Abstract

This work presents an “in situ” spectroelectrochemical study of the ethanol oxidation reaction on Pt/C electrocatalysts prepared by the polymeric precursor method. Characterization of the electrocatalysts was performed with X-ray diffraction, Raman spectroscopy, and cyclic voltammetry measurements. The average crystallite size was estimated as 7 nm, in agreement with the value reported in the literature for these types of electrocatalysts. The cyclic voltammetry characterization in an acidic medium presented the expected voltammetric behavior for polycrystalline Pt/C. The ethanol oxidation process was successfully employed “in situ”, making use of an optical probe for excitation and collection of the Raman scattering signal. In this configuration it was possible to track the formation of the main products—CO, CO2 indirectly, acetaldehyde, and acetic acid—and to measure the decay of the ethanol concentration. The results indicate that the optical probe-based Raman spectroscopy technique is a very effective tool for studying “in situ” electrochemical oxidation reactions of ethanol. It might also be a very promising characterization technique for studies of the “in situ” electrochemical oxidation of small organic molecules.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Currently, ethanol electroxidation on Pt-based electrocatalysts is one of the most intensively studied subjects in surface (interfacial) electrochemistry [1–5]. Ethanol is safer, can be produced in great quantities from biomass [6], and, when compared with methanol, has a higher energy density (8.01 vs 6.09 kWh kg−1) [7]. Thus, ethanol is considered to be a more attractive fuel for direct alcohol fuel cells.

The main challenge for the wide development of direct ethanol fuel cells and new catalytic materials technologies is the lack of detailed knowledge concerning the reaction mechanism. Currently, in spite of the lack of conclusive information concerning the ethanol oxidation process, it is well accepted that in acidic solutions the reaction proceeds through a series of parallel reactions, summarized in the following scheme [8]:

The complete electro-oxidation of ethanol to CO2 involves the cleavage of the C–C bond, which requires rather high activation energy. In this process two adsorbed intermediates, C1ad and C2ad, with one and two carbons, respectively, are formed. Small C1 and C2 intermediates are of special interest due to their direct oxidation in energy-conversion designs, such as fuel cell devices [9, 10]. Therefore, their identification in methanol, ethanol, and formic acid on platinum-group metals had been widely investigated [11, 12].

Unfortunately, it is impossible to discuss the detailed mechanism of electro-oxidation based only on cyclic voltammetry and chronoamperommetry. The superficially adsorbed intermediate species of organic molecular oxidation processes have usually been identified by surface analytical techniques such as “in situ” IR spectroscopy [10–13], sum frequency generation [14], differential electrochemical mass spectrometry [15–17], ellipsometry [18], and others. The main limitation of these techniques lies in the high quality requirements of the surface in order to get reliable spectral data. Usually, smooth or single crystalline electrodes are able to fulfill these requirements; however, there are many papers that used carbon supported nanoparticles [19–22] using a gold disc as substrate for working electrodes, because both its reflective properties and its good quality spectra. Thus, the development of more versatile experimental probes to monitor the electrochemical process in highly roughened electrode surfaces without reflective supports as, for example, gold disc is of obvious interest.

In this way, the inelastic scattering of light by Raman spectroscopy could be assigned as a useful probe to obtain spectral information on diverse surface bonding, revealing details about the nature of the surface interaction, coverage, and co-adsorption. This is of great practical importance when applied to surface catalytic processes, such as C1 and C2 oxidation, especially under vigorous reaction conditions [11]. One example of the potential of this technique is the pioneering work of Ren et al. [23], which studied methanol oxidation in an aqueous sulfuric acid solution as a function of the surface roughness of platinum. Surface-enhanced Raman spectroscopy has also been performed [9, 11, 24–29] on some rough transition metal electrodes to detect species produced during electrochemical redox processes [24–31]. However, to the best of our knowledge, all “in situ” Raman studies presented in the literature were restricted to the methanol case. Thus, this work concerns the “in situ” monitoring of the ethanol oxidation with electrocatalysts containing a very low Pt load on carbon by Raman spectroscopy.

Experimental

Preparation of Electrocatalysts

Pt/C (20% w/w on black carbon) electrocatalyst were prepared using the polymeric precursor method as described by De Souza et al. [32–34], and the mass ratio was 1:50:400 (metallic precursor/citric acid (CA)/ethylene glycol (EG)). The catalysts were prepared by placing a predetermined volume of each resin into an appropriate amount of carbon vulcan XC-72R (Cabot Corporation), followed by the addition of enough EG to cover the carbon powder. These mixtures were homogenized in an ultrasonic bath for over 60 min and then thermally treated at 400 °C for 2 h in a N2 atmosphere.

