Abstract

The preservation of foods at low temperatures is a well-established concept. While conventional methods of food freezing rely on the isobaric (constant pressure) approach, they often result in a series of irreversible changes that can significantly hamper the quality of frozen foods. In recent years, taking its roots from the biomedical industry, isochoric (constant volume) freezing is gaining both research and commercial interest as an effective method of food preservation. The focus of this review is to present the state of the art of isochoric freezing of foods, highlighting the underlying mechanisms that make it unique, and understanding its impact on food quality, considering reports published in the past decade. An exclusive section is dedicated to its non-food applications, and this work also provides insights into the costs and economics of the process. Importantly, as this is an emerging area, the review concludes by highlighting the challenges and provides perspectives on the directions for future research.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Food Freezing

Freezing is an ancient method of food preservation, and apart from its domestic application, it is used at various levels of the commercial food supply chain. In general, the conventional food freezing process involves lowering the temperature of the food material to −18 °C or below. When exposed to the freezing medium, with heat transfer, the temperature of the food lowers. Several aspects such as system designs, ice crystallization, and phase change, freezing time, and others affect the quality of foods. The freezing process is associated with several challenges; for example, non-uniformity in freezing rates and costs involved, apart from the use of improper temperature ranges/freezing conditions that can result in significant detrimental effects. In general, the process of food freezing involves five stages [1]. During the pre-cooling stage, the temperature of the product is reduced to the initial freezing point (~0 °C). Further removal of heat to less than 10 °C results in the super-cooling phase [2]. Ice nucleation begins after this super-cooling stage, followed by the release of latent heat of crystallization. In the next stage, the temperature of the food is further lowered as more water gets converted to ice and reaches the eutectic point. Finally, the temperature of the product would equal the freezing medium’s temperature. What makes the process challenging is the intricate nature of the food matrix and its composition; foods are composed of a mixture of solutes with different freezing temperatures. Nevertheless, all foods are subject to these stages during the freezing process [1].

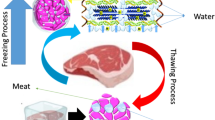

Conventional freezing processes employ an isobaric approach in which temperature and volume vary in tandem. An unrestricted amount of solution in the food gets frozen in the isobaric system. Ice crystal formation inside the food causes damage to the cellular structure of foods. Overcoming such limitations, isochoric freezing of biological systems can avoid the risk of such cell integrity losses.

Thermodynamics of Isochoric Systems

The thermodynamic principles of isochoric preservation were first studied in the year 2005 by Rubinsky and his fellow researchers [3]. During isochoric freezing, the volume of the system remains constant while variables like pressure and temperature vary in tandem. The phase diagram of pure water in Fig. 1 shows that isochoric freezing is followed by a liquidus path that lies between ice I, ice III, and liquid water. The system exhibits equilibrium pressure until the triple point at the given sub-zero temperature. For pure water, the triple point is a temperature of 21.985 °C and a pressure of 209.9 MPa. Importantly, unique conventional freezing process, ice growth cannot occur due to the constant volume, which in turn generates a hydrostatic pressure in the isochoric system [4]. Theoretical and experimental data confirm that 45% of the volume remains unfrozen at the triple point in a constant volume freezing process [3, 5]. This effect takes the benefit of the Le Chatelier’s principle which explains that the high pressure developed inside a system upon freezing would restrict any further development of ice [6]. In an isochoric system, the freezing temperature of an aqueous solution can be given by Eq. (1).

where Tph is the phase change temperature, T° is the freezing temperature of pure water at the reference pressure of 1 atm, ∆T(P) is the temperature depression due to an increase in pressure, and ∆T(c) is the temperature depression as a function of solute concentration, c [3].

