Abstract

The chemistry of pore water plays an important role on the hydraulic and mechanical properties of compacted bentonite used as buffer/backfill material in the repository of high-level radioactive waste (HLW). In this study, a series of compacted GMZ bentonite specimen with a dry density of 1.7 Mg/m3 were prepared and initially saturated with NaCl solutions of different concentrations (0, 0.5, 1.0 and 1.5 mol/L), respectively. The drying process was brought forward on the specimens through increasing their suction by using vapor phase technique. During the drying process, the cracking behavior of the specimens was observed; the volume shrinkage and the water retention characteristics (WRCs) were investigated with the consideration of the chemistry. The results obtained show that the compacted specimen initially saturated with distilled water was observed with cracking when its suction increased to 82 MPa and others were found to crack off as their suctions increased to 139 MPa, while no cracks could be observed for the specimens below the suction of 82 MPa. For the confined specimens, volume shrinkage occurred with increase of the suction, accordingly changing their porosity; the void ratio of the specimens decreased as the suction of the soil increased and increased with the chemistry of the pore water. Meanwhile, the chemistry of the pore water has more significant impact on the WRCs of the specimens at a lower suction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nowadays, geological repository is being considered for disposal of high-level radioactive waste (HLW) in several countries such as China, Belgium, France, Germany, Japan and Sweden (Dixon et al. 2002; Nakashima 2004; Rodríguez et al. 2007; Ye et al. 2007; Hurel and Marmier 2010). For such a repository, the multi-barrier concept includes the natural barrier (host rock), engineering barriers made from bentonite-based materials (placed around waste containers or used as buffer/backfill elements) and the metal canisters in proper order [Swedish Nuclear Fuel and Waste Management Company (SKB), 2001]. Due to its high swelling behavior, low permeability property and good adsorption characteristics, compacted bentonite has been chosen as the first choice of buffer/backfill material in HLW repository. The swelling pressure of compacted bentonite makes it possible to maintain the stability of the repository structure; the low permeability and good adsorption make it possible to restrict the transfer of radionuclide released from the waste packages after possible failure of the canister (Zhang et al. 2004; Nguyena et al. 2005; Ye et al. 2007; Chen et al. 2012a, 2015). Up to now, several kinds of bentonites have been studied for this purpose, such as MX-80 (Nakashima 2006), FEBEX (Lloret and Villar 2007), Kunigel-V1 (Sato and Miyamoto 2004), and GMZ bentonites (Ye et al. 2009).

Once compacted bentonite is emplaced in the HLW repository at great depth, the hydraulic behavior is a key issue in this context. However, most studies till now refer to water flux in bentonite-based materials that are supposed to be homogeneous (Westsik et al. 1983; Cho et al. 1999; Ahn and Jo 2009; Ye et al. 2009, 2012; Wang et al. 2013a, b). In reality, there are technological voids existing between the canister and the bentonite bricks, among the bentonite bricks themselves, and between the bricks and the host rock (Chen et al. 2014). Once the repository is closed and local groundwater conditions are re-established, the compacted bentonite absorbs groundwater from the host rock and swells, thereby filling those technological voids. On the other hand, the saturation degree of compacted bentonite is likely to decrease by means of evaporation due to the high temperature of 50–210 °C originated from the waste canister (Garcia et al. 2006) or ventilation (Guillon et al. 2012); thus, the compacted bentonite experiences cyclic wetting/drying processes. Meanwhile, the chemical concentration of pore water in the repository varies with the geological environment, such as groundwater infiltration from surrounding rock, temperature increase due to nuclear decay, and chemical composition produced by concrete decay (Ye et al. 2009; Thyagaraj and Rao 2013). Therefore, the compacted bentonite is subjected to cyclic wetting/drying processes accompanied by cyclic salinization/desalination processes, which have a great effect on its hydro-mechanical behavior (Castellanos et al. 2008).

The drying of compacted bentonite and the evaporation of its pore water decrease its volume by shrinkage, thereby resulting in desiccation cracks (Uday and Singh 2013). Tang et al. (2011) investigated the shrinkage process of soil resulting from progressive drying; they found that the soil volume shrinkage was induced by water loss from the deformable pores. Morris et al. (1992) reported that the presence of cracks in soil resulted in decreasing the overall mechanical behavior and increasing the hydraulic properties. For example, the hydraulic conductivity of cracked soil is typically several orders of magnitude greater than that of intact soil (Boynton and Daniel 1985; Albrecht and Benson 2001; Chen et al. 2009). Thus, the understanding of volume shrinkage in compacted bentonite is an issue for the safety analysis of the HLW repository (Hallett and Newson 2005).