Physical Characterization

The crystalline structures of the investigated catalysts were determined by using the powder X-ray diffraction (XRD) technique. The data were recorded with a Rigaku diffractometer (Miniflex model), using Cu KR radiation source (1.5406 Å, 30 kV, and 15 mA). Approximately, 30 mg of the powdered samples was placed in a glass sample holder and compressed with a glass slide to obtain a uniform distribution. The 2θ Bragg angles were scanned over a range of 30–70° at a rate of 2°/min with a 0.02° angular resolution.

Electrochemical Measurements

Electrochemical measurements were performed at room temperature using an Autolab PGSTAT 302N potentiostat. Glassy carbon (GC) electrodes were employed as support for the working ones (0.166 cm2 of geometric area). In a three-compartment electrochemical cell, a large Pt ring was used as a counter electrode. All potentials were referred to a reversible hydrogen electrode. Before each experiment, the GC support was polished with alumina suspension (1 μm) to a mirror finish and washed in a mixture of ethanol and water. We used Milli-Q water (Millipore®) in all experimental procedures.

The working electrodes were constructed by dispersing 10 mg of electrocatalyst powder in 1 ml water and mixing for 5 min in an ultrasonic bath. Soon afterwards, 20 μl of 5% Nafion® solution was added to the suspension, and it was mixed again in an ultrasonic bath for 15 min. Aliquots of 16 μl of the dispersion fluid were pipetted onto the GC surface. Finally, the electrode was dried at 60 °C for 20 min and hydrated for 5 min in water.

The cyclic voltammetric and chronoamperometric experiments were performed in solutions of (1) 0.5 mol L−1 HClO4 and (2) 0.5 mol L−1 HClO4 plus 2 mol L−1 of ethanol.

“In Situ” Raman Spectroscopy

The “in situ” Raman setup consisted of a tunable Lithrow-configuration diode laser with =785 nm (Sacher Lasertechnik) for Raman excitation, a spectrometer (PiActon SpectraPro model 2500i) equipped with a N2-cooled CCD detector (Princeton Instruments Spec-10) and an optical probe (EMVISION LLC) for both exciting and collecting the signal. Attached to the spectrometer end of the optical probe, there was a set of notch filters for stray-light removal. All measurements were made in the backscattering configuration. The laser power was fixed to 40 mW on the sample, and the typical acquisition time was 60 s.

Experimental Arrangement

The experimental apparatus for the Raman measurements were taken making use of a commercial optical fiber probe (EMVISION LLC). This optical probe is composed of a set of seven 600 μm diameter optical fibers arranged as shown on Fig. 1a below. In this setup the central fiber deliver the laser light to the sample and the other six collect the scattered light. Thus the laser spot had 600 μm of diameter. The best signal to noise ratio was found positioning the fiber 3 mm above the electrode. The solution layer was nearly 2 mm above the electrode as shown in Fig. 1b.

Results and Discussion

Characterization of Pt/C Eletrocatalysts

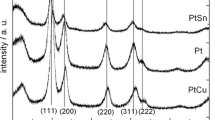

The XRD peak pattern analysis was carried out to estimate the mean crystallite sizes and also for the structural characterization of the Pt/C electrocatalysts. It is well known that it is possible to estimate the average particle size from XRD data, which are in good agreement with transmission electron microscopy data (less than 6% deviation) [35].

Figure 2a shows the XRD diffractogram of the Pt/C electrocatalysts prepared using the precursor solution 1/50/400 (Pt/CA/EG) mass ratio and thermally treated at 400 °C. The characteristic (1 1 1), (2 0 0), and (2 2 0) Pt Bragg peaks were observed at 2θ = 39.800o, 46.200o, and 67.460o, respectively, in good agreement with the Pt standard (JCPDS PDF#04-0802). The average crystallite size was estimated applying the Debye–Scherrer equation [36] to the (1 1 1) reflection. The value obtained was 7 nm, in agreement with that reported on literature for this kind of electrocatalyst [37, 38].

