Abstract

This study aims to investigate the ability of the fungus Trichoderma koningiopsis 2OI2A1M to produce enzymes that act in the depolymerization of the lignocellulosic biomass of agro-industrial by-products and its application in the saccharification of barley bagasse. The production of xylanase by the fungus T. koningiopsis 2OI2A1M using the barley bagasse provided the highest activity (53.6 U/mL). The CMCase activity was obtained with carboxymethylcellulose (2.1 U/mL). Among the best inducers for β-xylosidases were sugarcane bagasse (11.8 U/mL) and for β-glucosidases were carboxymethylcellulose (36.4 U/mL) grown for 120 h in submerged culture. The higher production of fermentable sugars from the enzymatic saccharification of in natura barley bagasse, yielded a concentration of total reducing sugars (10.7%), glucose (5.9%) and xylose (1.6%) after 24 h. The comparative analysis of the morphological structure of the barley bagasse by scanning electron microscopy demonstrated that the simultaneous action of T. koningiopsis 2OI2A1M enzymes does not require previous structural modifications in the barley bagasse for effectiveness in the saccharification process. Thus, barley bagasse is a candidate for a sustainable alternative to produce fermentable sugars, a primary focus in the production of second-generation fuels.

Graphic Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of Novelty

We focus on prospecting for the hydrolytic enzymes of the hemicellulolytic complex from T. koningiopsis 2OI2A1M using barley bagasse as an inducer to produce enzymes and as a hydrolysis substrate in the saccharification. This fungus induced the production of the main cellulose and hemicellulose degradation enzymes, using different agricultural residues as carbon sources. Furthermore, significant amounts of total reducing sugar, xylose and glucose were obtained using crude enzymatic extract in the hydrolysis of in natura barley bagasse. The analysis of the morphological structure of the barley bagasse by SEM demonstrated that the simultaneous action of T. koningiopsis 2OI2A1M enzymes does not require previous treatment in the barley bagasse for effectiveness in the saccharification process.

Introduction

Brazil generates large amounts of lignocellulosic biomass annually due to agro-industrial activities, resulting from huge amounts of waste during the harvest or in the processing of its raw materials. These residues become an environmental problem if they are not treated and disposed of correctly, presenting potential risks of soil and water contamination. Among these agricultural residues, several can be used for the final production of food and bioenergy, such as sugarcane bagasse, rice husk, wheat bran, corn cob, bean straw, and barley [1, 2].

Therefore, using this waste as an alternative source of raw materials for biotechnological products or energy production becomes a renewable, low-cost, and sustainable option. Barley (Hordeum vulgare L.) is the fourth most important cereal in the world in terms of total production, after wheat, rice, and corn. It is used mainly in the beer industry and for animal feed [3, 4]. For the purposes of brewers, the southern region of Brazil concentrates the largest Brazilian production of barley, whose production in 2019 exceeded 428 thousand tons, in about 118.8 thousand hectares (ha) [5, 6]. The barley grain is mainly composed of starch, dietary fiber and protein, even less, lipids, minerals and vitamins. The insoluble fraction of the total dietary fiber contains a large proportion of cellulose. Grain processing can lead to chemical and physical changes in nutrients, inactivation of enzymes, polysaccharide hydrolysis and changes in vitamin and mineral percentage [3, 7].

Lignocellulosic biomass, which consists mainly of cellulose, hemicellulose, and lignin, is a promising renewable raw material that can be converted into biofuels or value-added products, when converted by multi-enzymatic systems, composed predominantly of cellulases and xylanases [8]. In addition, these lignocellulosic materials are important sources of carbon that serve as substrates in the cultivation of microorganisms such as filamentous fungi. Fungi of the genera Trichoderma, Aspergillus, Fusarium, and Pichia are considered good xylanase producers [2, 9]. In general, Trichoderma species are known to produce several enzymes for the degradation of homopolysaccharides and heteropolysaccharides, mostly enzymes belonging to the glycosyl hydrolases family [10]. As the T. reesei species is among the largest producers of cellulases, it has been widely studied. A collection of cellulolytic and hemicellulolytic enzymes catalyzes the hydrolysis of glycosidic bonds of complex lignocellulosic biomass residues to release simple reducing sugars [11]. The enzymes involved in the cellulose bioconversion process are exoglucanases (EC 3.2.1.91), endoglucanases (carboxymethylcellulase; CMCase; EC 3.2.1.4) and β-glucosidases (EC 3.2.1.21) [12].

Xylan is the most abundant hemicellulose present in the cell wall of plants, occurring mainly in nature as heteropolysaccharides. Due to its heterogeneity, xylan requires the action of different enzymes for its total degradation, with endo-1.4-β-xylanases (EC 3.2.1.8) being key enzymes in the process, responsible for internally hydrolyzing the main xylan chain, and randomly cleaving β-1.4-glycosidic bonds between xylopyranosyl residues. Once xylan is cleaved randomly by xylanases, its products are diverse, including xylobiose, xylotriose, and xylotetraose and xylo-oligosaccharides (XOS) with short or longer chains [9, 13, 14]. In addition, β-xylosidases (EC 3.2.1.37) are responsible for hydrolyzing the non-reducing end of XOS by removing the D-xylose units [15, 16].