The water retention characteristics (WRCs) are widely used to describe unsaturated soil; its permeability functions, shear parameters, and volume change properties could be predicted based on its WRCs (Ye et al. 2013). Generally, the WRCs are affected by soil structure, mineralogy, dry density, initial water content, temperature, and confining conditions (Lu and Likos 2004; Villar and Lloret 2004; Thu et al. 2007; Thyagaraj and Rao 2010). For the HLW repository, the chemical environment at near field plays a very important role in the WRCs of compacted bentonite (Mata 2003; Mokni 2011; Ravi and Rao 2013). Many experiments for the WRCs of compacted bentonite showed that the measured total suction was higher for specimens saturated with salt solution than that saturated with distilled water, while the measured matric suction for specimens hydrated with salt water was smaller than that hydrated with distilled water (Mata 2003; Thyagaraj and Rao 2010; Mokni 2011; Ravi and Rao 2013). In addition, many empirical equations were developed for describing the WRCs of compacted bentonite taking into account the effects of dry density (Jacinto et al. 2009; Villar et al. 2010) or volume change (Gallipoli et al. 2003). However, in-depth research about the chemical effects of pore water on the WRCs of compacted bentonite is still scarce.

In the Chinese concept of the HLW disposal, Beishan in Gansu Province has been chosen as the preferred construction site (Ye et al. 2009). Previous in situ investigations indicated that the average total dissolved solids (TDS) of the groundwater in Beishan was 3–12 g/L, up to 80 g/L (Guo et al. 2001). Meanwhile, a local Na-bentonite named GMZ bentonite, collected from Gaomiaozi County (Inner Mongolia, China), has been selected as the first choice of buffer/backfill material because of its low permeability, high swelling property, and availability in huge amounts (Ye et al. 2010). Many experiments have been set up to investigate the hydraulic performance (Ye et al. 2009, 2012a), mechanical properties (Ye et al. 2013), and adsorption characteristics (Chen et al. 2012b, 2013, Chen et al. 2015a, b). Some attempts have also been made to study the effects of chemistry on its hydro-mechanical behavior (Ye et al. 2014a, b; Chen et al. 2015a). Definitely, investigation on the chemical effects on the hydro-mechanical behavior, such as volume change properties and WRCs, is of great importance for compacted GMZ bentonite.

In the present work, to investigate the chemical effects on GMZ bentonite, various concentrations of solution (0, 0.5, 1.0 and 1.5 mol/L) were considered for the specimen preparation. The drying process was conducted on the specimens through increasing their suction by using the vapor phase technique; the cracking behavior of the specimen surface was observed, the volume shrinkage properties and the WRCs of compacted bentonite were analyzed.

Materials and methods

Materials

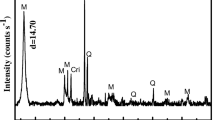

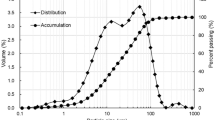

A local Na-bentonite named GMZ (GaoMiaoZi) bentonite tested in the present work was extracted from the northern Chinese Inner Mongolia autonomous region, 300 km northwest from Beijing. It presents a grain size of no more than 200 μm as shown in Fig. 1. The basic properties of this material are listed in Table 1 (Ye et al. 2012a). A high cation exchange capacity and adsorption ability can be identified. It appears that the proportion of montmorillonite is dominant in the GMZ bentonite, with a high smectite content of 75.4 %. The bulk chemical components of the sample were analyzed using the X-ray fluorescence spectrometry as follows (in mass): SiO2 67.43 %, Al2O3 14.20 %, TFe2O3 2.40 %, Na2O 1.75 %, CaO 1.13 %, K2O 0.73 %, FeO 0.29 %, TiO2 0.12 %, MgO 0.10 %, P2O5 0.02 %, MnO 0.02 %. Besides, GMZ bentonite also contains some lanthanon, such as La, Ce, and Nd (Chen et al. 2012a).

