Abstract

Maize is a good substrate for fungal growth and production of toxic secondary metabolites or mycotoxins. The relationships between the fungal biomarker ergosterol (ERG) and mycotoxins such as aflatoxins (AFs), ochratoxin A (OTA) and zearalenone (ZEA) were investigated in maize collected from four different geographic locations. ERG and mycotoxins were measured by high-performance liquid chromatography with UV and fluorescence detection. ERG did not correlate with AFs in 139 analysed samples. OTA contamination was found in only one sample from the North American region. A significant correlation (r 2 = 0.82) was observed between ERG and ZEA. AFs and ZEA were found in 47 % of all samples. Half of the samples contained more than two mycotoxins. Levels of ERG and mycotoxin contamination differed by geographical region. North American and Asian samples had higher frequencies and levels of ERG and mycotoxin contamination. No AF contamination was observed in European samples (limit of detection 0.025 μg/kg for AFB1). We conclude that samples containing less than 3 mg/kg ERG in most cases do not exceed the EU maximum limits for AFs, OTA and ZEA.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Maize is one of the most widely distributed cereal crops in the world. It is a staple of the human diet and an important feed ingredient for livestock. Major mycotoxigenic fungi such as Aspergillus, Penicillium and Fusarium often contaminate maize and produce secondary toxic metabolites called mycotoxins, of which aflatoxins (AFs), ochratoxin A (OTA) and zearalenone (ZEA) are of major concern for their toxicity and occurrence (Pitt 2006).

Mycotoxins produce a wide range of acute and chronic toxicological effects on human and animal health. AFs are the most well-studied mycotoxin produced by Aspergillus species. AFB1 is genotoxic in vivo and in vitro (EFSA 2007) and was classified as a group 1 carcinogen (carcinogenic to human) by the International Agency for Research on Cancer (IARC) (1993). Other AFs (AFB2, G1 and G2) are associated with hepatitis, haemorrhage, oedema, immunosuppression and hepatic carcinoma (Speijers and Speijers 2004). The European Commission (EC 2006) has set maximum AF levels in maize for human consumption or use as a food ingredient at 5 μg/kg for AFB1 and 10 μg/kg for total AF.

OTA is a nephrotoxic mycotoxin mainly produced by Aspergillus ochraceus and Penicillium verrucosum. OTA produces carcinogenic, nephrotoxic, teratogenic, immuno-toxic and hepatotoxic effects and has been classified as a group 2B carcinogen (possible carcinogen to humans) by the IARC (1993). Due to the public health significance of OTA, the EC (2006) has established a permissible limit of 5 μg/kg for unprocessed cereals and 3 μg/kg for processed cereal products and direct human consumption. ZEA is an estrogenic mycotoxin produced primarily by Fusarium graminearum. It causes reproductive disorders in female swine and hyper-oestrogenic syndromes in humans (Zinedine et al. 2007). It is considered a group 3 carcinogen (carcinogenicity not classifiable to human) according to the IARC (1993) with a permissible limit of ZEA which is 200 μg/kg in unprocessed maize (EC 2006).

A recent worldwide survey of over 19,000 samples of feed and feed ingredients revealed contamination frequencies of 26 % for AFs, 25 % for OTA and 37 % for ZEA (Schatzmayr and Streit 2013). The co-occurrence of several mycotoxins in the same sample may produce antagonistic, additive or synergistic effects. Due to the chemical diversity of mycotoxins and their varying concentrations between samples, simultaneous analysis of multiple mycotoxins is a great challenge for analytical chemists (Ibáñez-Vea et al. 2011). A few reports have described simultaneous assessment of AFs, OTA and ZEA by HPLC-FLD after immunoaffinity column (IAC) purification in cereals (maize, wheat and rice) from Malaysia (Rahmani et al. 2010; Soleimany et al. 2011), breakfast cereals and barley from Spain (Ibáñez-Vea et al. 2011, 2012) and breakfast cereals from Pakistan (Iqbal et al. 2014).