Phase diagram of pure water. The liquidus curve between liquid water, ice I, and ice III marks the equilibrium pressure that an isochoric system will experience at a given subzero temperature higher than the triple point [4]

The Helmholtz free energy can be used to explain the thermodynamic equilibrium conditions in an isochoric system on contrary to the minimization of Gibbs free energy that results in the thermodynamic equilibrium of isobaric systems [7]. The differentiation of Gibbs free energy and Helmholtz free energy explains the critical cluster radius (rcritical) of ice in an isochoric system and can be obtained from Eq. (2)

where σ is the surface tension between ice and liquid in J/m2, υi is the specific volume of ice (m3/kg), υl is the specific volume of liquid (m3/kg), L is the latent heat of fusion per unit mass (J/m3), Tm is the melting temperature (K) at a given pressure (N/m2), and k is the slope at any point of the curve (m3/J) [7]. Theoretical analyses show that the critical radius for ice nucleation in an isochoric process requires temperatures less than −100 °C, much lower than the 0 °C requirement in isobaric systems [7]. Mathematical data explains that the chances of vitrification (direct transition of a liquid to a glassy state) are higher in an isochoric process because of the reduced chances of random ice nucleation. The maintained intracellular and extracellular osmolality also play an important role in hindering the formation of ice during isochoric preservation. On the contrary, enhanced extracellular osmolality due to ice crystal formation causes damages in conventional isobaric processes [5]. Table 1 shows the major differences between the isobaric and isochoric freezing systems. A unique thermodynamic behavior is recently being studied in isochoric systems by coupling the latent and sensible heats at all sub-zero temperatures, associated with temperature fluctuations in an isochoric storage. This explains that foods stored in isochoric systems act like an optimized phase change material that enhances the thermal mass. Increment in the thermal mass provides temperature stability to the system with a plethora of benefits focusing on improved food quality by avoiding moisture migration, weight loss, and freeze burn [4].

Isochoric Freezing and System Designs

In a typical isochoric process, the food material is immersed in an isotonic solution inside a rigid container that is capable of withstanding elevated pressures. Depending on the pressure and temperature, materials such as stainless steel cylinders, carbon fiber composites, and hard phenolic thermosets with pressure transducers and rupture disks are employed for isochoric processes. Sugar or salt solutions are used for preservation. Then, ice crystals are introduced in the container as the nucleation site and the chamber is tightly packed. To preserve food materials in their aqueous phase without the formation of ice crystals, it is important to insert this nucleator. The chamber is then sealed with a metal screw to restrict any passage of air in and out of the container [3]. This preserves the food material in a two-phase thermodynamic condition, without the risk of cellular injury (Fig. 2). The two-phase isochoric system is achievable only if the system is tightly packed and no air or liquid can escape out of it. A temperature bath is used to cool the system. Most systems also have pressure transducers and thermistors linked to the data acquisition card and connected to a computer for data processing [6].

Schematic of an isochoric (constant-volume) system in exterior and cross-sectional views at various sub-freezing temperatures [27]

The principles of thermodynamics explain that temperature and pressure are dependent on an isochoric process and the system is also characterized by the quality of the solution (that is, the relative percentage between the ice and liquid fractions). The phase change can occur at multiple pressure–temperature combinations. When freezing takes place at a particular temperature and pressure, the percentage of ice and water will also self-adjust to attain a state of thermodynamic equilibrium [3].

Non-food Applications of Isochoric Freezing

To better understand the reason behind its growing interest in food systems, this section explains the origins of this method of preservation, focusing primarily on biomedical applications. While the material of interest is different, these concepts and salient findings can serve as a valuable resource for food technologists.

Organ transplants are extremely significant for patients who suffer organ failure. Nevertheless, it is limited to the availability of the matching donor organ, preservation facility, and the transportation time for the donor organ to reach the patient [8]. The kidney was the first organ that was successfully transplanted in 1954 and the process involved a static cold storage preservation approach, considered as the gold standard for organ preservation. Ideally, the organ is stored in an icebox under static storage conditions. Transplantation of the highest quality organ within hours of organ procurement is performed using this method [9]. While the metabolism is not completely stopped in this process, depletion of adenylate triphosphate (ATP) and formation of ischemia–reperfusion injury (IRI) metabolites can result in injury during subsequent processes [10, 11]. By decreasing the temperature by several degrees during preservation, metabolic reaction rates can be retarded, with associated changes in ATP loss and the formation of IRI metabolites [12].