Specimen preparation

The cylindrical specimen of 20 mm diameter and 6 mm height was compacted at a dry density of 1.7 g/cm3. For specimen preparation, a given quantity of GMZ bentonite power with a water content of 11.76 % was statically compacted in a stainless steel ring mold to a target dry density. The displacement-controlled compaction method described by Ye et al. (2009, 2012b) was followed and the compaction speed was controlled at 0.1 mm/min. Once the target displacement was reached, the current load was kept for 60 min to minimize the possible rebound during the following unloading. Then, the vertical load was released and the compacted specimen was pushed out from the compaction mold at a rate of 0.2 mm/min (Fig. 2). Finally, the specimen was confined in ring preventing it from swelling deformation laterally.

Experimental methods

Firstly, the specimen was saturated with different concentrations of NaCl solution of 0 (distilled water), 0.5, 1.0 and 1.5 mol/L, respectively. After that, its corresponding water content was measured. Specifications of the compacted specimens prepared for this study are listed in Table 2.

Secondly, the specimen was subjected to a drying process through increasing its suction. In this process, the vapor phase technique proposed by Delage et al. (1998) was employed for controlling suction of the specimen. For a given saturated salt solution, specific relative humidity was found and the corresponding total suction could be calculated (Table 3). The drying process applied in the present work was induced by increasing suction from 4.2 to 139 MPa. Once a specimen was placed in a desiccator filled with the target saturated salt solution, it was regularly weighted until equilibrium was reached.

When the drying process was finished, the cracking phenomena on the specimen surface were observed by the microsoft for crack measurement (KON-FK(B)). This apparatus is composed of a probe, a host with a visual interface, a power supply and a USB cable. The host and the probe shown in Fig. 3 are the key components. Once cracking occurred on the specimen surface, the maximum width was measured and the crack pattern images were also recorded.

Lastly, the water content and density of the specimen were measured. The gravimetric water content w was measured by drying for 24 h at 105 °C in an oven. The density was measured using paraffin-coated specimens (ASTM 2002). Thereby, the void ratio of the specimen could be calculated as follows:

where w is water content, ρ is density, G s is specific gravity, and e is the void ratio of the specimen.

Results and discussion

Cracking behavior

The cracking patterns for the specimens initially saturated with different concentrations of the solution are shown in Fig. 4. It can be seen from Fig. 4 that the cracking occurred for the specimen initially saturated with distilled water (concentration = 0) when the suction increased to 82 MPa; the cracks were also observed for all the specimens when the suction increased to 139 MPa. Besides these, no cracks were found in the specimen surface when a lower suction was applied, indicating that the soil would not crack below the suction of 82 MPa.

Generally, when the microsoft for crack measurement is applied, the various shades of gray in the crack pattern images can reflect the water content of the specimen. It is obvious that the shade of the crack pattern image changed from charcoal gray to light gray when the suction of the specimen increased from 82 to 139 MPa. The phenomena indicated that more residual water retained in the specimen with a lower suction, which was also confirmed by the terminal water content of the specimen related to the corresponding suction. On the other hand, the maximum width of the crack was related to the initial concentration of the solution applied to saturate the specimen. It is evident that the maximum width of the crack in the specimen surface increased with increase of the initial solution concentration from 0 to 1.5 mol/L. Additionally, for each cracked specimen, the cracking patterns look like “T” shapes. Similar results were also reported by Tang et al. (2011).

Volume shrinkage

During the drying process, volume shrinkage was recorded for the specimen when the suction increased, resulting in its porosity change. The relationship between the void ratio (e) and the corresponding suction (s) is presented in Fig. 5. It can be seen from Fig. 5 that the void ratio of the specimen decreased as the suction increased. For the same suction, the void ratio of the specimen increased with the solution concentration conducted to saturate it. This phenomenon demonstrates that the chemistry of pore water plays a very important role in the volume change properties of compacted bentonite during the wetting/drying process.

Alonso et al. (1990) has pointed out that with the increasing suction in soil, the drying process may result in volume shrinkage and then a decrease in the void ratio. The vapor phase technique is usually employed to control the total suction in the specimen. At a given total suction, the specimen initially saturated with high concentration solution deservedly has a larger osmotic suction and consequently has a lower matric suction (Mata 2003; Mokni 2011; Zhang et al. 2012). According to the WRCs, a lower matric suction corresponds to a higher water content, resulting in a higher degree of hydration for the soil. Therefore, the specimen initially saturated with high concentration solution was hydrated and induced a large porosity.