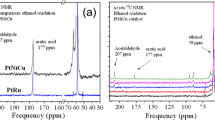

a XRD diffractogram of the Pt/C electrocatalysts. The characteristic (1 1 1), (2 0 0), and (2 2 0) Pt Bragg peaks were observed at 2θ = 39.800°, 46.200°, and 67.460°, respectively. b Voltammetric profile for the Pt/C electrocatalyst in acidic medium: HClO4 aqueous solution (0.5 mol L−1), scan rate = 10 mV s−1. c) “In situ” Raman spectra of the Pt/C electrocatalyst immobilized with Nafion® suspension at the glass carbon electrode, under three conditions: in air (curve I), in HClO4 aqueous solution (0.5 mol L−1) (curve II), and in an aqueous solution of HClO4 (0.5 mol L−1) plus 1 mol L−1 of ethanol (curve III). Characteristic vibrational bands are also shown

The typical voltammetric profile for the Pt/C electrocatalyst in an acidic medium is presented in Fig. 2b. The fairly resolved Pt features (hydrogen adsorption/desorption and formation and reduction of PtO) are in accordance with those discussed in the literature [32, 38, 39].

Figure 2c shows the “in situ” Raman spectra of the Pt/C electrocatalyst immobilized with Nafion® suspension at the GC electrode, under three conditions: (1) in air (spectrum I), (2) in HClO4 aqueous solution (0.5 mol L−1) (spectrum II), and (3) in an aqueous solution of HClO4 (0.5 mol L−1) plus 2 mol L−1 of ethanol (spectrum III).

In spectrum I, it is possible observe the D and G bands of carbon at 1,338 and 1,593 cm−1 [38, 40, 41], respectively. Additionally, bands at 794, 974, and 1,166 cm−1 could be assigned to ν (C–S), νs (C–O–C), and ν (CF2) of Nafion® [42]. The flat band at 1,938 cm−1 corresponds to ν2 (OH) [42].

Spectrum II presented only one new band at 934 cm−1, which corresponds to ν (Cl–O4) of HClO4 [43].

In addition to the above-cited vibrational bands, spectrum III presented two characteristic bands of ethanol at 882 and 1,456 cm−1 (νs (C–C–O) [44, 45] and δ (C–O–H) [42, 45], respectively) and three remaining tiny bands at 1,051, 1,095, and 1,276 cm−1, associated with νa (C–C–O) [45], γ (C–O–H) [44, 45], and t (CH2) + δ (C–O–H) [44–46], respectively.

Electrochemical Profiles for Ethanol Oxidation on Pt/C Electrocatalysts

Figure 3 presents the cyclic voltammetry and chronoamperommetry (inset) results for the ethanol oxidation reaction on Pt/C electrocatalysts in an acidic medium. To the best of our knowledge, this is the first reported profile concerning the precursor polymeric method to obtain only Pt/C as an electrocatalyst. The observed feature is in agreement with those reported by several papers [4, 17, 47]. The observed onset potential for the ethanol oxidation was close to 0.35 V, which is lower than that found in the literature (0.38 V) [17]. Furthermore, it is important to stress that the chronoamperometric curve presents a high current density of 5.2 mA mg −1Pt compared with that observed in the literature for the same process [17]. We can understand these findings by recalling that we are working with higher ethanol concentrations.

“In Situ” Raman Results

The Raman spectra obtained along the ethanol oxidation process are shown in Fig. 4. At zero voltage, almost all bands presented well defined and intense shapes. By increasing the potential, the intensity and linewidth of several peaks were modified. In order to associate these changes with increasing or decreasing concentrations of specific species produced during the ethanol oxidation, all bands were deconvoluted to Lorentzian lineforms. Thus, the intensity and linewidth of each band were individually analyzed. In this work, we will focus on only the intensity variations (Fig. 5). Unfortunately, some weak vibrational bands were superimposed with other ones, smearing out their voltage dependence. In particular, this occurred with the D band (1,338 cm−1) and δ (C–O–H) (1,453 cm−1).

Voltage dependence of the vibrational band intensities, acquired for deconvoluted to Lorentzian lineforms of all bands shown in Fig. 4. (More details in text.)