The use of sub-zero temperature is another technique for the preservation of organs. This was proved with studies on the sustenance of wood frogs (Rana sylvatica) in extremely low temperatures for months. In this process, ice formation is confined to the extracellular space, and the process is termed “partial freezing” [13]. Synthesis of low molecular weight carbohydrates in the wood frog provides tolerance to freezing conditions and stabilizes the phospholipid bilayer, avoiding the formation of intracellular ice [14, 15]. This type of preservation method involves the use of cryoprotectants (such as 3-O-methyl glucose (3-OMG), trehalose) via injection before freezing and ice nucleating approaches further increase the survival from 14 to 49 days [13, 16]. It is hypothesized that the use of biocompatible ice nucleators can minimize cryoinjury, and a recent preliminary investigation on simple blood vessels supports this hypothesis [13].

Super-cooling is a non-equilibrium process in which the complete removal of ice is achieved at high sub-zero temperatures. It is an effective approach; for example, rat liver super-cooled to −6 °C could be preserved for 3–4 days [17, 18]. Despite advancements in organ preservation using such techniques, it is important to note that the risk of random ice formation as ice nucleation is a stochastic process [19]. Ice crystals formed in a highly super-cooled solution have a sharper dendritic shape, causing more cellular damage [20]. Cryopreservation (using liquid nitrogen at −196 °C) and vitrification by the utilization of cryoprotectants are other freezing techniques for organ preservation. However, such cryoprotectants can cause toxicity and osmotic effects, which subsequently result in cell injury [21]. Such limitations explain the rising interests in the isochoric approach.

Isochoric freezing is providing a novel paradigm in organ transplantation and eliminates the harmful effects of cryoprotective agents and suppresses ice formation inside the organ through the thermodynamic approach. A whole model multicellular organism (Caenorhabditis elegans) survived at a sub-freezing temperature in isochoric conditions (−5 °C and 60 MPa), proving its promising potential for biotechnology and medical applications [22]. Isochoric preservation of mammalian cells (Madin–Darby canine kidney epithelial cells) in phosphate buffer solution at −10 °C and 96.5 MPa for 60 min resulted in 60% alive cell and only 18% survived after 120 min. With further increase in pressure, at −15 °C (162 MPa) and −20 °C (205 MPa), alive cell percentages were around 19 and none, respectively [23]. In another study, preserving a rat’s heart in isochoric freezing conditions showed that mammalian organs can survive at low-temperature freezing without utilizing cryoprotective additives. Preservation of the heart in a specifically prepared solution at a sub-freezing temperature of −4 °C and 41 MPa pressure showed relative results to the heart preserved in hypothermic conditions at 0 °C (atmospheric pressure). The interstitial edema was much lower under isochoric conditions than in the conventional hypothermic freezing approach, indicating low vascular injuries in isochoric preservation (−4 °C and 41 MPa) [24]. Further decreasing the temperature to −6 °C (60 MPa) and −8 °C (80 MPa) was found to cause cell injury and extensive edema because of elevated pressures [24]. Preservation of pancreatic islets without the use of the cryoprotective agents at − 3 °C and 34 MPa pressure could survive up to 72 h with good morphological integrity and showed intact clusters of cells without any dissociation [25]. Therefore, isochoric freezing allows preservation of organs with good structural integrity and low vascular injuries.

This approach when applied to foods proved its potential in preserving foods with good cellular integrity when compared with conventional freezing as explained in the following sections.

Emerging Food Applications

Almost all biological materials hold significant levels of water and lowering down the temperature to the freezing point of water can cause physical injury. Intracellular and extracellular ice formation brings a marked difference in the overall quality of the stored material. Isochoric preservation in the food industry is being explored as an approach to lower food wastage and preserve the nutritional and sensory attributes, apart from enhancing the shelf-life of perishable products. A summary list of biological materials preserved at various isochoric conditions and key highlights of these studies is presented in Table 2. This section focuses on how isochoric freezing can be used as a food preservation method.

Effect on Microorganisms

In general, the isochoric process results in changes in the physical integrity of microorganisms. Isochoric cooling of Escherichia coli at −15 °C was found to result in membrane damage, alteration in the shape and size of the cell, protrusions, ruptured membrane, and expulsion of intracellular matter [26]. Another study reported a 2.5 log decrease in the E. coli load at −15 °C (145 MPa) and −20 °C (186 MPa) after 12 h of freezing. A decrement by 75% in the survived organism was observed after 24 h at −20 °C [27]. Isochoric preservation also helps in decreasing the pathogenic bacteria (Listeria monocytogenes and Salmonella typhimurium) to unrecoverable levels at −15 °C and 135 MPa for 24 h.

