Abstract

Microalgae have received considerable attention due to several applications in which they can be used, such as bioremediation and the production of high-value products. Microalgal biomass is known for its richness and variety of bioproducts such as lipids, carbohydrates, proteins, pigments and antioxidants. They can be used for several purposes, for example, in the production of biofuels, food nutrition (human and animal), pharmacology and cosmetology. However, despite the importance of these applications, there are still certain difficulties to produce microalgae bioproducts in large-scale. The high general cost of microalgal production is one of the major disadvantages, since cultivation, extraction and biorefining steps are necessary. Unfortunately, these processes are frequently not compensated by the final product sales price. The identification of the target compounds present in biomass as well as the costs involved in these steps are necessary to promote microalgal development for agricultural, commercial and industrial applications. To focus on the main aspects related to the bioproducts present in biomass, this review aims to demonstrate the main concepts regarding bioproducts and microalgae, the relevant data about the sectors of application, and the main challenges and perspectives associated with these subjects by using bibliometric mapping.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The current energy sector profile drives the search for alternatives to provide energy, minimize greenhouse gases emissions and for biomass valorization [1]. However, the development of new proposals is a challenging task. In this context, microalgae are a promising source to produce biomass due to several applications they can offer, such as bioremediation [2, 3], biofuel production [4,5,6,7] carotenoids, phycobiliproteins and polyunsaturated acids [8], among others [9].

Microalgal biomass has been widely studied and applied in many areas. The ability of these microorganisms to grow in inhospitable conditions, as well as the ability for metabolic adaptation under stress conditions, makes microalgal biomass an attractive raw material for large-scale cultivation and industrial applications [10]. Microalgae can also accumulate several types of metabolites in their structure and their susceptibility when they grow under stress conditions may be a factor to increase production. The nutritional value of these products can be influenced by the size, shape, digestibility and biochemical composition of microalgae. When the composition and concentration of the substances present in the biomass are modified, different properties and consequently different applications are obtained. The properties are mainly influenced by the conditions and the physiological state of the culture [11].

According to Grobbelaar [12], the interest in microalgal production to obtain biomass for different applications began essentially at Stanford University (USA) in a pilot plant. Subsequently, this activity also occurred in other countries, such as Japan, Germany, Israel, the Czech Republic and China. The first large-scale research of microalgal biomass production began in 1960 in Trebon, Czech Republic. At this time, it was also reported that the cyanobacterium Spirulina platensis (classified as Arthrospira sp.) grew naturally in lakes and was harvested and used as a food source by local people in Africa and China. In 1982, Spirulina sp. was for the first time described as polyhydroxyalkanoate (PHA) producer, however, nowadays is considered as one of the most prospective cyanobacterial for production of bioproducts like protein, phycocyanin or phycoerythrin [13, 14] and in recent years, biopolymers [15].

Initially, the main purpose of microalgal cultivation was producing functional foods; however, this branch of activity was not very well developed and did not instigate a great demand. This factor was considered to be one of the main limitations to the increase of the development of microalgal production on an industrial scale [16]. The development of new bioproducts is an innovative proposal in the field of microalgae. Considering the several applications obtained from microalgal bioproducts, it is possible to highlight their use in the pharmaceutical, food nutrition, cosmetic and biofuel industries [17, 18]. Effectively, microalgae show promising prospects for obtaining bioproducts due to the high value of their metabolites [19]. However, the costs required for their production should be considered, mainly in aspects related to efficient cultivation systems and bioproduct introductions on commercial and industrial scales.

There is a significant difference between the currently available technology for microalgal production and that needed to supply the global demand for some bioproducts. Technologies should be expanded by several orders of magnitude to be sufficient for commercial scale and to contribute significantly to economic development. Thus, in addition to the technological aspects, the production cost should also be taken into consideration. To achieve this economic progress, it is still necessary to solve some factors, which are usually related to biological, engineering and biomass separation [20,21,22].

In recent years, many review articles about microalgae and bioproducts were published, for example: biorefinery to obtain high value products from microalgae [22], biofuel production from microalgal biomass by using pyrolysis method [23] or ultrasound treatment [24], biogas from microalgae emphasizing aspects related to cultivation, harvesting and pretreatment for anaerobic digestion [25], possibilities for conversion of microalgae oil into aviation fuel [26], recent developments on sustainable based biofuel and bioenergy production with microalgae [27], the use of marine microalgae for production of biofuels and chemicals [28] upstream and downstream processing of microalgae for biodiesel production [29] and advances in the field of liquid transportation biodiesel using these microorganisms [30]. All these publications are important, but most of these reviews present the current scenario and recent developments of biofuels, the main steps and methodologies to produce them and strategies to reinforce this sector. However, many of the bottlenecks in this area are justified by the difficult commercialization of these bioproducts. Even though the information related to the importance of bioproducts from microalgae is widespread, it is clear that several challenges are found and need to be considered in the production on an industrial scale. The difficulty of finding information in the literature to gain a current perspective of this scenario is another limitation in the economic analysis of the different compounds obtained from microalgae. Nowadays, there are relatively few industries that already work in this sector and these data are difficult to find. Cultivation systems described in the literature are generally based on small-scale plants associated with short-term studies on production. In addition, the industrial plants already well-established do not reveal their production costs, which hinders obtaining a general view of the situation [31]. Thus, it is important to demonstrate some capital costs involved in industries that already operate in this area, to serve as support and to contribute for people who intend to start a business in this sector as well as to supply new information for future studies. Another aspect to be highlighted is that the reviews found in literature usually discuss the bioproducts from microalgae individually [32,33,34,35], which demonstrates the need to report studies that provide these information in a single review.

Considering the numerous applications that can be achieve by microalgae and due to the high value of biomass, the present review was developed in order to track and compile information about the production of microalgae and bioproducts on a commercial scale which were not identified until this moment in published reviews articles. The bibliometric mapping was used to evaluate the last 10 years of publications regarding bioproducts obtained from microalgae using VOSviewer software based on the Web of Science database. The systematic information, collection and critical analysis about the evolution, potential, obstacles to insert biomass in the market considering the already established industries worldwide correspond to an advance in this field. The estimation of future trends and perspectives about this subject through industry reports containing production data, costs and forecast in general can offer relevant and new information promoting a relevant impact in the area of this review.

Research Methodology

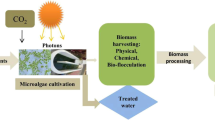

The research for this review focused on the main aspects involving microalgae bioproducts, general perspectives and main challenges in order to visualize the most relevant topics in this context, to bring new information about these points as well as to aggregate general concepts. First, a general search was conducted in different databases, such as Science Direct, Scopus and Web of Science. In this context, Fig. 1 was schematized to present the main bioproducts obtained from microalgal biomass and their applications. To facilitate access to information about microalgae and bioproducts Table 1 was created by searching the main studied microalgae, the target bioproducts, cultivation medium and system, extraction procedure, determinations and bioproduct content.

The bibliometric mapping was applied in order to verify the main topics discussed to date in the literature and investigate the relationships between the most cited words. The present review was organized via a search of studies described to date that could easily accessed with relevant information for consultation and the development of future studies.

For bibliometric analysis, VOSviewer version 1.6.6 was applied using the database of Web of Science from Thomson Reuters due to its comprehensiveness regarding the target subject, high-quality studies and availability of data analysis in VOSviewer. The articles were initially selected in Web of Science based on a combination of the words “microalgae” and “bioproducts” and by selecting data based on titles, abstracts and keywords of studies published between 2007 and 2017. As a result, 12,655 original publications were found and exported in Web of Science format for further analysis in VOSviewer. After this analysis, the topic “microalgae” AND “application” was searched using the same parameters as the previous search, and 1007 original publications were found. In the VOSviewer software, bibliometric maps were created based on text data using the previous exported database from Web of Science. The Web of Science fields from which terms were extracted were “title and abstract”, and binary counting was used with a minimum number of 10 occurrences of a term. Then, the words presented in Figs. 2, 7 and 8 were selected.

Based on the results from bibliometric mapping, and during the development of the writing, the main bioproducts and sectors of application were described and discussed. Figures 3, 4, 5 and 6 were developed to complement important information and to be a didactic source for consultation. It was also verified that topics about the main challenges involving microalgae bioproducts for industrial applications had to be explored (Fig. 8).

Lastly, the critical opinion of the authors of this review was synthesized in order to facilitate the understanding of the subject in general, provide an outlook, critical analysis and prospects about microalgae, bioproducts and possibilities to commercialization.