Hydrolytic enzymes that degrade xylan have several applications in different industrial processes, such as bleaching paper pulp, de-inking recycled paper, and improving the digestibility and nutritional properties of animal feed [17]. Degumming of vegetable fibre in the manufacture of beverages such as beer and wines, in the clarification of fruit juices, in the bakery industry, in the extraction of coffee, in the saccharification of agricultural products, and in the production of biofuels [18, 19].

Thus, in this study, we focus on prospecting for the hydrolytic enzymes of the hemicellulolytic complex from T. koningiopsis 2OI2A1M, a mesophilic fungus isolated from the Atlantic Forest biome of Paraná-Brazil, due to the lack of knowledge about its biotechnological potential. In addition, barley bagasse was used as an inducer for the production of enzymes, and as a hydrolysis substrate in the process of saccharification of this residue using the crude enzymatic extract of T. koningiopsis 2OI2A1M for the production of fermentable sugars.

Materials and Methods

Isolation and Maintenance of the Fungus

The filamentous fungus T. koningiopsis 2OI2A1M was isolated from a sample collected from the Bela Vista river located (53°35′41″ W. 25°26′43″ S) in the Atlantic rainforest biome (Foz do Iguassu, Paraná, Brazil). Strain identification was based on the analysis of the amplified products of the Internal Transcribed Spacer (ITS) regions of the extracted ribosomal DNA of the fungus according to the methodology described by White et al. [20] and the ITS sequence deposited in the GenBank database by accession number MN662532.1.

The fungus T. koningiopsis 2OI2A1M was grown in medium potato dextrose agar, incubated at 28 °C for ten days, and then it was kept in a refrigerator.

Enzyme Production Under Submerged Fermentation (SmF)

The enzyme production by the fungus T. koningiopsis 2OI2A1M was carried out in duplicate, in 125 mL Erlenmeyer flasks containing 25 mL of Czapek mineral medium supplemented with 1% (w/v) of different carbon sources (cotton, avicel®, sugarcane bagasse, barley bagasse, carboxymethylcellulose (CMC), cellulose, nutshell, paper (filter, newspaper, kraft and sulphite), straw (rice, beans and corn), sawdust, corn cob and panicle sorghum bagasse. One mL of spore suspension (2.2 × 105 spores/mL) was inoculated and the submerged fermentation was incubated at 28 ℃ in a stationary condition for 120 h. The extracellular crude extract was obtained by vacuum filtration of the cultures, and the cell-free filtrates after dialysis were used to determine enzyme activity and protein quantification.

Enzymatic Assays and Quantification of Proteins

The enzymatic activities of xylanase, CMCase and FPase were carried out through the determination of reducing sugars with 3.5-dinitrosalicylic acid (DNS), described by Miller [21]. The reaction mixture for determining the enzymatic activity was composed of 50 µL of enzymatic extract and 50 µL of the respective substrate 1% (w/v) (beechwood xylan for xylanase; CMC for CMCase, and Whatman filter paper for FPase) in an acetate buffer (0.05 mol/L pH 5.0). This mixture was incubated at 50 °C for 10, 30 and 60 min, respectively for xylanase, CMCase and FPase, and stopped by adding 100 µL of DNS. The estimations of the reducing sugars at 540 nm in a spectrophotometer using D-xylose (xylanase) or D-glucose (CMCase and FPase) were used as standards. A unit of enzymatic activity (U) was defined as the amount of enzyme capable of releasing 1 μmol of reducing sugar per minute, under the experimental conditions. The protein concentration was determined using the Bradford method [22] and using bovine serum albumin as a standard.

The activities of β-xylosidase and β-glucosidase were determined according to the method described by Tan et al. [23]. The reaction mixture consisted of 90 µL of the substrate at 2 mM of p-nitrophenyl-β-D-xylopyranoside (β-xylosidase) or p-nitrophenyl-β-D-glycopyranoside (β-glucosidase) with 10 µL of the crude enzyme extract; the reaction was incubated at 50 °C, and after 30 min it was stopped by adding 200 µL of saturated sodium carbonate solution (Na2CO3). The quantification of the products was performed in a spectrophotometer at 410 nm, using a p-nitrophenol standard. One unit of enzyme activity (U) was defined as the amount of enzyme that releases 1 μmol of p-nitrophenol per minute under the experimental conditions. All enzymatic assays and protein quantification were performed in triplicate.

Saccharification of Barley Bagasse

The barley bagasse obtained from a local brewery was washed several times with distilled water and dried in an oven at 50 °C, then pretreatments (alkaline, acid and themal) were carried out, and the untreated residue was named barley bagasse “in natura”. The residue equivalent to 5% (w/v) was pre-treated with 0.1 M NaOH or 0.1 M HCl for 16 h or autoclaved at 121 °C for one hour. Thereafter, the residues were washed with distilled water until reaching pH neutrality and dried in an oven at 50 °C. The enzymatic hydrolysis of barley bagasse was performed in duplicate as described by Saha and Gosh [24], with modifications, using 100 mg of pre-treated or in natura barley bagasse in a 50 mM sodium acetate buffer of pH 5.5 and a crude enzymatic extract of T. koningiopsis 2O2A1M (1 IU/mg of substrate) obtained from cultivation also induced with barley bagasse as a carbon source. The hydrolysis reaction was carried out at 40 °C under 200 rpm orbital agitation over 24 and 48 h. At the end of the process, the samples were vacuum filtered, obtaining filtrate, and the barley bagasse was hydrolyzed, which, after drying, was analyzed by scanning electron microscopy (SEM). The filtrates were centrifuged at 1500 rpm for five minutes and used to determine total reducing sugars using the DNS method [21] using xylose as standard, quantification of D-xylose (Kit D-xylose, Megazyme) and quantification of D-glucose (Kit Glucose-oxidase). The percentage of saccharification was determined by Baig et al. [25] using a method based on the production of fermentable sugars (reducing sugar, xylose, and glucose).

