Abstract

The steam-bending behavior of seven poplar hybrid clones from three growing sites was evaluated on kiln-dried specimens following two types of drying, an elevated-temperature and conventional schedule. The bending quality was assessed using quantitative and qualitative methods. In general, the poplar hybrid clones have poor steam-bending properties. The proportions of excellent pieces was low (13 %) compared to red oak (100 %), which was included as a reference for its excellent bending properties. Poplar specimens also showed a great memory effect and poor surface quality after bending. Among the parameters studied, only the clones showed a significant effect on bending properties. Hence, a clone selection could be done for bending improvement but it may be of minor significance.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the late 1960s, the Canadian wood industry started the improvement of poplar natural resource productivity through sylviculture, conventional tree breeding, and biotechnology programs [1]. Although these programs have resulted in great advances (improved growth, stem form, adaptability, and disease resistance), certain areas including wood utilization require further investigation.

Bending solid wood could be a good option to generate more value-added products using poplar hybrid clones. Bent wood pieces allow creating curved objects that are generally stronger and stiffer than objects made with pieces shaped by sawing. When wood is bent, the interior face (concave) is subjected to compressive strains while the exterior face (convex) is exposed to tensile strains. Softening treatment greatly increases wood compressibility, but in contrast has a little effect on tensile properties [2]. To restrict elongation of the convex side a tension strap is normally used. Without restraint, tension and compression stresses are balanced on opposite sides of a quasi-centrally located neutral axis. Moreover, the addition of a steel strap with end-blocks will provoke a shift of the neutral axis of the fibres towards the convex side. As a result, the portion of the wood in tension will be reduced and the one in compression increased [3–5]. A successful bend is achieved when permanent wood deformation is obtained without obvious wood failure [6].

During bending two kinds of deformation appear: plastic and viscoelastic deformations. Softening treatments drive the wood to a viscoelastic state. After bending, the wood is still in the viscoelastic state. Thus, the relative amount of elastic deformation will spring-back; while the relative amount of plastic deformation will remain in the desired shape. To avoid spring-back, the bent workpiece has to be fixed to its position until the elastic deformation changes to plastic deformation. This change is considered as stress relaxation [7].

There are two principal ways to bend wood: using heat, humidity and pressure, known as steam bending, or using chemical products. In steam bending, wood pieces are placed in a steaming machine at about 100 °C, bent and then kept in a bending plate until cooling is completed and the moisture content (MC) required for final use is achieved. In general, steam bending is conducted mainly in hardwoods that have initial MC between 12 % and 25 %. The level of curvature and deformation followed by the pieces after bending is a function of the initial MC and the setting conditions. Jorgensen [8] suggested an initial MC between 12 % and 20 %, Stevens and Turner [4] 25 % MC, and Kollmann and Côté [9] between 17 % and 25 % MC.

The suggested steaming times also vary among studies. The most common estimates are 1 h per 25.4 mm of thickness for dry wood (12 % MC or less) and 30 min per 25.4 mm of thickness for green wood [2, 3]. Lemoine and Koch [10] steamed at atmospheric pressure southern pine pieces of 12.7 mm and 25.4 mm thick at 17 % MC during only 10 and 20 min, respectively, with adequate results. On the other hand, the maximum curvature that can be obtained when bending a given species for a particular thickness can be roughly estimated using the ratio of radius to thickness, called the thickness ratio. According to Kubler [11], this ratio should be 30 for dry wood at ambient temperature, 13 with steamed wood, and 3 when using a steel strap.

The present study evaluates the steam bending behavior of wood pieces coming from seven poplar hybrid clones grown in three sites, after two wood drying treatments. Bending quality was assessed using quantitative and qualitative methods. The first method evaluated the curvature recovery, often known as spring-back of the wood pieces. The second method classified visually the wood pieces by type and degree of ruptures. The results would provide knowledge on steam bending performance of wood from poplar hybrid clones for the development of value-added wood products in Canada.

Materials and methods

Material for this study came from the experimental sites of Platon, St-Ours, and Windsor, which were established by the Ministry of Natural Resources and Wildlife of Quebec. The sites, originally abandoned agricultural lands, represent typical soil types available for planting hybrid poplar clones in southern Quebec. Detailed description of the experimental sites is given elsewhere [12].

