Abstract

Following on from our previous research into the prehistoric aceramic distillation and production of birch bark tar, this series of exploratory experiments investigated the use of raised structures within a fire. These field-based experiments were conducted using sand, gravel, wood fuel, and bark from Betula pubescens (downy birch). The structures that were created were simple raised sand mounds, which reflected known Neanderthal combustion surfaces from the Middle Palaeolithic. The bulk of the experiments were recorded throughout using a thermocouple to provide temperature readings from the base of the bark pyrolysis chamber. The experiments proved successful at producing birch bark tar and several containers were used to catch the tar for later analysis. Based on the results, the authors contend that not only could Neanderthals control fire but that regular birch bark tar production by Neanderthals was most likely a result of specific chaînes opératoires in order to provide the necessary control and outcomes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The use of tar extracted from the bark of Betula sp. (birch species) stretches from the Middle Palaeolithic, through to the Mesolithic (Aveling and Heron 1998), the Neolithic (Bosquet et al. 2001; Urem-Kotsou et al. 2002), the Iron Age (e.g. Regert et al. 2003; Charters et al. 1993; Sauter et al. 2002), until modern times. Its use takes many forms, adhesive agent, possibly a masticant medicine (Aveling and Heron 1999) while the Ojibwa in North America used birch bark tar (mainly from Betula papyrifera) for waterproofing birch bark canoes (Lyford 1943).

Birch bark tar may well be the first synthetic product constructed by humans (Grünberg 2002: 15), and finds from Campitello Quarry in the Upper Valdarno Basin, Italy, may as yet be the earliest, potentially dating to c.250–260 000 BP (Mazza et al. 2006).

Other finds of note come from the Micoquian site of Inden-Altdorf in the Inde Valley, Germany, where 82 artefacts dating to c.120 000 BP yielded small amounts of a black residue that were confirmed to be birch bark tar. The residue was observed on a range of artefacts, from scrapers to projectile points as well as a flat sandstone pebble; many implements were also associated with hafting use-wear (Pawlik and Thissen 2011b).

Notable finds of birch bark tar also come from Königsaue in Saxony-Anhalt, Germany, dating to c.50 000 BP. One specimen, Königsaue B, forms an oblong lump, seemingly kneaded by a hand. The other specimen, Königsaue A, is assigned to the Micoquo-Prodnikien culture and has imprints of both a flint blade and a wooden haft, suggestive of its function as an adhesive (Grünberg 2002; Koller et al. 2001).

Some procedures for the production of small amounts of birch bark tar are well known, most employing some sort of airtight, fireproof container such as ceramic plant-pots or metal tins, neither of which have a particularly long history (Pawlik 2004: 173; Weiner 2005: 25–26). The production of birch bark tar usually involves pyrolysis (the chemical decomposition of the bark) under controlled circumstances, usually resulting in charred bark, tar and gas (Vreugdenhil and Zwart 2009). The process takes place in an anoxic atmosphere between the temperature ranges of 250–400 °C. If this threshold is exceeded or oxygen enters the pyrolysis chamber, the tar will combust. Conversely, if the temperature is too low, the transformation will not occur (Charters et al. 1993; Koller et al. 2001: 393; Meijer and Pomstra 2011). In short, the procedure demands full control and the attention of the producer. As such, we believe that it was unlikely that birch bark tar would have been regularly produced by Neanderthals by accident.

Currently, no pre-ceramic tar-extraction structures are known, yet fire remains from the Neanderthal site of Abric Romaní, in Capellades, Spain (70,000–40,000 Cal BP), have shown a presence of liquid hydrocarbons, interpreted as fuel, but not a by-product of the predominantly coniferous wood (Courty et al. 2012). Furthermore, the flat sandstone pebble from Inden-Altdorf may have been involved in the production and collection of tar (Pawlik and Thissen 2011b).

The questions remain as to what Neanderthal technology could create birch bark tar and would such a production event have occurred without leaving any archaeological trace? We sought to tackle these questions experimentally, as the second part of a series of experiments that started in 2009 (Groom et al. 2015).

