wearing blender. The SSCW chips were washed with 1:10 (w/v) ratio of tap water for two times using a planetary mixer in order to remove the unwanted material such as soil and sand particles and dried at 55 ± 2 °C for overnight in a drying oven. The washed and dried SSCW chips were milled with an electric wearing blender and sieved through a 22 mesh sieve. The SSCW powder with <22 mesh particle size were collected, stored in dry place at room temperature in air tight container and used as solid SSCW substrate for SSF without any further demineralization or deproteinization treatment. The CWB procured from local market was washed with 1:5 (w/v) ratio of tap water for two times and the washed CWB residue were dried at 55 ± 2 °C for overnight in a mechanical drier. The dried CWB was stored in dry place at room temperature in air tight container and used as another substrate for SSF.

Microorganism and preparation of inoculum: C. lindemuthianum

ATCC 56676 was maintained on PDA slants, subcultured monthly and stored at 4 °C. The inoculum was prepared by growing the fungus on PDA slants at 25 ± 2 °C for 15 days. The conidia from newly raised slant cultures were dispersed in 0·1% (w/v) solution of Tween 80 by scraping with a sterile inoculum loop under strictly aseptic conditions. The concentration was adjusted to 5.3 × 106 cfu/ml suspension and used as inoculum.

Preparation of solid SSCW and CWB media and fermentation

Five grams of the substrate was taken in 100 ml Erlenmeyer conical flasks and moistened with 5.5 ml tap water. In CWB medium chitosan powder (85% deacetylated, <22 mesh particle size) was added at 1% (w/w) level. After thorough mixing with glass rod the moist media was autoclaved at 15 psi for 30 min. After cooling to room temperature the moist SSCW and CWB media were inoculated with 2 ml of the prepared conidial suspension (arbitrary selected) and mixed carefully with sterile glass rod under strictly aseptic conditions to achieve a uniform distribution of inoculum throughout the solid medium. The inoculated moist SSCW and CWB media had 55% (w/w) initial moisture content. The inoculated flaks were then incubated at 25 ± 2 °C in an incubator for desired incubation period.

Extraction of enzyme

After completion of desired incubation time, enzymes from fermented solid SSCW and CWB medium were recovered using phosphate buffer (pH 8, 0.1 M). The fermented material in each flask, were mixed with 50 ml (ten volumes based on the initial dry weight of the substrate) of buffer and mixture kept on a rotary shaker (150 rpm) for 20 min at 20 ± 2 °C. The slurry was then filtered through dampened cheese cloth and the extracts were clarified by centrifugation at 10,000 rpm at 4 °C for 20 min. The clear supernatant was used as crude enzyme.

Analytical methods

The moisture, crude protein, fat and ash content of the SSCW substrate (AOAC 2000), chitin content of the SSCW substrate (Spinelli et al. 1974), the pH of solid SSCW and CWB substrates (Suresh and Chandrasekaran 1998) were determined.

Assay of chitin deacetylase (EC 3.5.1.41)

Chitin deacetylase activity was assayed colorimetrically using glycol chitin as the substrate. Glycol chitin was prepared from glycol chitosan by acetylation using acetic anhydride according to the method of Araki and Ito (1975). The assay of chitin deacetylase was carried out according to Kauss and Bauch (1988) as described below. The reaction mixture consisting of 100 μg of glycol chitin in 100 μl of distilled water, 100 μl of sodium tetraborate/HCl buffer (pH 8.5, 50 mM) and 50 μl of enzyme solution was incubated at 30 ± 2 °C for 1 h. The reaction was terminated by heating in boiling water bath for 5 min followed by the addition of 250 μl of 5% (w/v) KHSO4. Blanks were prepared by adding substrate solution after the KHSO4 solution. The amount of glucosamine residues produced by the enzymatic reaction was determined. 250 μl of 5% (w/v) NaNO2 was added to the assay mixture and incubated for 15 min with occasional shaking followed by addition of 250 μl of 12.5 (w/v) ammonium sulfamate. After incubation for 5 min freshly prepared 250 μl of 0.5% (w/v) 3-methyl-2-benzothiazoline hydrazone was added and the mixture was heated in a boiling water bath for 3 min. After cooling under tap water, 250 μl of 0.5% (w/w) FeCl3 was added and incubated for 30 min. The absorbance of blue colour developed was measured at 650 nm using GlcN-HCl as standard. One unit of chitin deacetylase activity was defined as the amount of enzyme which released 1 μg of GlcN under the reaction conditions and the enzyme production in SSF was expressed as units/g of initial dry substrate (U/g IDS, Suresh and Chandrasekaran 1998).

