Abstract

To further understand the permeation and pore distribution properties of compacted soil, the contact angle measurements and mercury intrusion porosimetry under different compaction conditions were performed. Experimental results show that the wettability of the compacted loess decreased slightly, but it was not significantly changed when the number of poundings increased from 10 to 75. The contact angle had a significantly linear positive correlation with the dry density and the volume of micropores, whereas it had a linear negative correlation with the total pore volume per unit mass and the volumes of macropores and mesopores. The distribution of different pore sizes varied depending on the compaction process. The macropore volume of the compacted loess samples decreased sharply when the number of poundings increased and almost became zero after 30–40 poundings. The mesopore volume decreased consistently until it reached a steady state. In contrast, the small pore volume increased firstly, reaching the peak value at the 30th–40th pounding, and then decreased until it reached a steady state. Finally, the micropore volume increased slightly at the beginning and then decreased slightly, with a peak value comparable to that of the small pores. During the compaction process of these samples, large deformations occurred when the number of poundings was less than 30–40, and the deformation was mainly caused by the reduction of macropores and mesopores. Relatively small deformations occurred when the number of poundings was greater than 30–40, and the deformation was mainly caused by the reduction of small pores.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Contact angle and pore diameter are important parameters reflecting the physical and mechanical properties of soil, and these parameters can be used to calculate the height of capillary water rise and evaluate soil wettability (Bayraktar et al. 2019; Jiang et al. 2016; Myeongsoo et al. 2017; Sara et al. 2016). Capillarity affects the structure and strength of soil, causes a decrease in soil stability, and leads to several adverse geologic phenomena such as subgrade frost heaves and soil salinization (Lourenco et al. 2018; Cetin et al. 2018a). The contact angle is the most convenient standard to evaluate the wettability (Vladimir et al. 2018; Cetin 2015a). In many production processes that involve wettability, such as oil exploitation, film manufacturing, and mineral flotation, the contact angle is the accepted measure for the evaluation of wettability (Wang et al. 2003; Min et al. 2003). Contact angle is an important index for describing permeability of rock-soil and is also often used to evaluate surface energy and surface tension of solid materials (Ankitha and Kumar 2019; Hind et al. 2019; Wajdi et al. 2019; Weng 2019).

Ewa et al. (2018) measured the contact angle of plant leaves. It was found that the contact angle had a great influence on the hydrological process, the growth of plant pathogens, and the absorption and deposition of pyrethroids and pesticides. Factors that influence the contact angle include viscosity, fluid temperature and salinity, porosity, combinations and relations of the material particles, chemical composition, and saturability of solid materials (Shedid and Mamdouh 2004). Most studies and applications related to the contact angle focus on the fields of biomedicine surface science and petrochemical engineering. Some research results have also been achieved in geotechnical engineering. The contact angles of kaolin, montmorillonite, and carbonatite were tested and found to be greater than 45°, indicating that carbonatite had a weak wettability (Vladimir et al. 2018; Cetin 2016; Matthew et al. 2014). Contact angles of cohesive soil and sands were tested by the capillary rise method to investigate soil wettability, and the angles measured exceeded 48° and 70°, respectively. Specimens of cohesive soil tested in this research were compact, resulting in a large contact angle (Liu et al. 2016). In addition to direct testing, the contact angle can also be studied by other methods, such as the distinct element method combined with relevant theoretical analysis (Jérôme and Richard 2017). The relationship between the number of capillary pores and the contact angle was theoretically analyzed by scholars using molecular dynamics to discuss the wettability of minerals (Alireza et al. 2018; Zhang et al. 2016).