Figure 5a shows the voltage dependence of the ν (C–S), γ (C–H), and G band intensities. The band at 2,415 cm−1 remained unidentified. A commonly observed feature was the sudden and strong intensity decrease (∼1/3) when setting 50 mV voltage. Recalling that all these bands are related to electrode compositional elements (Nafion and carbon), this decrease could originate from the adsorption of intermediate species on the electrode. At 0.35 V, a transient intensity decrease was observed in all bands. This point coincides with the onset of the oxidation process. For higher voltages, all bands, except the G band, show a smooth decreasing behavior. The G band intensity behavior needs to be considered with relative care due to the presence of a shoulder at 1,587 cm−1. This shoulder is probably due to (C = C) vibration [45], which could be related to intermediates of ethanol oxidation. Above 0.35 V, this shoulder collapses into the G-band position, and the reported intensity behavior is a superposition of these two species. An almost constant G-band intensity is expected. Otherwise, the 1,587 cm−1 shoulder intensity could vary in a complex way.

Figure 5b shows the behavior of four ethanol bands: νs (C–C–O), νa (C–C–O), ν (C–O–H), and γ (C–O–H). A transient intensity decrease at 0.35 V was also observed in all cases. Due to ethanol consumption, all bands displayed a consistent intensity decreasing.

Figure 5c shows the voltage dependence of the t (CH2) + δ (C–O–H) (1,274 cm−1) [44, 46] and δ (C = O) (1,695 cm−1) [48] band intensities, these bands could be assigned to acetic acid and acetaldehyde respectively. Several works using FTIR in situ have also reported the formation of acetic acid and acetaldehyde in the ethanol oxidation process on different substrates [11, 14, 22, 49–52]. Giz et al. [49] studying ethanol oxidation reaction on Pt report the appearance of acetaldehyde and acetic acid bands at 0.38 V. Regarding the band associated to acetic acid on Pt it has been observed in the literature an stabilization of the intensity near at 0.9 V [51] including experiments on Pt single crystals as substrates [11, 49, 53]. This behavior is in agreement with one here measured as can be seen in Fig. 5c. Another similarity here found with the literature [49] is that acetaldehyde band which starts decreasing at 0.75 V.

In the experiment of Fig. 5 the intensity of acetaldehyde production is lower than the one for acetic acid and CO2. This fact is associated to the products acetic acid and CO2 requires more oxygen [49, 50, 54]. As the set up here used was in atmospheric air it can be suggested that the oxygen excess favors acetic acid and CO2 production.

CO2 and CO are common and extensively measured during ethanol oxidation on Pt/C electrocatalysts [5, 14, 22, 52]. In the experiments here carried out it was possible to identify only CO. The bands for this specie was presented in Fig. 5d, ν (C–O) (1,912 cm−1), νs (C–O) (2,089 cm−1) [55], and νas (C–O) (2,158 cm−1) [56]. Regarding the behavior associated to CO it has been found in the literature [46, 47] both an increasing beginning at 0.3 V and a decreasing after 0.6 V. This feature is similar to one in Fig. 5d. Again, considering the literature for CO2 it has been observed that there is increasing band intensity from 0.8 up to 1.0 V. After that, there is a stabilization of the band intensity [11, 22, 49, 53] following by an increasing close to 1.1 V. This is what has been found in Fig. 5d, but for CO rather than CO2. For the reasons pointed out above, we can suggest that the increasing of CO bands intensities after 0.6 V could be associated to CO2 production from CO, since during ethanol oxidation CO2 produced depends on the breaking of C–C bond and formation of CO. As CO2 Raman active band shift (symmetric stretch) is only present at 1,340 cm−1 and in this case is overlapped with the d-band of carbon at 1,345–1,350 cm−1 and it is was not possible to measure, probably the increasing in the CO bands after 0.6 V are related to CO2 production from CO at the time of the experiment. One can see CO but not CO2, than we have a possible indirect measurement of CO2.

Conclusions

This work is the first detailed report employing an “in situ” Raman spectroelectrochemical setup for studying the ethanol oxidation process on Pt/C electrocatalysts. It was possible to trigger the formation of the main species produced during the electrochemical process, namely, CO, CO2 (indirectly), acetic acid, and acetaldehyde. Furthermore, one of the two carbons intermediates was detected as well as the consumption of the ethanol. Besides, the data obtained using Raman “in situ” are complementary of the ones obtained using “in situ” FTIR reported in the literature. Other important point of this technique is the possibility of obtain spectra without use a reflective substrate, required for the FTIR “in situ” experiments. In others words, Raman spectroscopy technique “in situ” approach is very promising for the study of small organic molecule oxidation processes.