The influence of suction variety on porosity can be described by the following equation (Alonso et al. 1990; Hu et al. 2013):

where s is the total suction (MPa), e is the void ratio at current suction, \(e_{0}\) is the initial void ratio, and \(\lambda\) is the deformation parameter related to suction.

Considering the different concentrations of the solution used in the test, the values of e 0 and \(\lambda\) presented in Fig. 5 can be fitted using Eq. (2):

where C is the concentration of the solution (mol/L).

Using Eq. (2), the simulated parameters are presented in Table 4 and the fitted results are shown in Fig. 5. It can be seen from Fig. 5 that Eq. (2) can satisfactorily describe the relationship between the void ratio of the soil and its suction with consideration of the chemistry effects of its pore water.

Changes of water content and porosity versus salt concentration for the specimen under a suction of 139 MPa are plotted in Fig. 6. As it can be seen, for the specimen under the suction of 139 MPa, the water content as well as its void ratio continuously decreased with increase of the chemistry of pore water. The explanation to this observation could be that under the high suction, the specimen which contained salt contracted sharply by the coupling effects of chemical consolidation and evaporation, resulting in cracking off in the soil (Barbouarn and Fredlund 1989). Therefore, increasingly more channels appeared in the interior of the specimen, increasingly more cracks occurred on the sample surface, and then increasingly more moisture was lost from the soil by evaporation.

Water retention characteristics

The WRCs for the confined compacted GMZ bentonite initially saturated with the solution were measured by following a drying path and the results are presented in Fig. 7. It can be observed from Fig. 7 that the chemistry of pore water has a considerable influence on the WRCs. For all the specimens initially saturated with different concentration solutions, the water content decreases as the suction increases. For a given suction, the water content increases with increase of the solution concentration, which means that the specimen saturated with a high concentration solution has a high water retention capacity. Furthermore, the effects of the chemistry on the WRCs also depend on the suction in soil. For lower suction (lower than 82 MPa), water retention capacity increases as the concentration increases, while for higher suction (higher than 82 MPa), the influence can be negligible, as confirmed by Fig. 7 that all the specimens have the same water content in the suction of 139 MPa. This observation could be interpreted that for low suction, the high saturation degree induced the increase of macro-pore size in the specimen (Mata 2003; Musso et al. 2013), which was enhanced by the increasing pore-water concentration. However, this phenomenon fades as the suction increases, which may result from the decreasing water content.

Many attempts have been made on modeling WRCs (van Genuchten 1980; Fredlund and Xing 1994; Houston et al. 2006). Among these, the study of the deformation effects on the WRCs is still scare (Gallipoli et al. 2003; Zhou et al. 2012). van Genuchten (1980) and Gallipoli et al. (2003) proposed the following equation to describe the water content variety for a deformable soil:

where a, φ, n, and m are model parameters.

Substituting Eqs. (2) and (3) into Eq. (1), the following equation can be obtained:

Combining Eqs. (5) and (6), the WRCs could be described for the confined compacted GMZ bentonite with the consideration of concentration of pore water and deformation of soil. In this study, the WRCs for the specimen were fitted by using Eqs. (5) and (6), and the parameters obtained are presented in Table 5 and the fitting curves are shown in Fig. 8. Comparison between the calculated results and the measured ones indicate that the proposed equations well describe the influences of the chemistry of pore water and the deformation of soil on the WRCs for the tested specimen.

Conclusions

In this study, the chemistry of pore water took into account the hydro-mechanical properties of compacted GMZ bentonite. The cracking behavior induced by the drying process was observed; the volume shrinkage resulted from increasing suction was also recorded. Finally, the water retention characteristics were analyzed with consideration of the influence of chemistry and deformation. Based on the obtained results, the main conclusions can be extracted as below:

-

1.

For compacted GMZ bentonite, the chemistry of pore water plays an important role on its cracking behavior during the drying process. The specimen initially saturated with distilled water was observed with cracking when its suction increased to 82 MPa and others were found to crack off as the suction increased to 139 MPa. No cracks could be observed for the specimen below the suction of 82 MPa.

-

2.