Features of pores in the soil are important manifestations of soil microstructure, and hence, understanding the features of the consolidation and structure of soil through pores is an effective approach to understanding soil properties. There are various methods of studying soil pores, many of which have been applied in research. Analysis performed on the structure of cohesive soils using scanning electron microscopy (SEM) shows that the extent of soil settlement was greater when the soil was more porous, and some of the pores turned into sealed pores after the soil was consolidated (Varol et al. 2019; Cui and Jia 2013). Structural features of soil were obtained through X-ray computed microtomography scans. A mathematical model was then established, the analysis of which shows strong correlations between soil pores and water content, structure, content of clay particles, and specific surface area (Yan et al. 2016; Cetin 2015b; Lars et al. 2012). The microstructure and porosity of red clay were studied using the mercury intrusion method and SEM, and the results indicated a close relationship between the pore sizes of red clay and soil loss (Tang et al. 2016). The microstructure of lime soil is affected by differences in lime content and curing time. The addition of lime reduced the sizes of pores in the soil, decreasing connectivity and causing stronger cementation (İlknur 2018). An analysis of pore structure, porosity, and connectivity of fly ash showed that when adhesives were added to fly ash in different proportions, the structures, connectivities, and curvatures of pores were different (Cetin et al. 2018b; Zeng et al. 2012).

Very little research effort has been directed at compacted loess. No research published hitherto has studied the relationships among contact angle, pore sizes, and pore distributions in compacted loess. However, such studies are of vital importance for understanding water infiltration in the aerated zone and the height of capillary rise.

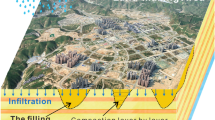

In this paper, contact angle measurements and mercury intrusion porosimetry were performed on compacted loess sampled from a northern suburb of Xi’an city, Shaanxi province, China, to reveal the variations of the contact angle and pore distribution of compacted loess under different compactness, and wetting and permeability properties were also studied.

Experimental materials and approaches

Experimental materials

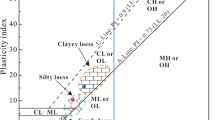

The loess studied in this paper was sampled from a northern suburb of Xi’an city, Shaanxi province, China, which belongs to the geomorphic unit of loess plateau. The tawny and macroporous loess sample has a depth of 1.0 m, a liquid limit of 27.6%, a plasticity limit of 16.7%, and a relative particle density of 2.71. The measurements of the liquid limit, plastic limit, and relative particle density were conducted according to the “Standard for Soil Test Method GB/T 50123-1999” (Ministry of Water Resources of the People’s Republic of China, 1999). Herein, the pycnometer method was used to measure the relative particle density.

The liquid and plastic limits were measured using a liquid-plastic combined measurement apparatus (LG-100D), which was produced by Shanghai LuDa Experimental Instrument Co., Ltd. (Fig. 1). The soil sample was first broken up and passed through a 0.5-mm sieve and then prepared into three samples with different water contents. Placing the soil sample on the plate of the apparatus and measuring the depth of the cone penetration, the relationship between the depth and the corresponding water contents can be obtained, as shown in Fig. 2. According to the standard method, the liquid limit (wL in Fig. 2) and plastic limit (wp in Fig. 2) are defined as the moisture contents corresponding to a cone penetration of 10 mm and 2 mm, respectively. The details of the test steps are presented in the literature (Ministry of Water Resources of the People’s Republic of China, 1999).

Contact angle measurement

To maintain the chemical and mineral compositions and water contents of all samples, remolded loess samples were used in the experiments. The loess sample obtained from the field was smashed into pieces and then dried for 8 h at 105 °C. After drying, the loess sample was crushed down and sifted by a sieve with a mesh size of 2 mm. Tap water was added to the dried and sifted soil to make a loess solution with a water content of 12%. The evenly mixed loess solution was then divided into eight samples, which were tightly sealed in plastic bags and cured for 24 h. To measure the contact angles of the compacted loess under different dry densities, the loess samples, after being cured for 24 h, were placed in three layers into a standard light compactor. Each layer was compacted separately and successively in a cylindrical mold with a volume of 947.4 cm3 using a 2500-g rammer dropped from a height of 305 mm. Each layer of the eight samples received 10, 15, 20, 25, 30, 40, 50, and 75 poundings. All eight compaction specimens were sampled separately using a cutting ring, dried for 8 h at 105 °C, removed, cooled to room temperature, and then kept in clean and dry wares. The disturbance of the loess specimen surface sampled by the cutting ring was minimized as much as possible during sampling. During soil sample production, the sampling knife was straight and longer than the diameter of the cutting ring. To obtain a flat soil surface, the soils that exceed the cutting ring were cut off by the middle part of the knife instead of the tip. Additionally, the knife was moved from the ring edge towards its center to avoid the soil being severed.