The distillation and production of birch bark tar using one or two vessels is well documented (e.g. Piotrowski 1999; Pollard and Heron 2008: 246ff; Groom et al. 2015); birch bark tar can be easily produced using a double-pot or single-pot method. A double-pot method involves a fire-resistant, oxygen-excluding pot that is full of birch bark; this is placed directly over another pot that is dug into the ground to catch the tar. Ceramic flower pots are often used as the top-pot, the lid of the top-pot is sealed and any gap between this and the lower pot is insulated, either with sand or clay. This is to prevent combustion as the tar runs from the bark in the top-pot, down through the hole in the flower pot base and into the lower pot. A fire is lit around the top-pot, being careful not to knock the top-pot and expose the lower pot. Using this method, we have produced birch bark tar in 15 min. A single-pot method involves the distillation of bark in a single container, often a metal can. The container requires a ventilation hole to allow for the evaporation of volatiles. If the bark in the can is not totally charred, the product is a ready-to-use adhesive. However, given that the pyrolysis of the bark has occurred in one container, any tar produced tends to be contaminated with charred bark.

As of yet, few researchers have experimented with aceramic tar production. Those who have achieved tar without air-excluding containers have either not published their experiments, rely on de facto containers or structures (that if used in Prehistory are likely to have left distinct archaeological trace) or have not necessarily produced tar as such (Czarnowski and Neubauer 1992; Osipowicz 2005; Palmer 2007). Most often, the amount produced is very small (e.g. Meijer and Pomstra 2011).

Experiments, series 1: summary

The first series of experiments (series 1) took place in 2009. Series 1 attempted to simplify the technical method of birch bark tar production to explore the possible production methods available to pre-ceramic societies (Groom et al. 2015; Schenck 2011). Though series 1 proved unsuccessful at producing useable tar, we regularly achieved charring of the birch bark and produced several tarry residues. As such, results from these initial experiments suggested a model for the second series of experiments, where simple raised structures could be used.

Methods and materials—pyrolysis in simple raised structures

Series 2 was a series of exploratory experiments, where the results of one dictated the parameters of the next. The initial aim of the research was to find a way of creating birch bark tar by using the simplest means possible. This would not only provide us with an answer to this question but would also establish whether a Neanderthal birch bark tar production event could have occurred without leaving any significant archaeological trace. We decided to simulate a possible Neanderthal combustion surface using a roll of bark from Betula pubescens (downy birch), sand and firewood. As such, the size of the combustion surface including the structures was based on some of the known hearth sizes of Neanderthal origin (Preece et al. 2006; Roebroeks and Villa 2011; Vallverdú et al. 2012: 2, 7; Aldeias et al. 2012: 2415; Mentzer 2012).

We focussed on simple raised structures, since pits (see Groom et al. 2015) appeared to be unsuccessful due to apparent insufficient heat penetration from the fire, downwards into the pit through the soil cover, compounded by the lack of an enveloping heat source. The idea was to create raised structures in order to surround the bark pyrolysis chamber with as much heat as possible. Therefore, the simple structures in series 2 were designed as small sand mounds which could be encircled by a fire.

We had been fortunate enough to have seen some of the archaeological samples of Betula sp. bark rolls from the Mesolithic site of Star Carr, Yorkshire, England. Based on these, we used small tight rolls of B. pubescens bark c.10 cm long and c.5 cm wide in the series 2 experiments.

To ensure that the raised structures had matching foundations for all experiments, a c.5-cm-deep layer of building sand (Diall’s building sand with grits) was used as a base; this lay on top of the underlying quartzite gravel. Observations from series 1 demonstrated that sand tended to set hard during the firing; therefore, no cementing agent would be necessary to maintain the stability of the structures.

To be successful, the simple raised structures would need to withstand the necessary heat penetration for bark pyrolysis yet provide airtight conditions to prevent bark combustion. With reference to conventional bark tar production methods, a small mound of sand could create similar conditions to a single-pot structure, although the sand mound structures were not designed with vents as is often done with double-pot or single-pot methods to encourage volatile evaporation (e.g. Weiner 2005: 26). In one sense, a mound of sand is the simplest form of kiln. The sand mound encloses the object to be heated, in this case, a roll of birch bark, the temperature in the bark chamber is increased by using an external heat source, in this case a wood fire.

The experiments were conducted outdoors in October 2013 and were sheltered from frequent heavy rain by a tarpaulin. Although the site was not particularly exposed to the wind, a good breeze was present on most days which helped both to fan the fire and raise the temperature of the fire. Fires were built so that they surrounded the mounds, and the fuel used was pine (Pinus sylvestris) logs or sticks, therefore reducing the chances of contamination of the birch bark chamber by use of a hardwood fuel such as birch.