Assay of endo-chitinase (EC 3.2.1.14)

Endo-chitinase activity was assayed using colloidal chitin as the substrate (Suresh and Chandrasekaran 1999). The reaction mixture consisting of 1 ml of 1% (w/v) colloidal chitin in citrate phosphate buffer (pH 6.8, 0.1 M) and 1 ml of enzyme solution was incubated at 30 ± 2 °C for 2 h with occasional shaking. Heat inactivated enzyme with substrate was used as blank. The reaction was terminated by heating the reaction mixture in boiling water bath for 10 min. The undigested materials were removed by centrifugation at 8,000 rpm for 10 min and the amount of GlcNAc produced in the supernatant was estimated with ρ-dimethyl aminobenzaldehyde reagent according to Ressing et al. (1955). One unit of endo-chitinase activity was defined as the amount of enzyme which released 1 μmol of GlcNAc under the reaction conditions and enzyme production in SSF was expressed as U/g IDS.

Assay of β-N-acetylhexosaminidase (EC 3.2.1.52)

β-N-acetylhexosaminidase activity was assayed using ρ-NPGlcNAc as the substrate according to Akira (1988) with slight modifications. The reaction mixture contained 0.45 ml of 1 mM ρ-NPGlcNAc in citrate phosphate buffer (pH 6.8, 0.1 M) and 50 μl of enzyme solution. Heat inactivated enzyme with substrate was used as blank. After incubation for 20 min at 30 ± 2 °C, the reaction was stopped by adding 2 ml of 0.2M Na2CO3 solution and the absorbance of ρ-nitrophenol released was measured at 420 nm. One unit of enzyme activity is defined as the amount of enzyme which released 1 μmol of ρ-nitrophenol under the reaction conditions and enzyme production in SSF was expressed as U/g IDS.

Scanning Electron Microscopy (SEM)

The growth and performance of C. lindemuthianum ATCC 56676 on moist SSCW and CWB medium under SSF was observed under SEM as described below. Samples were collected from fermented solid substrate, fixed by immersion in 2.5% (v/v) glutaraldehyde for 12 h at 4 °C, washed with phosphate buffer (0.1 M, pH 7.0) for 1 h at room temperature and further dehydrated in a graded 20%–100% (v/v) ethyl alcohol series and dried under vacuum at room temperature. The dried samples were coated on a double sided conducting adhesive tape pasted on to a metallic stub and subjected to gold covering (~100°A). Finally the prepared samples were examined in a Scanning Electron Microscope (LEO 435 VP, LEO Electron Microscopy Ltd., Cambridge, UK) at 20 kV.

Statistical analysis

The enzyme production in two substrates was compared by Analysis of variance Techniques (ANOVA) using the statistical software STATISTICA (1999). All experiments were conducted in triplicate and the mean values are reported.

Results and discussion

General

During washing soil and sand particles, some amount of soluble protein was removed from SSCW (Table 1). Washed and dried SSCW had a pH of 8.7 ± 0.2. Washed SSCW contained 13.5% lower in chitin, 45% lower in protein and 80% higher in ash as compared with an earlier report (Suresh and Chandrasekaran 1998) was an excellent substrate for SSF growth of fungus and enzyme production. The washed CWB substrate had a pH of 6.4 ± 0.2. The chitin prepared from fresh SSCW abdominal shell had 97%–98% purity and with 0.15% ± 0.04% ash content.