Currently, many different measuring methods exist for the contact angle. Direct measuring methods include goniometry, the length method, and the permeating method. According to measuring principles, testing methods can be divided into the capillary rise and fall method, the sessile drop method, and the tilting plate method (Sara et al. 2016; Zhang et al. 2011; Smedley and Coles 2005). In this paper, the contact angle was measured with the sessile drop method using an XG-CAMB3 contact angle measurement instrument produced by the Shanghai Xuan Yi Chong Industrial Equipment Co. Ltd., as shown in Fig. 3. The experimental steps are as follows: First, the instrument is debugged to ensure that the sample table and camera are on the same level. After adding distilled water, the Water-Adding Instrument was installed. The sample was placed on the sample stage, and the surface with a relatively smaller disturbance was selected as the testing plane. The position of the sample was calibrated manually to have a 1~2-mm distance from the needle tip to the sample. Water drops were added automatically drop-by-drop onto the sample to be tested. The whole process image of water droplets falling on the soil sample in a continuous snap are read using a high-speed camera. Then, the appropriate picture should be selected from the intercepted image and select the highest point of the droplet and the left and right endpoints to calculate the contact angle using hypsometry. The above procedure was repeated for five randomly chosen points on the testing surface, and their average value was considered the result of the measurement. Figure 4 shows the collected images.

Pore distribution testing

Regular or irregular specimens with dimensions of approximately 2~5 mm in size were cut out from the samples, and the contact angles were measured. These cut specimens were again placed in a drying oven, dried for 8 h at 105 °C, cooled down to room temperature, and then kept in dry wares.

Common measuring methods of pore diameter and its distribution of porous material include direct observation of the fracture surface, the bubble method, the permeating method, the mercury intrusion method, the gas adsorption method, the liquid-liquid method, the suspension liquid filtering method, and the small-angle X-ray scattering method (Yang et al. 2018; Enrique and Paul 2008; Liu 2006). In this study, the pore distribution was tested by the mercury intrusion method using a Micromeritics Auto Pore IV 9510 Automatic Mercury Intrusion Porosimeter, as shown in Fig. 5.

The 1.5~2.0-g specimen was weighed and then placed into a 5-cc dilatometer selected for this test. After installation, the low-pressure test was performed first. The specimen was vacuumized until the pressure inside the specimen was lower than 50 μm Hg pressure. After finishing the low-pressure test, the dilatometer was disassembled, and the high-pressure test was then performed. The pore diameter of the specimen was calculated according to the Washburn equation (Mario et al. 2014), or Formula 1:

where P is the applied pressure; σ is the mercury surface tension, which is 0.4842 N/m at 25 °C and 0.472 N/m at 50 °C; θ is the contact angle between the measured porous material and mercury, with a variation of 135 to 142°; and r is the cylindrical pore radius. The equivalent radius r corresponding to pressure P was calculated according to Formula 1, based on which the pore distribution in the soil sample was calculated.

Pore distribution characteristics are important factors affecting the contact angle and wettability of the loess. The pore structure of the loess is complicated, and a unified understanding of pore divisions has not yet been attained. Through the mercury intrusion method, Lei (1987) classified pores in unsaturated soil into four types, as shown in Table 1, and this classification method has been used in this study.

Experimental results and analysis

Experimental results and analysis of contact angle

Table 2 lists the measurement results of basic indexes and contact angles of the compacted loess.