References

B.C.H. Steele, A. Heinzel, Nature 414, 345 (2001)

R. Dillon, S. Srinivasan, A.S. Aricò, V. Antonucci, J. Power Sources 127, 112 (2004)

S. Song, P. Tsiakaras, Appl. Catal. B 63, 187 (2006)

K.-S. Lee, I.-S. Park, Y.-H. Cho, D.-S. Jung, N. Jung, H.-Y. Park, Y.-E. Sung, J. Catal. 258, 143 (2008)

C. Coutanceau, S. Brimaud, C. Lamy, J.M. Léger, L. Dubau, S. Rousseau, F. Vigier, Electrochim. Acta 53, 6865 (2008)

G. Li, P.G. Pickup, J. Power Sources 161, 256 (2006)

C. Xu, P.K. Shen, J. Power Sources 142, 27 (2005)

E. Antolini, J. Power Sources 170, 1 (2007)

P. Cao, Q. Zhong, Y. Sun, R. Gu, Chem. Phys. Lett. 376, 806 (2003)

J.-T. Li, Q.-S. Chen, S.-G. Sun, Electrochim. Acta 52, 5725 (2007)

V. Pacheco Santos, V. Del Colle, R.B. de Lima, G. Tremiliosi-Filho, Electrochim. Acta 52, 2376 (2007)

G.A. Camara, R.B. de Lima, T. Iwasita, J. Electroanal. Chem. 585, 128 (2005)

J. Ribeiro, D.M. dos Anjos, K.B. Kokoh, C. Coutanceau, J.M. Léger, P. Olivi, A.R. de Andrade, G. Tremiliosi-Filho, Electrochim. Acta 52, 6997 (2007)

J.F. Gomes, B. Busson, A. Tadjeddine, G. Tremiliosi-Filho, Electrochim. Acta 53, 6899 (2008)

J. Barranco, A.R. Pierna, J. Power Sources 169, 71 (2007)

T. Seiler, E.R. Savinova, K.A. Friedrich, U. Stimming, Electrochim. Acta 49, 3927 (2004)

H. Wang, Z. Jusys, R.J. Behm, J. Power Sources 154, 351 (2006)

L. Zhou, S. Günther, D. Moszynski, R. Imbihl, J. Catal. 235, 359 (2005)

C. Lamy, S. Rousseau, E.M. Belgsir, C. Coutanceau, J.M. Leger, Electrochim. Acta 49, 3901 (2004)

F.C. Simões, D.M. dos Anjos, F. Vigier, J.M. Léger, F. Hahn, C. Coutanceau, E.R. Gonzalez, G. Tremiliosi-Filho, A.R. de Andrade, P. Olivi, K.B. Kokoh, J. Power Sources 167, 1 (2007)

M. Li, A. Kowal, K. Sasaki, N. Marinkovic, D. Su, E. Korach, P. Liu, R.R. Adzic, Electrochim. Acta 55, 4331 (2010)

J.M. Léger, S. Rousseau, C. Coutanceau, F. Hahn, C. Lamy, Electrochim. Acta 50, 5118 (2005)

B. Ren, X.Q. Li, C.X. She, D.Y. Wu, Z.Q. Tian, Electrochim. Acta 46, 193 (2000)

M. Bron, R. Holze, Surf. Sci. 457, 178 (2000)

J. Solla-Gullón, R. Gómez, A. Aldaz, J.M. Pérez, Electrochem. Commun. 10, 319 (2008)

Y.-C. Liu, K.-H. Yang, L.-H. Lin, J.-F. Tsai, Electrochem. Commun. 10, 161 (2008)

T. Marui, S. Kajita, Y. Katayama, K. Chiba, Electrochem. Commun. 9, 1331 (2007)

R. Mazeikiene, G. Niaura, A. Malinauskas, Electrochim. Acta 51, 5761 (2006)

H.J. Salavagione, J. Arias-Pardilla, J.M. Pérez, J.L. Vázquez, E. Morallón, M.C. Miras, C. Barbero, J. Electroanal. Chem. 576, 139 (2005)

K. Dokko, N. Anzue, M. Mohamedi, T. Itoh, I. Uchida, Electrochem. Commun. 6, 384 (2004)

K. Crowley, J. Cassidy, J. Electroanal. Chem. 547, 75 (2003)

R.F.B. De Souza, A.E.A. Flausino, D.C. Rascio, R.T.S. Oliveira, E.T. Neto, M.L. Calegaro, M.C. Santos, Appl. Catal. B 91, 516 (2009)