The impact of high pressure in isochoric freezing seems advantageous in terms of microbial destruction. Isochoric preservation completely exterminated E. coli at −15 °C because bacterial suspension at this temperature is in a metastable and amorphous liquid state, not conducive for the bacteria to survive [26]. It was observed that partial destruction of E. coli occurs at −20 °C and −30 °C in the isochoric freezing process due to the ice III and ice Ih formations where some E. coli try to shelter inside ice crystals and replicate after the freezing process [26].

Elevated pressure and low temperature are the factors responsible for the decrement in microbial survival, but the mechanism behind the bactericidal effect needs to be further explored [28]. The simplicity of isochoric design makes it convenient to be utilized even in domestic freezers and provides the means to sterilize food items at home [28].

Effect on Enzymes

The isochoric approach can reduce the browning of foods. Potatoes when stored at −5 °C under isochoric refrigeration showed substantial differences in color as compared with those stored under isobaric freezing at −5 °C [5]. The oxidation of phenolic compounds by the action of polyphenol oxidase (PPO) produces quinones that polymerize further to form insoluble melanins and a dark color in potatoes. A breach in the cell membrane releases the enzyme from the potatoes, resulting in enzymatic browning. Isochoric preservation can maintain cell integrity; therefore, the release of PPO from the cell membrane of potatoes can be reduced, in turn lowering browning effects [5]. Figure 3 shows the onset of browning in fresh and thawed potatoes when stored under isochoric, isobaric, and individual quick freezing conditions at varying freezing times [29]. The presence of ice crystals during freezing of foods as in the conventional freezing process at atmospheric pressure might alleviate undesirable enzymatic reactions owing to the release of enzymes from the cell membrane [30]. The release of enzymes from damaged membranes and a higher concentration of pro-oxidants in unfrozen tissues were found to increase the thiobarbituric acid reactive substances (TBARS) after preserving fish fillets under super-chilling conditions for 1 week [31].

Photographic images of fresh and thawed potatoes showing the onset of browning when stored under isochoric, isobaric, and individual quick freezing conditions at varying freezing times [29]

Further, damage in cell membrane because of conventional freezing can facilitate enzyme–substrate reactions and also result in the degradation of ascorbic acid. Isochoric freezing (−4 °C and −7 °C) of cherries can preserve the ascorbic acid content unlike isobaric freezing (−4 °C and −7 °C) that shows around 63% and 51% losses, respectively. Individual quick freezing (IQF) can also degrade ascorbic acid contents of cherries (−72% loss) because of the oxidation of ascorbic acid oxidase [32]. Minimally processed potatoes showed losses in ascorbic acid content when stored for 4 weeks in an isochoric freezing system at a temperature of − 3 °C and a pressure of 30 MPa. Isochoric frozen minimally processed potatoes could retain only 6.9% ascorbic acid, whereas isobaric system frozen counterparts retained around 10.4% ascorbic acid. Broken cells which were damaged during the pre-processing (peeling, cutting, freezing) of potatoes, release ascorbate oxidase enzyme that results in increased interaction between ascorbate oxidase and ascorbic acid, in turn, causing a reduction in the ascorbic acid content of potatoes in the isochoric system [29].

Effect on Food Quality (Nutritional and Sensory Aspects)