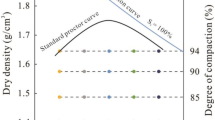

The measurement results summarized in Table 2 show that the water content of most remolded loess specimens was approximately 11.5%, and hence, it can be considered that the compaction tests of loess specimens were performed under the same water content. Therefore, the possibility that the large difference in water contents would cause heterogeneity in loess can be excluded, which means that the effect of water content can be neglected. Figure 6 shows the relationship curve between the dry density and the number of poundings, which indicates that with increasing poundings, the dry density also increases with a decreasing slope. Figure 7 shows the relationship curve between the contact angle and the dry density, which indicates that the contact angle increases with an increase in the dry density, and they presented a linear positive correlation with a correlation coefficient as high as 0.99. For compacted loess, which is a special porous material, the wetting contact angles under unsaturated conditions were all smaller than 30°; therefore, compacted loess is a typical hydrophilic material. According to the variation trends shown in Fig. 7, it can be speculated that with the decrease in dry density, the wetting contact angle will become 5° or even smaller, which signifies near-complete wetting and spreading in the loess. Therefore, the dry density significantly influenced the contact angle and wettability. Figure 8 shows the relationship curve between the total pore volume and the number of poundings, which indicates that with more pounding, the total pore volume decreased linearly, presenting a linear negative correlation. Figure 9 shows the relationship curve between the contact angle and the total pore volume in the compacted loess per unit mass, which indicates that when the compacted loess was more compacted, the pores were smaller and the contact angle was larger; hence, the contact angle and the total pore volume presented a linear negative correlation, with a significant correlation coefficient of 0.96.

Based on the analysis of Figs. 6, 7, 8, and 9, it can be concluded that when the loess with the same water content was compacted, with increasing pounding, the dry density of compacted loess increased, the total pore volume of the compacted loess per unit mass decreased linearly, and the contact angle increased.

Experimental results and analysis of pore distribution

Table 3 lists the pore characteristics of the compacted loess.

Figure 10 shows relationships of variations such as increment and decrement in the volumes of different types of pores in compacted loess per unit mass, where histograms above the horizontal axis indicate a decrement in volume, while histograms below the horizontal axis indicate an increment in volume. Figure 11 shows the variation of pore volume with the number of poundings. Figure 12 shows the proportional distribution map of volumes of different types of pores in the total pore volume of the compacted loess per unit mass for different numbers of poundings received.

Figures 10 and 11 show that when the number of poundings increased from 25 to 30 (indicated by “25~30” in Fig. 10), the volumes of all pores (macropore, mesopore, small pore, and micropore) increased, indicating that the loess would not be compacted. Combined with Table 2, the results show that as the number of poundings increases, both the density and dry density decreased with no large amplitudes, which indicates that the loess structure sustained a certain extent of damage during this process. When the number of poundings exceeded 30, the pore volume decreased with the increase in the number of poundings, indicating that the compacted loess structure was established again under the effect of compaction. Therefore, within a range of a certain number of poundings, large compaction energy was not always beneficial; too large a value of compaction energy would damage soil structure and reduce soil strength. This is partially the reason for the stipulation of the number of poundings for light compaction as 25 in the “ Standard for soil test method” (Ministry of Water Resources of the People’s Republic of China, 1999). Meanwhile, the relationships established based on this study also attest to the validity and scientific integrity of the aforementioned stipulation.

Figures 10, 11, and 12 show that the proportion of macropore volume was small. It reached its maximum of 15.3% at the 10th pound and dropped rapidly to 2~4% after the 25th pound. With the increase in the number of poundings, the typically small proportion of macropore volume varied significantly before the 25th pound but changed little after the 25th pound. The proportion of mesopore volume showed a variation trend similar to that of macropore volume, which, in the compacted loess per unit mass, decreased from 32.7 to 1.5% when the number of poundings increased from 10 to 75.