Seven clones, each represented by five trees from each site, were selected for this study (Table 1). These clones are mainly recommended for southern Quebec, based on growth rate, bolt form, adaptability, and disease resistance [13]. From July to early September 2007, 105 trees were harvested. Trees from St-Ours and Windsor were cut after 15 growing seasons. Trees from Platon were cut after 17 growing seasons, except for those of clone 915508, which were felled after 13 growing seasons. Each tree was cross-cut in three segments: a butt log of 1.50 m followed by two logs of 2.45 m long. Specimens for bending tests were all obtained from the 2.45-m log farthest from the butt. Boards of 34 mm thick were sawn with a WoodMizer (Indianapolis, IN) portable bandsaw and stored in a freezer at approximately −4 °C before drying.

To study the effect of two drying schedules on wood bending, boards that were kiln dried in a previous study [14] were used. Boards were dried to a target moisture content of 8 % in a 2.5 m3 experimental kiln using two treatments: a conventional schedule (dry bulb temperature [Tdb] between 60 and 82 °C), and an elevated-temperature schedule (Tdb between 60 and 90 °C) with top restraint loading (7.5 kN/m2) in each case. After drying, boards were evaluated for drying quality, planed to 25 mm thick and stored in a conditioning room at 20 °C and 40 % of relative humidity (RH) to reach nominal equilibrium moisture content (EMC) of 8 %.

Some of the material was not suitable for bending tests due to drying defects and presence of knots in the boards. Consequently, 130 boards were selected and just one parallel to the grain oriented sample of 15(R) × 30(T) × 560(L) mm could be obtained from each board. A block of 15 × 30 × 50 mm was then cut from each sample to obtain the basic density (oven-dry weight by green volume ratio) (Table 1). The final dimensions of steam bending samples were 15(R) × 30(T) × 500.5(L) mm. The ends of each sample were sealed with two coats of varnish to prevent excessive absorption of moisture by the ends and minimize end checking and splitting [3]. Twenty samples of red oak (Quercus rubra L.), a wood species commonly used for making bent members [3, 4], were also prepared to be used as reference materials.

Bending experiments

The experiments began with the measurement of the initial weight of specimens. Steaming was then performed with a steaming cylinder GHEbavaria during 40 min (based on preliminary tests) at a pressure of 0.2 bar and temperature of about 105 °C. After steaming, each sample was immediately weighted and inserted into a steel strap with fixed end-stops with the growth rings facing up. The assembly was then fixed in the bending machine GHEbavaria, model Stuzama II, by two clamps, one at each end. Bending was performed using a circular-shape mould of 200 mm of radius and with an arm pressure of 4 bar. The steel strap containing the bent sample was then cramped with a metal clamp. Finally, this assembly was placed in a conditioning room at 20 °C and 40 % RH for 8 days (setting time) for MC stabilization.

Qualitative assessment

To make a successful bend, the wood must be deformed without provoking visible failures either in tension or in compression. Thus, all bent wood samples were evaluated according to five quality grades. The grades were established according to the degree of failure in the tangential faces. Samples without signs of failure were classified as grade 1 (excellent), those with superficial compression failures no longer than 3 mm were in grade 2 (good), samples with compression failures that did continue across the width of the sample were in grade 3 (acceptable), those with compression ruptures all the way across the width of the sample were in grade 4 (poor), and finally samples with rupture in tension were considered as grade 5 (very poor).

Quantitative assessment

Spring-back

After the initial setting time (8 days), the chord (C) of the bent sample was measured before (C0) and immediately after removal from the cramped plate (C8). The nominal chord of the circular-shape mould was 374.5 mm. Chords of un-cramped samples were then successively measured over time at days 9, 11, 18, 30, and 60 (C9 to C60). Therefore, the memory recovery was evaluated according to two parameters: instantaneous spring-back and spring-back over time. The instantaneous spring-back was the difference between C8 and C0 (both measured at day 8). The spring-back over time was the difference between the chord measured over time (C9, C11…C60) and C8. The sample weight was also taken at days 9 to 60 to assess the variation in MC. The samples remained all the time in the conditioning room.