Analysis of Enzymatic Hydrolysis of Barley Bagasse by Scanning Electron Microscopy

The effect of enzymatic action on in natura barley bagasse (without previous treatment) was verified in a SEM. The samples were prepared on an aluminum platform using double-sided carbon tape, covered with 20 nm gold in an evaporator (Denton vacuum desk V) and analyzed in a TESCAN VEGA3 device operated at 25 kV. The control consisted of fresh barley bagasse without enzymatic treatment.

Partial Purification of Extracellular Xylanase

The crude extract obtained with 120 h of liquid cultivation grown with barley bagasse 1.5% of T. koningiopsis 2OI2A1M was dialyzed and loaded onto a CM-Sephadex chromatographic column (2 × 20 cm) previously equilibrated with 20 mM sodium acetate buffer, pH 5.0. The enzyme was eluted from the column using a gradient of NaCl (0.05–1.0 M). Five-milliliter fractions were collected to monitor the protein (A280) and enzyme activity. The fractions containing the highest xylanase activity were pooled, dialyzed and characterized.

Analysis of the Degradation Products of Xylan by Thin Layer Chromatography

The mode of action of partially purified xylanase was evaluated by analyzing its hydrolysis products. The reaction consisted of a mixture of 400 µL of xylanase enzyme and 400 µL of 1% beechwood xylan in 50 mM sodium acetate buffer, pH 5. The hydrolysis reaction occurred at 50 °C, and aliquots were withdrawn after 0, 15, 30, 60, and 120 min, and boiled for five min. The hydrolysis products of beechwood xylan were analyzed qualitatively by thin layer chromatography (TLC) using a solvent system composed of n-butanol:ethanol:water 5:3:2 (v/v/v), respectively. The products were detected by spraying with 0.2% (w/v) orcinol in a 9:1 (v/v) methanol:sulfuric acid solution, and placed in an oven at 100 °C. The standards used were xylose, xylobiose, xylotriose and xylotetraose, all at a concentration of 3 mg/mL.

Statistical Analysis

All experiments were performed in at least two independent experiments and the results are presented as the mean of replicates ± SD. Significant differences between the means of enzymatic activities and saccharification yields were analyzed with one-way analysis of variance (ANOVA) followed by Tukey’s test at the 5% level of significance (p < 0.05).

Results and Discussion

Influence of Carbon Sources in the Production of Enzymes of the Cellulolytic and Xylanolytic Complex

The fungus T. koningiopsis 2OI2A1M exhibits potential for production mainly of the enzymes xylanase, β-xylosidase, and β-glucosidase (Table 1). The production of xylanase by T. koningiopsis 2OI2A1M reached the highest activity values (53.68 and 51.93 U/mL) obtained after 120 h of cultivation with barley bagasse and kraft paper, respectively. However, other sources of carbon, rich in cellulose and hemicellulose were also able to induce the production of xylanase, such as avicel® (47.28 U/mL), sugarcane bagasse (40.93 U/mL) and CMC (37.13 U/ml). Supplementation with insoluble substrates from plant polymers containing hemicellulose and cellulose has been reported as one of the important inducing factors for obtaining high amounts of hemicellulases [26].

The production of extracellular xylanase and β-xylosidase was more efficient in the presence of vegetable sources such as sugarcane bagasse (40.93 and 11.88 U/mL, respectively), compared to enzymatic activities obtained with a commercial substrate such as CMC (37.13 and 4.73 U/mL, respectively). These values of xylanase activity were considerably higher than that described for T. koningiopsis TM3 (8.27 U/mL) [27] and T. koningiopsis AN251 (2.14 U/mL) [28]. To date, there are no reports on the production of β-xylosidases by T. koningiopsis, on the other hand, the T. gamsii M501 strain grown in an optimized medium composed of microcrystalline cellulose as a carbon source reached 0.6 U/mL β-xylosidase activity [29].

In the study, β-glucosidase exhibited higher enzyme production (36.40 U/mL) in cultivation supplemented with CMC and barley bagasse (16.43 U/mL). These results were superior to those reported for T. koningiopsis FCD3-1 (1.18 U/mL) supplemented with microcrystalline cellulose [30]. In contrast, the cellulolytic activities of CMCase and FPase by T. koningiopsis 2OI2A1M were not significant. The highest CMCase activity was obtained with CMC (2.17 U/mL). Blaszczyk et al. [28] described the ability of the Trichoderma species to degrade cellulose (FPase activity), in which low cellulose decomposition potential (filter paper) was reported for T. koningiopsis. This result is similar to the low FPase activity (0.32 U/mL) found in the present study, in which the cultivation of the fungus T. koningiopsis 2OI2A1M was supplemented with corn straw.

For the degradation of biopolymers of the plant cell wall, the synergistic action of several extracellular enzymes is required. Several species of Trichoderma are known to be good producers of cellulolytic and hemicellulolytic enzymes, especially the T. reesei species, widely studied as a major producer of cellulases [28]. The fungus T. koningiopsis 2OI2A1M did not prove to be a good producer of cellulases; on the other hand, it showed potential in the production of hemicellulolytic enzymes, such as xylanases and β-xylosidases.