As the temperature of an outdoor wood fire can vary between several hundred degrees within the same fire, particularly when the wind is multidirectional, this creates a problem with temperature control (Gosselain 1992). Such variables are common when undertaking actualistic experimental archaeology in the field, often giving rise to uncertain interpretations; where possible, we attempted to mitigate against these variables by the use of scientific recording instruments.

For measurement, a Jenway 220 Temp Meter Thermocouple and a handheld anemometer with integrated thermometer from LaCrosse Technologies were used at 10-min intervals for recording the bark chamber temperature and wind speed, respectively; ambient air temperatures were measured at 30-min intervals. The experiments were documented throughout using digital photography and drawings.

Results

The first experiment in series 2 sought to evaluate the effectiveness of a simple raised structure.

Experiment 1 consisted of a simple mound of sand 5 cm thick covering a horizontal roll of B. pubescens bark c.10 cm long and c.5 cm wide (Fig. 1, for details see Table 1).

For this initial experiment, (Fig. 2) temperatures were not monitored; this prevented accidental disturbance of the structure by use of the thermocouple. After 20 min of extensive fire cover, tar odour could be detected; tar odour was a feature we encountered consistently during the experiments in series 1, and is usually indicative of the release of tar volatiles (Groom et al. 2015). The fire was maintained and burned for a further 2 h and 40 min. Experiment 1 was one of only two experiments in series 2 where we ended the fire based on intuition; experiments 3 to 5 were terminated after the appropriate temperatures had been achieved for pyrolysis to have succeeded (c.320 °C thermocouple reading).

Upon excavation, it became evident that pyrolysis of the birch bark roll had occurred as the sand around the bark roll chamber was black with tar and had baked/solidified to c.3 cm away from roll. It was therefore obvious that the heat from the fire was sufficient to pass through the 5-cm cover of sand. The bark roll was intact and almost exclusively affected on the top surface (Fig. 3), presumably due to the proximity of the fiercest and most sustained part of the fire. Upon opening the bark roll, several layers were fused together by a glossy burnt tar. In order to produce a more even heat distribution into the bark chamber, the structure size was decreased in subsequent experiments to allow for full envelopment by the fire; however, the dimensions of the bark roll were consistent (length 10 cm, diameter 5 cm).

Experiment 2 was not a raised structure and is therefore excluded from this paper. Experiment 3 was a simultaneous double firing of two raised structures (Fig. 4). Of the two, structure 3a was the first simple raised mound in which temperature data was recorded. Since heat penetration appeared to have been the primary obstacle during the pit firings of series 1 (Groom et al. 2015), experiment 3 was designed to explore the minimum layer of sand that would be required to produce tar, while protecting the bark from combustion. Theoretically, the thinnest cover of sand possible would be the most economical choice in terms of wood fuel efficiency as it would require less fuel to generate the heat necessary to pyrolyse the bark roll within the mound. However, too thin, a cover of sand could collapse due to fuel wood movement during burning and potential thermal stress.

Based on observations from series 1 and the initial experiment 1, 3a was constructed with a 5-cm cover of sand and 3b with a 3-cm cover of sand. The reason for the difference in thickness of sand was to deliberately test the limits of the cover of sand. The thermocouple was inserted through a copper tube into the base of the bark chamber in the 5-cm mound (3a), leaving a gap of <1 cm from the base of the bark roll to prevent tar contamination of the thermocouple sensor. To prevent air ingress into the thermocouple tube, the outlet was covered with gravel and sand. The thermocouple was used in 3a because the temperature recordings taken from the base of this mound would be the minimum for the two mounds given that the sand cover in 3b was 2 cm less and, therefore, the heat penetration was expected to be more effective through the 3-cm cover. A fire was then built around both structures.

Throughout the experiment, the temperature at the base of the bark chamber in 3a rose steadily (Table 1 ), with occasional plateaus. The experiment was terminated after 4 h when liquid tar from mound 3a began trickling through and along the thermocouple tube (Fig. 5), at a temperature of 320 °C, an obvious indicator that pyrolysis had occurred.

Upon excavation of the mounds and examination of the bark remains, 3a was glossy and slightly charred; however, 3b was black, very charred and had no tar residue. We assume that any tar produced in 3b had combusted due to the thinner 3-cm sand cover and likely higher temperature of the bark chamber. Both bark chambers were surrounded by blackened sand to a distance of c.3–4 cm and both chamber walls were baked/solidified, probably due to heat (Henderson 2000: 132–133).