Microalgae

Microalgae are living organisms that have photosynthetic ability and can be found in marine or freshwater environments. These microorganisms have simple requirements for their development, for example, water, light, CO2 and other nutrients [36]. They can develop in several habitats, under extreme temperature, salinity and pH conditions [37, 38]. Microalgal growth occurs in general between 1 and 2 weeks and, under appropriate cultivation conditions, it is possible to achieve approximately 1–2 cell divisions per day [23].

During the photosynthetic process, microalgae can accumulate high-value compounds that are of commercial interest [39]. In addition, the high growth rate, the potential to produce biofuels without competing with food resources and good development with CO2 consumption, allowing great efficiency in the greenhouse gas mitigation are the main advantages of using microalgae as a feedstock [40].

Biomass characterization is necessary due to the high biological variability that can influence the composition and bioproducts [41, 42]. Microalgae may contain in their biomass several compounds, for example, vitamins from Nannochloropsis sp., Pavlova pinguis, Stichococcus sp., Tetraselmis sp. [11] and Spirulina sp. [43]; antioxidants from Ecklonia radiata; pigments from Phormidium autumnale [44]; fatty acids and proteins from Chlorella sp., Chlorella saccharophila, Chlorella minutíssima and Chlorella vulgaris [45]; carbohydrates from Kirchneriella sp. [46] and Ecklonia radiata [47]; and simultaneous bioproducts such as fatty acids, pigments, carbohydrates and proteins from Kirchneriella sp. [46]. All these microalgae provide possible commercial applications and can be used mainly in the production of biofuels, human and animal feed and high-value compounds for commercial applications such as pharmaceutical, food and cosmetology purposes (Fig. 1).

Microalgal Bioproducts

Microalgal bioproducts can be obtained from different culture media and by different extraction techniques. To reveal more information about the studies involving bioproducts from microalgae, bibliometric mapping was used to evaluate the trends and the studies developed in this area in the last 10 years. The publications were evaluated with the VOSviewer software using the Web of Science database. Initially, the bibliometric search was made through a combination of the words microalgae and their main bioproducts (Fig. 2).

Combined mapping of the most frequently cited keywords that appeared in the field of bioproducts from microalgae in the period 2007–2017 using the Web of science database. Publications are labeled according to the a relationship between microalgae and their main bioproducts and b the main microalgae studied and their respective bioproducts

Several studies about microalgae and bioproducts have been reported. The keywords obtained by bibliometric mapping separated the bioproducts into main groups related specially to lipids, carbohydrates, proteins, antioxidants and pigments (Fig. 2a). A search for the combination of the most cited microalgae in the recent years and their relation to specific types of bioproducts was also carried out (Fig. 2b) and the main species related to these bioproducts were: Chlorella sp. and Neochoris oleoabundan for lipids, Isochrysis galbana, Tetraselmis chuii and Skeletonema Costatum for proteins, Haematococcus pluvialis and Spirulina sp. for pigments and antioxidants and Chlorella sp. for carbohydrates.

Reinforcing the results of the bibliometric mapping, Table 1 was developed. It is possible to visualize in Table 1 that microalgae were obtained in laboratory, pilot-scale, indoor or outdoor reactors. The compound analysis requires equipment such as spectrophotometers and chromatographs. Considering that the extraction methods for different compounds use solvents, the technology is still expensive, as is the production of microalgae. Depending on the type of bioproducts, it is possible to cultivate these microorganisms in wastewater, which has already been thoroughly investigated, especially for biofuels [48].

Each of the major bioproducts and the challenges involved in the production of biomass or the product itself will be discussed further. In addition, there is a possibility of using crude extracts for applications in anti-inflammatory, anti-cancer, anti-diabetes and antibacterial activities [56]. This potential brings several health benefits and may be an option to enable microalgae commercialization. The financial impact is directly linked to the production and separation due to the requirements for pharmaceutical use. Furthermore, by avoiding the extraction and biorefining steps, the products obtained from microalgae can be developed more quickly at larger scales, the benefits provided by these microorganisms can be exploited, and the costs reduced.

Lipids

Microalgae can contain a high amount of lipids, generally in the range of 15–77%, and the composition of this bioproduct can differ considerably in different species [57]. According to Chew et al. [22], the lipid content also depends on the environmental conditions, such as the high ratio between carbon and nitrogen (C/N) since higher C/N ratios can increase the lipid content. In unfavorable environmental conditions or stress, many microalgae alter their biosynthetic pathways to form and accumulate lipids. It is possible to increase lipid productivity by stress conditions such as by nitrogen inhibition, higher temperatures, changes in pH and high salt concentrations.

Triacylglycerols are the major constituent of lipid molecules [58]. The most common fatty acid composition in the triacylglycerols of the microalgal lipids is a mixture of unsaturated fatty acids, palmitoleic (16:1), oleic (18:1), linoleic (18:2) and linolenic (18:3), and saturated fatty acids, palmitic (16:0) and stearic (18:0) [59].

Antioxidants

Antioxidants are biological macromolecules that protect organisms or biological compounds against oxidative radicals. The advantages of consuming antioxidants have been disseminated to the public in general and are related to the improvement of life quality and to mortality and morbidity prevention. These molecules may prevent or minimize the oxidative damage caused by reactive oxygen species in lipids, proteins and nucleic acids. Thus, antioxidants can delay aging and several chronic conditions, such as heart disease, atherosclerosis and cancer, induced by free radicals [60, 61].

Among the sources of natural antioxidants, microalgal biomass is considered a promising alternative to sustain the growing demands, especially in the food and pharmaceutical industries. This can be justified by the great variety of physiological and pharmacological effects [62]. According to Li et al. [63], microalgae represent an almost unexplored source of natural antioxidants due to their enormous biodiversity, which is considered higher than that of some plants.

Several compounds can be potentially used as antioxidant sources such as pigments (including carotenoids), phenolic compounds, sulfated polysaccharides and long-chain fatty acids [10]. According to Marxen et al. [64], 2,2-diphenyl-1-picrylhydrazyl is a common example of that enables the screening of microalgae as promising candidates in a commercial sense. These authors tested microalgae Anabaena sp., Isochrysis galbana, Phaeodactylum tricornutum, Porphyridium purpureum, and Synechocystis sp. PCC6803 in their ability to reduce the DPPH radical. The example of the antioxidant activity of DPPH is shown in Fig. 3.

Proteins

Proteins are composed of different amino acids, and the nutritional quality of these bioproducts is related basically to their content, proportion and the availability of amino acids [65]. Microalgal biomass composition can contain generally approximately 50–70% of proteins, and they are of fundamental importance in human and animal feed [22]. Examples of different microalgae with the potential of protein obtention include: Ankistrodesmus falcatus (5.2%) and Aphanothece microscopica Nägeli (0.5%) [66], Aphanizomenon flos-aquae (62%), Chlorella pyrenoidosa (57%), Dunaliella salina (57%) and Scenedesmus obliquus (50–55%) [65], Chlorella fusca (52%) and Spirulina sp. (52%) [50].

The proteins contained in the microalgal biomass compete favorably, in terms of quantity and quality, with proteins presented in conventional foods, such as soy, eggs and fish [34]. The amounts of proteins accumulated in these microorganisms depend upon the species, growth phase and light. Modification of the protein content can be accomplished through nutritional adjustment and environmental stress [67]. Another interesting application is the BioProtein development. BioProtein is produced by a mixed methanotrophic and heterotrophic bacterial culture or other microorganisms using natural gas as the main source of energy [68]. The production of BioProteins is a great alternative since carbon dioxide can be used for faster growth of bacteria and microalgae with a high protein content of 60–70% compared to 30–36% in soy and 20% in meat [69].

Carbohydrates

Carbohydrates are molecules composed of carbon, hydrogen, and oxygen, such as sugars, sugar derivatives and their polymers [70, 71]. The main representatives of this group are glucose, starch, cellulose and polysaccharides (Fig. 4). Glucose or starch are conventionally used for the production of biofuels, such as bioethanol and biohydrogen. Polysaccharides have biological functions as protection and storage and are structural molecules. In addition to these advantages, they can also modulate the immune system to inflammatory reactions, making them highly favorable to act as sources of active molecules for insertion in cosmetics, food ingredients and as natural therapeutic agents [22].