Due to the complexity of the polymers that make up the lignocellulosic biomass, cocktails containing hemicellulolytic enzymes have become valuable resources for industrial applications. Considering the importance of β-glucosidase in cellulose metabolism associated with the key role of β-xylosidases and xylanases in the hydrolysis of hemicellulose, the combined action of these enzymes is essential in the process of saccharification of lignocellulosic biomass, aiming at obtaining fermentable sugars such as glucose and xylose [31,32,33].

Saccharification of Barley Bagasse

The production of fermentable sugars from the enzymatic hydrolysis process of barley bagasse is summarized in Table 2. The best conditions for the release of these products occurred in reactions over 24 h. Although the formation of glucose has already reached its highest result in 24 h of reaction of the enzymatic extract of T. koningiopsis 2OI2A1M with the residue of in natura barley bagasse (5.9%), only in 48 h were results obtained from the production of glucose with the residues that underwent previous treatment to remove lignin, namely, acid (5.5%), thermal (5.3%) and alkaline pretreatment (5.2%). The higher glucose production is due to the action of the enzyme β-glucosidase present in high amounts in the crude extract of T. koningiopsis 2OI2A1M. β-glucosidase has wide use in several biotechnological processes, including the production of biofuel and ethanol from cellulosic agricultural residues [32]. The production of bioethanol can be summarized in three stages: the pretreatment that involves the preparation of the raw material, the saccharification in which the hydrolysis of cellulose and hemicellulose occurs in fermentable sugars, and the fermentation stage, the final stage of conversion of these sugars in bioethanol [34].

Although the formation of xylose was greater in 48 h with the enzymatic extract of T. koningiopsis 2OI2A1M and barley bagasse residue that underwent alkaline pretreatment (3.4%), the release of total reducing sugar was statistically significant both barley bagasse in natura (13.3%) and alkaline pretreatment (12.8%) conditions. From this result, it can be concluded that in the enzymatic hydrolysis of barley bagasse by T. koningiopsis 2OI2A1M, no previous treatment would be necessary, as the best results obtained were with in natura barley bagasse in 24 h for glucose (5.9%), total reducing sugar (10.7%) and xylose (1.6%).

This result obtained with the in natura barley bagasse is suggested because this residue had undergone the barley cooking stage commonly carried out in the brewery. This cooking step could have been sufficient for the fragmentation of the fibers that contributed to the performance of the enzymes of the cellulolytic and hemicellulolytic complex in the hydrolysis, mainly of the superficial layers of this barley bagasse. The pretreatments carried out with acid, alkali and thermal could have removed the lignin and uronic acid from the hemicelluloses of the barley bagasse, resulting in greater accessibility for the enzymes to hemicellulose and cellulose [35]. However, during the enzymatic hydrolysis of the lignocellulosic biomass, certain compounds, such as the sugars (glucose, xylose and maltose) and fermentation inhibitors (furfural, 5-HMF, phenol and coumarin) that were generated, may have decreased the efficiency of the enzymes due to the inhibition caused by the accumulated hydrolysis products that resulted in low product yields (reducing sugars, glucose and xylose [35, 36].

On the other hand, Mussatto et al. [37] evaluated the enzymatic hydrolysis of brewer's spent grain from commercial cellulase, in which the untreated residue provided the lowest glucose formation and the lowest cellulose conversion rate, suggesting that the chemical composition of the substrate negatively affected the enzymatic hydrolysis of cellulose.

The effectiveness in the formation of fermentable sugars from enzymatic hydrolysis of residues submitted to acid or alkaline pretreatment has been reported in previous studies [34, 38]. According to Phadtare et al. [39], the use of alkalis is more effective because it removes lignin from biomass, making cellulose and hemicellulose more accessible to enzymatic action. However, it is known that the enzymatic conversion of lignocellulosic biomass into fermentable sugars is preferable when compared to chemical methods since the generation of inhibitory compounds such as weak acids, furans, and phenolic compounds is avoided, which complicate downstream processing [40].

Barley bagasse is mainly composed of cellulose (12.3%), hemicellulose (23.4%) and lignin (26.1%) [41]. Regarding the reducing sugars obtained from saccharification of in natura barley bagasse, a positive result is observed when compared to barley bagasse treated by alkali, since the percentage was higher for the untreated residue within 24 h, demonstrating that no pretreatment is required under the evaluated conditions. Thus, the results obtained in this study are promising, since the percentage of reducing sugars formed in saccharification demonstrates the efficiency of the joint action of cellulolytic and xylanolytic enzymes produced by T. koningiopsis 2OI2A1M.

Scanning Electron Microscopic Analysis of Barley Bagasse

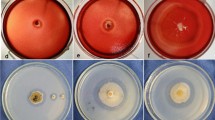

SEM micrograph of in natura barley bagasse without enzymatic treatment (control) revealed an organized but irregular morphology with deformed and fragmented fibrous structures, resembling the structures of tree bark (Fig. 1a). Although the surface shows structural irregularity, the exposure of the fibers indicates that the lignocellulosic constituents are present. In Fig. 1b, it is possible to verify a smooth coating, the effect of the enzymatic treatment by T. koningiopsis 2OI2A1M on the hydrolysis of the biomass, even without the previous treatment for removal of lignin. Similar results were reported by Ibarra-Díaz et al. [42] on the morphology of barley straw analyzed by SEM before and after treatment with commercial enzymes, initially being observed in an organized and characteristic structure of lignocellulosic material with elongation of cellulose fibers surrounded by a structure composed of hemicellulose and lignin resembling the structure of a network. However, after the enzymatic hydrolysis of barley straw with alkaline treatment, it exhibited a material with no defined structure, only isolated granules.