Most analytical methods for mycotoxins have been developed and validated for specific mycotoxins in a specific matrix. Even with advanced liquid chromatography-tandem mass spectrometry (LC-MS/MS) instrumentation, it is impossible to analyse all major (approximately 25) known mycotoxins in a single run (Tang et al. 2013). On the other hand, ergosterol (ERG) is a general fungal component, which can be used as an indicator of fungal invasion in grains (Seitz et al. 1977; Lamper et al. 2000). Therefore, if the level of mycotoxin contamination in grains was estimated using as a simple ERG analysis, it would be preferable. Several studies have investigated the association between ERG levels and mycotoxin contamination with AFs (Gourama and Bullerman 1995; Castro et al. 2002; Pietri et al. 2004; Karaca and Nas 2006; Ekinci et al. 2014), OTA (Olsson et al. 2002; Varga et al. 2002), ZEA (Zill et al. 1988; Pietri et al. 2004), deoxynivalenol (Lamper et al. 2000) and patulin (Kadakal et al. 2005; Ekinci et al. 2014). Therefore, ERG determination prior to single or multi-mycotoxin analysis could be a fast and useful tool for quality control in the grain industry.

The major aim of this study was to investigate the relationship between ERG content and contamination by six mycotoxins. Another objective was to identify regional variations in ERG content and mycotoxin contamination in maize samples collected from different geographical regions.

Materials and methods

Samples

We studied 139 maize samples obtained from North America (n = 76), South America (n = 24), Asia (n = 32) and Europe (n = 7) in the 2011 and 2013 harvesting years. These samples were collected from two analytical laboratories in Singapore (for Asian samples) and the USA (for North and South American and European samples), where samples were submitted for analysis. The sampled Asian countries included Thailand, Taiwan, Cambodia, Indonesia, Philippines, Australia, India and Pakistan. American countries included the USA, Brazil and Argentina. European countries included Ukraine, Russia and Azerbaijan. The minimum size of each sample was 500 g. All samples were ground by milling through a 1-mm mesh (variable-speed Rotter mill pulverisette 13, Fritsch, Germany). Samples were stored at −20 °C.

Materials and reagents

ERG standard (98 %) was obtained from Acros (Geel, Belgium). Analytical standards of AFs (AFB1, B2, G1 and G2) and OTA were purchased from Biopure (Tulln, Austria), and ZEA was purchased from Sigma-Aldrich (St. Louis, USA). AO ZON PREP® IAC was purchased from R-Biopharm Rhône. HPLC-grade methanol was purchased from Wako Pure Chemical Industries (Osaka, Tokyo). All other chemicals and reagents, including methanol and acetonitrile (reagent grade and HPLC grade), hexane (reagent grade), ethanol (HPLC grade), disodium phosphate dodecahydrate, potassium phosphate, potassium chloride, sodium chloride and acetic acid were purchased from Kanto Chemical. The water was purified with a water purification system (Autopure WT100, Yamato, Tokyo, Japan).

Phosphate buffer (PB, 0.1 mol/L) was prepared by dissolving sodium phosphate dibasic and potassium dibasic in ultrapure water, adjusted to pH 7.4. After autoclaving at 121 °C for 15 min, the solution was stored at 4 °C. To make phosphate buffer saline (PBS, 0.01 mol/L, pH 7.4), the solution was diluted tenfold and sodium chloride was added.

Standard solutions

ERG stock solution (2000 μg/mL) was prepared by dissolving in methanol. Standard calibration solutions (0.2, 0.5, 1, 5, 10, 20, 40 μg/mL) were made daily by diluting the stock solution with methanol. Standard stock solutions of AFB1 and AFG1 (9 ng/mL), AFB2 and AFG2 (2.25 ng/mL), OTA (135 ng/mL), and ZEA (4.5 μg/mL) were prepared by diluting in acetonitrile. Standard calibration curves were made daily by diluting the stock solution as follows: AFB1 and AFG1 (0.1–4.5 ng/mL), AFB2 and AFG2 (0.025–1.125 ng/mL), OTA (1.5–67.5 ng/mL), and ZEA (0.05–2.25 μg/mL). All solutions were stored at −20 °C.

ERG analysis

ERG extraction, clean-up, and analysis were performed as described by Miyagawa et al. (2009). Briefly, 10 g sample, 5 g sodium hydroxide and 40 mL methanol were placed in a 300-mL flat-bottom flask. The samples were refluxed with a mantle-type heater for 1 h. After cooling at room temperature, methanol was added to compensate for evaporation during refluxing. The samples were filtered through Whatman No. 2 filter paper. Then, 10 mL of the filtrate was transferred to a 200-mL separating funnel; 10 mL 3 % aqueous potassium chloride was added and mixed. After adding 10 mL hexane, the mixture was shaken vigorously by hand for 3 min. A 5-mL sample of the hexane layer was collected and passed through a Sep-Pak® Plus silica cartridge (690 mg sorbent/cartridge) (Waters, Milford, USA) after pre-conditioning with 5 mL hexane. Elution was performed with 5 mL methanol in an 8-mL amber vial and stored at −20 °C until HPLC-UV analysis.