With an increased number of poundings, the proportion of small pores increased before the 25th pound but decreased after the 40th pound, reaching its maximum value of 24.6% at the 40th pound. The proportion of micropore volume was always dominant and increased from 44.8 to 85.9% during the compacting process. With the increase in the number of poundings, the proportion of micropore volume in the total pore volume per unit mass of the loess increased. However, as pounding proceeded, the absolute amount of micropore volume first increased and then decreased in a manner similar to the small pores. This may be because before the 30th~40th pound, the pore diameter of macropores and mesopores decreased, and many macropores and mesopores became small pores and micropores due to compaction. Therefore, the volume of the small pores and micropores increased. Conversely, after the 30th~40th pound, the dimensions of macropores and mesopores were more or less stabilized, and the compaction was caused by the reduction in volumes of small pores and micropores.

From the above analysis, it can be concluded that the compaction of loess was mainly caused by reductions in volumes of macropores and mesopores, while it was largely unrelated to small pores during the compacting process. As the poundings proceeded, the volume of micropores remained almost unchanged, with an initial slight increase followed by a slight decrease, indicating that pounding cannot significantly reduce the volume of micropores. Therefore, under the conditions of standard compaction effort, compaction had little influence on the micropores.

After the 50th pound, as the pounding proceeded, the volumes of various types of pores showed no significant change, indicating that after the 50th pound, the compaction effort had little effect on the pores in the compacted loess, and the compactness could not be increased by pounding.

Contact angle and pore distribution

Figures 13, 14, 15, and 16 show the variation of contact angle as a function of the proportion of macropore volume, mesopore volume, small pore volume, and micropore volume in the total pore volume. Figure 13 shows that with decreasing proportion of macropore volume in the total pore volume, the contact angle increased, presenting a linear negative correlation. Figure 14 shows that with decreasing proportion of mesopore volume in the total pore volume, the contact angle increased, also presenting a linear negative correlation. Figure 15 shows the variation in contact angle as a function of the proportion of small pore volume in the total pore volume. The proportion of small pore volume in the total pore volume was small, ranging from 7 to 24.6%, while first increasing and then decreasing during the compacting process. Therefore, it had a special effect on the contact angle. Before the 40th pounding, the contact angle increased with the increase in the proportion of small pore volume in the total pore volume. After the 40th pounding, the contact angle increased with the decrease in the proportion of small pore volume in the total pore volume. Figure 16 shows that with the increasing proportion of micropore volume in the total pore volume, the contact angle also increased, presenting a linear positive correlation.

When the compacted loess was more compacted, the pores were smaller and the contact angle was larger. The percentage of macropore and mesopore volumes of the soil decreased, which indicated that the compactness of the soil increased, so the contact angle increased (Figs. 13 and 14). For the small pores, when the number of poundings increased from 10 to 40, with an increased number of poundings, the density of the soil increased. This is because the pore diameter of macropores and mesopores decreased, and many macropores and mesopores became small pores due to compaction, so the proportion of small pores increased. In addition, the contact angle is increased because of the density. When the number of poundings increased from 40 to 75, with the number of hits increasing, the compression of soil is mainly caused by the compression of small pores because the number of macropores and mesopores is very small, so the proportion of small pores decreased while the number of hits increased. Meanwhile, the percentage of small pores decreased, and the compactness of the soil increased; thus, the contact angle increased (Fig. 15). For micropores, when the proportion of pores increased, larger pores such as macropores, mesopores, or small pores are compressed to supplement the micropores. At the same time, with the larger (macropores, mesopores, and small pores) pores compressed and the proportion of micropores increased, the soil density increased, so the contact angle increased (Fig. 16).

Wettability analysis

The contact angles in this study ranged from 0 to 180°. Based on the contact angles, solid surfaces can be classified as totally wet surfaces with strong wettabilities, high-extent wet surfaces, low-extent wet surfaces, and completely dry surfaces. The smaller the contact angle, the larger the wettability of the solid (Zhao 2000).