Statistical analysis

A binary analysis was applied on the qualitative assessment to find the probability to get wood pieces of good bending quality using a glimmix procedure. Also, the influence of the sources of variation (clone, site and drying time) on this probability was evaluated. Results of instantaneous spring-back were analyzed with a mixed procedure in a split-plot design. The clones and sites were the sources of variation as principal plots and the drying treatment was the source of variation as sub-plot. The spring-back over time was analyzed in a split-split-plot design considering the storage time as a source of variation as sub-sub-plot. Given the changes in spring-back over time, this data was analyzed as repeated measures design. Moreover, the MC variation between, after steaming and day 8, and between day 8 and days 9, 11, 18, 30, 60 were added as co-variables in the instantaneous spring-back and spring-back over time analyses, respectively. When a source of variation was statistically significant, multiple comparison tests with Bonferonni corrections were carried out to determine which factor level differed from the others. These comparisons were done at the comparison-wise error rate of 0.05/c, where c is the total number of independent comparisons. The normality of data was verified using Shapiro-Wilk test. Statistical analyses were performed using SAS software, version 9.3 [15].

Results and discussions

Qualitative assessment

The qualitative analysis for poplar hybrid clones showed that defect-free bent samples (grade 1) were absent. Grade 2 represented 13 %, grade 3 39 %, grade 4 36 %, and grade 5 12 % of the total samples. Hence, 88 % of the poplar hybrids samples (grades 2 to 4) showed failures by compression and 12 % (grade 5) presented failures by tension. Failures occur if the steamed wood is stressed beyond its tensile or compressive strength limit. Compressive failures are principally due to high stress, defects or zones of weakness. Tensile failures occur when the strap and end blocks are not applying sufficient pressure to keep the tension of the convex side below the limit (1 to 2 % of wood piece length [3]). In the present work, pieces of poplar hybrids presented compression failures in form of a crosswise fold or wrinkles, sometimes extending across the width on the concave side. Some pieces also presented crushing at the ends and tensile failures in the convex side.

The binary analysis was applied to find the probability of obtaining wood pieces of good bending quality. Thus, the four grades were grouped into two classes. Class 0 corresponded to the grades 3, 4, and 5, while class 1 represented grade 2. Pieces of grade 2 were absent in Platon and therefore this site was eliminated from the analysis. Results showed that the probability to get wood pieces of good bending quality was not affected by the sources of variation (site, clone, and drying treatment). However, the statistical power of this analysis was low due to the number of pieces removed.

Consequently, to classify the seven clones according to their performance on steaming bending, a different approach, based on Ozarska and Daian [16], was applied. According to these authors [16], various studies use a 95 % confidence level to indicate a safe level to which wood pieces may be bent, so that no more than 5 % of the total number of bent pieces will fracture (grade 5) during the process. Accordingly, the frequency distribution of the visual ranking was first expressed as percentage of samples in different ranking groups (Table 2). Then, the cumulative frequency distribution was used to establish the minimum level at which the bent pieces of a clone could fail at a 95 % confidence level (Table 3). According to Table 3, only the clone 3570 bent just satisfactorily. This means that at least 95 % of the samples passed the qualitative criteria described for this level (1 + 2 + 3 + 4). The rest of the clones did not meet this threshold and therefore were rated as wood having bad bending quality.

Quantitative assessment

Instantaneous spring-back

The instantaneous spring-back of poplar clones, measured at day 8, was on average 10.6 mm. This parameter varied among the clones between 8.6 mm and 12.9 mm. The ANCOVA showed that the clones affected significantly the instantaneous spring-back. The growing sites and drying treatments did not affect spring-back (not shown). According to the Bonferroni test, clones 3570, 4813 and 3230 were significantly different from clone 915508. The first ones showed the lowest instantaneous spring-back while 915508 presented the highest instantaneous spring-back (Table 4).

The results also showed that the instantaneous spring-back was affected by the loss in MC that occurred during the setting period. The MC decreased on average from 14.7 % immediately after steaming to 9.6 % at day 8 (day when all bent pieces were un-cramped). This decrease in MC negatively affected the instantaneous spring-back. The samples with higher MC decrease showed lower values of instantaneous spring-back. This indicates that the pieces that gained more MC by steaming probably became more plastic and therefore showed lower memory effect. Hence, this could indicate that either a higher initial MC or a longer steaming should improve the bending performance of wood pieces. On the other hand, it could also indicate that the remaining rigidity of wood increases as final MC decreases.