ERG was analysed by HPLC with UV detection (Shimadzu LC-10 series, Shimadzu) on an ODS column (ODS-SP, 4 mm i.d. × 150 mm, 5 μm, GL Sciences) and a guard cartridge (Inertsil ODS-SP, 4 mm i.d. × 10 mm, 5 μm, GL Sciences, Tokyo, Japan). The column oven temperature was maintained at 40 °C. Mobile phase A was a mixture of methanol and water (80:20, v/v) and mobile phase B was a mixture of methanol and ethanol (70:30, v/v). The ratio of mobile phases A and B was 1:1 for the first 5 min. After that, the ratio of B was increased to 70 % for 5 min and 90 % for 3 min. This last ratio was maintained for another 5 min. The mobile phase flow rate was 1 mL/min, and 10 μL of the sample was subjected to HPLC analysis. UV absorption was measured at 282 nm.

Mycotoxins analysis

Twenty-five grammes of ground sample and 100 mL of a methanol and water mixture (80:20, v/v) were placed in a 300-mL Erlenmeyer flask. This flask was shaken for 30 min at 220 rpm by a reciprocal shaker (SA-31, Yamato Scientific, Tokyo, Japan). The sample was filtered through Whatman No. 113 filter paper (Maidstone, UK) and 10 mL of the filtrate was diluted with 40 mL PBS (0.01 mol/L). The IAC was conditioned with 3 mL PBS before loading the filtrate. A 20-mL sample of the diluted filtrate was passed through the AO ZON PREP® IAC. After passing the sample, the IAC was washed with 20 mL PBS followed by 10 mL of water. Air was passed through the column to remove residual liquid. Elution was performed with 2 mL acetonitrile followed by 1 mL methanol. After N2 gas evaporation of the eluted sample, the residue was re-dissolved in 1 mL of 50 % acetonitrile for HPLC-FLD analysis.

AFs, OTA and ZEA were analysed by HPLC with fluorescence detection (Shimadzu, Kyoto, Japan). Mycotoxins were separated on an ODS column (Develosil ODS-UG-5, 5 μm, 4.6 mm i.d. × s100 mm) with a guard cartage (4 mm i.d. × 10 mm) (Nomura Chemical, Aichi, Japan). The column oven temperature was set at 45 °C. A 20-μL sample was injected with the mobile phase flow rate at 1 mL/min. Mobile phase A was a mixture of acetonitrile/methanol/0.1 % acetic acid in water (5:35:60, v/v/v), and mobile phase B was a mixture of acetonitrile/methanol/0.1 % acetic acid in water (70:10:20, v/v/v). The initial ratio of mobile phases A and B was set at 88:12 for the first 3.5 min. The ratio of B increased to 20 % for 4.5 min, and then 30 % for 21 min. The ratio of B increased to 60 % for the next 6 min and then returned to 12 %. To enhance detection of AFB1 and G1, post-column derivatization was performed with a photochemical reactor (PHRED, Aura Industries, NY, USA). Excitation and emission wavelengths were set at 365 and 435 nm for AFs, 336 and 464 nm for OTA, and 274 and 440 nm for ZEA. After AF detection by fluorescence (0–10 min), fluorescence detection was changed for ZEA from 10 to 20.8 min and OTA from 20.8 to 35 min.