R.F.B. De Souza, L.S. Parreira, D.C. Rascio, J.C.M. Silva, E. Teixeira-Neto, M.L. Calegaro, E.V. Spinace, A.O. Neto, M.C. Santos, J. Power Sources 195, 1589 (2010)

A. S. Polo, M. C. Santos, R. F. B. de Souza, W. A. Alves, J. Power Sources 196, 872 (2011)

K.J.J. Mayrhofer, J.C. Meier, S.J. Ashton, G.K.H. Wiberg, F. Kraus, M. Hanzlik, M. Arenz, Electrochem. Commun. 10, 1144 (2008)

B.D. Cullity, Elements of X-ray diffaction (Addison-Wesley, Massachusetts, 1967), p. 262

L. Jiang, G. Sun, S. Sun, J. Liu, S. Tang, H. Li, B. Zhou, Q. Xin, Electrochim. Acta 50, 5384 (2005)

D. Yuan, S. Tan, Y. Liu, J. Zeng, F. Hu, X. Wang, P. Shen, Carbon 46, 531 (2008)

J.-G. Oh, C.-H. Lee, H. Kim, Electrochem. Commun. 9, 2629 (2007)

S. Liu, C. Cai, J. Electroanal. Chem. 602, 103 (2007)

A.E. Galetti, M.F. Gomez, L.A. Arrúa, M.C. Abello, Appl. Catal. A 348, 94 (2008)

V. Di Noto, R. Gliubizzi, E. Negro, M. Vittadello, G. Pace, Electrochim. Acta 53, 1618 (2007)

M. Ibrahim, M. Kuchinskas, H. Youn, R.L. Kerby, G.P. Roberts, T.L. Poulos, T.G. Spiro, J. Inorg. Biochem. 101, 1776 (2007)

B. Chazallon, Y. Celik, C. Focsa, Y. Guinet, Vib. Spectrosc. 42, 206 (2006)

R.J. LeBlanc, C.T. Williams, J. Mol. Catal. A 220, 207 (2004)

S.W. Lee, Y.-B. Shin, K.S. Jeon, S.M. Jin, Y.D. Suh, S. Kim, J.J. Lee, M.-G. Kim, Ultramicroscopy 108, 1302 (2008)

M.L. Calegaro, H.B. Suffredini, S.A.S. Machado, L.A. Avaca, J. Power Sources 156, 300 (2006)

G. Socrates, Infrared and Raman characteristic group frequencies: tables and charts, 3rd edn. (Wiley, West Sossex, 2004), p. 122

M.J. Giz, G.A. Camara, J. Electroanal. Chem. 625, 117 (2009)

M.J.S. Farias, G.A. Camara, A.A. Tanaka, T. Iwasita, J. Electroanal. Chem. 600, 236 (2007)

F.H.B. Lima, E.R. Gonzalez, Electrochim. Acta 53, 2963 (2008)

F. Vigier, C. Coutanceau, F. Hahn, E.M. Belgsir, C. Lamy, J. Electroanal. Chem. 563, 81 (2004)

X.H. Xia, H.D. Liess, T. Iwasita, J. Electroanal. Chem. 437, 233 (1997)

G.A. Camara, T. Iwasita, J. Electroanal. Chem. 578, 315 (2005)

A. Bruckbauer, A. Otto, Surf. Sci. 502–503, 394 (2002)

I. Mrozek, C. Pettenkofer, A. Otto, Surf. Sci. 238, 192 (1990)

Acknowledgements

The authors wish to thank the Brazilian Funding Institutions (CNPq 474742-32/2008-8), CAPES, and FAPESP (Processes Numbers: 05/59992-6, 301018/2006-5, 09/09145-6) and UFABC for their financial support. In addition, the authors thank Prof. Vera R.L. Constantino from IQ-USP for the use of the XRD instrument; Dr. Ângela A. Teixeira Neto for assistance with XRD analysis; and Prof. Dr. Airton A. Martin from UniVap for the use of the Raman instrumentation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

De Souza, R.F.B., Neto, É.T., Calegaro, M.L. et al. Ethanol Electro-oxidation on Pt/C Electrocatalysts: An “In Situ” Raman Spectroelectrochemical Study. Electrocatal 2, 28–34 (2011). https://doi.org/10.1007/s12678-010-0031-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12678-010-0031-0