The quality of the foods can be better preserved using a constant-volume preservation technique in a closed rigid container. Potatoes when stored in isochoric refrigeration (−5 °C) system immersed in 10% (w/w) sucrose solution experience no weight loss as cell integrity is maintained due to isosmotic conditions whereas in an isobaric freezing, potato at the same temperature experiences weight loss [5]. Minimally processed potatoes also showed good quality attributes when stored under isochoric conditions at −3 °C and 30 MPa [29]. The total phenolic content and antioxidant activity were found to be higher with decreased drip loss and volume shrinkage in isochoric freezing of pre-cut potatoes [29]. Similarly, isochoric freezing of baby-leaf spinach (Spinacia oleracea L. Regiment) in a 10°brix sucrose solution at −4.0 ± 0.9 °C and 29.7 ± 0.2 MPa could maintain the cell integrity, turgidity, and nutritional properties, whereas isobaric freezing at −4 °C showed a loss in weight, thickness, and nutrient value due to ice crystal formation in the cell, which in turn affected cell compartmentalization [33]. In a recent study on isochoric freezing of tomatoes, it was observed that the process resulted in better physicochemical and nutritional properties as compared with tomatoes stored under cold storage and IQF conditions [34].

In another study, sweet cherry (Prunus avium) was stored in an isochoric freezing system in a 17.5°brix sucrose solution [32]. These researchers stored cherries at −4 °C (29.5 MPa) and −7 °C (62.1 MPa) for 1 day in the isochoric system and compared their quality with isobaric frozen (−4 °C and −7 °C for 24 h) and individually quick-frozen counterparts. Preservation of sweet cherries in the isochoric system could better retain the textural and nutritional properties with good color values and reduced drip loss, whereas conventional freezing resulted in significant losses in quality, texture, and nutritional parameters [32]. Lowering the temperature to −7 °C showed drip loss and slight decrement in firmness and rigidity of cherries because of the high hydrostatic pressure which affected the permeability across the cell membrane [32].

Isochoric freezing does not cause cell dehydration and maintains morphological integrity as the extracellular osmolality is comparable to the intracellular osmolality of the cell [30]. Tilapia fish (Oreochromis aureus) fillets when preserved at −5 °C for 3 h in isotonic saline solution of 0.9% showed no difference when compared with fresh tissues as shown in Fig. 4. Whereas, in the case of isobaric frozen fish muscles, the morphology of the tissue is changed, showing shrunk muscle fiber and split regions between the connective tissues [30]. Interestingly, tilapia fillets stored in an isochoric system at −3 °C and 37 MPa pressure showed similar texture as of the fresh fillets, with superior quality as compared with those stored under the traditional chilling method at 5 °C, the super-chilling method at −3 °C, and frozen at −20 °C that showed softer fillets.

Comparison between A fresh muscle tissue, B tissue after 3-h isobaric preservation at −5 °C, and C tissue after 3-h isochoric preservation at −5 °C [30]

Importantly, isochoric freezing increases the amount of water but not the amount of salt in fish fillets when stored in the isotonic salt solution. A study reported a 4% increase in the mass of fish fillet when stored under isochoric conditions while super-chilling and freezing caused drip losses that resulted in a significant reduction of mass as the muscles could not reabsorb water due to their shrunk fibers, cellular damage, denaturation, and aggregation of protein [31]. TBARS in isochoric frozen samples of fish were also found to remain similar to that of fresh samples during 2 weeks of storage as the low pressure of 37 MPa may not be enough to produce auto-oxidation reactions. However, TBARS values were found to increase to 53%, 55%, and 34% in chilled, super-chilled, and frozen samples, respectively [31]. Similarly, the total volatile basic nitrogen (TVB-N) content in isochoric preservation of fish fillets showed no significant difference from fresh samples after 2 weeks of storage, whereas conventional chilling and super-chilling preservation show three- and a two-fold increase in TVB-N content, respectively, subsequently resulting in bacterial spoilage of the food [31].

Combined Techniques (Spontaneous)

Isochoric cryopreservation can tolerate liquid nitrogen temperatures and pressures ranging up to 413 MPa, explaining that pressure measurement is crucial for the control of vitrification and devitrification in aqueous solutions [35]. Such ideas further helped in the experimental validation of the isochoric vitrification process. Vitrification in isochoric freezing can be facilitated using additives such as propane-diol and dimethyl sulfoxide (Me2SO) at concentrations ranging from 0 to 49% (w/v), and this has been proven for cryopreservation of organs and tissues [36]. The concentration of cryoprotective additives for isochoric vitrification is substantially less in isochoric freezing than in the case of isobaric vitrification at 1 atm and a hyperbaric process at 1000 atm. Therefore, isochoric techniques promote vitrification more effectively than hyperbaric systems [36].