Method performance

The performance characteristics of the analytical method were assessed in terms of selectivity, linearity, sensitivity and recovery. Both methods were selective after using IAC and Silica cartridge clean-up with FLD and UV detection. Figure 1 shows the chromatograms of a standard ERG solution with a naturally contaminated maize sample at 13.1 mg/kg. Naturally contaminated maize samples with various levels of AFs, OTA and ZEA are shown in Fig. 2. Retention times for ERG and each mycotoxin peak corresponded with the standard solutions with a tolerance of ±2.5 %. Calibration curves for ERG and mycotoxins (AFB1, B2, G1, G2; OTA; ZEA) showed linearity within the tested ranges with a co-efficient of determination in excess of 0.999. The limit of detection (LOD, signal/noise = 3) was determined to be 0.24 mg/kg for ERG, 0.025 μg/kg for AFB1, 0.0125 μg/kg for AFB2, 0.05 μg/kg for AFG1, 0.025 μg/kg for AFG2, 0.5 μg/kg for OTA and 15 μg/kg for ZEA in maize. The limit of quantification (LOQ, signal/noise = 10) was determined to be 0.1 μg/kg for AFB1, 0.05 μg/kg for AFB2, 0.2 μg/kg for AFG1, 0.08 μg/kg for AFG2, 1.5 μg/kg for OTA and 50 μg/kg for ZEA in maize. Recovery of ERG was checked at two concentration levels (3 and 8 mg/kg) with six replicates on ERG-free maize samples, which yielded mean recoveries of 71–81 % with relative standard deviations (repeatability) of 5.7–12 %. For mycotoxins, blank maize samples were spiked simultaneously at 5 μg/kg AFB1 and AFG1, 1.5 μg/kg AFB2 and AFG2, 2.5 μg/kg OTA, and 0.5 mg/kg of ZEA with triplicates. The mean recoveries were AFB1 (76 %), AFB2 (83 %), AFG1 (80 %), AFG2 (85 %), OTA (90 %) and ZEA (89 %), with relative standard deviations (repeatability) of 0.6–4.9 %

HPLC chromatograms of AFs, OTA and ZEA in maize samples. a OTA in a naturally contaminated maize sample at 19.3 μg/kg. b Naturally contaminated AFB1, AFB2 and AFG1 at 6.2, 0.6 and 0.1 μg/kg, respectively, in maize. c Standard solutions of AFs (AFB1 and AFG1 at 2 ng/ml, AFB2 and AFG2 at 0.5 ng/mL), OTA at 45 ng/mL and ZEA at 1 μg/mL. d Naturally contaminated ZEA at 331 μg/kg in maize sample

Statistics

Concentration means and medians were calculated in Microsoft Excel (ver. 2010). Regression analysis was used to assess the correlation between ERG and each mycotoxin group. The Kruskal-Wallis or median test was used to evaluate regional differences (SPSS ver. 15, IBM, USA). A probability value of 0.05 indicated statistical significance.

Results and discussion

ERG levels in maize

ERG was detected in all 139 samples, with an average content of 9.5 mg/kg and a maximum of 119 mg/kg (Table 1). According to Pietri et al. (2004), the quality of maize is acceptable if the ERG content is less than 3 mg/kg. If the ERG content is more than 8 mg/kg, the potential of fungal invasion or mycotoxin contamination is high. Low mycotoxin contamination was observed in samples with less than 3 mg/kg ERG. As shown in Fig. 3, 20 % of the maize samples contained less than 3 mg/kg ERG; 48 % of the samples contained 3–8 mg/kg; 13 % of samples contained between 8 and 12 mg/kg ERG and 19 % of samples contained more than 12 mg/kg.

AFs, OTA and ZEA levels in maize

After determining ERG, the same 139 maize samples were analysed for mycotoxins. The frequency and contamination levels of AFs, OTA and ZEA are presented in Table 1. Mycotoxin occurrence was considered positive if contamination levels were higher than the LOD. Results showed that 74 % of the samples were positive for AFB1, with mean and maximum levels of 11.8 and 327 μg/kg, respectively. In this study, 25 % of samples contained more than the maximum permissible limit of AFB1 (5 μg/kg; Fig. 3) and 73 % of the samples contained AFB1 levels greater than the LOQ. About 10 % of the samples contained above-limit levels of total AFs (10 μg/kg). The contamination frequencies of AFB2, AFG1 and AFG2 were 43, 4 and 0.8 %; AFB2 contamination ranged from 0.01 to 33.8 μg/kg.

Surprisingly, only one sample contained a high level of OTA (19.8 μg/kg) that exceeds the EU permissible limits for unprocessed maize (5 μg/kg). In addition, 24 % of samples were contaminated with ZEA, with mean and maximum levels of 118 and 626 μg/kg, respectively (Table 1). In this study, 22 % of samples contained more than 100 μg/kg ZEA (Fig. 3), whereas only 4 % of samples were above the EU maximum permissible limits in unprocessed maize (200 μg/kg).