For confined specimen, volume shrinkage occurred with increase of the suction and accordingly changed its porosity. The void ratio of the specimen decreased as the suction increased and increased with the chemistry of pore water.

-

3.

The chemistry of pore water has a considerable influence on the WRCs. For all the specimens, the water content decreased as the suction increased. For a given suction, the water content increased with increase of the solution concentration. The chemistry of pore water has more significant impact on the WRCs at a lower suction.

References

Ahn HS, Jo HY (2009) Influence of exchange cations on hydraulic conductivity of compacted bentonite. Appl Clay Sci 44(1–2):144–150

Albrecht BA, Benson CH (2001) Effect of desiccation on compacted natural clay. J Geotech Geoenviron 127(1):67–75

Alonso EE, Gens A, Josa A (1990) A constitutive model for partially saturated soils. Géotechnique 40(3):405–430

ASTM D1188-96 (2002) Standard test method for bulk specific gravity and density of compacted bituminous mixtures using paraffin-coated specimens. American Society for Testing Material

Barbouarn SL, Fredlund DG (1989) Mechanisms of osmotic flow and volume change in clay soils. Can Geotech J 26:551–562

Boynton SS, Daniel DE (1985) Hydraulic conductivity tests on compacted clay. ASCE J Geotech Eng 111(4):465–478

Castellanos E, Villar MV, Romero E, Lloret A, Gens A (2008) Chemical impact on the hydro-mechanical behaviour of high-density FEBEX bentonite. Phys Chem Earth 33:516–526

Chen YG, Ye WM, Zhang KN (2009) Strength of copolymers grouting material based on orthogonal experiment. J Cent South Univ Technol 16(1):143–148

Chen YG, He Y, Ye WM, Lin CH, Zhang XF, Ye B (2012a) Removal of chromium(III) from aqueous solutions by adsorption on bentonite from Gaomiaozi, China. Environ Earth Sci 67(5):1261–1268

Chen YG, Zhu CM, Wu DB, Sun YH, Ye WM, Duan HY (2012b) Adsorption of La (III) onto GMZ bentonite: effect of contact time, bentonite content, pH value and ionic strength. J Radioana Nucl Ch 292(3):1339–1347

Chen YG, He Y, Ye WM, Sui WH, Xiao MM (2013) Effect of shaking time, ionic strength, temperature and pH value on desorption of Cr(III) adsorbed onto GMZ bentonite. Trans Nonferrous Met Soc China 23(11):3482–3489

Chen YG, Cui YJ, Tang AM, Wang Q, Ye WM (2014) A preliminary study on hydraulic resistance of bentonite/host-rock seal interface. Géotechnique 64(12):997–1002

Chen YG, He Y, Ye WM, Jia LY (2015a) Competitive adsorption characteristics of Na(I)/Cr(III) and Cu(II)/Cr(III) on GMZ bentonite in their binary solution. J Ind Eng Chem 26:335–339

Chen YG, Zhu CM, Ye WM, Cui YJ, Wang Q (2015b) Swelling pressure and hydraulic conductivity of compacted GMZ01 bentonite under salinization–desalinization cycle conditions. Appl Clay Sci 114:454–460

Cho WJ, Lee JO, Chun KS (1999) The temperature effects on hydraulic conductivity of compacted bentonite. Appl Clay Sci 14(1–3):47–58

Delage P, Howat MD, Cui YJ (1998) The relationship between suction and swelling properties in a heavily compacted unsaturated clay. Eng Geol 50:31–48

Dixon D, Chandler N, Graham J, Gray MN (2002) Two large-scale sealing tests conducted at Atomic Energy of Canada’s underground research laboratory: the buffer-container experiment and the isothermal test. Can Geotech J 39(3):503–518

Fredlund DG, Xing A (1994) Equations for the soil–water characteristic curve. Can Geotech J 31(3):521–532

Gallipoli D, Wheeler S, Karstunen M (2003) Modelling the variation of degree of saturation in a deformable unsaturated soil. Géotechnique 53(1):105–112

Garcia SG, Jonsson M, Wold S (2006) Temperature effect on the stability of bentonite colloids in water. J Coll Interface Sci 298:694–705

Guillon T, Giot R, Giraud A, Armand G (2012) Response of Callovo-Oxfordian clay stone during drying tests: unsaturated hydro-mechanical behavior. Acta Geotechnica 7:313–332