The instantaneous spring-back is a natural reaction of wood to the release of compressive stress imposed during the bending operation. To limit this tendency, the piece should be held in its clamp until it has cooled and dried. The results show that the setting time for poplar clones was not adequate. The pieces should have remained cramped for a longer period in order to reach the nominal EMC and reduce the instantaneous spring-back effect. The MC of pieces was on average 9.6 % at day 8 and continued to decrease afterwards. This confirms the importance of the total stabilization of MC after bending (during the setting time), in order to limit the instantaneous spring-back.

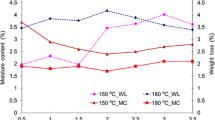

Spring-back over time

The equilibrium moisture content of wood was not reached after 8 days of conditioning. The spring-back and MC of pieces were monitored during the 52 days following the un-cramping of the specimens. Bent pieces sprang-back further during this period (Fig. 1). The spring-back over time was on average 10.9 mm. The MC varied on average from 9.6 % at day 8 to 9.0 % at day 60 (Fig. 2). The ANCOVA showed that this quite small variation in MC had a significant effect on spring-back over time (not shown). Pieces with higher MC presented higher spring-back over time. Clones and drying treatment did not affect spring-back over time. In addition, a statistically significant double interaction between site and storage time existed. However, the differences in spring-back among the three sites were not statistically significant. The significant double interaction found was due to the different spring-back rate of St-Ours site, with respect to Windsor and Platon sites (Fig. 1).

The spring-back continued to increase over time for all clones and sites even up to 60 days (Fig. 1). At the same time the bent pieces continued to lose MC, especially until day 30 (Fig. 2). It appears that the variation of MC during storage time affected the spring-back over time. This again demonstrates that MC of bent pieces needs to be stable in order to limit the spring-back effect. According to Jalaludin [17], the MC uptake had a strong linear relationship on spring-back effect, especially for thin pieces.

Among the studied factors, only the clones showed a significant effect on steam bending properties. The instantaneous spring-back differed among the clones. Site and drying treatment did not show a significant effect on bending performance. Similarly, Stevens and Turner [4] reported that the growth site is not a major factor in determining bending quality. Difference in temperature between the two drying processes was so low (8 °C) that any effect was negligible or not detectable. Hernández et al. [14] also observed that site and drying treatment were the less relevant factors affecting the machining properties of the same poplar hybrid clones. Hernández et al. [14] also reported that clones 3570 and 4813 (P. deltoides × P. nigra) performed best for most machining processes while clone 915508 (P. × euramericana × P. maximowiczii) performed worst for most machining processes. The present research also identified the same clones as having the best and the poorest performance in steam bending.

Comparison between red oak and poplar hybrid clones

Results showed that 100 % of red oak pieces were graded 1 (no signs of failure). In contrast, for poplar clones grade 1 was absent and only 13 % (grade 2) of samples could be used in furniture, but after a surfacing treatment to remove the compression failure traces. The defects in all other grades cannot be re-machined due to the seriousness of the failures, and hence 87 % of the samples could not be used. The proportion of good samples could increase from 13 % to 20 % if only the best clones 3570 and 4813 are selected. Comparing this proportion with the values found by Davis [18], the poplar hybrid clones can even be considered as one of the woods with worst steam bending behavior. Similar results were obtained by Murakami et al. [19] for Populus maximowiczii. They attributed the low bending quality of this wood to the very low density of earlywood, in which concentrated wrinkles are easy to occur near to ray-crossing areas.

Red oak samples showed an instantaneous spring-back of 7.1 mm and a spring-back over time (from day 8 to day 60) of 3.9 mm, for a total of 11 mm (Fig. 1). Poplar hybrid samples showed a total spring-back of 21.5 mm, that is an instantaneous spring-back of 10.6 mm and a spring-back over time of 10.9 mm (Fig. 1). The memory effect was hence two times greater in poplar samples than in red oak samples. Again, performance respect to spring-back of studied poplars could be improved if only the best clones are considered (3570 and 4813). In this case their total spring back was of 19.7 mm, but still higher than red oak values.