Co-occurrence of AFs, OTA and ZEA

Thirty-four percent of samples contained one mycotoxin, 42 % contained two mycotoxins, 7 % contained three and 1 % of samples contained four mycotoxins. No mycotoxins were observed in 16 % of samples. Grains are often contaminated with multiple mycotoxins that potentiate their toxic effects (Prelusky et al. 1994). After reviewing 100 studies on mycotoxin interactions with adverse effects on animal health, Grenier and Oswald (2011) concluded that most co-occurring mycotoxins produce additive or synergistic effects. Thus, determining single mycotoxins in grains cannot assure the toxicity of fungal metabolites. We found two or more mycotoxins in 50 % of samples, higher than the findings of Schatzmayr and Streit (2013), who reported that 39 % of samples contained two or more mycotoxins. Our study also revealed the co-occurrence of AFs and ZEA in 47 % of samples. This confirms previous findings ZEA-contaminated maize samples are frequently also contaminated with AFs (EFSA 2004a). AFB1 and AFB2 were present in about 58 % of samples. Thus, the co-occurrence of mycotoxins should be considered when making exposure risk assessments.

Relationships between ERG content and mycotoxin contamination

ERG has been used an indicator of fungal biomass in grains. The relationship between carcinogenic AFB1 and ERG content has been investigated in a few previous studies (Pietri et al. 2004; Castro et al. 2002; Gourama and Bullerman 1995). We observed no significant correlation between ERG and the presence of AFB1or total AFs in maize, consistent with Pietri et al. (2004). When we compared ERG content in 25 samples with >5 μg/kg AFB1, a very weak correlation (r 2 = 0.253) was observed. All 25 samples contained more than 3 mg/kg ERG. We analysed 139 samples, of which 26 samples (19 %) contained less than 3 mg/kg ERG and AFB1 levels of 0.03–3.1 μg/kg. With the exception of two samples that contained 1.5 and 3 μg/kg AFB1, the samples contained less than 1 μg/kg AFB1. Castro et al. (2002) and Gourama and Bullerman (1995) reported that AFB1 positively correlates with ERG content in grains, but AFB2 and AFG1 do not follow similar trends, as shown in our study. ERG content is not always consistent with AF production in grains as AF depends on the fungal species and environment.

No significant correlation was observed between ERG and OTA production in maize because only one sample contained OTA at 19.3 μg/kg with an ERG level of 4.79 mg/kg at this time. However, a positive correlation between ERG content and the presence of OTA has been observed in grains (Saxena et al. 2001; Olsson et al. 2002; Abramson et al. 2005; Tangni and Pussemier 2006). Thus, to understand the correlation of occurrence between ERG and OTA, more samples with an OTA contamination need to be examined.

ZEA production is favoured in humid and low-temperature regions and is found mainly in high-moisture corn (CAST 2003). A significant correlation (r 2 = 0.82) was observed between ERG content and ZEA production in maize (Fig. 4). This relationship between ERG and ZEA levels has been reported elsewhere (Pietri et al. 2004; Neuhof et al. 2008; Zill et al. 1988). A positive correlation was reported between ERG and combined DON with ZEA contamination by Pietri et al. (2004). Another study by Neuhof et al. (2008) showed a relationship between ERG and ZEA with a correlation coefficient of 0.999 on fractioned wheat kernels. In this study, samples contaminated with higher ZEA levels (>100 μg/kg) also contained more than 3 mg/kg ERG. No samples with ZEA <50 μg/kg showed ERG levels above 3 mg/kg. Among 26 samples with less than 3 mg/kg ERG, only one sample contained 32 μg/kg ZEA.

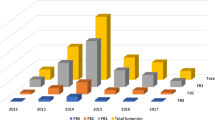

ERG and production of mycotoxins based on origins of samples

Mycotoxin contamination on grains was caused by both plant pathogenic and storage fungi. Therefore, mycotoxin contamination was effected by various factors such as climate, plant, storage, insect damage, pest attack and so on (Paterson and Lima 2010). Fungal-specific sterol (ERG) and levels of mycotoxins by different geographic region are summarised according to geographic origin in Table 2. Higher mean and maximum values (>8 mg/kg) of ERG were found in North American and Asian samples. North American and Asian samples also showed higher levels of contamination with AFB1, AFB2 and ZEA. Nevertheless, no significant difference was observed for ERG between regions (Kruskal-Wallis or median test). We observed more than 3 mg/kg ERG in 83 % of North American samples, 79 % of South American samples, 72 % of Asian samples and 79 % of European samples. ERG content >8 mg/kg was observed in 32 % of North American samples, 29 % of South American samples, 37 % of Asian samples and 7 % of European samples.