Super-cooling in isochoric conditions improves the stability of the system when exposed to various mechanical stimuli such as drop impact, vibration, ultrasonication, and thermal fluctuations. This effect is achieved by combined thermodynamic and kinetic factors that reduce the microscopic density fluctuation, eliminate the air–water interface, and provide resistance to cavitation [37]. Another combined technique is the modification of the existing isochoric system in which multiple aqueous phases are employed, separated by a membrane impermeable to mass transfer but transmit heat and pressure. This multiphase isochoric freezing model can be used for the complete removal of hypertonicity and ice crystal formation in cryopreservation protocols [38].

Energy and Cost Comparisons

Slow freezing processes employed in industries for freezing of food items involve the use of deep cryogenic temperatures to reduce the size of ice crystals and then storing foods under freezing temperature, accounting to be an energy-intensive process. The consumption of energy in an isochoric system is significantly lesser than an isobaric system of equal mass. This is because of the reduction in total frozen mass and the temperature dependence of the latent heat of fusion of water. In an isochoric system, only a portion of the mass is frozen at a given sub-freezing temperature higher than the triple point, decreasing the total energy for ice fusion. However, in an isobaric system, phase transition takes place at the atmospheric freezing point and the latent heat of fusion decreases with temperature, consequently requiring more energy to freeze. Thermodynamic analyses showed that fish or meat when stored in an isochoric system at −5 °C consume 70% less energy than the conventional freezing process. Further, more energy savings can be achieved when foods like fruits and berries with high sugar contents are preserved. Isochoric storage can reduce energy expenditure at an industrial level as no ice formation takes place inside the food [4]. Such systems aim to increase efficiency and can be designed by altering existing industry-scale freezers. This can be achieved without major infrastructural alterations and appliance wastages. Further, the simple design of isochoric systems makes them convenient and relatively economic in terms of usage [6].

Challenges and Research Needs

Isochoric preservation offers several advantages as compared to the conventional freezing processes. Nevertheless, there are several research and commercialization aspects that require a better focus. For example, there are instances when the high pressures used in isochoric systems have shown detrimental effects. The viability of organs was found to be affected when elevated pressures were used for the preservation of rat’s heart [24]. This also emphasizes the need for optimized protocols for temperature and pressure combination for food freezing applications. Further, detailed mechanisms behind the delayed on-set of enzymatic browning and loss in ascorbic acid content in minimally processed vegetables [29] should be examined further. Similarly, the underlying principles that are responsible for the bactericidal effects of isochoric freezing are not well documented [28]. In terms of equipment designs and process control, theoretical and experimental studies must be conducted to explain the super-cooling stability of isochoric systems by considering varying chamber rigidity ranges [37]. Such aspects must be further explored before the technology is explained as one that is viable for industrial applications.

Conclusion

Food freezing is a significant method of food preservation. While conventional methods may result in several detrimental effects on foods, the focus of this work was to highlight the emerging applications of isochoric freezing as a food preservation technique. With promising applications in handling biological organs, optimized isochoric freezing processes can prove to be extremely beneficial for agricultural and food products. With better process economics and simpler engineering designs, research must now focus on developing processes for large-scale applications.

References

You Y, Kang T, Jun S (2020) Control of ice nucleation for subzero food preservation. Food Eng Rev. https://doi.org/10.1007/s12393-020-09211-6

Muthukumarappan K, Marella C, Sunkesula V (2019) Food freezing technology. Handb Farm, Dairy Food Mach Eng 389–415. https://doi.org/10.1016/b978-0-12-814803-7.00015-4

Rubinsky B, Perez PA, Carlson ME (2005) The thermodynamic principles of isochoric cryopreservation. Cryobiology 50:121–138. https://doi.org/10.1016/j.cryobiol.2004.12.002

Powell-Palm MJ, Rubinsky B (2019) A shift from the isobaric to the isochoric thermodynamic state can reduce energy consumption and augment temperature stability in frozen food storage. J Food Eng 251:1–10. https://doi.org/10.1016/j.jfoodeng.2019.02.001