Table 2 shows that under different compaction efforts, the compacted loess contact angle ranged from 5.9 to 19.0°. The above result indicates that when the number of poundings increased from 10 to 75, the soil wettability was still high, and with increasing density and dry density, the decrease in wettability was not considerable. This indicated that normal compacted loess cannot be used as impermeable material by changing the compactness (increasing the number of poundings) alone. Rather, changes must be made in the constituents of the soil. This also explains why compacted lime soil is used instead of compacted plain soil in foundation waterproofing in collapsible loess areas. The contact angle of the 2:8 lime soil was tested using the same method applied to other specimens listed in Table 2. In the lime soil, the respective percentages of lime and loess were 20% and 80%. The water content of the lime soil was 11.6%. Relative to plain soil (compacted loess listed in Table 2) with a contact angle of 5.9° under the same number of poundings, the 2:8 lime soil had a much larger contact angle (57.3°), a much larger amplitude in decreasing wettability, and significantly reduced permeability.

Conclusions

The contact angle of the compacted loess increased with the increase in dry density and number of poundings, presenting an obviously linear positive correlation. The contact angle decreased with an increase in the total pore volume of the compacted loess, presenting a linear negative correlation with a correlation coefficient of 0.96.

With decreasing total pore volume in the compacted loess, the contact angle increased. However, the volume proportions of macropores, mesopores, small pores, and micropores in the total pore volume were different, and therefore, their effects were different. The contact angle increased with decreasing proportions of macropore and mesopore volumes in the total pore volume, presenting a linearly negative correlation. The contact angle increased with increasing proportion of micropore volume in the total pore volume, presenting a linearly positive correlation.

With the increase in compaction effort, the wettability of compacted loess decreased slightly but not significantly. This, to some extent, explains why normal compacted loess cannot be used as an impermeable material by changing the compactness alone and why lime loess is applied instead of compacted plain loess in the waterproofing of foundations. For the same compaction effort, the contact angle of compacted lime soil was much larger than that of compacted loess.

During the pounding process, compaction of the loess was mainly caused by the reduction in volumes of macropores and mesopores, while small pores and micropores played very small and negligible roles, respectively. The deformation of the compacted loess mainly occurred before the 30th~40th pounding. After the 50th pounding, the compaction had little or no effect on deformation.

During the compaction process of loess, the selection of compaction energy should be appropriate. Excessive energy will not only cause economic waste but also cause the destruction of soil structure, and on the contrary, reduce the strength of soil.

References

Alireza MK, Jonathan PR, Pirouz K (2018) Experimental study of dynamic contact angles on rough hydrophobic surfaces. J Colloid Interface Sci 513:658–665. https://doi.org/10.1016/j.jcis.2017.11.075

Ankitha EB, Kumar A (2019) A conditional justification for the determination of surface energy of solids using contact angle methods. Mater Chem Phys 234:168–171. https://doi.org/10.1016/j.matchemphys.2019.06.008

Bayraktar OY, Saglam CG, Belgin CM, Cetin M (2019) Investigation of the mechanical properties of marble dust and silica fume substituted Portland cement samples under high temperature effect. Fresenius Environ Bull 28(5):3865–3875

Cetin M (2015a) Consideration of permeable pavement in landscape architecture. J Environ Prot Ecol 16(1):385–392

Cetin M (2015b) Using recycling materials for sustainable landscape planning, environment and ecology at the beginning of 21st century, ST. Kliment Ohridski University Press

Cetin M (2016) Determination of bioclimatic comfort areas in landscape planning: a case study of Cide coastline. Turkish Journal of Agriculture-Food Science and Technology 4(9):800–804

Cetin M, Adiguzel F, Kaya O et al (2018a) Mapping of bioclimatic comfort for potential planning using GIS in Aydin. Environ Dev Sustain 20(1):361–375. https://doi.org/10.1007/s10668-016-9885-5

Cetin M, Zeren I, Sevik H, Cakir C, Akpinar H (2018b) A study on the determination of the natural park’s sustainable tourism potential. Environ Monit Assess 190(3):167