Microalgae can have approximately 50% of their dry weight as carbohydrates depending on the species [22]. For these organisms, carbohydrate production has two main purposes: acting as structural components in the cell wall and as storage components inside the cells, thereby providing the energy required for their metabolism [71].

Beta-glucans are one of the most important representative carbohydrate classes, since they are responsible for initiating host defense reactions in response to the molecules of pathogens. Chlorella sp. is recognized as the microalgae that has the most beta-glucans in its composition [72]. In addition, other microalgae can produce carbohydrates, such as: Chlorella fusca, Dunaliella salina [50] and Kirchneriella sp. [46].

Pigments

Color, which is one of the most visible characteristics of microalgae, is determined by the pigments present in its structure. Pigments are chemical substances that present different colors and are part of the photosynthetic material of the microalgae system [73]. Natural pigments are essential in photosynthetic metabolism and algae pigmentation. In addition to these factors, they have biological activities as antioxidants, anticancer, anti-inflammatory, anti-obesity and neuroprotective agents [74]. Different environmental parameters that may influence the content of individual pigments of microalgae include temperature, irradiation, wavelength, photoperiod, pH, nutrient limitation, nitrogen, salinity, pesticides and heavy metals [75]. As the result of the influence of environmental conditions, the carotenoid-to-chlorophyll ratio (Car/Chl) can be cited as example for preferable indicator of carotenogenesis in microalgae since increases with combined stress of high irradiance and nitrogen deprivation due to the accumulation of secondary carotenoids [76].

Carotenoids, chlorophylls and phycobiliproteins are considered to be the main natural pigments present in microalgae. These pigments are usually applied in human and animal feed, additives, cosmetics, the pharmaceutical industries, food colorants and biomaterials [22]. Chlorophyll, carotenoids and phycobiliproteins present colors that range from green, yellow and brown to red. These colors vary according to each microalga, for example, blue pigment from Spirulina (provided by phycocyanins), yellow pigment from Dunaliella (by β-carotene presence) and yellow to red pigments from Haematococcus (due to astaxanthin) [77]. The main pigments and their different applications are shown in Fig. 5.

Rodrigues et al. [44] identified twenty-four carotenoids, three phycobiliproteins and two chlorophylls in the microalga Phormidium autumnale. The major pigments found in the biomass were all-trans-β-carotene (225.44 µg g−1), all-trans-lutein (117.56 µg g−1) and all-trans-zeaxanthin (88.46 µg g−1), chlorophyll a (2.700 µg g−1) and C-phycocyanin (2.05 × 105 µg g−1). When the microalga Coelastrum cf. pseudomicroporum Korshikov was cultivated in urban wastewater and under salt stress, this species accumulated carotenoids in the range of 1.73–91.2 pg cell−1.

Vitamins

Vitamins are nutrients required for normal physiological functioning. A bioavailability study of these components is fundamental to the evaluation of their feed quality. Microalgae present high levels of essential vitamins and have suitable availability of these compounds. Vitamin production from microalgae may be directly related to the presence of nitrogen in the medium [22]. Several vitamins can be found in microalgae such as: vitamins A (retinoids and carotene), B1 (thiamin), B2 (riboflavin), B3 (niacin), B6 (pyridoxine), B7 (biotin), B9 (folic acid), B12 (cobalamin), C (ascorbic acid) and E (alpha-tocopherol).

According to Tang and Suter [54], Spirulina, Chlorella and Dunaliella are concentrated sources of provitamins A, C and B12 (Fig. 6). These microalgae are produced worldwide and have several health benefits, acting as dietary supplements of macro- and micronutrients. In addition, it is important to emphasize that the use of these microalgae for the production of high-value products is generally safe; however, care must be taken to cultivate them in secure environments to avoid contamination by cyanobacteria, for example.

Potential of Microalgae Bioproducts

According to recent data, more than 30,000 species of microalgae have been identified; however, fewer than 10 are commercially produced. Despite the fact that some of these species are used as feed, current industrial production still does not reach the expected level due to the difficulty of producing at in larger scale as well as the stage of biomass biorefining, which demands high costs [16]. In studies, several microalgae have been cultivated annually to produce high value compounds. According to Pulz and Gross [78], the annual average production of some microalgae is approximately Spirulina (3000 t/year), Chlorella (2000 t/year), and Dunaliella (1200 t/year).

To highlight the major sectors in which microalgae have been inserted in recent years, bibliometric mapping was performed using a combination of the word “microalgae” related to the application sectors that were available in the results of keywords obtained by the software. The bibliometric research of the main sectors in which microalgae have been studied are shown in Fig. 7.

According to the bibliometric mapping, it was possible to verify the separation of three main groups, divided into biofuels (with emphasis on biodiesel, biogas, bioethanol and biomethane), pharmacy and cosmetology (with progress of studies about pharmaceutical industry, cosmetic application and anti-inflammatory action) and human and animal nutrition (specially as a potential food source in diets and dietary supplementation).

Biofuels

Biofuel production from microalgae has been the target subject of several studies. The use of microalgae was extensively tested and reported in studies to produce different types of biofuels, such as biodiesel [79,80,81,82,83], bioethanol [84,85,86,87], biogas [88,89,90,91,92,93], biohydrogen [94, 95], bio-oil [96, 97] and biokerosene [98].

The main advantages related to the production of biofuels from microalgae are higher productivity per unit area, high photosynthetic efficiency and non-competition with food crops [18]. Furthermore, depending on the species involved, microalgae are supposed to be in a better position to produce biodiesel due to their lipid content, which may be considerably higher than other biomasses used for this purpose [99]. However, although it has been stated that biofuel production from microalgae is relatively close to being economically feasible, the data reported by [100, 101] demonstrate that technologies must be optimized to substantially reduce the operating costs. Additional research is required in this field since several parameters have not yet been adequately assessed to understand the potential for macroalgae-based production. These parameters include: appropriate cultivation step, species of seaweed and seaweed yield per hectare, time and method of harvesting, carbon balance, costs of the harvested seaweed and cost of the produced biofuel [102]. According to the Environment Committee of the European Parliament, “advanced biofuels sourced from seaweed or certain types of waste should account for at least 1.25% of energy consumption in transport by 2020” [103]. The costs associated with oil extraction, biodiesel processing and the variability of algal biomass production should focus on methods of the oil-rich algae itself [104].

Despite the presence of the bottlenecks to produce biofuels from microalga, some proposals are forthcoming to produce biofuels from microalgae at larger scales. The Government of Japan wants to introduce bio-jet fuel for commercial flights in 2020, and the volume of production is ambitiously estimated to be 100,000 to 1 million liters [105]. The Bioenergy Technologies Office (BETO) estimates that by 2017, this model would be able to supply 1 million metric tons of ash-free dry weight cultivated algal biomass. By 2022, the sustainable model would supply 20 million metric tons, and in 2030, the production of 5 billion gallons per year of algal biofuels would be possible [106].

Human and Animal Nutrition

The estimate of annual microalgal biomass production until 2016 is approximately 5000–7500 tons, which generates an annual average income of US$1.25 billion. Spirulina and Chlorella are the main microalgae that have already been inserted on the market. The annual worldwide sales volume of Chlorella sp. is generally over US$38 billion for human nutrition, animal feed and food additives. In addition, approximately US$10 billion are intended for the production of nutritional supplements that can be produced by microalgae such as Schizochytrium sp. and Crypthecodinium sp. [107].

One of the main advantages of using microalgae in nutrition is the possibility to offer several compounds of interest simultaneously. According to Blecker and Barka [16], some microalgae such as Spirulina, Chlorella, Dunaliella and Scenedesmus, when correctly processed, present an attractive flavor and can be incorporated into several types of food. In addition to their high protein content, microalgae present fatty acids, a favorable amino acid content, pigments and vitamins that are essential for use in the feed industry and to add value to milk [41, 108].

The study of microalgal bioproducts as food sources is increasing due to the several benefits that can be obtained, such as the ability to improve nutrition due to probiotic effects that positively affects human and animal health. Microalgae can also be used to increase product shelf life and to act as a source of natural dyes in foods such as pasta, snacks, chocolate and gums. In addition, they may be inserted into drinks and supplements in the form of tablets and capsules [109].