Scanning electron microscopy of in natura barley bagasse. Control, barley bagasse in natura without enzymatic treatment with a magnification of 500-fold (a) and 1000-fold (c), respectively; barley bagasse after treatment with enzymatic extract of T. koningiopsis 2OI2A1M for 48 h at 40 °C with a magnification of 500-fold (b) and 1000-fold (d), respectively

The morphological analysis of the residue with 1000-fold magnification (Fig. 1d) showed an extensive smooth surface area, in which a large part of the cellulose material was degraded, indicating the effectiveness of the action of enzymes of the T. koningiopsis 2OI2A1M hemicellulolytic complex in removing lignin and hemicellulose, resulting in high accessibility to crystalline cellulose fibers. In contrast to the results found by Mussatto et al. [37], when evaluating the enzymatic hydrolysis of brewer's spent grain with commercial cellulase, the structure of the untreated substrate was practically not modified, confirming the low efficiency of the hydrolysis obtained; however, when the lignin was treated and removed, the material structure was heavily modified, being highly hydrolyzed.

The effectiveness of pretreatments in improving hydrolysis is usually related to the structural modification caused in the waste, through chemical or physical treatment. In addition, another limitation reported in the enzymatic hydrolysis of cellulose corresponds to the type and composition of the cellulolytic system used in the process [43]. In this study of the enzymatic hydrolysis of barley bagasse, the substrate's morphological structure did not interfere with the action of enzymes present in the crude extract of T. koningiopsis 2OI2A1M, since even with the three different types of pretreatments carried out on the residue, the best saccharification yield was obtained with barley bagasse without any treatment (in natura). The SEM images show the results of the action promoted by T. koningiopsis 2OI2A1M enzymes on barley bagasse, thus revealing the potential for saccharification of barley bagasse biomass, without the need for previous treatment of the substrate.

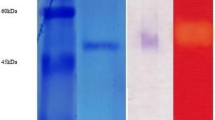

Analysis of the Degradation Products of Xylan by Partially Purified Xylanase

The analysis of the xylan hydrolysis products indicated the presence of xylose, xylobiose, xylotriose, and xylotetraose (Fig. 2). These results suggest a combined action between enzymes that act on the main chain of xylan, forming XOS (endo-xylanase) and enzymes that catalyze the hydrolysis of the non-reducing end of XOS, releasing xylose (action of β-xylosidase). The release of the xylose monosaccharide was lower, as observed in the saccharification results, in which a higher concentration of total reducing sugars and a lower concentration of xylose were found, and in the enzyme activity dosages of the crude extract of T. koningiopsis 2OI2A1M, which showed considerably higher activity of endo-xylanase compared to the activity of β-xylosidase.

Due to its great structural complexity, the complete hydrolysis of xylan requires the action of several enzymes of the xylanolytic complex, such as endo-xylanase and β-xylosidase [44]. Although there are several reports on endo-xylanases [45, 46] and fungal β-xylosidases [47, 48], there are few reports on native fungi producers of both enzymes. Thus, enzymatic cocktails containing endo-xylanases and β-xylosidases are of great importance in the biotechnological context, since the synergistic action of these enzymes significantly increases the efficiency of biomass hydrolysis in industrial processes.

In saccharification of xylan, β-xylosidase is a crucial enzyme, as it cleaves the greater number of glycosidic bonds in hemicellulose, compared to other xylanolytic enzymes [49]. XOS are potent inhibitors of endo-xylanases and cellulases, so β-xylosidase activity can improve the efficiency of the saccharification process, by degrading XOS, and thus reduce the inhibitory components of these enzymes in the reaction medium [19]. The degradation of xylan demonstrates the presence of enzymes with different specificities, such as endo-xylanase and β-xylosidase, key enzymes in the process of degradation of this complex heteropolysaccharide.

Conclusion

The novel fungus T. koningiopsis 2OI2A1M isolated from the Brazilian Atlantic Forest is capable of inducing the production of the main cellulose and hemicellulose degradation enzymes, using different agricultural residues as carbon sources. In addition, significant amounts of total reducing sugar were obtained using crude enzymatic extract in the hydrolysis of barley bagasse, mainly in natura conditions and with alkaline treatment. Thus, the results of this study are promising, since the yield of reducing sugars obtained by saccharification demonstrates the efficiency of the joint action of cellulolytic and xylanolytic enzymes produced by T. koningiopsis 2OI2A1M.

