Abstract

When the tunnel passes through the soft rock area, the deformation problem is unavoidable, which affects the construction of the tunnel. In this paper, a method is proposed to predict the deformation grade of soft rock tunnel. Six influencing factors of soft rock tunnel deformation are selected as evaluation indexes, including tunnel depth, excavation method, support closure time, groundwater condition, angle of bedding, and uniaxial compressive strength of rock. Vault subsidence and clearance convergence are selected as actual grading indexes, and the deformation grade was divided into four grades. The entropy weight method is used to calculate the weight of the actual grading index, and the excavation section deformation is graded based on extension theory. Then the weight of influencing factors is calculated based on rough set theory, and the main factors controlling deformation are highlighted. Finally, an extension prediction model of soft rock tunnel deformation grade is established and applied to the prediction of deformation grade of the Huangjiagou tunnel of the Zhengwan high-speed railway. The prediction model is in good agreement with the field observation results, and the accuracy rate reaches 90%, which provides a new idea for the prediction of deformation grade of soft rock tunnel.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, with the rapid development of global traffic construction, tunnel engineering construction has also made great progress. As underground engineering, tunnel engineering is faced with complex and diverse engineering environment, among which the problem of large deformation of soft rock with high stress has always been an important factor affecting project construction (Ping et al. 2016). When the tunnel passes through the soft rock area with high stress, the initial in-situ stress of the original rock will be released due to the excavation and unloading of the tunnel, and the stress of the surrounding rock will be redistributed, resulting in the deformation of the tunnel (Luo et al. 2018; Bian et al. 2017; Lai et al. 2018). If the deformation of surrounding rock is not effectively controlled, the deformation will continue to increase and eventually lead to tunnel instability and collapse (Hoek 2001). For example, Tauern highway tunnel in Austria (Steiner 1996), Bolu Mountain tunnel in Turkey (Brox and Hagedorn 1999; Dalgıç 2002), Chibbro-Khodri tunnel in India (Dwivedi 2013), Jieling tunnel (Wu et al. 2018), Zhegu Mountain tunnel (Meng et al. 2013), and Jiazhuqing (Zhang 2003) tunnel in China all suffered from different degrees of tunnel deformation and instability. The maximum deformation of vault subsidence and clearance convergence of the Jiazhuqing tunnel and Muzhailing tunnel is more than 1000 mm. Therefore, it is of great practical significance to study the deformation of soft rock tunnel with high stress and predict the deformation grade of the tunnel.

Many scholars at home and abroad have studied the deformation mechanism, control measures and deformation prediction of soft rock tunnel. Bian et al. (2017) studied the large deformation of soft rock in the Huangjiazhai tunnel through mineral composition monitoring, microstructure observation and in-situ stress test, and considered that the high stress and groundwater infiltration were the main reasons for the large deformation of surrounding rock. Based on the analysis of the soft rock characteristics and geological conditions of the Zhegu Mountain tunnel, Meng et al. (2013) concluded that the soft rock expansion was not the leading cause of the large deformation of the tunnel, and three mechanisms of large deformation of the tunnel, namely the plastic flow of the soft rock, the shear slide of the wedge and the bending of the thin layer of the soft rock, were proposed. Bizjak and Petkovek (2004) explained the development and evolution of the excavation failure zone in the surrounding rock of the tunnel by the analysis of displacement monitoring results of the Golovec tunnel. They calculated the stress field around the tunnel using the finite difference method. The results showed that the installation time and stiffness of the initial support are the essential factors affecting tunnel deformation. Based on a series of model development and experiments, Erguler and Ulusay (2009) explained that the uniaxial compressive strength and elastic modulus of rock would decrease with the increase of water content, thus proved the water is an important factor leading to tunnel deformation. Jiang et al. (2014) detected the weakening effect of water on soft rock intuitively using computerized X-ray tomography. Through real-time visual observation, the evolution mechanism of water-induced fracture was divided into three steps: water invasion, soft rock volume expansion, and fracture expansion. Li et al. (2010) used the Flac3D numerical simulation software to simulate the displacement, stress and plastic zone of soft rock tunnel after excavation, and proposed the failure mechanism of surrounding rock at the intersection of soft rock tunnel. Besides, a new support method was proposed, which can effectively restrain the deformation of surrounding rock: the Double-Bolt Control Technology (DBCT). Based on field investigation and deformation mechanics analysis, Wang et al. (2009) proposed two deformation mechanisms of soft rock tunnel: stress expansion type and structural deformation type. A rigid, flexible layer supporting technique was proposed, which successfully solved the problem of high stress and large deformation of soft rock tunnel. Anagnostou (1993) regarded the rock expansion during tunnel excavation as a process of hydraulic coupling, which can simulate the observed floor deformation in a real sense. In addition to the importance of seepage, the influence of rock strength was also explained.