Functional foods or nutraceuticals produced by microalgae present health benefits and are an attractive option for consumers. In 2004, [78] predicted that the functional food market would be one of the most dynamic sectors in the food industry and could constitute up to 20% of the entire food market. Although in recent years there has been an increase of the consumption of nutraceuticals, this sector is still under development [110]. Algae Technology Limited [111] related that a wide range of algae and microalgae are commercially produced for use in human health and food supplement applications and that the global market in 2015 was estimated to be US$800 million. In addition, more than 40 different species have been developed for nutraceutical applications; however, Arthrospira (Spirulina), Chlorella, Dunaliella, Nannochloropsis, Haematococcus and Schizochytrium represent over 95% of the current market. The nutraceutical prices can range from US$15 to over US$100 per kilogram, depending on the algal species, product quality and nutritional value. Another important detail is that more than 90% of the total nutraceutical algae production worldwide is based on open cultivation systems.

According to Rocca et al. [104], approximately 9200 dry wt tons of microalgae are produced annually, worldwide. The application focus is in diet or health food for human consumption and feed additives for aquaculture. It is highlighted that in Asia, the US and Israel, the microalgae Arthrospira platensis and Haematococcus pluvialis are the most abundant strains for this purpose, with production of approximately 3000 dry wt tons each.

Microalgae as a source of food are widely discussed and are a suitable alternative for future sustainability. In 2030, the estimate is that there will be 9 billion people on Earth, of which 1 billion will suffer from hunger. More critical opinions also relate that this will not be remedied with fish or shrimp but with microalgae [112].

Pharmacy and Cosmetology

The use of microalgae in pharmacology and cosmetology has also attracted considerable attention due to their beneficial effects on human health. 1,3-β-Glucan is one of the most important substances in the pharmaceutical industry and can be obtained from Chlorella. This compound acts as an active immunostimulator, eliminates free radicals and has the ability to reduce blood lipids. In addition, other effects of this microalga have been found to promote health (efficacy against gastric ulcers, wounds and constipation and preventive action against atherosclerosis and antitumor action) [8].

Microalgae contain omega-3 fatty acids, which are one of major types of compounds that can be sold in pharmaceutical and cosmetic markets [113] The strain of Schizochytrium sp. is widely studied to produce omega-3 fatty acids. In addition, this microalga can produce eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) in high concentrations as well as being able to obtain its energy from dextrose [114]. Pages [115] presented the following valuable market calculation data about omega-3 production showing that the Schizochytrium product available in industry has a long chain (LC) omega 3 content of approximately 20% of the total dry whole cell algae. These data give the following market size indicators of LC omega 3 and indicates an annual requirement of 40,000 tons of actual LC omega 3, which translates to 200,000 tons of Schizochytrium whole-cell dry algae.

Pigments obtained from microalgae are a suitable alternative to be inserted in the pharmaceutical and cosmetic sectors due to the toxic effects of synthetic dyes [116]. The estimated worldwide market for astaxanthin production by Haematococcus pluvialis was approximately US$200 million in 2016 [107]. In addition, according to Zegarac [117], the global astaxanthin market is projected to reach $1.1 billion by 2020.

The bioactive substances derived from microalgae have functional roles that can act as secondary metabolites, and consequently, can be applied in the development of cosmetics [118]. Although the relation of microalgae and these sectors are being discussed, the information about the economic aspects in this context are very scarce and difficult to find.

Challenges of Microalgae in Industrial Applications

In general, microalgal growth seems to be simple since it is possible to verify the natural presence of these microorganism in several environments; however, conversion of biomass into bioproducts at an industrial level is challenging. It is known that microalgae require light energy and CO2 sources for autotrophic growth, organic sources for heterotrophic growth or the intermediate between these two levels, which is the mixotrophic condition. According to Grobbelaar [12], between these two extremes, there are several intermediate trophic routes. The cultivation in photobioreactors implies the necessity of autotrophic growth, nutrient additions, carbon source insertion, temperature control and a suitable pH.

According to Acién et al. [101], it is necessary to reduce the cost of cultivation systems to be inserted at commercial and industrial scales. The use of photobioreactors are a suitable alternative; however, the design simplification and the materials used must be optimized. Another option is to use wastewater and combustion gases, thereby reducing energy and labor consumption in production. All the aforementioned aspects involve direct economic expenses, so the alternatives of production must be well studied. According to Walker [119], these aspects are essential to plan and start a business involving microalgae to avoid unnecessary expenses as well as the loss of money by investors.

Microalgae cultivation requires large amounts of water and nutrients, often resulting in high production costs and consequently making it difficult for the insertion of microalgal bioproducts on a commercial scale. However, a good option to solve this problem is the development of the association of microalgae cultivation in freshwater, effluent or another medium containing available organic compounds while performing bioremediation [99].

Another option to reduce costs and increase productivity is the use of open pound systems such as the Algae Turf Scrubber [120]. This system is modeled on algae communities found in coral reefs. The source of light used for cultivation may be either natural or artificial. The high rate of biomass production is one of the main advantages of this system since they present higher production yields than the values recorded in other cropping systems. Many pollutants are absorbed in the algae biomass and can be removed by the system itself. If the absence of toxic compounds is ensured, the biomass can be converted into products of commercial interest, such as fertilizers and animal feed [121]. However, according to Michel [122], the main drawback of open pond systems is their relatively low biomass yield of 10–25 g/(m2d) compared to closed systems which presents 25–50 g/(m2d). In addition, another disadvantage is that a limited number of microalgae can be cultivated in open ponds and some species are very vulnerable to contamination and evaporative water loss.

In addition to the possibilities for cultivation step, photobioreactors can be a suitable option since appropriate configurations lead to effective photosynthesis, higher biomass yield and also have the advantage of optimal removal efficiency of nitrogen and phosphorus. Currently, many photobioreactors have been invented and developed for microalgae cultivation and some of them have achieved large scale commercial production. Besides, it is an option for axenic cultivation of microalgae and to generates high-value added products [123].

Other parameters must be considered as challenges to be overcome for the application of microalgae on an industrial scale. In this context Spolaore et al. [8] highlights the fact that microalgae with high fatty acid content, rapid growth and resisting performance, combined with the oil-containing organisms, which have gone through genetic engineering, will be sorted out. This can be explained since the use of transgenic microalgae for commercial applications has not been reported until now, however holds significant promise considering that these modified strains could overproduce traditional or newly discovered algal compounds. Advances in technological developments, especially related to cultivating oil-containing microalgae as a biofuel, the large-scale production technology associated with the decrease in greenhouse gases must be improved to produce liquid fuel from oil-containing microalgae.

In relation to microalgae as a source of bioproducts, there are some studies that have attempted to improve the production to reduce costs. Malik et al. [124] investigated whether algal bio-crude production is environmentally, economically and socially sustainable using a life cycle assessment. Bio-crude, also known as bio-oil, is a suitable alternative which consist process semi-dry biomass by hydrothermal liquefaction and can later be distilled into its fractions at a refinery [124]. The results indicate that the production of 1 million tons of bio-crude would be possible to generate almost 13,000 new jobs and US$4 billion worth of economic stimulus. Benvenuti et al. [125] presented a projection for a two-step 100-ha-scale process involving microalgal triacylglycerides (TAGs). As a result, the suggested improvements could decrease production costs to 3.3€ per kg of biomass containing 60% TAG (w/w) within the next 8 years. In 2017, a company in Japan announced that it was doubling production capacity of food-use microalgae Euglena to 160 tons. This production facility will increase from 80 to 160 tons. This improvement will meet the increasing demand in a market as well as allow the company to respond to the diversifying needs of its customers [126].

Finally, to visualize the perspectives between microalgae and economy, bibliometric mapping was performed with a combination of the keywords “microalgae” that were related to “costs”, “economies”, “obstacles and challenges” and “industrial and commercial scale” (Fig. 8).

Figure 8 presents the change of the search profile results in relation to microalgae and economy over the last 10 years. After bibliometric analysis it was possible to verify that the expression “production cost” is the main challenge of microalgae in industrial applications. This expression was interconnected to valuable parameters that must be taken into consideration in this field, such as “industrial scale”, “commercialization”, “economy”, “high cost”, “economic viability”, “major bottleneck” and others.

These results demonstrate that the future prospect for microalgae bioproducts is more optimistic about the parameters that could enable the commercialization of bioproducts on an industrial scale. However, considering the demonstrated data, the aspects that aim at economic viability and the reduction of energy cost cannot be left aside, and these are the main challenges that must be discussed and overcome.