References

Moraes, S.L., Massola, C.P., Saccoccio, E.M., Silva, D.P., Guimarães, Y.B.T.: Brazilian scenario of production and use of densified biomass. IPT 1, 58–73 (2017)

Pereira Scarpa, J.C., Marques, N.P., Monteiro, D.A., Martins, G.M., Paula, A.V., Boscolo, M., Silva, R., Gomes, E., Bocchini, D.A.: Saccharification of pretreated sugarcane bagasse using enzymes solution from Pycnoporus sanguineus MCA 16 and cellulosic ethanol production. Ind. Crops Prod. 141, 111795 (2019). https://doi.org/10.1016/j.indcrop.2019.111795

Yalçin, E., Çelik, S., Akar, T., Sayim, I., Köksel, H.: Effects of genotype and environment on β-glucan and dietary fiber contents of hull-less barleys grown in Turkey. Food Chem. 101, 171–176 (2007). https://doi.org/10.1016/j.foodchem.2006.01.010

Jadhav, S.J., Lutz, S.E., Ghorpade, V.M., Salunkhe, D.K.: Barley: chemistry and value-added processing. Crit. Rev. Food Sci. Nutr. 38, 123–171 (1998). https://doi.org/10.1080/10408699891274183

CONAB: Acompanhamento da safra brasileira de grãos, Safra 2019/20, Terceiro levantamento, 7. 1–109. Brasília https://www.conab.gov.br/info-agro/safras/graos/boletim-da-safra-de-graos?limitstart=0 (2019). Acessed 26 Sept 2020

EMBRAPA: Indicações técnicas para a produção de cevada cervejeira nas safras 2019 e 2020. Embrapa Trigo. 1–116. Passo Fundo https://www.infoteca.cnptia.embrapa.br/infoteca/handle/doc/1115411 (2019). Acessed 26 Sept 2020

Aman, P., Newman, C.W.: Chemical composition of some different types of barley grown in Montana, USA. J. Cereal Sci. 4, 133–141 (1986). https://doi.org/10.1016/S0733-5210(86)80016-9

Delabona, P.S., Pirota, R.D.P.B., Codima, C.A., Tremacoldi, C.R., Rodrigues, A., Farinas, C.S.: Effect of initial moisture content on two Amazon rainforest Aspergillus strains cultivated on agro-industrial residues: biomass-degrading enzymes production and characterization. Ind. Crops Prod. 42, 236–242 (2013). https://doi.org/10.1016/j.indcrop.2012.05.035

Motta, F.L., Andrade, C.C.P., Santana, M.H.A.: A review of xylanase production by the fermentation of xylan: classification, characterization and applications. In: Chandel, A., Silva, S.S. (eds.) Sustainable Degradation of Lignocellulosic Biomass–Techniques, Applications and Commercialization, pp. 251–275. InTech, Rijeka (2013). https://doi.org/10.5772/53544

Silva, R.N., Steindorff, A.S., Monteiro, V.N.: Metabolic diversity of Trichoderma. In: Gupta, V.K., Schmoll, M., Herrera-Estrella, A., Upadhyay, R., Druzhinina, I., Tuohy, M.G. (eds.) Biotechnology and Biology of Trichoderma, pp. 363–376. Elsevier, Amsterdam (2014). https://doi.org/10.1016/B978-0-444-59576-8.00027-8

Kumar, A.K., Parikh, B.S.: Cellulose-degrading enzymes from Aspergillus terreus D34 and enzymatic saccharification of mild-alkali and dilute-acid pretreated lignocellulosic biomass residues. Bioresour. Bioprocess. 2, 7 (2015). https://doi.org/10.1186/s40643-015-0038-8

Bajaj, P., Mahajan, R.: Cellulase and xylanase synergism in industrial biotechnology. Appl. Microbiol. Biotechnol. 103, 8711–8724 (2019). https://doi.org/10.1007/s00253-019-10146-0

Malgas, S., Mafa, M.S., Mkabayi, L., Pletschke, B.I.: A mini review of xylanolytic enzymes with regards to their synergistic interactions during hetero-xylan degradation. World J. Microbiol. Biotechnol. 35, 187 (2019). https://doi.org/10.1007/s11274-019-2765-z

Wierzbicki, M.P., Maloney, V., Mizrachi, E., Myburg, A.A.: Xylan in the middle: understanding xylan biosynthesis and its metabolic dependencies toward improving wood fiber for industrial processing. Front. Plant Sci. 10, 1–29 (2019). https://doi.org/10.3389/fpls.2019.00176

Goswami, G.K., Pathak, R.R.: Microbial xylanases and their biomedical applications: a review. Int. J. Basic Clin. Pharmacol. 2, 237–246 (2013). https://doi.org/10.5455/2319-2003.ijbcp20130602

Kousar, S., Mustafa, G., Jamil, A.: Microbial xylosidases: production and biochemical characterization. Pak. J. Life Soc. Sci. 11, 85–95 (2013)

Bhardwaj, N., Kumar, B., Verma, P.: A detailed overview of xylanases: an emerging biomolecule for current and future prospective. Bioresour. Bioprocess. 6(40), 1–36 (2019). https://doi.org/10.1186/s40643-019-0276-2

Olsson, L., Hahn-Hägerdal, B.: Fermentation of lignocellulosichydrolysates for ethanol production. Enzyme Microb. Technol. 18, 312–331 (1996). https://doi.org/10.1016/0141-0229(95)00157-3

Rohman, A., Dijkstra, B.W., Puspaningsih, N.N.T.: β-Xylosidases: structural diversity, catalytic mechanism, and inhibition by monosaccharides. Int. J. Mol. Sci. 20, 5524 (2019). https://doi.org/10.3390/ijms20225524

White, T.J., Bruns, S.L., Taylor, J.: Amplification and direct sequencing of fungal ribosomal RNA genes for phylogenetics. In: Innis, M.A., Gelfand, D.H., Sninsky, J.J., White, T.J. (eds.) PCR Protocols: A Guide to Methods and Applications, pp. 315–322. Academic Press, New York (1990)