Experiment 4 was designed to investigate the further effectiveness of the 3-cm sand cover used in 3b and to test whether such a thin cover of sand could produce tar yet remain sound. Based on the accidental experience of tar spill in 3a, a copper run-off tube was introduced into the base of the bark chamber of 4 to provide a means of run-off for any tar produced. This was deemed necessary as the experiments at this stage were not concerned with catchment methods and the tar appeared to be running off into the sand or combusting. In order to prevent another unintentional run-off of tar into the thermocouple tube, this was placed at a slight incline from the base of the bark chamber, whereas the tar run-off tube declined away from the chamber. As a collector for the tar, a small sheet of lime (Tilia cordata) bark was placed at the outlet. Finally, to prevent air ingress into both tubes, the outlets were covered with gravel and sand.

Experiment 4 (Fig. 6) was the slowest firing of the simple raised structures at 5 h and 10 min, weather conditions of mist, rain and 87 % humidity limited the fierceness of the fire. The fire was left to die down once the temperature of 317 °C was reached.

Upon excavation, it was confirmed that tar had collected in the run-off tube, but had unfortunately soaked through the lime bark sheet and into the soil to a depth of c.4 cm, though this was difficult to verify accurately due to the substrate. The structure displayed blackened baked/solidified walls and blackened sand immediately surrounding the bark chamber, which lessened with increasing distance from the site of the bark roll to a distance of c.2–5 cm (Fig. 7).

Experiment 4. Bark roll chamber after firing and excavation. Copper collection tube bottom left, copper thermocouple tube at top. Charred bark roll has been removed to reveal a roll-shaped chamber with blackened baked/solidified walls. The reducing atmosphere has also produced a near black sediment in the centre of the structure, which lessens with increasing distance from the site of the bark roll. Scale in millimetres

Experiment 5 was again designed as a simultaneous double firing of two raised structures following the template of 3. However, on this occasion, the thermocouple was inserted into the base of the bark chamber in the 3-cm sand-covered mound (5b). For this experiment, glass jars were used as tar collectors and were linked to both bark chambers using copper tubes. As the glass jars had to be protected from the heat of the fire, they were covered with a layer of sand and a small bank of sand between the jars and the fire (Fig. 8). This slightly limited the fire in that it would not completely surround the mounds as in the previous experiments. The thermocouple tube was again placed at a slight incline from the base of the bark chamber, as this had proved successful in the previous experiment. Finally, to prevent air ingress into all three tubes, the outlets were covered with gravel and sand.

In 5b, the temperature at the base of the bark chamber increased rapidly, possibly aided by less humid conditions and an average wind speed of 0.5 m/s (Table 1). The chamber reached 321 °C after only 2 h and 10 min, upon which the feeding of the fire stopped and die-down was allowed. Measurements of temperatures continued until 5 h had passed, in order to record the declining temperature (Fig. 15).

Upon excavation, it was clear that both mounds had produced tar as the sand surrounding the bark chamber was black (Fig. 9) and tar had collected in both jars (e.g. Fig. 10). Both bark rolls were very charred but intact and the bark chamber walls were black and baked/solidified (Fig. 11) resembling all previous experiments in series 2.

Experiment 5. From left: 5a (5-cm sand cover T), right: 5b (3-cm sand cover T). Both sand mounds are discoloured, demonstrating the spread of tar gas from the pyrolysis chamber outwards. The darkest material is adjacent to the bark roll chamber at the centre of each mound. Note: the thermocouple tube front right

Tar from mound 5a (5-cm sand cover). The star-shaped pattern on the jar represents the outlet point of the collection tube and resulted from the jar’s almost horizontal position in the ground. This photo was taken 2 weeks after the experiments and some of the viscous tar still clings to the side of the jar

Experiment 6 was the final experiment of series 2. Given that the sand mounds had proven successful in producing tar, the natural extension to the results so far obtained in series 2 was to include a collector in the mound itself. In addition, this final experiment simultaneously compared four different methods in one fire (Fig. 12), the methods were as follows:

-

1.

Single-pot (metal can with hole pierced in lid)

-

2.

Four birch branches placed beneath the sand under the fire

-

3.