Aflatoxigenic fungi are native to arid, semi-arid, warm, tropical climate; changes in climate may generate large fluctuations in the quantity of AF producers (Bock et al. 2004; Shearer et al. 1992). In our study, the mean values of AFB1 from North American and Asian samples were 8.2 and 23.3 μg/kg, both of which exceed the EU maximum permissible limits (5 μg/kg) for AFB1 (Table 2). As expected, significant differences were observed for AFB1 and AFB2 between regions. According to Wu et al. (2011), high temperature and drought stress directly impact maize and Aspergillus flavus growth. High temperature and low rainfall favour the infection of maize with A. flavus, which produce high levels of AFs (Jones et al. 1980; Payne et al. 1985; Shearer et al. 1992). Our study observed that North American and Asian maize samples have a high level of fungal invasion and AFs contamination, especially AFB1 and AFB2. Grains generally grown in warm climates have a greater chance of aflatoxigenic fungal infection and in some regions, infection only observed when temperatures rise in association with drought (Sanders et al. 1984; Schmitt and Harburgh 1989). In contrast, AFG1 and AFG2 contamination were detected on five samples from North America. No European maize samples were contaminated with AFs as these toxins are favoured by tropical and sub-tropical climate (EFSA 2004b).

OTA-producing fungi are found across a wide range of climatic conditions and include species of Aspergillus and Penicillium. The production of OTA is considered a storage-related, rather than pre-harvest problem (Petzinger and Weidenbach 2002). In the four geographical regions covered in our study, we observed only one North American sample that contained 19.3 μg/kg OTA (Table 2). Our findings differ from those of Schatzmayr and Streit (2013), whose study on feed and raw materials showed OTA in 25 % of samples.

ZEA-producing fungi may be found in the field and in improperly stored animal feeds (Kuiper-Goodman et al. 1987). In this study, ZEA did not significantly differ by region. North American samples showed the highest maximum level of ZEA contamination (626 μg/kg), with a mean value of 186 μg/kg (Table 2). The higher maximum (331 μg/kg) and mean values (83.2 μg/kg) were also observed in Asian maize with a contamination frequency of 22 %. South American (25 %) and European (57 %) samples showed low levels (mean values <50 μg/kg) of ZEA contamination.

The natural co-occurrence of mycotoxin in individual maize samples varies by geographic region (Table 3). Two or more mycotoxins co-occurred in North American (52 %) and South American (22 %) maize samples. Asian countries showed the highest number of samples (79 %) with more than two mycotoxins. No mycotoxin combinations were found in European samples.

Conclusion

Fungal growth and mycotoxin contamination are an unavoidable problem for agricultural commodities. Maize is susceptible to fungal attack and the mycotoxins that affect human and animal health. As an economically important worldwide crop, mycotoxin-contaminated maize is a global trade concern. ERG determination would be an ideal method for initial screening of bulk samples for fungal and mycotoxin contamination. We investigated the relationship between ERG and simultaniously analyzed AFs, OTA and ZEA after IAC clean-up in maize. Several influencing factors such as fungal strain, microbial interactions, substrate, humidity and temperature play a pivotal role in fungal proliferation and mycotoxin production. These diverse factors mean the correlation between ERG and mycotoxin is not absolute, although we observed a good correlation (r 2 = 0.82) between ERG and ZEA contamination. No significant correlation was found between ERG and total AFs or OTA. Results also indicate that North American and Asian samples showed the highest frequency and the levels of contamination. However, maize samples containing less than 3 mg/kg of ERG were less likely to exceed the maximum permissible limits of AFs, OTA and ZEA set by the EU. This indication of ERG might be useful in the grain industry to monitor fungal invasion and, on a merely qualitative basis, mycotoxin contamination on maize.