Guo YH, Yang TX, Liu SF (2001) Hydro-geological characteristics of Beishan preselected area, Gansu province for China’s high-level radioactive waste repository. Uranium Geol 17(3):184–189 (in Chinese)

Hallett PD, Newson TA (2005) Describing soil crack formation using elastic-plastic fracture mechanics. Eur J Soil Sci 56:31–38

Houston WN, Dye HB, Zapata CE, Perera YY, Harraz A (2006) Determination of SWCC using one point suction measurement and standard curves. Geotechnical special publication, American Society of Civil Engineers, Reston, VA 20191-4400, United States, Carefree, AZ, United States, pp 1482–1493

Hu R, Chen YF, Zhou CB (2013) A water retention curve model for deformable soils based on the pore size distribution. Chin J Geotech Eng 35(8):1451–1462

Hurel C, Marmier N (2010) Sorption of europium on a MX-80 bentonite sample: experimental and modelling results. J Radioanal Nucl Ch 284(1):225–230

Jacinto AC, Villar MV, Roberto GE, Alberto L (2009) Adaptation of the van Genuchten expression to the effects of temperature and density for compacted bentonites. Appl Clay Sci 42:575–582

Lloret A, Villar MV (2007) Advances on the knowledge of the therm-hydro-mechanical behaviour of heavily compacted “FEBEX” bentonite. Phys Chem Earth 32(8–14):701–715

Lu N, Likos WJ (2004) Unsaturated soil mechanics. Wiley, New York

Mata C (2003) Hydraulic behaviour of bentonite based mixtures in engineered barriers: the backfill and plug test at the ÄSPÖ HRL (Sweden). Ph.D. thesis, Technical University of Catalonia, Department of Geotechnical Engineering and Geosciences, School of Civil Engineering, Barcelona

Mokni N (2011) Deformation and flow driven by osmotic processes in porous materials. Ph.D. thesis, Department of Geotechnical Engineering and Geo-Science (ETCG), Technical University of Catalunya, UPC, Barcelona, Spain

Morris PH, Graham J, Williams DJ (1992) Cracking in drying soils. Can Geotech J 29:263–277

Musso G, Romero E, Della Vecchia G (2013) Double structure effects on the chemo-hydro-mechanical behaviour of compacted active clay. Geotechnique 63:206–220

Nakashima Y (2004) Nuclear magnetic resonance properties of water-rich gels of Kunigel-V1 bentonite. J Nucl Sci Technol 41:981–992

Nakashima Y (2006) H2O self-diffusion coefficient of water-rich MX-80 bentonite gels. Clay Miner 41:659–668

Nguyena TS, Selvadura APS, Armand G (2005) Modelling the FEBEX THM experiment using a state surface approach. Int J Rock Mech Min 42:639–651

Ravi K, Rao SM (2013) Influence of infiltration of sodium chloride solutions on SWCC of compacted bentonite-sand specimens. Geotech Geol Eng. doi:10.1007/s10706-013-9650-6

Rodríguez R, Sánchez M, Ledesma A, Lloret A (2007) Experimental and numerical analysis of desiccation of a mining waste. Can Geotech J 44:644–658

Sato H, Miyamoto S (2004) Diffusion behaviour of selenite and hydroselenide in compacted bentonite. Appl Clay Sci 26:47–55

Tang CS, Shi B, Liu C, Suo WB, Gao L (2011) Experimental characterization of shrinkage and desiccation cracking in thin clay layer. Appl Clay Sci 52:69–77

Thu TM, Rahardjo H, Leong EC (2007) Soil-water characteristic curve and consolidation behavior for a compacted silt. Can Geotech J 44:266–275

Thyagaraj T, Rao TT (2010) Influence of osmotic suction on the soil-water characteristic curves of compacted expansive clay. J Geotech Geoenviron Eng ASCE 136(12):1695–1702

Thyagaraj T, Rao SM (2013) Osmotic swelling and osmotic consolidation behaviour of compacted expansive clay. Geotech Geol Eng 31(2):435–445

Uday KV, Singh DN (2013) Investigation on cracking characteristics of fine-grained soils under varied environmental conditions. Dry Technol 31:255–1266

van Genuchten MTH (1980) A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci Soc Am J 44(5):890–898