Outlook and Future Prospects

Studies on microalgae and bioproducts must be updated, since the scenarios to develop high-value compounds are constantly changing. The current production of bioproducts through these microorganisms can be unsustainable if the process is not well established. Hence, economic study and processing are required to improve commercialization aspects. As demonstrated in this review, microalgae can synthesize lipids, pigments, vitamins, antioxidant and others compounds.

Despite the large number of studies that were described in this review, microalgae biomass is still considered for many researchers as not viable for commercial biofuels production due to the extensive energy input. This can be justified since the demand of biofuels in commercial scale exceeds the accessibility of these kinds of feedstock. However, there are some industries that related promising perspectives in this field, but some parameters must be simplified to obtain long-term sustainability and environmental benefits.

As shown in the bibliometric mapping performed in our study, new markets for high value compounds should be explored. The demanding market of bioproducts from microalgae and their subsequent utilization in food nutrition may be a suitable option in the next years to support the goals to establish microalgae at industrial scale. Considering the increasing concern to have healthy lifestyles and as the economy increase, more consumers can afford the costs of pharmaceuticals, cosmetics and nutritious feed from microalgae, and this sectors can be another option to promote bioproducts in the near future. As most of the microalgae are being consumed as health food or supplements, there is a high expectation with respect to the quality and the market sustainability for commercial scale, then high-value products must be considered. In this context, several concerns need to be addressed such as the relatively small market for different bioproducts, culture growth conditions to avoid losses caused by product degradation and long term stability studies of the microalgae products.

Cultivation technologies are a suitable option to promote new strategies to commercialize the desired final product and to achieve economic progress. As shown in the topic “Challenges of microalgae in industrial applications” some barriers must be overcome to provide suitable technologies of design for culture conditions, light control and to induce and activate the accumulation of bioproducts. In addition, genetically modified microalgae (considered as a positive promise in this context) can also help to improve the targeted bioproducts in industrial scale.

Cost-effectiveness assessment is necessary to evaluate the economics options of microalgal commercialization. The association between microalgae and technologies, especially through life cycle assessment tool (LCA), can be a suitable alternative for future developments since it is possible to obtain an inventory of input and output mass and energy. This allow the quantification of generated environmental impacts of valuable parameters to increase viability for industrial applications. Also, appropriate policy environment and sufficiently low costs are required for these technologies to be introduced and recognized as a promising alternative to commercialize bioproducts from microalgae.

Conclusions

This review presented several application possibilities of the bioproducts obtained from microalgae and that could be valuable to intensify industrial applications; however, overcoming the high costs involved is one of the crucial factors to boost the production at larger scales. Studies are still needed in this area to select the best species to achieve good productivity and to design the best processes. The constant search for new technologies is fundamental to solve these challenges and to find efficient ways to commercialize bioproducts. In addition, it is essential to find means of obtaining and characterizing bioproducts to use smaller amounts of solvents and to avoid unnecessary energy costs in order to reduce environmental impacts and costs. The data obtained through bibliometric mapping allowed a general evaluation of the items that were most searched in the last 10 years. This made possible an overview of the studies that were being carried out and the future trends involving microalgae. The study of all these aspects are fundamental for microalgae to enter the market with greater force and to boost the commercialization of products of interest to generate production on an industrial scale.

References

Baicha, Z., Salar-García, M., Ortiz-Martínez, V., Hernández-Fernández, F., de los Ríos, A., Labjar, N., Lotfi, E., Elmahi, M.: A critical review on microalgae as an alternative source for bioenergy production: a promising low cost substrate for microbial fuel cells. Fuel Process. Technol. 154, 104–116 (2016)

Gressler, P., Bjerk, T., Schneider, R., Souza, M., Lobo, E., Zappe, A., Corbellini, V., Moraes, M.: Cultivation of Desmodesmus subspicatus in a tubular photobioreactor for bioremediation and microalgae oil production. Environ. Technol. 35(2), 209–219 (2014)

Raeesossadati, M., Ahmadzadeh, H., McHenry, M., Moheimani, N.: CO2 bioremediation by microalgae in photobioreactors: impacts of biomass and CO2 concentrations, light, and temperature. Algal Res. 6, 78–85 (2014)

Özçimen, D., Gülyurt, M., İnan, B.: Algal biorefinery for biodiesel production. In: Fang, Z. (ed.) Biodiesel-Feedstocks, Production and Applications, pp. 25–57. InTechOpen (2012)

Hallenbeck, P., Grogger, M., Mraz, M., Veverka, D.: Solar biofuels production with microalgae. Appl. Energy 179, 136–145 (2016)

Milano, J., Ong, H.C., Masjuki, H., Chong, W., Lam, M.K., Loh, P.K., Vellayan, V.: Microalgae biofuels as an alternative to fossil fuel for power generation. Renew. Sustain. Energy Rev. 58, 180–197 (2016)

Chernova, N., Kiseleva, S.: Microalgae biofuels: induction of lipid synthesis for biodiesel production and biomass residues into hydrogen conversion. Int. J. Hydrog. Energy 42(5), 2861–2867 (2017)

Spolaore, P., Joannis-Cassan, C., Duran, E., Isambert, A.: Commercial applications of microalgae. J. Biosci. Bioeng. 101(2), 87–96 (2006)

Koller, M., Muhr, A., Braunegg, G.: Microalgae as versatile cellular factories for valued products. Algal Res. 6, 52–63 (2014)

Maadane, A., Merghoub, N., Ainane, T., El Arroussi, H., Benhima, R., Amzazi, S., Bakri, Y., Wahby, I.: Antioxidant activity of some Moroccan marine microalgae: pufa profiles, carotenoids and phenolic content. J. Biotechnol. 215, 13–19 (2015)

Brown, M., Mular, M., Miller, I., Farmer, C., Trenerry, C.: The vitamin content of microalgae used in aquaculture. J. Appl. Phycol. 11(3), 247–255 (1999)

Grobbelaar, J.U.: Microalgal biomass production: challenges and realities. Photosynth. Res. 106(1–2), 135–144 (2010)

Koller, M., Marsalek, L.: Cyanobacterial polyhydroxyalkanoate production: status quo and quo vadis? Curr. Biotechnol. 4(4), 464–480 (2015)

Drosg, B., Fritz, I., Gattermayr, F., Silvestrini, L.: Photo-autotrophic production of poly (hydroxyalkanoates) in cyanobacteria. Chem. Biochem. Eng. Q. 29(2), 145–156 (2015)

Singh, A.K., Sharma, L., Mallick, N., Mala, J.: Progress and challenges in producing polyhydroxyalkanoate biopolymers from cyanobacteria. J. Appl. Phycol. 29(3), 1213–1232 (2017)

Barka, A., Blecker, C.: Microalgae as a potential source of single-cell proteins. A review. Biotechnol. Agron. Soc. Environ. 20(3), 427–436 (2016)

Yu, X., Chen, L., Zhang, W.: Chemicals to enhance microalgal growth and accumulation of high-value bioproducts. Front. Microbiol. 56(6), 1–10 (2015)

Esquivel-Hernández, D.A., Ibarra-Garza, I.P., Rodríguez-Rodríguez, J., Cuéllar-Bermúdez, S.P., Rostro-Alanis, M.d.J., Alemán-Nava, G.S., García-Pérez, J.S., Parra-Saldívar, R.: Green extraction technologies for high-value metabolites from algae: a review. Biofuels Bioprod. Biorefin. 11(1), 215–231 (2016)

Tibbetts, S.M., Milley, J.E., Lall, S.P.: Chemical composition and nutritional properties of freshwater and marine microalgal biomass cultured in photobioreactors. J. Appl. Phycol. 27(3), 1109–1119 (2015)

Richmond, A.: Microalgal biotechnology at the turn of the millennium: a personal view. J. Appl. Phycol. 12(3–5), 441–451 (2000)

Bauer, F., Coenen, L., Hansen, T., McCormick, K., Palgan, Y.V.: Technological innovation systems for biorefineries: a review of the literature. Biofuels Bioprod. Biorefin. 11(1), 215–231 (2017)

Chew, K.W., Yap, J.Y., Show, P.L., Suan, N.H., Juan, J.C., Ling, T.C., Lee, D.-J., Chang, J.-S.: Microalgae biorefinery: high value products perspectives. Bioresour. Technol. 229, 53–62 (2017)

Azizi, K., Moraveji, M.K., Najafabadi, H.A.: A review on bio-fuel production from microalgal biomass by using pyrolysis method. Renew. Sustain. Energy Rev. 82(Part 3), 3046–3059 (2017)