The deformation prediction of soft rock tunnel has also attracted extensive attention from scholars. Guan et al. (2012) proposed a Markov geological prediction method, which uses a Bayesian method to update the geological parameters in the tunnel in real-time, to predict the deformation in front of the tunnel dynamically. Jiang (2007) proposed a nonlinear intelligent prediction method based on particle swarm optimization to predict the deformation of an underground cavern. Aydan et al. (1996) proposed a method for predicting the extrusion potential and degree of surrounding rock, which was applied to the deformation grade prediction of the circular tunnel, and the comparison between the predicted value and the actual observed value verified the applicability and effectiveness of the proposed method. Based on the Weighted Voting method, Zhang et al. (2020a, b) proposed a new classifier integration method. Seven independent machine learning classifiers were aggregated. By classifier ensemble, the prediction accuracy of rock extrusion problems in tunnels was improved. Agan (2016) studied a new rock mass classification system: RMQR, which was used to predict the risk of rock mass extrusion. With the development of computer technology, nonlinear prediction and artificial intelligence provide new ideas for solving complex problems. Mahdevari et al. (2013) used support vector machine (SVM) to establish the dynamic prediction model of tunnel convergence. Xue et al. (2020) used artificial neural network (ANN) to predict non-uniform deformation and established a deformation prediction model. However, artificial neural network has a complex structure and takes a long time to calculate.

Previous researches on deformation prediction of soft rock tunnels have made significant contributions. However, the degree of influence of various factors on tunnel deformation is rarely studied at present, and previous nonlinear prediction methods have shortcomings. In this paper, based on rough set theory and extension theory, the influence degree of each influencing factor on tunnel deformation is quantitatively analyzed, the main factors controlling tunnel deformation are highlighted, and the deformation grade prediction model is established. A flowchart of deformation risk assessment for soft rock tunnels is shown in Fig. 1.

Project overview

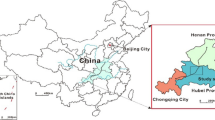

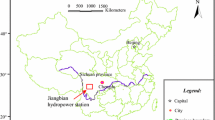

Huangjiagou tunnel of the Zhengwan high-speed railway is located in Hubei Province, with a total length of 7827 m and a maximum depth of 210 m. This area belongs to the low mountain landform area of tectonic erosion. The overall terrain is high in the middle and low on both sides, with an altitude of 380–859 m, and the terrain fluctuates wildly.

The rock stratum in the project area is sandy shale of Silurian Xintan formation (S1x), with argillaceous structure, bedding structure, developed joints and fissures, and relatively soft rock. The mineral composition is mainly clay minerals, with partial carbon content. Affected by the structure, the rock layer is thin-layered, with specular phenomena between layers and disordered occurrence. It contains a large amount of white calcite (Fig. 2a) and a weak intercalated layer (Fig. 2b).

The tunnel is located in the north wing of the inverted anticline of Jindou-Anzizhai and is in the fold belt of the Upper Yangtze block. It passes through the footwall of Tianjiagou reverse fault. The fault is located on the right side of the tunnel, and the line runs parallel to the tectonic fault line, 100–1000 m away from the line. Affected by the fault, the rock mass of the tunnel is broken, and the fault has a great influence on the surrounding rock of the tunnel.

The groundwater near the project area is mainly supplied by the bedrock fissure water. Bedrock fissure water occurs in the weathering and structural fissures of the shallow surface, mainly from atmospheric precipitation and surface water supply. The groundwater level changes significantly with the seasons. The rainy season is rich, while the dry season is poor. Because the sandy shale of the Silurian Xintan Formation contains carbonaceous locally, the groundwater in the tunnel body has certain erosiveness.

The New Austrian Tunneling Method is adopted to monitor the deformation of vault subsidence and clearance convergence (Fig. 3a) during the excavation process. The tunnel has been faced with serious collapse (Fig. 3b) and deformation (Fig. 3c) in the process of excavation. Therefore, some measures were taken to control the deformation (Fig. 3d).