Villar MV, Lloret A (2004) Influence of temperature on the hydro-mechanical behaviour of a compacted bentonite. Appl Clay Sci 26:337–350

Villar MV, Gómez-Espina R, Lloret A (2010) Experimental investigation into temperature effect on hydro-mechanical behaviours of bentonite. J Rock Mech Eng 2(1):71–78

Wang Q, Cui YJ, Tang AM, Barnichon JD, Saba S, Ye WM (2013a) Hydraulic conductivity and microstructure changes of compacted bentonite/sand mixture during hydration. Eng Geol 164:67–76

Wang Q, Tang AM, Cui YJ, Delage P, Barnichon JD, Ye WM (2013b) The effects of technological voids on the hydro-mechanical behavior of compacted bentonite-sand mixture. Soils Found 53(2):232–245

Westsik JH Jr, Hodges FN, Kuhn WL, Myers TR (1983) Water migration through compacted bentonite backfills for containment of high-level nuclear waste. Waste Manag 4(4):291–299

Ye WM, Schanz T, Qian LX, Wang J, Arifin Y (2007) Characteristics of swelling pressure of densely compacted gaomiaozi bentonite GMZ01. Chin J Rock Mech Eng 26:3861–3865

Ye WM, Cui YJ, Qian LX, Chen B (2009) An experimental study of the water transfer through confined compacted GMZ bentonite. Eng Geol 108:169–176

Ye WM, Chen YG, Chen B, Wang Q, Wang J (2010) Advances on the knowledge of the buffer/backfill properties of heavily-compacted GMZ bentonite. Eng Geol 116(1–2):12–20

Ye WM, Wan M, Chen B, Chen YG, Cui YJ, Wang J (2012a) Temperature effects on the unsaturated permeability of the densely compacted GMZ01 bentonite under confined conditions. Eng Geol 126:1–7

Ye WM, Zhang YW, Chen B, Zheng ZJ, Chen YG, Cui YJ (2012b) Investigation on compression behaviour of highly compacted GMZ01 bentonite with suction and temperature control. Nucl Eng Des 252:11–18

Ye WM, Zhang YW, Chen YG, Chen B, Cui YJ (2013) Experimental investigation on the thermal volumetric behaviour of highly compacted GMZ01 Bent. Appl Clay Sci 83–84:210–216

Ye WM, Borrell NC, Zhu JY, Chen B, Chen YG (2014a) Advances on the investigation of the hydraulic behaviour of compacted GMZ bentonite. Eng Geol 169:41–49

Ye WM, Zhang F, Chen B, Chen YG, Wang Q, Cui YJ (2014b) Effects of salt solutions on the hydro-mechanical behaviour of compacted GMZ01 bentonite. Environ Earth Sci 72(7):2621–2630

Zhang KN, Chen YG, Deng FY, Tian QY (2004) Retention of clay-solidified grouting curtain to Cd2+, Pb2+, Hg2+ in landfill of municipal solid waste. J Cent South Univ Technol 11(4):419–422

Zhang M, Zhang HY, Jia LY, Cui SL (2012) Salt content impact on the unsaturated property of bentonite–sand buffer backfilling materials. Nucl Eng Des 250:35–41

Zhou AN, Sheng D, Carter JP (2012) Modelling the effect of initial density on soil-water characteristic curves. Géotechnique 62(8):669–680

Acknowledgments

The authors are grateful to the National Natural Science Foundation of China (41422207, 41272287 and 41527801), the Scientific Research Fund of Hunan Provincial Education Department (15A009), and Fundamental Research Funds for the Central Universities and the Open Research Fund of State Key Laboratory of Geomechanics and Geotechnical Engineering, Institute of Rock and Soil Mechanics, Chinese Academy of Sciences (Z013006). The authors also wish to acknowledge the support of the European Commission via the Marie Curie IRSES project GREAT ‘Geotechnical and geological Responses to climate change: Exchanging Approaches and Technologies on a world-wide scale’ (FP7-PEOPLE-2013-IRSES-612665).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

He, Y., Chen, YG., Ye, WM. et al. Influence of salt concentration on volume shrinkage and water retention characteristics of compacted GMZ bentonite. Environ Earth Sci 75, 535 (2016). https://doi.org/10.1007/s12665-015-5228-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-015-5228-3