Cui ZD, Jia YJ (2013) Analysis of electron microscope images of soil pore structure for the study of land subsidence in centrifuge model tests of high-rise building groups. Eng Geol 164:107–116. https://doi.org/10.1016/j.enggeo.2013.07.004

Enrique R, Paul HS (2008) Microstructure investigation in unsaturated soils: a review with special attention to contribution of mercury intrusion porosimetry and environmental scanning electron microscopy. Geotech Geol Eng 26:705–727. https://doi.org/10.1007/s10706-008-9204-5

Ewa P, Sylwia S, Joanna S et al (2018) Contact angle measurements and water drop behavior on leaf surface for several deciduous shrub and tree species from a temperate zone. Trees. 32:1253–1266. https://doi.org/10.1007/s00468-018-1707-y

GB/T 50123-1999. Ministry of Water Resources of the People’s Republic of China Standard for soil test method. China Planning Press, Beijing, 1999

Hind EO, El-houssaine A, Francois B, et al. (2019) New method for determining paper surface energy per contact angle. Cellulose. pp 1–15. https://doi.org/10.1007/s10570-019-02695-4

İlknur B (2018) Microfabric evaluation of lime-treated clays by mercury intrusion porosimetry and environment scanning electron microscopy. Int J Civ Eng 16:443–456. https://doi.org/10.1007/s40999-017-0151-5

Je’roˆme D, Richard W (2017) Contact angle mechanical influence in wet granular soils. Acta Geotech 12:67–83. https://doi.org/10.1007/s11440-016-0500-6

Jiang JJ, Guo Q, Wang BL et al (2016) Research on variation of static contact angle in incomplete wetting system and modeling method. Colloids and Surfaces A: Physicochem. Eng Aspects 504:400–406. https://doi.org/10.1016/j.colsurfa.2016.05.051

Lars JM, Richard JH, Bill D (2012) Soil pore characteristics assessed from X-ray micro-CT derived images and correlations to soil friability. Geoderma 181:22–29. https://doi.org/10.1016/j.geoderma.2012.02.024

Lei X (1987) Pore types and collapsibility of unsaturated soil in China, China. Sci China (series B) (12): 1309–1316 (in Chinese)

Liu P (2006) Determining methods for aperture and aperture distribution of porous materials, China. Titanium Industry Progress 23(2):29–34. https://doi.org/10.3969/j.issn.1009-9964.2006.02.008 (in Chinese)

Liu Z, Xu X, Wan L (2016) Capillary rise method for the measurement of the contact angle of soils. Acta Geotech 11:21–35. https://doi.org/10.1007/s11440-014-0352-x

Lourenco SD, Saulick Y, Zheng S et al (2018) Soil wettability in ground engineering: fundamentals, methods, and applications. Acta Geotech 13:1–14. https://doi.org/10.1007/s11440-017-0570-0

Mario Z, Simone H, Alexander P et al (2014) Investigations of the pore-size distribution of wood in the dry and wet state by means of mercury intrusion porosimetry. Wood Sci Technol 48:1229–1240. https://doi.org/10.1007/s00226-014-0671-y

Matthew A, Branko B, Martin JB (2014) Pore-scale contact angle measurements at reservoir conditions using X-ray microtomography. Adv Water Resour 68:24–31. https://doi.org/10.1016/j.advwatres.2014.02.014

Min T, Yoo JY, Choi H et al (2003) Drag reduction by polymer additives in a turbulent channel flow. J Fluid Mech 486:213–238. https://doi.org/10.1017/S0022112003004610

Myeongsoo K, Gunhwi K, Jinyoung K (2017) New continuous process developed for synthesizing sponge-type polyimide membrane and its pore size control method via non-solvent induced phase separation (NIPS). Micropor Mesopor Mat 242:166–172. https://doi.org/10.1016/j.micromeso.2017.01.013