Enzyme production

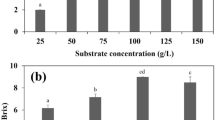

CWB medium supplemented with chitosan supported significantly (p ≤ 0.001) higher production of chitin deacetylase of 460.4 ± 14.7 U/g IDS at 96 h of incubation as compared with the maximum yield of 392.0 ± 6.4 U/g IDS at 192 h of incubation in SSCW medium (Fig. 1). The incubation time required for maximal chitin deacetylase yield varied according to the type of the substrates. In both substrates, enzyme yield decreased gradually beyond the optimum period of incubation. Visual observation showed that fungus grew profusely and uniformly on moist SSCW and CWB medium as a white cottony mass. Black coloured fruiting bodies were observed on cottony mycelium after 144 h of incubation of CWB medium. However, in case of SSCW medium, no such black coloured fruiting bodies were observed.

Chitin deacetylase activity in the culture filtrate of C. lindemuthianum ATCC 56676 was between 6–25 fold higher than in the corresponding cell extracts in liquid cultivation (Kauss et al. 1983; Kauss and Bauch 1988; Tsigos and Bouriotis 1995). Most of reports of chitin deacetylase were discussed from the viewpoint of purification and characterization (Kauss et al. 1983; Kauss and Bauch 1988; Tsigos and Bouriotis 1995; Tokuyasu et al. 1996) or their mode of action on substrate and their substrate specificity (Tsigos et al. 1999; Tokuyasu et al. 1997; Win and Stevens 2001) and no sufficient information regarding the fermentation processes and yield is addressed. A maximal extracellular chitin deacetylase yield of 0.6 U/mL on 3 days of incubation in yeast peptone glucose medium containing 2% glucose at pH 5.0 and 28 °C with 150 rpm employing submerged fermentation from Mortierella sp. DY-52 was reported very recently (Kim et al. 2008). They determined the enzyme activity using a water soluble chitin (WSCT-50) as a substrate and release of acetic acid. Due to lack of relevant information in the literature, comparison with the chitin deacetylase yields obtained in this investigation is not feasible.

The variation in optimum incubation time required for maximal enzyme yield with CWB and SSCW medium could be attributed to the differences in their physical nature and biochemical status, which consequently influence the oxygen transfer rate and nutrient availability for the fungus during SSF. The physical nature and water-holding capacity are important criteria for a solid substrate for its use in SSF processes (Pandey et al. 1999) and the moisture content of the medium is a critical factor that determines the microbial growth and product yield in SSF (Suresh and Chandrasekaran 1998; Suresh and Chandrasekaran 1999). In this investigation it appears that the nature of the substrates had significantly influenced the incubation period on overall chitin deacetylase yield. The extended incubation time required for maximal enzyme production with SSCW may be accounted for by its comparative nutritionally inert and complex nature. Comparable observation was reported for extracellular L-glutaminase production under SSF using different organic substrates (Prabhu and Chandrasekaran 1996). The reduction in chitin deacetylase yield from both substrates after optimum incubation time is probably due to enzyme denaturation by protease secreted by the fungus and also due to the reduced available nutrient level in the medium. Similar drops in enzymes yield were reported in the SSF production of chitinase by Beauveria bassiana BTMF S10 (Suresh and Chandrasekaran 1998; Suresh and Chandrasekaran 1999) and endo-chitinase and chitobiase by Penicillium aculeatum and Trichoderma harzianum (Binod et al. 2007).

SSCW was reported as a novel substrate in SSF production of chitinase (Suresh and Chandrasekaran 1998; Nopakarn et al. 2002) and β-N-acetylhexosaminidase (Yoyi et al. 2004). Even though C. lindemuthianum ATCC 56676 is a phytopathogenic fungus, it tolerated adverse conditions in high protein, CaCO3, presence of other components and high alkaline pH 8.7 ± 0.2 of SSCW. Chitin deacetylase was reported as a constitutive enzyme; however, addition of chitin or other sugars into the cultivation medium greatly enhanced the enzyme yield (Nahar et al. 2004; Kim et al. 2008).