Sand mound (3-cm sand cover) with a scallop shell (Pecten maximus) at the base of the bark chamber to hold the bark roll and collect any tar produced

-

4.

Double-pot (ceramic plant pot on surface and metal can buried as collector)

The use of four methods in one fire meant that the environmental conditions were the same for all; furthermore, the double- and single-pot methods would act as a control. No recording equipment was used; in this way, the management of the fire would rely on the recognition of tar smell rather than thermocouple readings. The length of the combustion surface was c.50 cm and the width c.35 cm.

The fire was started at 4.45 pm, and the first odour of tar came from the mound and double-pot at 6 pm; the feeding of the fire stopped at this point. The single-pot was placed into the hot ashes at 5.45 pm and white vapour and tar began emitting from the hole in the lid at 6.15 pm. The fire had burnt out naturally by 7 pm.

As expected, the single-pot method produced thickened tar which included small pieces of charred bark; however, this did not appear to limit the adhesive properties.

The double-pot method produced liquid tar, free from any charred bark. Though clearly affected by the heat and burnt in places, the birch branches showed no signs of pyrolysis or tar, despite another experimental attempt. The sand mound produced tar that collected in the scallop shell, and the shell showed no sign of burning (Fig. 13).

In order to investigate how liquid birch bark tar could be thickened, a common otter shell (Lutraria lutraria) was later placed in hot ashes and was used to simmer the liquid tar reducing it to a thicker, more viscous state (Fig. 14).

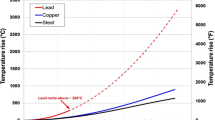

Figure 15 represents all tar-yielding experiments where recordings were taken (3a, 4, and 5b) which reached a minimum temperature in the vicinity of 320 °C. For consistency, the dimensions of the bark roll were roughly the same in all experiments c.10 cm in length and c.5 cm diameter (though the volume of bark differed slightly due to the shape and tension of the bark). This meant that once sand had covered the bark roll, the bark chamber in all of the experiments had an internal height of approximately 5 cm (the diameter of the bark roll itself). Therefore, the thermocouple sensor was only 5 cm away from the chamber ceiling, a maximum of 10 cm away from the fire and a minimum of 8 cm from the fire. Unfortunately, the temperature difference between the chamber ceiling and the base of the chamber is unknown, as the thermocouple was always placed at the base of the chamber, presumably measuring minimum temperatures only. An additional thermocouple placed on the mound surface would have measured the temperature at the base of the fire. This would have been useful in determining the temperature required at the base of the fire to cause pyrolysis in the bark chamber under the sand below. Some of the mound experiments could technically be classed as double-vessel types, due to the use of catchment tubes and external containers (in 3a the thermocouple tube itself), and in this way, the tar produced was unpolluted by char and sediment; however, the sand mound in experiment 6 resembled a single-pot method, with its integral shell collector.

Overall, the temperatures in the bark chambers of the friable sand mounds were sufficient to produce a clean tar, particularly when collection tubes and jars were used. For a summary of recorded data, see Table 1.

Discussion

The aim of the series 2 experiments was to simulate a possible Neanderthal combustion surface on which to create birch bark tar by the simplest means possible, while leaving little archaeological trace aside from general fire remains. To this extent, the experiments were successful.