Sivaramakrishnan, R., Incharoensakdi, A.: Microalgae as feedstock for biodiesel production under ultrasound treatment—a review. Bioresour. Technol. (2017). https://doi.org/10.1016/j.biortech.2017.11.095

Jankowska, E., Sahu, A.K., Oleskowicz-Popiel, P.: Biogas from microalgae: review on microalgae’s cultivation, harvesting and pretreatment for anaerobic digestion. Renew. Sustain. Energy Rev. 75, 692–709 (2017)

Bwapwa, J.K., Anandraj, A., Trois, C.: Possibilities for conversion of microalgae oil into aviation fuel: a review. Renew. Sustain. Energy Rev. 80, 1345–1354 (2017)

Raheem, A., Prinsen, P., Vuppaladadiyam, A.K., Zhao, M., Luque, R.: A review on sustainable microalgae based biofuel and bioenergy production: recent developments. J. Clean. Prod. 181, 42–59 (2018)

Maeda, Y., Yoshino, T., Matsunaga, T., Matsumoto, M., Tanaka, T.: Marine microalgae for production of biofuels and chemicals. Curr. Opin. Biotechnol. 50, 111–120 (2018)

Tan, X., Lam, M.K., Uemura, Y., Lim, J.W., Wong, C.Y., Lee, K.T.: Cultivation of microalgae for biodiesel production: a review on upstream and downstream processing. Chin. J. Chem. Eng. 26(1), 17–30 (2017)

Zhu, L., Nugroho, Y., Shakeel, S., Li, Z., Martinkauppi, B., Hiltunen, E.: Using microalgae to produce liquid transportation biodiesel: what is next? Renew. Sustain. Energy Rev. 78, 391–400 (2017)

Tredici, M.R., Rodolfi, L., Biondi, N., Bassi, N., Sampietro, G.: Techno-economic analysis of microalgal biomass production in a 1-ha Green Wall Panel (GWP®) plant. Algal Res. 19, 253–263 (2016)

Gong, M., Bassi, A.: Carotenoids from microalgae: a review of recent developments. Biotechnol. Adv. 34(8), 1396–1412 (2016)

Sibi, G., Shetty, V., Mokashi, K.: Enhanced lipid productivity approaches in microalgae as an alternate for fossil fuels—a review. J. Energy Inst. 89(3), 330–334 (2016)

Ejike, C.E., Collins, S.A., Balasuriya, N., Swanson, A.K., Mason, B., Udenigwe, C.C.: Prospects of microalgae proteins in producing peptide-based functional foods for promoting cardiovascular health. Trends Food Sci. Technol. 59, 30–36 (2016)

Schulze, C., Strehle, A., Merdivan, S., Mundt, S.: Carbohydrates in microalgae: Comparative determination by TLC, LC-MS without derivatization, and the photometric thymol-sulfuric acid method. Algal Res. 25, 372–380 (2017)

Zhu, L.: Microalgal culture strategies for biofuel production: a review. Biofuels Bioprod. Biorefin. 9(6), 801–814 (2015)

Brennan, L., Owende, P.: Biofuels from microalgae—a review of technologies for production, processing, and extractions of biofuels and co-products. Renew. Sustain. Energy Rev. 14(2), 557–577 (2010)

Pate, R., Klise, G., Wu, B.: Resource demand implications for US algae biofuels production scale-up. Appl. Energy 88(10), 3377–3388 (2011)

AlMomani, F.A., Örmeci, B.: Performance of Chlorella vulgaris, Neochloris oleoabundans, and mixed indigenous microalgae for treatment of primary effluent, secondary effluent and centrate. Ecol. Eng. 95, 280–289 (2016)

Demirbas, A.: Use of algae as biofuel sources. Energy Convers. Manag. 51(12), 2738–2749 (2010)

Tibbetts, S.M., Whitney, C.G., MacPherson, M.J., Bhatti, S., Banskota, A.H., Stefanova, R., McGinn, P.J.: Biochemical characterization of microalgal biomass from freshwater species isolated in Alberta, Canada for animal feed applications. Algal Res. 11, 435–447 (2015)

Davis, R., Aden, A., Pienkos, P.T.: Techno-economic analysis of autotrophic microalgae for fuel production. Appl. Energy 88(10), 3524–3531 (2011)

Kumudha, A., Kumar, S.S., Thakur, M.S., Ravishankar, G.A., Sarada, R.: Purification, identification, and characterization of methylcobalamin from Spirulina platensis. J. Agric. Food Chem. 58(18), 9925–9930 (2010)

Rodrigues, D.B., Menezes, C.R., Mercadante, A.Z., Jacob-Lopes, E., Zepka, L.Q.: Bioactive pigments from microalgae Phormidium autumnale. Food Res. Int. 77, 273–279 (2015)

Hempel, N., Petrick, I., Behrendt, F.: Biomass productivity and productivity of fatty acids and amino acids of microalgae strains as key characteristics of suitability for biodiesel production. J. Appl. Phycol. 24(6), 1407–1418 (2012)

Frampton, D.M., Gurney, R.H., Dunstan, G.A., Clementson, L.A., Toifl, M.C., Pollard, C.B., Burn, S., Jameson, I.D., Blackburn, S.I.: Evaluation of growth, nutrient utilization and production of bioproducts by a wastewater-isolated microalga. Bioresour. Technol. 130, 261–268 (2013)

Charoensiddhi, S., Franco, C., Su, P., Zhang, W.: Improved antioxidant activities of brown seaweed Ecklonia radiata extracts prepared by microwave-assisted enzymatic extraction. J. Appl. Phycol. 27(5), 2049–2058 (2015)

Koller, M., Salerno, A., Tuffner, P., Koinigg, M., Böchzelt, H., Schober, S., Pieber, S., Schnitzer, H., Mittelbach, M., Braunegg, G.: Characteristics and potential of micro algal cultivation strategies: a review. J. Clean. Prod. 37, 377–388 (2012)

Safi, C., Ursu, A.V., Laroche, C., Zebib, B., Merah, O., Pontalier, P.-Y., Vaca-Garcia, C.: Aqueous extraction of proteins from microalgae: effect of different cell disruption methods. Algal Res. 3, 61–65 (2014)

Díaz–Palma, P., Stegen, S., Queirolo, F., Arias, D., Araya, S.: Biochemical profile of halophilous microalgae strains from high-andean extreme ecosystems (NE-Chile) using methodological validation approaches. J. Biosci. Bioeng. 113(6), 730–736 (2012)

Úbeda, B., Gálvez, J., Michel, M., Bartual, A.: Microalgae cultivation in urban wastewater: Coelastrum cf. pseudomicroporum as a novel carotenoid source and a potential microalgae harvesting tool. Bioresour. Technol. 228, 210–217 (2017)

Jaeschke, D.P., Rech, R., Marczak, L.D.F., Mercali, G.D.: Ultrasound as an alternative technology to extract carotenoids and lipids from Heterochlorella luteoviridis. Bioresour. Technol. 224, 753–757 (2017)

Jaeschke, D.P., Menegol, T., Rech, R., Mercali, G.D., Marczak, L.D.F.: Carotenoid and lipid extraction from Heterochlorella luteoviridis using moderate electric field and ethanol. Process Biochem. 51(10), 1636–1643 (2016)

Tang, G., Suter, P.M.: Vitamin A, nutrition, and health values of algae: Spirulina, Chlorella, and Dunaliella. J. Pharm. Nutr. Sci. 1, 111–118 (2011)

Pohndorf, R.S., Camara, ÁS., Larrosa, A.P., Pinheiro, C.P., Strieder, M.M., Pinto, L.A.: Production of lipids from microalgae Spirulina sp.: influence of drying, cell disruption and extraction methods. Biomass Bioenergy 93, 25–32 (2016)

Lauritano, C., Andersen, J.H., Hansen, E., Albrigtsen, M., Escalera, L., Esposito, F., Helland, K., Hanssen, K., Romano, G., Ianora, A.: Bioactivity screening of microalgae for antioxidant, anti-inflammatory, anticancer, anti-diabetes, and antibacterial activities. Front. Mar. Sci. 3, 68 (2016)

Chisti, Y.: Biodiesel from microalgae. Biotechnol. Adv. 25(3), 294–306 (2007)

Mubarak, M., Shaija, A., Suchithra, T.: A review on the extraction of lipid from microalgae for biodiesel production. Algal Res. 7, 117–123 (2015)