Methodology

The deformation risk assessment of soft rock tunnel is a multi-objective evaluation and decision-making problem, and each factor is contradictory and mutually restricted. The key is to establish a comprehensive evaluation system and use reasonable algorithms to assign values to evaluation indexes. Commonly used nonlinear prediction methods include analytic hierarchy process, fuzzy comprehensive evaluation method, grey correlation theory and artificial neural network, which have their shortcomings. For example, the learning speed of artificial neural networks is slow, and the optimization function may make the training process pause. Analytic hierarchy process has strong subjectivity in determining weights. The results of fuzzy comprehensive evaluation are only determined by one or several factors, which will miss a lot of information. The weight of evaluation index is calculated by entropy weight method, which can avoid the interference of subjective factors. Rough set does not need to deal with any information outside the data set, through the known data to reveal the potential law. Extension evaluation can not only evaluate the risk level of surrounding rock deformation, but also determine its degree of bias to a certain level. Therefore, using entropy weight method-extension theory can make the parameters more objective and accurate. Finally, the processed parameters are used as the input parameters of rough set-extenics to establish the deformation risk assessment model of soft rock tunnel.

Entropy weight method

The concept of entropy was first proposed by Shen Nong in 1951. As an objective weighting method, the entropy weighting method is not affected by subjective factors. The weight is calculated based on the degree of uncertainty of each index (Wang et al. 2018).

In this paper, the entropy weight method is used to determine the weight of two kinds of tunnel deformation: vault subsidence and clearance convergence. The steps are as follows (Fang et al. 2020; Xie et al. 2019):

(1) The deformation grades are divided into \(m\) grades, with \(n\) evaluation indexes for each grade. The original data matrix \(A = (a_{ij} )_{m \times n}\) is constructed and \(A\) is standardized to obtain matrix \(B = (b_{ij} )_{m \times n}\):

where \(\max a_{j}\) and \(\min a_{j}\) are the maximum and minimum index values of the deformation grade under the jth evaluation index.

(2) Calculating the entropy \(e_{j}\)

where \(p_{ij} = {{b_{ij} } \mathord{\left/ {\vphantom {{b_{ij} } {\sum\nolimits_{i = 1}^{m} {b_{ij} } }}} \right. \kern-\nulldelimiterspace} {\sum\nolimits_{i = 1}^{m} {b_{ij} } }}\).

(3) Calculating the degree of variation coefficient \(d_{j}\),

where \(e_{j}\) is the entropy value of the evaluation index.

(4) Calculating the weight \(\omega_{j}\) of the \(j{ - }th\) index

Extension theory

The theory of extensions was first proposed by Cai Wen, a famous scholar in China (Cai 1998). Based on matter-element theory and extension set theory, extension theory aims to solve incompatible problems in the real world. At present, extension theory has been widely used in the field of civil engineering (Wang et al. 2015; Shang et al. 2013).

Based on extension theory, this paper classifies excavated sections' deformation levels and predicts the deformation levels of unexcavated sections. The steps are as follows (Qiao et al. 2020):

(1) Determining the classical field \(R_{oi}\) and node field \(R_{p}\)

where \(N_{{}}\) is the evaluation grade, \(C\) is the evaluation index, and \(V\) is the value range of the evaluation grade.

(2) Determining the matter-element \(R_{i}\) to be evaluated

where \(M\) is the thing to be evaluated.

(3) Calculating the correlation degree of the single index.

The correlation degree of every single index to every evaluation grade is as follows:

where

(4) Calculating the comprehensive correlation degree

where \(K_{i} (M)\) is the comprehensive correlation degree of the \(j{ - }th\) level, and \(\omega_{i}\) is the weight of the ith evaluation index. If \(K_{i} = \max \left\{ {K_{i} (M)} \right\}\), then, the grade of \(M\) is level \(i\).

Rough set theory

Rough set theory is a nonlinear mathematical method proposed by Polish scholar Z. Pawlak, which eliminates the uncertainty of data by discretization without any prior information, and is used for quantitative analysis of inaccurate, incomplete and inconsistent information (Zhang et al. 2016). At present, rough set theory has been widely used in geotechnical engineering (Xue et al. 2018, 2020).

In this paper, rough set theory is adopted to analyze the weight of the influencing factors. The specific steps include (Huang et al. 2020):

(1) Building the decision table.