The discourse on Middle Palaeolithic pyrotechnology is extensive; Mentzer (2012: 21, Table 3) documents fire activities with evidence of anthropogenic reworking. Examples include Kebara Cave (Israel), La Quina Rockshelter (France) and Pech de l’Azé Cave (France). Similarly, at Roc de Marsal, France, reworking of combustion features may be evidence of hearth cleaning (Aldeias et al. 2012). Another site that may provide evidence of the controlled use of fire is Beeches Pit, Suffolk, UK, dating to 414 000 ± 30 000 BP, where shallow burnt depressions are interpreted as hearths that imply a sequence of burning (Preece et al. 2006: 491). At Abric Romaní, Roebroeks and Villa (2011) report 187 combustion structures throughout the levels of the site. Furthermore, the combustion structures display repeated use (Vallverdú et al. 2012: 9). Fireplaces have yielded mineralogical evidence of a production of liquid hydrocarbon that may be connected to heating in a reducing atmosphere (Courty et al. 2012: 309); this could be evidence of slow pyrolysis. The geological/stratigraphical dating for this site was c.70–40,000 BP, the same approximate period that the tar pieces at Königsaue were produced. Courty et al. (2012) proposed that the combustion structures indicate a variety of specific firing activities (Ibid. 295, 309). As experiment 6 in series 2 clearly demonstrates, a skilled practitioner can pyrolyse birch bark and produce tar using only the simplest of materials and a sense of smell; therefore, birch bark tar production seems to be a task that could fit with the interpretations at Abric Romaní. The series 2 experiments produced only small amounts of tar; however, the production of large amounts was not the remit of these experiments. Based on the series 2 method, further experiments could determine how larger amounts of birch bark tar could be made and explore potential collectors. These experiments would of course have to be conducted within the parameters of known Middle Palaeolithic technologies and archaeological evidence (as were series 2). Whether the small amounts of tar produced in series 2 accurately reflect the amounts produced during Middle Palaeolithic birch bark production events is difficult to answer. For example, would such activities in the Middle Palaeolithic have been conducted at the hearth in the ‘living area’, or would the acrid smell of the pyrolysing birch bark have driven the process ‘off-site’ or outside? Furthermore, if the production event did take place within the living area, perhaps the availability of fuel wood limited the sizes of fires, so that only small amounts of birch bark tar could be produced. The crucial point here being that a minimum temperature in the vicinity of 250 °C must have been achieved in order to create the birch bark tar that we see on the archaeological artefacts outlined earlier. Alternatively, could sampling bias be the reason why we have little evidence for large-scale production methods? Where would we look and what would we look for?

Mentzer (2012) discussed archaeological fire remains, looking specifically at microarchaeological techniques to aid identification and interpretation of activities. Combustion structure experiments conducted by Mallol et al. (2013a:10) demonstrated however that many anthropogenic activities associated with Middle Palaeolithic fires may be undetected. Every sand mound in series 2 contained a baked/solidified black sand layer surrounding the bark pyrolysis chamber. It may be that this was caused by a combination of heat and volatile tar spreading into the sand, though the sand covering each mound was unaffected and was still largely friable. This baked/solidified black sand layer is interesting as this is obviously a product of the firing process, though whether it occurred early or late in the pyrolysis event is unknown. In future experiments, it would be of great benefit to ascertain which, as if the baking/solidification of the bark chamber walls occurs early on then it may be that this mimics the protective environment of a ceramic pot.

Many Middle Palaeolithic combustion structures display black layers; for further discussion of the interpretation of black layers, see Mallol et al. (2013b). Whether the tar products of our sand mound fires are similar to Neanderthal examples is part of our ongoing research. We have already analysed the tar samples produced in series 2 and these will be the subject of our next paper. Future research could involve high-resolution analysis to compare the blackened hearth sediments produced by our series 2 method, with samples from Palaeolithic hearths. This, together with the analysis and comparison of the tar and residues produced using the series 2 method, with those obtained from Middle Palaeolithic contexts, would go some way to resolving just how birch bark tar was produced in the Middle Palaeolithic.

As Mallol et al. (2013b: 2516) state, most Middle Palaeolithic combustion structures are flat; with reference to the raised mounds in series 2, once the sand cover has been brushed aside and the pyrolysed bark and the tar collector have been removed, the surface is again flat (see Fig. 7).

Should the combustion structures at Abric Romaní, or similar structures elsewhere, be proven to be connected to birch bark tar production, this would lend support to the notion that Neanderthals could control fire (e.g. Roebroeks and Villa 2011; Aldeias et al. 2012). Some writers (e.g. Wadley 2010; Pawlik and Thissen 2011a) consider the production of compound adhesives in the Middle Stone Age as being a proxy for complex cognition. Indeed, in light of our experiments, we propose that regular birch bark tar production by Neanderthals is unlikely to have been a result of opportunistic accident, but was rather a result of specific chaînes opératoires in order to provide the necessary control and outcomes.

Conclusions

The experiments in series 2 produced several results that are highly relevant for the discourse on Palaeolithic birch bark tar production:

-

1.

Birch bark tar production is not difficult once the skill set is learnt

-

2.

A crucial competence in the production of birch bark tar is to assess how long it takes for pyrolysis to occur so that the fire can be terminated to prevent the tar from combusting. This can be determined with some accuracy by detecting the occurrence of tar odour (volatile evaporation) through smell alone, then managing the fire accordingly

-

3.