Sara LS, Sergio NM, Jaroslaw WD (2016) A novel method for contact angle measurements on natural fibers. Mater Lett 164:599–604. https://doi.org/10.1016/j.matlet.2015.11.039

Shedid AS, Mamdouh TG (2004) Factors affecting contact-angle measurement of reservoir rocks. J Petrol Sci Eng 44:193–203. https://doi.org/10.1016/j.petrol.2004.04.002

Smedley G, Coles DE (2005) A refractive tilting-plate technique for measurement of dynamic contact angles. Colloid Interface Sci 286(1):310–318. https://doi.org/10.1016/j.jcis.2005.01.090

Tang YQ, Sun K, Zhang XH et al (2016) Microstructure changes of red clay during its loss and leakage in the karst rocky desertification area. Environ Earth Sci 537:1–12. https://doi.org/10.1007/s12665-016-5419-6

Varol T, Ertuğrul M, Özel HB, Emir T, Cetin M (2019) The effects of rill erosion on unpaved forest road. Appl Ecol Environ Res 17(1):825–839. https://doi.org/10.15666/aeer/1701_825839

Vladimir AK, Evgeny YM, Andrey IK et al (2018) Irreversible sorption of humic substances causes a decrease in wettability of clay surfaces as measured by a sessile drop contact angle method. J Soils Sediments 18:1327–1334. https://doi.org/10.1007/s11368-016-1639-3

Wajdi A, Amr S, Nayef A (2019) Optimization of contact angle and interfacial tension measurements for fluid/rock systems at ambient conditions. MethodsX. 6:1706–1715. https://doi.org/10.1016/j.mex.2019.07.009

Wang XD, Peng XF, Wang BX (2003) A review on dynamic wetting and dynamic contact angle. J Basic Sci Eng 11(4):396–404. https://doi.org/10.16058/j.issn.1005-0930.2003.04.009 (in Chinese)

Weng M (2019) Statistical analysis of the accuracy of solid surface tensions calculated from error-included contact angle and liquid surface tension data by the multi-component approach. Int J Thermophys 40(26):1–18. https://doi.org/10.1007/s10765-019-2488-2

Yan ZF, Liu CX, Katherine E et al (2016) Pore-scale investigation on the response of heterotrophic respiration to moisture conditions in heterogeneous soils. Biogeochemistry 131:121–134. https://doi.org/10.1007/s10533-016-0270-0

Yang YH, Wu JH, Zhao SW et al (2018) Assessment of the responses of soil pore properties to combined soil structure amendments using X-ray computed tomography. Sci Rep-uk Scientific Reports 695:1–10. https://doi.org/10.1038/s41598-017-18997-1

Zeng Q, Li KF, Teddy FC, et al. (2012) Analysis of pore structure, contact angle and pore entrapment of blended cement pastes from mercury porosimetry data. Cement Concrete Comp 34: 1053–1060. doi: 10. 1016/j. cemconcomp. 2012. 06. 005

Zhang SJ, Cheng YH, Xing FF et al (2011) Study on contact angle and surface free energy current situation and prospect. Coal Mine Machinery 32(10):8–10. https://doi.org/10.13436/j.mkjx.2011.10.053 (in Chinese)

Zhang C, Liu Z, Deng P (2016) Contact angle of soil minerals: a molecular dynamics study. Comput Geotech 75:48–56. https://doi.org/10.1016/j.compgeo.2016.01.012

Zhao Z (2000) Contact angle and its application in surface chemistry research, China. Chem Res Appl 12(4):370–374. https://doi.org/10.3969/j.issn.1004-1656.2000.04.004 (in Chinese)

Funding

The research work was funded by the National Natural Science Foundation of China (No. 41472267).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Abdullah M. Al-Amri

Rights and permissions

About this article

Cite this article

Jing, Y., Zhang, Z., Tian, W. et al. Experimental study on contact angle and pore characteristics of compacted loess. Arab J Geosci 13, 103 (2020). https://doi.org/10.1007/s12517-020-5106-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-020-5106-5