As a knowledge representation system, the decision table can be defined as the division of \(U\) belonging to all possible relation pairs in \(R\), denoted as: \(F = (U,R)\), If \(R = C \cup D\) and \(C \cap D \ne \phi\), \(S = (U,R,C,D)\) is the decision table.

Where \(F\) is the knowledge base, \(U\) and \(R\) are all non-empty finite sets, \(C\) is the conditional attribute, \(D\) is the decision attribute.

(2) Calculating the dependence of decision attribute on conditional attribute.

where \(\left| {\gamma_{c} (D_{i} )} \right|\) is the compatibility number of samples, \(0 < k < 1\).

(3) Calculating the weight of the influencing factors.

After the deletion of the evaluation index \(i\), the dependence of the decision attribute on the conditional attribute is:

The weight coefficient of the conditional attribute set \(C\) is calculated as follows:

where \(\left| {\gamma_{{c - c_{i} }} (D_{i} )} \right|\) is the sample size after the evaluation index \(i\) is deleted, and \(\omega_{i}\) is the weight.

Rough set-extension prediction model

First, the weights of vault subsidence and clearance convergence were calculated by entropy weight method, and then the deformation classification of 30 tunnel sections is carried out by extension theory. Then, 30 groups of data and their deformation grades were used to establish a decision table, and the weights of 6 input parameters were calculated by rough set theory. Finally, the extension theory was used to establish the risk assessment model, and the accuracy of the model was verified by another 20 sets of data. (All calculations were performed in MATLAB).

Soft rock tunnel deformation risk evaluation system

Actual classification index of soft rock tunnel

The deformation monitoring of tunnel surrounding rock is a common means to ensure the safety of tunnel excavation (Kavvadas 2005; Zhang et al. 2020a, b), real-time deformation monitoring was carried out for the studied tunnel, and monitoring values of vault subsidence and clearance convergence were collected (Huang et al. 2017), obtain deformation information in time during excavation.

(1) Vault subsidence (A1).

The vault subsidence is the primary deformation type of soft rock tunnel, which reflects the vertical settlement of the tunnel. It is usually caused by the subsidence of the arch foot and mainly occurs before the closure of the initial support.

(2) Clearance convergence (A2).

The clearance convergence reflects the horizontal deformation of the tunnel, which will affect the stress distribution and the overall shape of the tunnel. If the convergence value is too large, it will lead to the cracking of the initial support and the collapse of the tunnel.

In summary, vault settlement and clearance convergence are selected as the actual indexes of tunnel deformation classification.

Influencing factors of soft rock tunnel deformation

According to the existing literature and engineering experience, the tunnel depth (B1), excavation method (B2), support closure time (B3), groundwater conditions (B4), angle of bedding (B5), the uniaxial compressive strength of rock (B6) are selected as the evaluation indexes of tunnel surrounding rock deformation risk.

(1) Tunnel depth (B1).

The tunnel depth refers to the vertical distance from the top of the excavation face to the ground. With the increase of the tunnel excavation depth, the rock mechanics characteristics and stress environment become more complex; correspondingly, the tunnel surrounding rock pressure and stress also increase (Li et al. 2013a, b), leading to greater deformation hazards (Sun et al. 2018). The tunnel depth will affect the stability of the surrounding rock (Li et al. 2019).

(2) Excavation method (B2).

The selection of tunnel excavation method is usually determined by factors such as tunnel length, section size, structure form, machinery and equipment, geological conditions. Different excavation methods have different disturbance degree and deformation control effect on tunnel surrounding rock (Zhang et al. 2015). In this study, the central diaphragm method (M1), three-bench seven-step excavation method (M2), three-bench method (M3), and two-bench method (M4) are adopted in the tunnel.

(3) Support closure time (B3).

Support closure time refers to the time from excavation to initial support closure, which varies with different excavation and support methods. The initial support should form a ring structure from top to bottom as soon as possible (Chen et al. 2020), and timely seal the invert, which can effectively reduce foundation disturbance.

(4) Groundwater conditions (B4).

The effects of groundwater on surrounding rock of the tunnel mainly include softening, segmentation and lubrication. When the soft rock contacts with water, the internal clay mineral will swell, disintegrate and soften rapidly, and its self-stabilization ability decreases, which causes the instability of the surrounding rock and the deformation of the initial support.

(5) Angle of bedding (B5).