It is not necessary to build or create a complex structure to produce birch bark tar. Rather, a simple mound of sand covering a roll of bark will suffice

-

4.

A suitable collector, such as a shell placed under the bark roll, is sufficient to capture any tar produced

-

5.

After firing, all sand structures displayed a blackened layer surrounding the bark chamber while the bark chamber walls were baked/solidified. This is interesting and demonstrates that as the sand hardens during the firing process, it is close to mimicking the protective environment of a ceramic pot

-

6.

The photographic documentation of each structure during creation and excavation provides a potential catalogue of reference for the interpretation of archaeological fire events

The experiments in series 2 lead us to propose that regular birch bark tar production by Neanderthals was easily achievable and the product of specific chaînes opératoires in order to provide control of the pyrolysis event.

Based on these experiments, we can now with some confidence present a potential scenario for the initial production of birch bark tar in the Middle Palaeolithic, one where multi-use hearths on which activities such as cooking, heating etc. occur. In the margins of the hearth adjacent to the fire, under piles of swept sand and ash, pieces of birch bark that were used in the initial fire lighting, accidentally pyrolyse and produce volatile vapour, oil and tar. An observant Neanderthal acknowledges the strange smell and later notices the product. Then, by finding a suitable container/collector and by placing this and rolls of bark under sand mounds at the edge of the hearth, a fire is lit and birch bark tar is intentionally produced.

References

Aldeias V, Goldberg P, Sandgathe D, Berna F, Dibble HL, McPherron SP, Turq A, Rezek Z (2012) Evidence for Neandertal use of fire at Roc de Marsal (France). J Archaeol Sci 39(2012):2414–2423

Aveling EM, Heron C (1998) Identification of birch bark tar at the Mesolithic site of Star Carr. Anc Biomol 2:69–80

Aveling EM, Heron C (1999) Chewing tar in the early Holocene. Antiquity 73(281):579–584

Bosquet D, Regert M, Dubois N, Jadin I (2001) Identification de brai de bouleau sur quatre vases du site rubané de Fexhe-le-Haut-Locher “Podrî l Cortri”. Premiers résultats. Notae Praehistoricae 21:119–127

Charters S, Evershed RP, Goad LJ, Heron C, Blinkhorn P (1993) Identification of an adhesive used to repair a Roman jar. Archaeometry 35(1):91–101

Courty M-A, Carbonnell E, Poch JV, Banerjee R (2012) Microstratigraphic and multi-analytical evidence for advanced Neanderthal pyrotechnology at Abric Romani (Capellades, Spain). Quat Int 247:294–312

Czarnowski E, Neubauer D (1992) Aspekte zu Produktion and Verarbeitung von Birkenpech. Acta Praehist Archaeol 23:11–13

Gosselain, O.P. 1992. Bonfire of the enquiries. Pottery firing temperatures in archaeology: what for? Journal of Archaeological Science 19.

Groom P, Schenck T, Pedersen G (2015) Experimental explorations into the aceramic dry distillation of Betula pubescens (downy birch) bark tar. Archaeol Anthropol Sci 7:47–58

Grünberg JM (2002) Middle Palaeolithic birch-bark pitch. Antiquity 66:15–16

Henderson J (2000) The science and archaeology of materials. An investigation of inorganic materials. Routledge, London

Koller J, Baumer U, Mania D (2001) High-tech in the Middle Palaeolithic: Neanderthal-manufactured pitch identified. Eur J Archaeol 4(3):385–397

Lyford CA (1943) Ojibwa crafts. Bureau of Indian Affairs, Lawrence, Kansas

Mallol C, Hernández CM, Cabanes D, Machado J, Sistiaga A, Pérez L, Galván B (2013a) Human actions performed on simple combustion structures: an experimental approach to the study of Middle Palaeolithic fire. Quat Int 2013:1–13

Mallol C, Hernández CM, Cabanes D, Sistiaga A, Machado J, Rodríguez Á, Pérez L, Galván B (2013b) The black layer of Middle Palaeolithic combustion structures. Interpretation and archaeostratigraphic implications. J Archaeol Sci 40(2013):2515–2537

Mazza PPA, Martini F, Sala B, Magi M, Colombini MP, Giachi G, Landucci F, Lemorini C, Modugno F, Ribechini E (2006) A new Palaeolithic discovery: tar-hafted stone tools in a European Mid-Pleistocene bone-bearing bed. J Archaeol Sci 33(9):1310–1318