Khan, S.A., Hussain, M.Z., Prasad, S., Banerjee, U.: Prospects of biodiesel production from microalgae in India. Renew. Sustain. Energy Rev. 13(9), 2361–2372 (2009)

Finkel, T., Holbrook, N.J.: Oxidants, oxidative stress and the biology of ageing. Nature 408(6809), 239–247 (2000)

Poprac, P., Jomova, K., Simunkova, M., Kollar, V., Rhodes, C.J., Valko, M.: Targeting free radicals in oxidative stress-related human diseases. Trend Pharmacol. 38(7), 592–607 (2017)

Morowvat, M.H., Ghasemi, Y.: Evaluation of antioxidant properties of some naturally isolated microalgae: identification and characterization of the most efficient strain. Biocatal. Agric. Biotechnol. 8, 263–269 (2016)

Li, H.-B., Cheng, K.-W., Wong, C.-C., Fan, K.-W., Chen, F., Jiang, Y.: Evaluation of antioxidant capacity and total phenolic content of different fractions of selected microalgae. Food Chem. 102(3), 771–776 (2007)

Marxen, K., Vanselow, K.H., Lippemeier, S., Hintze, R., Ruser, A., Hansen, U.-P.: Determination of DPPH radical oxidation caused by methanolic extracts of some microalgal species by linear regression analysis of spectrophotometric measurements. Sensors. 7(10), 2080–2095 (2007)

Becker, E.: Micro-algae as a source of protein. Biotechnol. Adv. 25(2), 207–210 (2007)

Kalita, N., Baruah, G., Chandra, R., Goswami, D., Talukdar, J., Kalita, M.C.: Ankistrodesmus falcatus: a promising candidate for lipid production, its biochemical analysis and strategies to enhance lipid productivity. J. Microbiol. Biotechnol. Res. 1(4), 148–157 (2011)

Fontes, A.G., Vargas, M.A., Moreno, J., Guerrero, M.G., Losada, M.: Factors affecting the production of biomass by a nitrogen-fixing blue-green alga in outdoor culture. Biomass. 13(1), 33–43 (1987)

Mølck, A.-M., Poulsen, M., Christensen, H.R., Lauridsen, S.T., Madsen, C.: Immunotoxicity of nucleic acid reduced BioProtein—a bacterial derived single cell protein-in Wistar rats. Toxicology. 174(3), 183–200 (2002)

Nakomcic-Smaragdakis, B., Stajic, T., Cepic, Z., Djuric, S.: Geothermal energy potentials in the province of Vojvodina from the aspect of the direct energy utilization. Renew. Sustain. Energy Rev. 16(8), 5696–5706 (2012)

Markou, G., Angelidaki, I., Georgakakis, D.: Microalgal carbohydrates: an overview of the factors influencing carbohydrates production, and of main bioconversion technologies for production of biofuels. Appl. Microbiol. Biotechnol. 96(3), 631–645 (2012)

Templeton, D.W., Quinn, M., Van Wychen, S., Hyman, D., Laurens, L.M.: Separation and quantification of microalgal carbohydrates. J. Chromatogr. A 1270, 225–234 (2012)

Yaakob, Z., Ali, E., Zainal, A., Mohamad, M., Takriff, M.S.: An overview: biomolecules from microalgae for animal feed and aquaculture. J. Biol. Res. 21(1), 6 (2014)

Christaki, E., Bonos, E., Florou-Paneri, P.: Innovative microalgae pigments as functional ingredients in nutrition. In: Handbook of Marine Microalgae: Biotechnology Advances, pp. 233–243. London, Elsevier Academic Press (2015)

D’Alessandro, E.B., Antoniosi Filho, N.R.: Concepts and studies on lipid and pigments of microalgae: a review. Renew. Sustain. Energy Rev. 58, 832–841 (2016)

Fatma, T.: Screening of cyanobacteria for phycobiliproteins and effect of different environmental stress on its yield. Bull. Environ. Contam. Toxicol. 83(4), 509–515 (2009)

Chen, J., Wei, D., Pohnert, G.: rapid estimation of astaxanthin and the carotenoid-to-chlorophyll ratio in the green microalga Chromochloris zofingiensis using flow cytometry. Mar. Drugs. 15(7), 231 (2017)

Dufossé, L., Galaup, P., Yaron, A., Arad, S.M., Blanc, P., Murthy, K.N.C., Ravishankar, G.A.: Microorganisms and microalgae as sources of pigments for food use: a scientific oddity or an industrial reality? Trends Food Sci. Technol. 16(9), 389–406 (2005)

Pulz, O., Gross, W.: Valuable products from biotechnology of microalgae. Appl. Microbiol. Biotechnol. 65(6), 635–648 (2004)

Sydney, E.B., da Silva, T.E., Tokarski, A., Novak, A.C., de Carvalho, J.C., Woiciecohwski, A.L., Larroche, C., Soccol, C.R.: Screening of microalgae with potential for biodiesel production and nutrient removal from treated domestic sewage. Appl. Energy 88(10), 3291–3294 (2011)

Song, C., Liu, Q., Ji, N., Deng, S., Zhao, J., Li, S., Kitamura, Y.: Evaluation of hydrolysis–esterification biodiesel production from wet microalgae. Bioresour. Technol. 214, 747–754 (2016)

Cheng, J., Huang, R., Li, T., Zhou, J., Cen, K.: Biodiesel from wet microalgae: extraction with hexane after the microwave-assisted transesterification of lipids. Bioresour. Technol. 170, 69–75 (2014)

Rashid, N., Ur Rehman, M.S., Sadiq, M., Mahmood, T., Han, J.-I.: Current status, issues and developments in microalgae derived biodiesel production. Renew. Sustain. Energy Rev. 40, 760–778 (2014)

Chung, Y.-S., Lee, J.-W., Chung, C.-H.: Molecular challenges in microalgae towards cost-effective production of quality biodiesel. Renew. Sustain. Energy Rev. 74, 139–144 (2017)

Peralta-Ruíz, Y., Pardo, Y., González-Delgado, Á, Kafarov, V.: Simulation of bioethanol production process from residual microalgae biomass. In: Ian David Lockhart, B., Michael, F. (eds.) Computer Aided Chemical Engineering, vol. 30. pp. 1048–1052. Elsevier, Amsterdam (2012)

Ho, S.-H., Huang, S.-W., Chen, C.-Y., Hasunuma, T., Kondo, A., Chang, J.-S.: Bioethanol production using carbohydrate-rich microalgae biomass as feedstock. Bioresour. Technol. 135, 191–198 (2013)

Kim, H.M., Oh, C.H., Bae, H.-J.: Comparison of red microalgae (Porphyridium cruentum) culture conditions for bioethanol production. Bioresour. Technol. 233, 44–50 (2017)

Reyimu, Z., Özçimen, D.: Batch cultivation of marine microalgae Nannochloropsis oculata and Tetraselmis suecica in treated municipal wastewater toward bioethanol production. J. Clean. Prod. 150, 40–46 (2017)

Ramos-Suárez, J.L., Carreras, N.: Use of microalgae residues for biogas production. Chem. Eng. J. 242, 86–95 (2014)

Caporgno, M.P., Trobajo, R., Caiola, N., Ibáñez, C., Fabregat, A., Bengoa, C.: Biogas production from sewage sludge and microalgae co-digestion under mesophilic and thermophilic conditions. Renew. Energy 75, 374–380 (2015)

Meier, L., Pérez, R., Azócar, L., Rivas, M., Jeison, D.: Photosynthetic CO2 uptake by microalgae: an attractive tool for biogas upgrading. Biomass Bioenergy 73, 102–109 (2015)

Wieczorek, N., Kucuker, M.A., Kuchta, K.: Microalgae-bacteria flocs (MaB-Flocs) as a substrate for fermentative biogas production. Bioresour. Technol. 194, 130–136 (2015)

Bohutskyi, P., Chow, S., Ketter, B., Shek, F., Yacar, C., Tang, D., Zivojnovich, Y., Betenbaugh, M., Bouwer, M.J.: E.J.: Phytoremediation of agriculture runoff by filamentous algae poly-culture for biomethane production, and nutrient recovery for secondary cultivation of lipid generating microalgae. Bioresour. Technol. 222, 294–308 (2016)

Molinuevo-Salces, B., Mahdy, A., Ballesteros, M., González-Fernández, C.: From piggery wastewater nutrients to biogas: microalgae biomass revalorization through anaerobic digestion. Renew. Energy 96(Part B), 1103–1110 (2016)