The tunnel in this study is stratified soft rock tunnel, and bedding bias is the main unfavorable geology. The tunnel has a large bedding angle and a poor adhesion force between layers, and is prone to bedding slip and deformation under the action of compressive stress. In general, the larger bedding angle will lead to worse self-stability of the surrounding rock (Bai et al. 2021). For the surrounding rock with a smaller bedding angle (Fig. 4a), the horizontal convergence deformation is small, and the sidewalls on both sides will not produce large deformation failure. For the surrounding rocks with a larger bedding angle (Fig. 4b), slippage, collapse, and over-excavation often occur at the hollow position of the arch roof, and the arch waist part causes the deformation and collapse of the initial support, which leads to the staggered (Fig. 4c) and broken deformation of the initial support arch frame that has been completed on the arch roof (Fig. 4d).

(6) Uniaxial compressive strength (B6).

The uniaxial compressive strength of rock directly represents the strength of surrounding rock (Li et al. 2019). The higher the uniaxial compressive strength of rock, the greater the deformation resistance of surrounding rock. On the contrary, the lower the strength, the more likely the tunnel deformation.

In summary, tunnel depth, excavation method, support closure time, groundwater conditions, angle of bedding and uniaxial compressive strength are considered to be important factors in the analysis of soft rock tunnel deformation.

Tunnel deformation risk classification standard

The influencing factors of soft rock tunnel deformation are analyzed as the evaluation index of deformation grade prediction. The deformation of the soft rock tunnel is divided into four grades: small (I), medium (II), large (III), and very large (IV). Where, as a qualitative indicator, the excavation method (B2) and groundwater conditions (B4) are treated with standard discretization in Table 1, corresponding to four grades.

According to the characteristics of the tunnel and previous research (Bai et al. 2021; Xue et al. 2018), the quantitative standard is determined by sorting out the geological survey and deformation monitoring data in Table 2.

Results

The weight coefficient of vault subsidence A1 and clearance convergence A2 are determined by the entropy weight method. Weights are calculated according to Eqs. (1)–(5). The results show that the weights of vault subsidence and clearance convergence are 0.4714 and 0.5286, respectively.

Monitoring data of 30 representatives excavated sections of the Huangjiagou tunnel are collected in Table 3. Based on the monitoring data, the actual deformation grades of 30 tunnels are classified using the extension method (Eqs. (6)–(11)). The results are shown in Table 4. The deformation level (Table 4) is taken as the decision attribute set, and the influencing factor (B1–B6) as a set of conditional attributes, the samples collected for rough set theoretical analysis are shown in Table 5.

Based on the grading standards of various factors in Table 2, the values (Table 5) are converted into discrete values (I:1, II:2, III:3, IV:4) to construct the decision table in Table 6. Equations (12)–(14) are used for weight analysis. The results are shown in Table 7 and Fig. 5.

Based on the division standard (Table 2) and the weight of each influencing factor (Table 7), rough set-extension model is established to predict the deformation grade of the unexcavated tunnel section, among which the influencing factors (B1–B6) as the evaluation indexes. To verify the correctness of the model, the model is used to conduct deformation grading prediction for another 20 samples, and the prediction grade is compared with the actual grade in Table 8 and Fig. 6.

Based on rough set theory, this paper conducts a weight analysis on the influencing factors of deformation. According to Table 7 and Fig. 5, tunnel depth (B1), excavation method (B2), support closure time (B3), groundwater conditions (B4), angle of bedding (B5), the uniaxial compressive strength of rock (B6), respectively, 10%, 19%, 33%, 24%, 10%, and 4%.

The results showed that support closure time, groundwater conditions and excavation method account for a large proportion (33%, 24%, and 19%, respectively), while the tunnel depth, angle of bedding and the uniaxial compressive strength of rock account for a small proportion (10%, 10%, 4%, respectively).

The parameter of support closing time has the largest weight, account for 33% in total, which means the support closing time plays an important role in the deformation of the surrounding rock of soft rock tunnels. However, the tunnel in this study is deformed greatly and often stops and reworks, which leads to the extension of support closing time. Therefore, it is necessary to determine the standard of support closure time according to the specific conditions of the tunnel. Besides, attention should be paid to shorten the support closing time, and support as soon as possible. For example, shorten the length of the footage, implement the initial support in time, and implement the secondary lining in time after the deformation is stabilized.