CWB is frequently used for SSF cultivation due to its favourable properties as a solid substrate for fungal growth (Suresh and Chandrasekaran 1999). Supplementation of chitosan in CWB medium favoured the higher amount of chitin deactylase yield and short incubation time, 96 h earlier in CWB medium as compared with SSCW medium, 96 and 192 h, respectively. Maximum chitin deacetylase production by C. lindemuthianum was on 18 days of incubation in liquid cultivation (Tokuyasu et al. 1996). The rapid production of chitin deacetylase by C. lindemuthianum ATCC 56676 under SSF using CWB has advantages for industrial application.

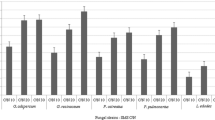

The production of endo-chitinase by C. lindemuthianum ATCC 56676 was significantly (p ≤ 0.01) higher (0.49 ± 0.05 U/g IDS at 264 h) in SSCW medium compared to 0.28 ± 0.03 U/g IDS at 144 h in CWB medium (Fig. 2). However, in contrast to the chitin deacetylase production (Fig. 1), SSCW medium recorded higher endo-chitinase activity as compared with CWB medium supplemented with chitosan. Chitinase and β-N-acetylhexosaminidase is produced as inducible enzymes using chitin or its degradation products as inducers (Binod et al. 2007; Suraini et al. 2008). The chitin or as mentioned above GlcNAc is released from SSCW medium during sterilization may function as inducer for the enhanced production of chitinase in SSCW medium by this fungus. Similar observation was reported in chitinase production by B. bassiana under liquid cultivation (Smith and Grula 1983). In case of SSCW, maximum chitinase yield reported by SSF from B. bassiana BTMF S10 was 248.0 U/g IDS (enzyme activity determined for reducing sugar from colloidal chitin) (Suresh and Chandrasekaran 1998) and from Aspergillus sp. S1-13 was 1.8 U/g IDS on 11 days incubation (Nopakarn et al. 2002). In case of CWB, maximum chitinase activity reported by SSF was 246.6 U/g IDS by B. bassiana BTMF S10 on wheat bran supplemented with colloidal chitin (Suresh and Chandrasekaran 1999), from B. felina RD 101 was 6.34 U/g IDS at 6 days (Pankaj et al. 2005a), from P. chrysogenum was 3809 U/g IDS (Pankaj et al. 2005b), from P. aculeatum NRRL 2129 was at 72 h (Binod et al. 2005) and from T. harzianum was 3.18 at 96 h (Nampoothiri et al. 2004). The differences in chitinase yields are related to fermenter design, specifically aeration and humidification suitable for growth (Yoyi et al. 2004) and also the difference in the procedures and substrate used for chitinase assays.

C. lindemuthianum ATCC 56676 produced maximum β-N-acetylhexosaminidase yield of 0.79 ± 0.009 U/g IDS at 192 h in CWB medium and 0.38 ± 0.04 U/g IDS at 96 in SSCW and the yield between two substrates was significantly (p ≤ 0.001) different (Fig. 3). The maximum β-N-acetylhexosaminidase production reported under SSF by Fusarium oxysporum F3 was 23.6 U/g IDS at 12 days of incubation using a mixture of wheat bran and chitin (Konstantinos et al. 2004) and by Verticillium lecanii utilizing mixture of shrimp waste silage and sugar cane pith bagasse was 1673 ± 84.1 U/g IDS and 1015.8 ± 93.4 at 144 h of incubation respectively with mycelium and spores inoculum (Yoyi et al. 2004).

Similar to chitin deacetylase yield the nature of the substrates had significantly influenced the incubation period on overall endo-chitinase and β-N-acetylhexosaminidase yield. Similarly the enzymes activity decreased beyond optimum incubation period in both substrates. Except endo-chitinase production, CWB supported maximum yield of chitin deacetylase and β-N-acetylhexosaminidase by this fungus, however, the optimum time varied according to enzymes. In C. lindemuthianum ATCC 56676 chitin deacetylase have multiple functions along with other chitinolytic enzymes such as endo-chitinase and β-N-acetylhexosaminidase. They play a role in nutrition, also active in fungal developmental processes and in morphogenesis, because chitin is a major cell wall component in fungi (Tsigos and Bouriotis 1995; Rachel and Ilan 1998). It has been reported that most chitin deacetylase were extracted from fungi in addition to chitinase or chitosanase (Win and Stevens 2001; Nahar et al. 2004; Kim et al. 2008). Elaborate discussion on the yield of endo-chitinase and β-N-acetylhexosaminidase is not provided as the emphasis was on chitin deacetylase yield in SSF process.