References

Abramson D, Hulasare R, York RK, White NDG, Jayas DS (2005) Mycotoxins, ergosterol and odor volatile in durum wheat during granary storage at 16 % and 20 % moisture content. J Stor Prod Res 41:67–76

Bock CH, Mackey B, Cotty PJ (2004) Population dynamics of Aspergillus flavus in the air of an intensively cultivated region of south-west Arizona. Plant Pathol 53:422–433

CAST (2003) Mycotoxins: risks in plant, animal and human systems. In Council for Agricultural Sciences and Technology, Ames, Iowa, USA, (Ed.), p 16

Castro MFPM, Bragagnolo N, Valentini SRD (2002) The relationship between fungi growth and aflatoxin production with ergosterol content of corn grains. Braz J Microbiol 33:22–26

EFSA (2004a) Opinion of the Scientific Panel on contaminants in the food chain on a request from the Commission related to zearalenone as undesirable substance in animal feed. EFSA J 89:1–35

EFSA (2004b) Opinion of the Scientific Commission in the food chain on a request from the Commission related to aflatoxin B1 as undesirable substance in animal feed. EFSA J 39:1–27

EFSA (2007) Opinion of the scientific panel on contaminants in the food chain on a request from the commission related to the potential increase of consumer health risk by a possible increase of the existing maximum levels for aflatoxins in almonds, hazelnuts and pistachios and derived products. EFSA J 446:1–127

Ekinci R, Otag M, Kadakal Ç (2014) Patulin ergosterol: new quality parameters together with aflatoxins in hazelnuts. Food Chem 150:17–21

European Commission (2006) Commission regulation (EC) No 1881/2006 of 19 December 2006 setting maximum levels for certain contaminants in foodstuffs. Off J Eur Union L 364:5–24

Gourama H, Bullerman LB (1995) Relationship between aflatoxin production and mould growth as measured by ergosterol and plate count. Lebensm Wiss Technol 28:185–189

Grenier B, Oswald IP (2011) Mycotoxin co-contamination of food and feed:meta-analysis of publications describing toxicological interactions. World Mycotoxin J 4:285–313

IARC (1993) Working group on the evaluation of carcinogenic risks to humans; some naturally occurring substances: food Items and Constituents, Heterocyclic Aromatic Amines and mycotoxins, Monographs on the Evaluation of Carcinogenic Risks to Humans 56

Ibáñez-Vea M, Corcuera LA, Remiro R, Murillo-Arbizu MT, González-Peñas E, Lizarraga E (2011) Validation of a UHPLC-FLD method for the simultaneous quantification of aflatoxins, ochratoxin A and zearalenone in barley. Food Chem 127:351–358

Ibáñez-Vea M, González-Peñas E, Lizarraga E, López de Cerain A (2012) Co-occurrence of aflatoxins, ochratoxin A and zearalenone in barley from a northern region of Spain. Food Chem 132:35–42

Iqbal SZ, Rabbani T, Asi MR, Jinap S (2014) Assessment of aflatoxins, ochratoxin A and zearalenone in breakfast cereals. Food Chem 157:257–262

Jones R, Duncan H, Payne G, Leonard K (1980) Factors influencing infection by Aspergillus flavus in silk-inoculated corn. Plant Dis 64:859–863

Kadakal C, Nas S, Ekinci R (2005) Ergosterol as a new quality parameter together with patulin in raw apple juice produced from decayed apples. Food Chem 90:95–100

Karaca H, Nas S (2006) Aflatoxins, patulin and ergosterol contents of dried figs in Turkey. Food Addit Contam A 23:502–508

Kuiper-Goodman T, Scott PM, Watanabe H (1987) Risk assessment of the mycotoxin zearalenone. Regul Toxicol Pharmacol 7:253–306

Lamper C, Teren J, Bartok T, Komoroczy R, Mesterhazy A, Sagi F (2000) Prediction DON contamination in Fusarium infected wheat grains via determination of ergosterol content. Cereal Res Commun 28:337–344

Miyagawa H, Umeda M, Sato T, Bandoh S, Nakamura S, Goto T (2009) Single-laboratory validation of a method for ergosterol determination in cereals. Food Addit Contam 26:201–206

Neuhof T, Koch M, Rasenko T, Nehls I (2008) Distribution of trichothecenes, zearalenone and ergosterol in fractionated wheat harvest lot. J Agric Food Chem 56:7566–7571

Olsson J, Borjesson T, Lundstedt T, Schnurer J (2002) Detection and quantification of ochratoxin A and deoxynivalenol in barley grains by GC–MS and electronic nose. Int J Food Microbiol 72:203–214

Paterson RRM, Lima N (2010) How will climate change affect mycotoxins in food? Food Res Int 43:1902–1914