Lyu C, Nastase G, Ukpai G et al (2017) Isochoric refrigeration of food products. https://doi.org/10.7287/peerj.preprints.2740v1

Preciado JA, Rubinsky B (2010) Isochoric preservation: a novel characterization method. Cryobiology 60:23–29. https://doi.org/10.1016/j.cryobiol.2009.06.010

Szobota SA, Rubinsky B (2006) Analysis of isochoric subcooling. Cryobiology 53:139–142. https://doi.org/10.1016/j.cryobiol.2006.04.001

Giwa S, Lewis JK, Alvarez L et al (2017) The promise of organ and tissue preservation to transform medicine. Nat Biotechnol 35:530–542. https://doi.org/10.1038/nbt.3889

Vries RJ, de Yarmush M, Uygun K (2019) Systems engineering the organ preservation process for transplantation. Curr Opin Biotechnol 58:192–201. https://doi.org/10.1016/j.copbio.2019.05.015

Bruinsma BG, Berendsen TA, Izamis M et al (2013) Determination and extension of the limits to static cold storage using subnormothermic machine perfusion. 36:775–780. https://doi.org/10.5301/ijao.5000250

Eltzschig HK, Eckle T (2011) Review Ischemia and reperfusion—from mechanism to translation. Nat Med 17:1391–1401. https://doi.org/10.1038/nm.2507

Yoshida K, Matsui Y, Wei T et al (1999) A novel conception for liver preservation at a temperature just above freezing point. J Surg Res 81:216–223. https://doi.org/10.1006/jsre.1998.5505

Tessier SN, Weng L, Moyo WD et al (2018) Effect of ice nucleation and cryoprotectants during high subzero-preservation in endothelialized microchannels. ACS Biomater Sci Eng 4:3006–3015. https://doi.org/10.1021/acsbiomaterials.8b00648

do Amaral MCF, Lee RE, Costanzo JP (2015) Hepatocyte responses to in vitro freezing and β-adrenergic stimulation: insights into the extreme freeze tolerance of subarctic Rana sylvatica. J Exp Zool Part A Ecol Genet Physiol 323:89–96. https://doi.org/10.1002/jez.1905

Storey KB (1999) Living in the cold: freeze-induced gene responses in freeze-tolerant vertebrates. Clin Exp Pharmacol Physiol 26:57–63. https://doi.org/10.1046/j.1440-1681.1999.02990.x

Layne JR, Costanzo JP, Lee RE (1998) Freeze duration influences postfreeze survival in the frog Rana sylvatica. J Exp Zool 280:197–201. https://doi.org/10.1002/(SICI)1097-010X(19980201)280:2<197::AID-JEZ11>3.0.CO;2-J

Bruinsma BG, Berendsen TA, Izamis ML et al (2015) Supercooling preservation and transplantation of the rat liver. Nat Protoc 10:484–494. https://doi.org/10.1038/nprot.2015.011

Berendsen TA, Bruinsma BG, Puts CF et al (2014) Supercooling enables long-term transplantation survival following 4 days of liver preservation. Nat Med 20:790–793. https://doi.org/10.1038/nm.3588

Taylor MJ, Weegman BP, Baicu SC, Giwa SE (2019) New approaches to cryopreservation of cells, tissues, and organs. Transfus Med Hemotherapy 46:197–215. https://doi.org/10.1159/000499453

Costanzo JP, Grenot C, Lee RE (1995) Supercooling, ice inoculation and freeze tolerance in the European common lizard, Lacerta vivipara. J Comp Physiol B 165:238–244. https://doi.org/10.1007/BF00260815

Fahy GM, Wowk B, Wu J et al (2004) Cryopreservation of organs by vitrification: perspectives and recent advances. Cryobiology 48:157–178. https://doi.org/10.1016/j.cryobiol.2004.02.002

Mikus H, Miller A, Nastase G et al (2016) The nematode Caenorhabditis elegans survives subfreezing temperatures in an isochoric system. Biochem Biophys Res Commun 477:401–405. https://doi.org/10.1016/j.bbrc.2016.06.089

Preciado J, Rubinsky B (2018) The effect of isochoric freezing on mammalian cells in an extracellular phosphate buffered solution. Cryobiology 82:155–158. https://doi.org/10.1016/j.cryobiol.2018.04.004