Miller, G.L.: Use of dinitrosalicylic acid for determination of reducing sugar. Anal. Chem. 31, 426–428 (1959). https://doi.org/10.1021/ac60147a030

Bradford, M.M.: A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Biochem. 72, 248–254 (1976). https://doi.org/10.1016/0003-2697(76)90527-3

Tan, L.U.L., Mayers, P., Illing, M., Saddler, J.N.: The copurification of beta-glucosidase, beta-xylosidase, and 1,3-beta-glucanase in two separate enzyme complexes isolated from Trichoderma harzianum E58. Biochem. Cell Biol. 65, 822–832 (1987). https://doi.org/10.1139/o87-107

Saha, S.P., Ghosh, S.: Optimization of xylanase production by Penicillium citrinum xym2 and application in saccharification of agro-residues. Biocatal. Agric. Biotechnol. 3, 188–196 (2014). https://doi.org/10.1016/j.bcab.2014.03.003

Baig, M.M.V., Baig, M.L.B., Baig, M.I.A., Yasmeen, M.: Saccharification of banana agro-waste by cellulolytic enzymes. Afr. J. Biotechnol. 3, 447–450 (2004). https://doi.org/10.5897/AJB2004.000-2088

da Silva Delabona, P., Rodrigues, G.N., Zubieta, M.P., Ramoni, J., Codima, C.A., Lima, D.J., Farinas, C.S., da Cruz Pradella, J.G., Seiboth, B.: The relation between xyr1 overexpression in Trichoderma harzianum and sugarcane bagasse saccharification performance. J. Biotechnol. 246, 24–32 (2017). https://doi.org/10.1016/j.jbiotec.2017.02.002

Nutongkaew, T., Prasertsan, P., O-Thong, S., Chanthong, S., Suyotha, W.: Improved methane production using lignocellulolytic enzymes from Trichoderma koningiopsis TM3 through co-digestion of palm oil mill effluent and oil palm trunk residues. Waste Biomass Valoriz. 11(10), 5123–5136 (2020). https://doi.org/10.1007/s12649-019-00838-z

Blaszczyk, L., Strakowska, J., Chelkowski, J., Gabka-Buszek, A., Kaczmarek, J.: Trichoderma species occurring on wood with decay symptoms in mountain forests in Central Europe: genetic and enzymatic characterization. J. Appl. Genet. 57, 397–407 (2016). https://doi.org/10.1007/s13353-015-0326-1

Baskaran, R., Krishnan, C.: Enhanced production of cellulase from a novel strain Trichoderma gamsii M501 through response surface methodology and its application in biomass saccharification. Process. Biochem. 99, 48–60 (2020). https://doi.org/10.1016/j.procbio.2020.08.006

Zhang, Z., Liu, J., Lan, J., Duan, C., Ma, Q., Feng, J.: Predominance of Trichoderma and Penicillium in cellulolytic aerobic filamentous fungi from subtropical and tropical forests in China, and their use in finding highly efficient β-glucosidase. Biotechnol. Biofuels 7(107), 1–14 (2014). https://doi.org/10.1186/1754-6834-7-107

Goldbeck, R., Gonçalves, T.A., Damasio, A.R.L., Brenelli, L.B., Wolf, L.D., Paixão, D.A.A., Rocha, G.J.M., Squina, F.M.: Effect of hemicellulolytic enzymes to improve sugarcane bagasse saccharification and xylooligosaccharides production. J. Mol. Catal B 131, 36–46 (2016). https://doi.org/10.1016/j.molcatb.2016.05.013

Singh, G., Verma, A.K., Kumar, V.: Catalytic properties functional attributes and industrial applications of β-glucosidases. 3 Biotech 6(3), 1–14 (2016). https://doi.org/10.1007/s13205-015-0328-z

Alokika, S., B. : Production, characteristics, and biotechnological applications of microbial xylanases. Appl. Microbiol. Biotechnol. 103, 8763–8784 (2019). https://doi.org/10.1007/s00253-019-10108-6

Gopalakrishnan, R.M., Manavalan, T., Ramesh, J., Thangavelu, K.P., Heese, K.: Improvement of saccharification and delignification efficiency of Trichoderma reesei Rut-C30 by genetic bioengineering. Microorganisms 8(159), 1–15 (2020). https://doi.org/10.3390/microorganisms8020159

Han, L., Feng, J., Zhang, S., Ma, Z., Wang, Y., Zhang, X.: Alkali pretreated of wheat straw and its enzymatic hydrolysis. Braz. J. Microbiol. 43, 53–61 (2012). https://doi.org/10.1590/S1517-83822012000100006

Oriente, A., Tramontina, R., Andrades, D., Henn, C., Silva, J.L.C., Simão, R.C.G., Maller, A., Polizeli, M.L.T.M., Kadowaki, M.K.: Characterization of a novel Aspergillus niger beta-glucosidase tolerant to saccharification of lignocellulosic biomass products and fermentation inhibitors. Chem. Pap. 69, 1050–1057 (2015). https://doi.org/10.1515/chempap-2015-0111