As shown in the results of the weight analysis, the groundwater is a factor that cannot be ignored for the deformation of the surrounding rock. To reduce the negative effect of groundwater, the method of combining drainage and water plugging can be adopted. Through advanced geological forecast to judge the position of the water body, and then advance boreholes is drilled to divert and drain groundwater and centralized to the channel. In addition, advanced pre-grouting can be used to improve the strength and compactness of the surrounding rock to achieve the purpose of water shutoff.

The surrounding rock of the tunnel in this study is layered sandy shale with low strength, broken rock mass, poor integrity, and self-stability of the surrounding rock, which results in a large amount of vault subsidence and horizontal convergence. To reduce the deformation of the vault and sidewall, grouting reinforcement can be combined with lengthening and encrypting bolts. The over-excavation part should be filled with concrete and grouted in time, and the under-excavation part should be supplemented by blasting and trimming. Besides, advanced support measures should be adjusted in time, and vault and sidewall support should also be strengthened.

Twenty typical soft rock tunnel sections were selected to verify the accuracy of the model. Except for the 1st and 7th sections, the deformation prediction results were consistent with the actual situation. The predicted grade of these two sections was large (III), but the actual grade was medium (II). Due to the instability of the tunnel face in the process of excavation, the construction personnel took measures such as grouting and strengthening advance support to control the deformation. Because these measures are not considered in the prediction model, the predicted deformation grade is higher than the actual grade.

In the construction process, the deformation risk grade can be obtained by the prediction model. If the predicted deformation grade of this section is high (III or IV), advance support, drainage, grouting reinforcement and other measures can be taken in advance. If the deformation grade is low (I or II), the support can be appropriately strengthened according to the construction site. Thus provide a reference for tunnel construction and ensure safety.

Discussion

Comparison with previous prediction methods

The rough set-extension model proposed in this paper is compared with the Artificial neural networks (ANN), extreme learning machine (ELM), wavelet neural network (WNN), and other machine learning prediction models, and the results are shown in Table 9. Compared with other machine learning models, the proposed rough set-extension prediction model achieved excellent results, with accurate predictions for 20 sets of data selected in this paper, with 90% accuracy. In the case of less samples, the accuracy of rough set-extension model is higher.

Limitations

Although the rough set-extension prediction model achieved satisfactory results, the model has some limitations and needs to be further solved in future research. There are many influencing factors for the deformation risk assessment of soft rock tunnels. Six most representative influencing factors are selected for deformation analysis, and other factors need to be further considered in future research, such as blasting disturbance, drilling location, and explosive quantity. In addition, the classification standard of soft rock tunnel deformation risk assessment is established based on the actual tunnel project and previous research, which is not unalterable and needs further improvement in future research.

Conclusion

(1) In this paper, six influencing factors, including the tunnel depth, excavation method, support closure time, groundwater condition, angle of bedding, and uniaxial compressive strength of rock, are selected as the evaluation indexes of soft rock tunnel deformation grade prediction. Vault subsidence and clearance convergence are selected as the actual classification indexes of excavation section deformation grade. The entropy weight method is used to calculate the weight of the actual grading index, and the weight of six influencing factors is analyzed based on rough set theory. The results show that support closure time, groundwater condition and excavation method are the most important factors to control deformation. These results provide scientific guidance for the actual construction.

(2) In this paper, the quantitative indexes are classified continuously, and the quantitative processing methods and classification standards for qualitative indicators are proposed. Based on the weight and grading standards of the influencing factors, a deformation grade prediction model is established using an extension method, which to predict the deformation grade of the unexcavated section. The deformation grade is divided into four levels: small (I), medium (II), large (III), and very large (IV), which provided a reference for deformation classification. Different classification standards should be selected for different research tunnels.

(3) Taking the Huangjiagou tunnel of the Zhengwan high-speed railway as an example, the prediction model of soft rock tunnel deformation grade is established. The predicted deformation grade is basically consistent with the actual deformation grade, and the accuracy rate reaches 90%, which verifies the reliability of the model.