SEM analysis of SSF growth of C. lindemuthianum ATCC 56676

Observation using SEM was carried out to visualize the growth of C. lindemuthianum ATCC 56676 on moist CWB and SSCW substrates under SSF. The micrograph of SEM for CWB and SSCW substrates was shown in Fig. 4a and b respectively. It was observed in the micrograph that C. lindemuthianum grew profusely throughout the moist solid substrates. The physico-chemical properties and nutritional complexity of different substrates had significant effect on the growth and morphology of this fungus. There was a significant variation in morphology of mycelium and hyphae of this fungus in different substrates. Typical hyphal morphology was more prominent in the micrograph of fermented CWB substrate and mycelia invasion were also observed. In the micrograph of fermented SSCW substrate typical hyphal morphology is not prominent and the hyphae are very thin, however, chitin microfibrils degradation was observed. The high complex nutritional and physical nature along with its high alkaline pH (8.7 ± 0.2) of SSCW might have influenced the mycelial and hyphae morphology of this fungus during the growth of on moist SSCW. The degree of substrate transformation in SSF depends upon the capability of fungal mycelia to penetrate deep into the intracellular space (Nampoothiri et al. 2004).

Conclusions

Chitin deacetylase, a biotechnologically important enzyme, can be produced under SSF by C. lindemuthianum ATCC 56676 using SSCW and CWB as substrates. C. lindemuthianum ATCC 56676 produced significantly (p ≤ 0.001) higher amount of enzyme in CWB medium (460.4 ± 14.7 U/g IDS) supplemented with chitosan as compared with yield in SSCW medium (392.0 ± 6.4 U/g IDS). Though the enzyme yield is comparatively lower the use of inexpensive SSCW as substrate will have an important economic advantage and offers great relevance in environmental issues. Along with chitin deacetylase C. lindemuthianum ATCC 56676 produced endo-chitinase and β-N-acetylhexosaminidase under SSF. These enzyme systems could be efficiently used for the bioconversion of crustacean shell chitin to novel chitosan with consistent properties. The results reported in this paper indicate the tremendous scope for industrial scale production extracellular chitin deacetylase by C. lindemuthianum ATCC 56676 through SSF process. For enhanced production of chitin deacetylase by C. lindemuthianum ATCC 56676 by SSF, investigation works are underway to optimize various physico-chemical processes parameters using different solid substrates.

References

Akira O (1988) Chitinase and β-N-acetyhesosaminidase from Pycnoporus cinnabarinus. In: Willis AW, Scott TK (eds) Methods in enzymology, vol 161. Academic, Londan, pp 462–470

Alfonso C, Nuero OM, Santamaria E, Reyes F (1995) Purification of a heat-stable chitin deacety1ase from Aspergillus nidulans and its role in cell wall degradation. Curr Microbiol 30:49–54

Association of Official Analytical Chemist (2000) Official methods of analysis, 17th edn. Association of Official Analytical Chemist, Maryland

Araki Y, Ito E (1975) A pathway of chitosan formation in Mucor rouxii. Eur J Biochem 55:71–78

Binod P, Tunde P, Vivina N, Chandran S, George S, Istvan P, Asok P (2005) Production and purification of extracellular chitinase from Penicillium aculeatum NRRL 2129 under solid state fermentation. Enzyme Microb Technol 36:880–887

Binod P, Tunde P, Chandran S, Pradeep S, George S, Istvan P, Asok P (2007) Fungal biosynthesis of endochitinases and chitobiase in solid state fermentation and their application for the production of N-acetyl-D-glucosamine from colloidal chitin. Bioresour Technol 98:2742–2748