Payne GA, Cassel DK, Adkins CR (1985) Reduction of aflatoxin levels in maize due to irrigation and tillage. Phytopathology 75:1283

Petzinger E, Weidenbach A (2002) Mycotoxins in the food chain: the role of ochratoxins. Livest Prod Sci 76:245–250

Pietri A, Bertuzzi T, Pallaroni L, Piva G (2004) Occurrence of mycotoxins and ergosterol in maize harvested over 5 years in northern Italy. Food Addit Contam 21:479–487

Pitt JI (2006) Fungal ecology and the occurrence of mycotoxins. In H. Njapau, S. Trujillo, H. P. Van Egmond, D. L. Park (Eds.), Mycotoxins and phycotoxins. Advances in determination, toxicology and exposure management. The Netherlands: Wageningen Academic Publishers

Prelusky DB, Rotter BA, Rotter RG (1994) Toxicology of mycotoxins. In: Miller JD, Trenholm HL (eds) Mycotoxins in grain. Compounds other than aflatoxin. Eagan Press, St. Paul, pp 359–403

Rahmani A, Jinap S, Soleimany F (2010) Validation of the procedure for the simultaneous determination of aflatoxins ochratoxin A and zearalenone in cereals using HPLC-FLD. Food Addit Contam 27:1683–1693

Sanders TH, Blankenship PD, Cole RJ, Hill RA (1984) Effect of soil temperature and drought on peanut pod and stem temperatures relative to Aspergillus flavus invasion and aflatoxin contamination. Mycopathologia 86:51–54

Saxena J, Munimbazi C, Bullerman LB (2001) Relationship of mould count, ergosterol and ochratoxin A production. Int J Food Microbiol 71:29–34

Schatzmayr G, Streit E (2013) Global occurrence of mycotoxins in the food and feed chain: facts and figures. World Mycotoxin J 6:213–222

Schmitt SG, Harburgh CR Jr (1989) Distribution and measurement of aflatoxin in 1983 Iowa corn. Cereal Chem 66:165–168

Seitz LM, Mohr HE, Burroughs R, Sauer DB (1977) Ergosterol as indicator of fungal invasion in grains. Cereal Chem 54:1207–1217

Shearer J, Sweets L, Baker N, Tiffany L (1992) A study of Aspergillus flavus/parasiticus in Iowa crop fields: 1988–1990. Plant Dis 76:19–22

Soleimany F, Jinap S, Rahmani A, Khatib A (2011) Simultaneous detection of 12 mycotoxins in cereals using RP-HPLC-PDA-FLD with PHRED and a postcolumn derivatization system. Food Addit Contam 28:494–501

Speijers GJA, Speijers MHM (2004) Combined toxic effects of mycotoxins. Toxicol Lett 153:91–98

Tang YY, Lin HY, Chen YC, Su WT, Wang SC, Chiueh LC, Shin YC (2013) Development of a quantitative multi-mycotoxin method in rice, maize, wheat and peanut using UPLC-MS/MS. Food Anal Methods 6:727–736

Tangni EK, Pussemier L (2006) Ochratoxin A and citrinin loads in stored wheat grains: impact of grain dust and possible prediction using ergosterol measurements. Food Addit Contam 23:181–189

Varga J, Rigo K, Lamber C, Teren J, Szabo G (2002) Kinetics of ochratoxinA production in different Aspergillus species. Acta Biol Hung 53:381–388

Wu F, Bhatnagar D, Bui-Klimke T, Carbone I, Hellmich R, Munkvold G, Paul P, Payne G, Takle E (2011) Climate change impacts on mycotoxin risks in US Maize. World Mycotoxin J 4:79–93

Zill G, Engelhardt G, Wallnofer PR (1988) Determination of fungal ergosterol as a measure of fungal growth using Si 60 HPLC. Z Lebens Unters Forsch A 187:246–249

Zinedine A, Soriano JM, Molto JC, Manes J (2007) Review on the toxicity, occurrence, metabolism, detoxification, regulations and intake of zearalenone: an oestrogenic mycotoxin. Food Chem Toxicol 45:1–18

Conflict of interest

The authors declare that there are no conflicts of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hossain, M.Z., Mari, N. & Goto, T. The relationship between ergosterol and mycotoxin contamination in maize from various countries. Mycotoxin Res 31, 91–99 (2015). https://doi.org/10.1007/s12550-015-0219-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12550-015-0219-5