References

Agan C (2016) Prediction of squeezing potential of rock masses around the Suru Water tunnel. Bull Eng Geol Environ 75:451–468

Anagnostou G (1993) A model for swelling rock in tunnelling. Rock Mech Rock Engng 26(4):307–331

Aydan Ö, Akagi T, Kawamoto T (1996) The squeezing potential of rock around tunnels: theory and prediction with examples taken from Japan. Rock Mech Rock Engng 29:125–143

Bai CH, Xue YG, Qiu DH, Su MX, Ma XM, Liu HT (2021) Analysis of factors affecting the deformation of soft rock tunnels by data envelopment analysis and a risk assessment model. Tunn Undergr Space Technol 116:104111

Bian K, Liu J, Liu ZP, Liu SG, Ai F, Zheng XQ (2017) Mechanisms of large deformation in soft rock tunnels: a case study of Huangjiazhai Tunnel. Bull Eng Geol Environ 78:1–14

Bizjak KF, Petkovšek B (2004) Displacement analysis of tunnel support in soft rock around a shallow highway tunnel at Golovec. Eng Geol 75:89–106

Brox D, Hagedorn H (1999) Extreme deformation and damage during the construction of large tunnels. Tunn Undergr Space Technol 14:23–28

Cai W (1998) Introduction of extenics. Syst Eng Theory Pract 1:76–84

Chen JX, Luo YB, Li Y, Zhao PY, Xu D, Wang QS (2020) The change of rock mass pressure of Lianchengshan tunnel. Environ Earth Sci 79:192

Dalgıç S (2002) Tunneling in squeezing rock, the Bolu tunnel, Anatolian Motorway, Turkey. Eng Geol 67:73–96

Dwivedi RD, Singh M, Viladkar MN, Goel RK (2013) Prediction of tunnel deformation in squeezing grounds. Eng Geol 161:55–64

Erguler ZA, Ulusay R (2009) Water-induced variations in mechanical properties of clay-bearing rocks. Int J Rock Mech Min Sci 46:355–370

Fang SS, Tian HT, Huang DZ, Liu WN (2020) Study on classification of stability of surrounding rock using entropy weight method and multi-dimensional cloud model. Saf Coal Mines 51(1):229–232

Guan ZC, Deng T, Du SZ, Li B, Jiang YJ (2012) Markovian geology prediction approach and its application in mountain tunnels. Tunn Undergr Space Technol 31:61–67

Hoek E (2001) Big Tunnels in Bad Rock. J Geotech Geoenviron Eng 127(9):726–740

Huang HW, Xiao L, Zhang DM, Zhang J (2017) Influence of spatial variability of soil Young’s modulus on tunnel convergence in soft soils. Eng Geol 228:357–370

Huang WH, Liu ST, Liu A, Wen QR, Qiu DH (2020) Dynamic risk assessment of tunnel construction process based on rough set and cloud model. HIGHWAY 5:329–333

Jiang AN (2007) Forecasting nonlinear time series of surrounding rock deformations of underground cavern based on PSO-SVM. Rock Soil Mech 28(6):1176–1180

Jiang Q, Cui J, Feng XT, Jiang YJ (2014) Application of computerized tomographic scanning to the study of water-induced weakening of mudstone. Bull Eng Geol Environ 73:1293–1301

Kavvadas MJ (2005) Monitoring ground deformation in tunnelling: current practice in transportation tunnels. Eng Geol 79:93–113

Lai JX, Wang XL, Qiu JL, Chen JX, Hu ZN, Wang H (2018) Extreme deformation characteristics and countermeasures for a tunnel in difficult grounds in southern Shaanxi. China Environ Earth Sci 77:706

Li SC, Wu J (2019) A multi-factor comprehensive risk assessment method of karst tunnels and its engineering application. Bull Eng Geol Environ 78:1761–1776

Li GF, He MC, Zhang GF, Tao ZG (2010) Deformation mechanism and excavation process of large span intersection within deep soft rock roadway. Min Sci Technol 20:28–34

Li PF, Zhao Y, Zhang DL, Wu D (2013a) Study of distribution laws of tunnel surrounding rock pressure based on field measured data statistics. Chin J Rock Mech Eng 32(7):1392–1399

Li PF, Zhou Y, Wu D (2013b) Calculation methods for surrounding rock pressure and application scopes. Chin Railw Sci 34(6):55–60

Li ZQ, Xue YG, Li SC, Qiu DH, Su MX, Zhao Y, Zhou BH (2019) An analytical model for surrounding rock classification during underground water-sealed caverns construction: a case study from eastern China. Environ Earth Sci 78:602

Luo YB, Chen JX, Chen Y, Diao PS, Qiao X (2018) Longitudinal deformation profile of a tunnel in weak rock mass by using the back analysis method. Tunn Undergr Space Technol 71:478–493