Meijer R, Pomstra D (2011) The production of birch pitch with hunter-gatherer technology: a possibility. Experimentelle Archäeologie in Europa, Bilanz 2011. Oldenburg, Europäische Vereinigung zur Förderung der Experimentellen Archäologie e.V., Heft 10, 199–204

Mentzer SM (2012) Microarchaeological approaches to the identification and interpretation of combustion features in prehistoric archaeological sites. Journal of Archaeological Method and Theory:1–53

Osipowicz G (2005) A method of wood tar production, without the use of ceramics. euroREA 2:11-17

Palmer F (2007) Die Entstehung von Birkenpech in einer Feuerstelle unter paläolithischen Bedingungen. Mitteilungen der Gesellschaft für Urgeschichte. 16:75–83

Pawlik AF (2004) Identification of hafting traces and residues by scanning electron microscopy and energy-dispersive analysis of X-rays. In: Walker EA, Wenban-Smith F, Healy F (eds) Lithics in action: papers from the conference lithic studies in the year 2000. Oxbow, Oxford

Pawlik AF, Thissen J (2011a) Hafted armatures and multi-component tool design at the Micoquian site of Inden-Altdorf, Germany. J Archaeol Sci 38(2011):1699–1708

Pawlik AF, Thissen J (2011b) The ‘Palaeolithic Prospection in the Inde Valley’ Project. Quaternary Science Journal (EuG) 60(1):66–77

Piotrowski, W. 1999. Wood-tar and pitch experiments at Biskupin Museum. In Experiment and design. Archaeological studies in honour of John Coles, edited by A F Harding, Oxford: Oxbow Books.

Pollard AM, Heron C (2008) Archaeological chemistry. Royal Society of Chemistry, Cambridge

Preece RC, Gowlett JAJ, Parfitt SA, Bridgland DR, Lewis SG (2006) Humans in the Hoxnian: habitat, context and fire use at Beeches Pit, West Stow, Suffolk, UK. Journal of Quaternary Science. 21(5):485–496

Regert M, Vacher S, Moulherat C, Decavallas O (2003) Adhesive production and pottery function during the Iron Age at the site of Grand Aunay (Sarthe, France). Archaeometry 45(1):101–120. doi:10.1111/1475-4754.00098

Roebroeks W, Villa P (2011) On the earliest evidence for habitual use of fire in Europe. Proc Natl Acad Sci U S A 108:5209–5214

Sauter F, Graf A, Hametner C, Fröhlich J, Neugebauer JW, Preinfalk F (2002) Analysis of an organic agglutinant used to fix Iron-Age clay figurines to their base. ARKIVOC 2002:35–39

Schenck, T. 2011. Experimenting with the unknown. In Experimental archaeology. Between Enlightenment and experience, edited by B Petersson, and L E Narmo, Lund: Lund University.

Urem-Kotsou D, Stern B, Heron C, Kotsakis K (2002) Birch-bark tar at Neolithic Makriyalos, Greece. Antiquity 76(294):962–967

Vallverdú J, Alonso S, Bargalló A, Bartrolí R, Campeny G, Carrancho Á, Expósito I, Fontanals M, Gabucio J, Gómez B, Prats JM, Sañudo P, Solé À, Vilalta J, Carbonell E (2012) Combustion structures of archaeological level O and Mousterian activity areas with use of fire at the Abric Romaní rockshelter (NE Iberian Peninsula). Quat Int 247:313–324

Vreugdenhil, B.J., Zwart, R.W.R. 2009. Tar formation in pyrolysis and gasification. Energy Research Centre of the Netherlands, ECN-E-08-087, pp 324–335

Wadley L (2010) Compound-adhesive manufacture as a behavioural proxy for complex cognition in the Middle Stone Age. Curr Anthropol 51(S1):111–119

Weiner J (2005) Another word on pitch. Some comments on a “Sticky Issue” from Old Europe. Bulletin of Primitive Technology 29, Berlin, p 2027

Acknowledgments

We thank Sharon Hartwell and Hanne Hongset for their help during the experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schenck, T., Groom, P. The aceramic production of Betula pubescens (downy birch) bark tar using simple raised structures. A viable Neanderthal technique?. Archaeol Anthropol Sci 10, 19–29 (2018). https://doi.org/10.1007/s12520-016-0327-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12520-016-0327-y