Wan L, Powell-Palm MJ, Lee C et al (2018) Preservation of rat hearts in subfreezing temperature isochoric conditions to – 8 °C and 78 MPa. Biochem Biophys Res Commun 496:852–857. https://doi.org/10.1016/j.bbrc.2018.01.140

Powell-Palm MJ, Zhang Y, Aruda J, Rubinsky B (2019) Isochoric conditions enable high subfreezing temperature pancreatic islet preservation without osmotic cryoprotective agents. Cryobiology 86:130–133. https://doi.org/10.1016/j.cryobiol.2019.01.003

Salinas-Almaguer S, Angulo-Sherman A, Sierra-Valdez FJ, Mercado-Uribe H (2015) Sterilization by cooling in isochoric conditions: the case of Escherichia coli. PLoS One 10:1–9. https://doi.org/10.1371/journal.pone.0140882

Powell-Palm MJ, Preciado J, Lyu C, Rubinsky B (2018) Escherichia coli viability in an isochoric system at subfreezing temperatures. Cryobiology 85:17–24. https://doi.org/10.1016/j.cryobiol.2018.10.262

Bridges DF, Bilbao-Sainz C, Powell-Palm MJ et al (2020) Viability of Listeria monocytogenes and Salmonella Typhimurium after isochoric freezing. J Food Saf 1–8. https://doi.org/10.1111/jfs.12840

Bilbao-Sainz C, Zhao Y, Takeoka G et al (2020) Effect of isochoric freezing on quality aspects of minimally processed potatoes. J Food Sci 00:1–9. https://doi.org/10.1111/1750-3841.15377

Năstase G, Lyu C, Ukpai G et al (2017) Isochoric and isobaric freezing of fish muscle. Biochem Biophys Res Commun 485:279–283. https://doi.org/10.1016/j.bbrc.2017.02.091

Bilbao-Sainz C, Sinrod AJG, Williams T et al (2020) Preservation of tilapia (Oreochromis aureus) fillet by isochoric (constant volume) freezing. J Aquat Food Prod Technol 00:1–12. https://doi.org/10.1080/10498850.2020.1785602

Bilbao-Sainz C, Sinrod A, Powell-Palm MJ et al (2019) Preservation of sweet cherry by isochoric (constant volume) freezing. Innov Food Sci Emerg Technol 52:108–115. https://doi.org/10.1016/j.ifset.2018.10.016

Bilbao-Sainz C, Sinrod AGJ, Dao L et al (2019) Preservation of spinach by isochoric (constant volume) freezing. Int J Food Sci Technol 0–2. https://doi.org/10.1111/ijfs.14463

Bilbao-Sainz C, Sinrod AJ, Dao L, Takeoka G, Williams T, Wood D, McHugh T (2021) Preservation of grape tomato by isochoric freezing. Food Res Int 110228. https://doi.org/10.1016/j.foodres.2021.110228

Ukpai G, Năstase G, Şerban A, Rubinsky B (2017) Pressure in isochoric systems containing aqueous solutions at subzero centigrade temperatures. PLoS One 12:1–16. https://doi.org/10.1371/journal.pone.0183353

Zhang Y, Ukpai G, Grigoropoulos A et al (2018) Cryobiology isochoric vitrification: an experimental study to establish proof of concept 83:48–55. https://doi.org/10.1016/j.cryobiol.2018.06.005

Powell-Palm MJ, Koh-Bell A, Rubinsky B (2020) Isochoric conditions enhance stability of metastable supercooled water isochoric conditions enhance stability of metastable supercooled water. Appl Phys Lett 123702. https://doi.org/10.1063/1.5145334

Powell-Palm MJ, Aruda J, Rubinsky B (2019) Thermodynamic theory and experimental validation of a multiphase isochoric freezing process. J Biomech Eng 141. https://doi.org/10.1115/1.4043521

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nida, S., Moses, J.A. & Anandharamakrishnan, C. Isochoric Freezing and Its Emerging Applications in Food Preservation. Food Eng Rev 13, 812–821 (2021). https://doi.org/10.1007/s12393-021-09284-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-021-09284-x