Mahdevari S, Haghighat HS, Torabi SR (2013) A dynamically approach based on SVM algorithm for prediction of tunnel convergence during excavation. Tunn Undergr Space Technol 38:59–68

Meng LB, Li TB, Jiang Y, Wang R, Li YR (2013) Characteristics and mechanisms of large deformation in the Zhegu mountain tunnel on the Sichuan-Tibet highway. Tunn Undergr Space Technol 37:157–164

Ping C, Wen YD, Wang YX, Yuan HP, Yuan BX (2016) Study on nonlinear damage creep constitutive model for high-stress soft rock. Environ Earth Sci 75:900

Qiao JG, Sun XT (2020) Extension stability evaluation model of soil-rock mixture slope of mountain roads based on rough set weighting. J Beijing Univ Technol 46(5):508–514

Shang JL, Hu JH, Mo RS, Luo XW, Zhou KP (2013) Predication model of game theory-matter-element extension for blastability classification and its application. J Min Saf Eng 30(1):86–92

Steiner W (1996) Tunnelling in squeezing rocks: Case histories. Rock Mech Rock Eng 29:211–246

Sun XM, Song P, Zhao CW, Zhang Y, Li G, Miao CY (2018) Physical modeling experimental study on failure mechanism of surrounding rock of deep-buried soft tunnel based on digital image correlation technology. Arab J Geosci 11:624

Wang SR, Liu ZW, Qu XH, Fang JB (2009) Large deformation mechanics mechanism and rigid-gap-flexible-layer supporting technology of soft rock tunnel. China J Highway Transp 22(6):90–95

Wang ZC, Wang C, Wang ZC (2018) The hazard analysis of water inrush of mining of thick coal seam under reservoir based on entropy weight evaluation method. Geotech Geol Eng 36:3019–3028

Wang MW, Xu XY, Li J, Jin JL, Shen FQ (2015) A novel model of set pair analysis coupled with extenics for evaluation of surrounding rock stability. Math Probl Eng 892549

Wu GJ, Chen WZ, Tian HM, Jia SP, Yang JP, Tan XJ (2018) Numerical evaluation of a yielding tunnel lining support system used in limiting large deformation in squeezing rock. Environ Earth Sci 77:439

Xie XG, Wang LO, Chen LY, Li WX, Zhao XW (2019) Risk assessment of the coal seam outburst based on entropy weight matter element extension. J Saf Environ 19(6):1869–1875

Xue YG, Zhang XL, Li SC, Qiu DH, Su MX, Li LP, Li ZQ, Tao YF (2018) Analysis of factors influencing tunnel deformation in loess deposits by data mining: a deformation prediction model. Eng Geol 232:94–103

Xue YG, Bai CH, Kong FM, Qiu DH, Li LP, Su MX, Zhao Y (2020) A two-step comprehensive evaluation model for rockburst prediction based on multiple empirical criteria. Eng Geol 268:105515

Zhang DM, Zhang BK, Liu ZG (2015) Impact of excavation procedures of shallow large cross-section tunnel with pipe-roofing and frozen soil on tunnel behavior and ground movement. Tunn Constr 35(11):1121–1126

Zhang QH, Xie Q, Wang GY (2016) A survey on rough set theory and its application. CAAI Trans Intell Technol 1:323–333

Zhang DM, Pang J, Ren H, Han L (2020a) Observed deformation behavior of Gongbei Tunnel of Hong Kong-Zhuhai-Macao Bridge during construction. Chin J Geot Eng 42(9):1632–1641

Zhang JF, Li D, Wang YH (2020b) Predicting tunnel squeezing using a hybrid classifier ensemble with incomplete data. Bull Eng Geol Environ 79:3245–3256

Acknowledgements

Much of the work presented in this paper was supported by the National Natural Science Foundations of China (grant numbers 41877239, 51379112, 51422904, 40902084, and 41772298), Key Technology Research and Development Program of Shandong Province (grant number 2019GSF111028), the Fundamental Research Funds of Shandong University (grant number 2018JC044), and the Natural Science Foundation of Shandong Province (grant number JQ201513).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xue, Y., Liu, H., Bai, C. et al. Extension prediction model of soft rock tunnel deformation grade based on entropy weight method and rough set. Environ Earth Sci 81, 24 (2022). https://doi.org/10.1007/s12665-021-10139-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-021-10139-1