Mussatto, S.I., Fernandes, M., Milagres, A.M.F., Roberto, I.C.: Effect of hemicellulose and lignin on enzymatic hydrolysis of cellulose from brewer’s spent grain. Enzyme Microb. Technol. 43, 124–129 (2008). https://doi.org/10.1016/j.enzmictec.2007.11.006

Xu, C., Zhang, J., Zhang, Y., Guo, Y., Xu, H., Xu, J., Wang, Z.: Enhancement of high-solids enzymatic hydrolysis efficiency of alkali pretreated sugarcane bagasse at low cellulase dosage by fed-batch strategy based on optimized accessory enzymes and additives. Bioresour. Technol. 292, 121993 (2019). https://doi.org/10.1016/j.biortech.2019.121993

Phadtare, P., Joshi, S., Satyanarayana, T.: Recombinant thermo-alkali-stable endoglucanase of Myceliopthora thermophila BJA (rMt-egl): biochemical characteristics and applicability in enzymatic saccharification of agro-residues. Int. J. Biol. Macromol. 104, 107–116 (2017). https://doi.org/10.1016/j.ijbiomac.2017.05.167

Palmqvist, E., Hahn-Hägerdal, B.: Fermentation of lignocellulosichydrolysates. I: inhibition and detoxification. Bioresour. Technol. 74, 17–24 (2000). https://doi.org/10.1016/S0960-8524(99)00160-1

Bernardi, A.V., Yonamine, D.K., Uyemura, S.A., Dinamarco, T.M.: A ThermostableAspergillus fumigatus GH7 endoglucanase over-expressed in Pichia pastoris stimulates lignocellulosic biomass hydrolysis. Int. J. Mol. Sci. 20(2261), 1–15 (2019). https://doi.org/10.3390/ijms20092261

Ibarra-Díaz, N., Castañón-Rodríguez, J.F., Gómez-Rodríguez, J., Aguilar-Uscanga, M.G.: Optimization of peroxide-alkaline pretreatment and enzymatic hydrolysis of barley straw (Hordeumvulgare L.) to produce fermentable sugars using a Box-Behnken design. Biomass Convers. Bioref. (2020). https://doi.org/10.1007/s13399-020-00853-4

Ramos, L.P., Nazhad, M.M., Saddler, J.N.: Effect of enzymatic hydrolysis on the morphology and fine structure of pretreated cellulosic residues. Enzyme Microb. Technol. 15, 821–831 (1993). https://doi.org/10.1016/0141-0229(93)90093-H

Heinen, P.R., Bauermeister, A., Ribeiro, L.F., Messias, J.M., Almeida, P.Z., Moraes, L.A.B., Vargas-Rechia, C.G., Oliveira, A.H.C., Ward, R.J., Filho, E.X.F., Kadowaki, M.K., Jorge, J.A., Polizeli, M.L.T.M.: GH11 xylanase from Aspergillus tamarii Kita: purification by one-step chromatography and xylooligosaccharides hydrolysis monitored in real-time by mass spectrometry. Int. J. Biol. Macromol. 108, 291–299 (2018). https://doi.org/10.1016/j.ijbiomac.2017.11.150

Silva, L.A.O., Terrasan, C.R.F., Carmona, E.C.: Purification and characterization of xylanases from Trichoderma inhamatum. Electron. J. Biotechnol. 18, 307–313 (2015). https://doi.org/10.1016/j.ejbt.2015.06.001

Heinen, P.R., Pereira, M.G., Rechia, C.G.V., Almeida, P.Z., Monteiro, L.M.O., Pasin, T.M., Messias, J.M., Cereia, M., Kadowaki, M.K., Jorge, J.A., Polizeli, M.L.T.M.: Immobilized endo-xylanase of Aspergillus tamarii Kita: an interesting biological tool for production of xylooligosaccharides at high temperatures. Process Biochem. 53, 145–152 (2017). https://doi.org/10.1016/j.procbio.2016.11.021

Corrêa, J.M., Christi, D., Torre, C.L.D., Henn, C., Conceição-Silva, J.L., Kadowaki, M.K., Simão, R.C.G.: High levels of β-xylosidase in Thermomyces lanuginosus: potential use for saccharification. Braz. J. Microbiol. 47, 680–690 (2016). https://doi.org/10.1016/j.bjm.2016.04.028

Ye, Y., Li, X., Zhao, J.: Production and characteristics of a novel xylose- and Alkali-tolerant GH 43 β-xylosidase from Penicillium oxalicum for promoting hemicellulose degradation. Sci. Rep. 7(11600), 1–11 (2017). https://doi.org/10.1038/s41598-017-11573-7

Jordan, D.B., Wagschal, K., Grigorescu, A.A., Braker, J.D.: Highly active β-xylosidases of glycoside hydrolase family 43 operating on natural and artificial substrates. Appl. Microbiol. Biotechnol. 97, 4415–4428 (2013). https://doi.org/10.1007/s00253-012-4475-4

Acknowledgements

Caroline M. C. Kerber and Letícia M. R. were recipient of fellowship from Brazilian Federal Agency for Support and Evaluation of Graduate Education (CAPES) and Fundação Araucária, Brazil.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

da Cruz Kerber, C.M., Rasbold, L.M., Heinen, P.R. et al. Production of Hemicellulolytic Enzymes by a Novel Trichoderma koningiopsis 2OI2A1M and Its Application in the Saccharification of Barley Bagasse. Waste Biomass Valor 12, 5949–5958 (2021). https://doi.org/10.1007/s12649-021-01401-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01401-5