Buitrón, G., Carrillo-Reyes, J., Morales, M., Faraloni, C., Torzillo, G.: 9 - Biohydrogen production from microalgae A2 - Gonzalez-Fernandez, Cristina. In: Muñoz, R. (ed.) Microalgae-Based Biofuels and Bioproducts, pp. 209–234. Woodhead Publishing, Sawston (2017)

Nagarajan, D., Lee, D.-J., Kondo, A., Chang, J.-S.: Recent insights into biohydrogen production by microalgae—from biophotolysis to dark fermentation. Bioresour. Technol. 227, 373–387 (2017)

Silva, C.M., Ferreira, A.F., Dias, A.P., Costa, M.: A comparison between microalgae virtual biorefinery arrangements for bio-oil production based on lab-scale results. J. Clean. Prod. 130, 58–67 (2016)

Nam, H., Kim, C., Capareda, S.C., Adhikari, S.: Catalytic upgrading of fractionated microalgae bio-oil (Nannochloropsis oculata) using a noble metal (Pd/C) catalyst. Algal Res. 24, 188–198 (2017)

Stepan, E., Enascuta, C.-E., Oprescu, E.-E., Radu, E., Radu, A., Galan, A.-M., Vasilievici, G., Lavric, V., Velea, S.: Intermediates for synthetic paraffinic kerosene from microalgae. Fuel. 172, 29–36 (2016)

Kang, Z., Kim, B.-H., Ramanan, R., Choi, J.-E., Yang, J.-W., Oh, H.-M., Kim, H.-S.: A cost analysis of microalgal biomass and biodiesel production in open raceways treating municipal wastewater and under optimum light wavelength. J Microbiol. Biotechnol. 25, 109–118 (2015)

Norsker, N.-H., Barbosa, M.J., Vermuë, M.H., Wijffels, R.H.: Microalgal production-a close look at the economics. Biotechnol. Adv. 29(1), 24–27 (2011)

Acién, F.G., Fernández, J.M., Magán, J.J., Molina, E.: Production cost of a real microalgae production plant and strategies to reduce it. Biotechnol. Adv. 30(6), 1344–1353 (2012). https://doi.org/10.1016/j.biotechadv.2012.02.005

Laurens, L.M., Chen-Glasser, M., McMillan, J.D.: A perspective on renewable bioenergy from photosynthetic algae as feedstock for biofuels and bioproducts. Algal Res. 24, 261–264 (2017)

Murphy, J.D., Drosg, B., Allen, E., Jerney, J., XiA, A., Herrmann, C.: A perspective on algal biogas. IEA Bioenergy. http://task37.ieabioenergy.com/files/daten-redaktion/download/Technical%20Brochures/AD_of_Algae_ebook_end.pdf (2015). Acessed 19 Oct 2017

Rocca, S., Agostini, A., Giuntoli, J., Marelli, L.: Biofuels from algae: technology options, energy balance and GHG emissions. In. Sci. Tech. Res. Rep., Off. Eur. Union, Luxembourg (2015)

Iijima, M.: Japan Biofuels Annual 2017. Global agricultural Information Network, pp. 1–22 (2017)

Efroymson, R.: Sustainable development of algae for biofuel. DOE Bioenergy Tevhnologies Office (BETO) 2017 project Peer Review - Oak Ridge National Laboratory (2017)

Abomohra, A.E.-F., Jin, W., Tu, R., Han, S.-F., Eid, M., Eladel, H.: Microalgal biomass production as a sustainable feedstock for biodiesel: current status and perspectives. Renew. Sustain. Energy Rev. 64, 596–606 (2016)

Ibekwe, A.M., Murinda, S.E., Murry, M.A., Schwartz, G., Lundquist, T.: Microbial community structures in high rate algae ponds for bioconversion of agricultural wastes from livestock industry for feed production. Sci. Total Environ. 580, 1185–1196 (2017)

Kay, R.A., Barton, L.L.: Microalgae as food and supplement. Crit. Rev. Food Sci. Nutr. 30(6), 555–573 (1991)

Paniagua-Michel, J.: Chap. 16 - Microalgal Nutraceuticals A2 - Kim, Se-Kwon. In: Handbook of Marine Microalgae, pp. 255–267. Academic Press, Boston (2015)

Hatfull, P.M.: Garnet Earl; James, Malcolm Raymond. Algae energy: a renewable, sustainable and emerging profitable business. Algae Tec. Limited. http://www.openbriefing.com/AsxDownload.aspx?pdfUrl=Report%2FComNews%2F20151113%2F01684665.pdf (2017). Acessed 18 Oct 2017

Matias, F.: Sustainable aquaculture in South America: trends and challenge. Summaries of the Monaco Blue Initiative 7th edition (2016)

Sillman, J.: Sustainability of protein production by bioreactor processes using wind and solar power as energy sources. Neo Carbon Energy. http://www.neocarbonenergy.fi/wp-content/uploads/2016/02/19_Sillman.pdf (2016) Acessed 24 Oct 2017

Kobler, C.a.N., David: Natural microalgae for healthy fish. Elements. Global challenges: sustainable nutrition 59, 1–40 (2017)

Pages, M.: Supply of micro-algae for sustainable salmon farming. Sirius Innovations. http://www.natuurlijkkapitaal.com/wp-content/uploads/2016/05/Sirius-Innovations-Study-Micro-algae-species-at-industrial-scale.pdf (2016). Acessed 19 Oct 2017

Begum, H., Yusoff, F.M., Banerjee, S., Khatoon, H., Shariff, M.: Availability and utilization of pigments from microalgae. Crit. Rev. Food Sci. Nutr. 56(13), 2209–2222 (2016)

Zegarac, J.P.: The science behind astaxanthin. Nutritional Outlook. http://www.nutritionaloutlook.com/herbs-botanicals/science-behind-astaxanthin (2017). Acessed 29 Sept 2017

Thomas, N.V., Kim, S.-K.: Beneficial effects of marine algal compounds in cosmeceuticals. Mar. Drugs. 11(1), 146–164 (2013)

Walker, D.A.: Biofuels, facts, fantasy, and feasibility. J. Appl. Phycol. 21(5), 509–517 (2009)

Mulbry, W., Kangas, P., Kondrad, S.: Toward scrubbing the bay: Nutrient removal using small algal turf scrubbers on Chesapeake Bay tributaries. Ecol. Eng. 36(4), 536–541 (2010)

Pizarro, C., Mulbry, W., Blersch, D., Kangas, P.: An economic assessment of algal turf scrubber technology for treatment of dairy manure effluent. Ecol. Eng. 26(4), 321–327 (2006)

Rohstoffe, F.N.: Final report on Collection, mapping and evaluation of R&D activities in the field of feedstock production and sustainability. Core-JetFuel. https://cordis.europa.eu/result/rcn/192392_en.html (2016). Acessed 19 Oct 2017.

Ting, H., Haifeng, L., Shanshan, M., Zhang, Y., Zhidan, L., Na, D.: Progress in microalgae cultivation photobioreactors and applications in wastewater treatment: a review. Int. J. Agric. Biol. Eng. 10(1), 1 (2017)

Malik, A., Lenzen, M., Ralph, P.J., Tamburic, B.: Hybrid life-cycle assessment of algal biofuel production. Bioresour. Technol. 184, 436–443 (2015)

Benvenuti, G., Ruiz, J., Lamers, P.P., Bosma, R., Wijffels, R.H., Barbosa, M.J.: Towards microalgal triglycerides in the commodity markets. Biotechnol. Biofuels. 10(1), 188 (2017)

Euglena: Recent updates - highlights. Shared Research Report. https://sharedresearch.jp/system/report_updates/pdfs/000/017/707/original/2931_EN_20180209.pdf?1518492097 (2017). Accessed 19 Oct 2017

Acknowledgements

The authors would like to thank CAPES for scholarships, the University of Santa Cruz do Sul (UNISC), TecnoUNISC, through the Center for Research in Chemical and Biotechnological Processes and Products and MCTIC (01.0144.00/2010) as well as Secretary of Development in Economy, Science and Technology of the state of Rio Grande do Sul (SDECT-RS).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

de Souza, M.P., Hoeltz, M., Gressler, P.D. et al. Potential of Microalgal Bioproducts: General Perspectives and Main Challenges. Waste Biomass Valor 10, 2139–2156 (2019). https://doi.org/10.1007/s12649-018-0253-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-018-0253-6