Cai J, Yang JH, Du YM, Fan LH, Qiu YL, Li J, Kennedy JF (2006) Purification and characterization of chitin deacetylase from Scopulariopsis brevicaulis. Carbohydr Polym 1–7

Chang WT, Chen YC, Jao CL (2007) Antifungal activity and enhancement of plant growth by Bacillus cereus grown on shellfish chitin waste. Bioresour Technol 98:1224–1230

Gao X, Katsumoto T, Onoder K (1995) Purification and characterization of chitin deacety1ase from Absidia coerulea. J Biochem 117:257–263

Kadokura K, Rokutani A, Yamamoto M, Ikegami T, Sugita H, Itoi S, Hakamata W, Oku T, Nishio T (2006) Purification and characterization of Vibrio parahaemolyticus extracellular chitinase and chitin oligosaccharide deacetylase involved in the production of heterodisaccharide from chitin. Appl Microbiol Biotechnol 75:357–365

Kafetzopoulos D, Martinou A, Bouriotis V (1993) Bioconversion of chitin to chitosan: Purification and characterization of chitin deacetylase from Mucor rouxii. Proc Natl Acad Sci USA 90:2564–2568

Kauss H, Bauch B (1988) Chitin deacetylase from Colletotrichum lindemuthianum. In: Willis AW, Scott TK (eds) Methods in enzymology, vol 161. Academic, Londan, pp 518–523

Kauss H, Jeblick W, Young DH (1983) Chitin deacetylase from the plant pathogen Colletotrichum lindemuthianum. Plant Sci Lett 28:231–236

Keisuke K (2006) Chitin and chitosan: functional biopolymer from marine crustaceans. Mar Biotechnol 8:203–226

Kim YJ, Yon Z, Oh KT, Nguyen VN, Park RD (2008) Enzymatic deacetylation of chitin by extracellualr chitin deacetylase from a newly screened Mortierella sp. DY-52. J Microbiol Biotechnol 18:759–766

Konstantinos G, Diomi M, Georgi N, Envangelos T, Poul C, Dimitris K, Basil JM (2004) Studies on N-acetyl-β-D-glucosanimidase produced by Fusarium oxysporum F3 grown in solid state fermentation. Process Biochem 39:599–1605

Kuk JH, Jung WJ, Kim KY, Park RD (2005) Enzymatic characteristics and applications of microbial chitin deacetylase. Kor J Microbiol Biotechnol 33:9–15

Martinou A, Tsigos I, Bouriotis V (1997) Preparation of chitosan by enzymatic deacetylation. In: Muzzarelli RAA, Peter MG (eds) Chitin handbook. European Chitin Society, Atec, Grottammare, Italy, pp 501–505

Mathew P, Nair KGR (2006) Ensilation of shrimp waste by Lactobacillus fermentum. Fish Technol 43:59–62

Nahar P, Ghonnade V, Deshpande V (2004) The extracellular constitutive production of chitin deacetylase in Metarhizium anisopliae: Possible edge to entomopathogenic fungi in the biological control of insect pests. J Invertebr Pathol 85:80–88

Nampoothiri KM, Baiju TV, Sandhya C, Sabu A, Szakacs G, Asok P (2004) Process optimization for antifungal chitinase production by Trichoderma harzianum. Process Biochem 39:1583–1590

Nopakarn R, Plikmol A, Yano S, Wakayama M, Tachiki T (2002) Utilization of shrimp shellfish waste a substrate for solid state cultivation of Aspergillus sp.S1-13: evaluation of a culture based on chitinase formation which is necessary for chitin assimilation. J Biosci Bioeng 93:550–556

Pandey A, Selvakumar P, Soccol CR, Nigam P (1999) Solid state fermentation for the production of industrial enzymes. Curr Sci 77:49–162

Pankaj P, Deepti A, Tushar B, Shidhar P (2005a) Chitinase production by Beauveria feline RD 101: optimization of parameters under solid substrate fermentation conditions. World J Microbiol Biotechnol 21:93–95

Pankaj P, Deepti A, Tushar B, Shridhar P (2005b) Optimization of process parameters for chitinase production by soil isolates of Penicillium chrysogenum under solid state fermentation. Process Biochem 40:2962–2967

Paul DB, Quan G, Thomas RAM, Michael H, Jaime LM (2007) Modification of chitin properties for enzymatic deacetylation. J Chem Technol Biotechnol 82:165–173

Prabhu GN, Chandrasekaran M (1996) L-Glutaminase production by marine Vibrio costicola under solid-state fermentation using different substrates. J Mar Biotechnol 4:176–179

Rachel CK, Ilan C (1998) The molecular biology of chitin digestion. Curr Opin Biotechnol 9:270–277

Ressing JL, Strominger JL, Leloir LF (1955) A modified colorimetric methods for estimation of N-acetyl amino sugars. J Biochem 217:959–962

Shimahara K, Takiguchi Y (1988) Preparation of crustacean chitin. In: Willis AW, Scott TK (eds) Methods in enzymology, vol 161. Academic, Londan, pp 417–423

Smith RJ, Grula EA (1983) Chitinase is an inducible enzyme in Beauveria bassiana. J Invertebr Pathol 42:319–326

Spinelli J, Lehman L, Wieg D (1974) Composition, processing and utilization of red crab (Pleronodes planipes) as an aquaculture feed ingredient. J Fish Res Board Can 31:1025–1030

STATSOFT (1999) Statistica for windows. Statsoft, Tulsa, UK

Suraini A-A, Teoh LS, Noorjahan A, Neelam S, Kamarulzaman K (2008) Microbial degradation of chitin materials by Trichoderma virens UKM1. J Biol Sci 8:52–59

Suresh PV, Chandrasekaran M (1998) Utilization of prawn waste for chitinase production by the marine fungus Beauveria bassiana by solid state fermentation. World J Microbiol Biotechnol 14:655–660

Suresh PV, Chandrasekaran M (1999) Impact of processes parameters on chitinase production by an alkalophilic marine Beauveria bassiana in solid state fermentation. Process Biochem 34:257–267

Synowiecki J, Al-Khateeb NA (2003) Production, properties and some new applications of chitin and its derivatives. Crit Rev Food Sci Nutr 43:45–171

Tokuyasu K, Kameyama MO, Hayashi K (1996) Purification and characterization of extracellular chitin deacety1ase from Colletotrichum lindemuthianum. Biosci Biotechnol Biochem 60:598–1603

Tokuyasu K, Ono H, Ohnishi-Kameyama M, Hayashi K, Mori Y (1997) Deaetylation of chitin oligosaccharides of dp 2-4 by chitin deacetylase from Colletotrichum lindemuthianum. Carbohydr Res 303:353–358

Tsigos I, Bouriotis V (1995) Purification and characterization of chitin deacetylase from Colletotrichum lindemuthianum. J Biol Chem 270:26286–26291

Tsigos I, Nathalie Z, Aggeliki M, Alain D, Bouriotis V (1999) Mode of action of chitin deacetylase from Mucor rouxii on N-acetylchitooligosaccharides. Eur J Biochem 261:1–9

Tsigos I, Aggeliki M, Dimitris K, Bouriotis V (2000) Chitin deacetylase: new versatile tools in biotechnology. TIBTECH 18:305–312

Win NN, Stevens WF (2001) Shrimp chitin as substrate for fungal chitin deacetylase. Appl Microbiol Biotechnol 57:334–341

Yoyi M, Gerardo SC, Sergio R, Keiko S (2004) Production of β-N-acetylhexosaminidase of Verticillium lecanii by solid state and submerged fermentation utilizing shrimp waste silage as substrate and inducer. Process Biochem 39:665–671

Acknowledgement

Thanks to Director, CFTRI, Mysore for encouragement and permission to publish this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Suresh, P.V., Sachindra, N.M. & Bhaskar, N. Solid state fermentation production of chitin deacetylase by Colletotrichum lindemuthianum ATCC 56676 using different substrates. J Food Sci Technol 48, 349–356 (2011). https://doi.org/10.1007/s13197-011-0252-0

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-011-0252-0