Red oak probably performed better than the poplar clones due to its higher wood density. Davis [18] indicated that heavy woods (those with a basic density of 500 kg/m3or over) bent better than light woods (those with a basic density of less than 400 kg/m3). Furthermore, when growth of poplar trees is accelerated, the presence of tension wood is considerably increased in juvenile wood [20]. Tension wood is difficult to machine smoothly, is commonly lower in mechanical properties, and is also more prone to collapse [20]. Furthermore, the initial moisture content of 8 % used in this experiment could have been too low for steam bending operations. It is known that plasticity of wood increases with moisture content [5]. MCs between 12 % and 25 % have been normally suggested by several authors. This implicates that more research is needed in order to obtain optimum steaming, drying, and setting conditions for steam bending.

Conclusions and recommendations

The wood of the poplar hybrid clones studied had poor steam bending properties. They showed a large memory effect and a poor surface quality after bending. Among the factors studied, only the clones showed a significant effect on bending performance. Also, the moisture content variation of the bent pieces had a significant influence on the spring-back. The sites and kiln drying schedules did not affect the steam bending properties of specimens. Results also showed that the clone (P. × euramericana × P. maximowiczii) 915508 had the worst performance. In contrast, the Euramericana clones (P. deltoides × P. nigra) 3570 and 4813 had the best response to steam bending. Further studies on these clones could be conducted in order to optimize the parameters of steam bending.

References

Richardson J (1998) Industrial potential of poplars in Canada. In: Proc of Annual Meeting of the Poplar Council of Canada, Quebec, Canada, 94 pp

Wangaard FF (1952) The steam bending of beech. J For Prod Res Soc 2:35–41

Peck EC (1957) Bending solid wood to form. Agric Handb 125 USDA Forest Service, Washington DC, 37 pp

Stevens WC, Turner N (1970) Wood bending handbook. Woodcraft & Supply Corp, Parkersburg, 109 pp

Sandberg D, Navi P (2007) Introduction to thermo-hydro-mechanical (THM) wood processing. School of Technology Design. Växjö University, Växjö, Sweden, 167 pp

Rice RW, Lucas J (2003) The effect of moisture content and bending rate on the work required to bend solid red oak. For Prod J 53:71–77

Eggert OT (1995) Stress relaxation in solid wood bending. In: Proc of the 12th International Wood Machining Seminar. Tokyo, Japan, pp 203–214

Jorgensen RN (1965) Furniture wood bending: an inquiry into the theory and practice of bending wood. Furnit Des Manuf 37:60–61

Kollmann FFP, Côté WA Jr (1975) Principles of wood science and technology. Solid Wood. Springer Verlag-New York, Heidelberg-Berlin

Lemoine TJ, Koch P (1971) Steam-bending properties of southern pine. For Prod J 21:34–42

Kubler H (1980) Wood as building and hobby material. Wiley, New York, 256 pp

Pliura A, Zhang SY, Mackay J, Bousquet J (2007) Genotypic variation in wood density and growth traits of poplar hybrids at four clonal trials. For Ecol Manag 238:92–106

Vallée G (1995) Projet du MRNQ sur l’amélioration génétique des peupliers dans la région du Saguenay—Lac Saint-Jean. In Proc Annual Meeting « Conseil du peuplier du Canada», Chicoutimi, Quebec, 181 pp

Hernández RE, Constantineau S, Fortin Y (2011) Wood machining properties of poplar hybrid clones from different sites following various treatments. Wood Fiber Sci 43:394–411

SAS Institute (2010) SAS/Stat user’s guide, release 9.3 ed. SAS Institute Inc, Cary

Ozarska B, Daian G (2010) Assessment of microwave bending capabilities for Australian wood species. For Prod J 60:64–68

Jalaludin Z, Samsi HW, Elham P (2007) Properties of bent rubberwood in different storing conditions. Born Sci (J Sci Tech) 20:56–64

Davis EM (1942) Machining and related characteristics of southern hardwoods. USDA Forest Service, Washington DC, 42 pp

Murakami R, Tanaka F, Norimoto M (2002) Relationship between bending quality and wood species. Wood Res 89:21–22

Bendtsen BA (1978) Properties of wood from improved and intensively managed trees. For Prod J 28:61–72

Acknowledgments

The authors acknowledge Pierre Gagné from Réseau Ligniculture Québec for his technical support. They are grateful to Luc Germain for their technical assistance on this project. They also thank M. Pierre Périnet from the Quebec Ministry of Natural Resources and Wildlife for providing the poplar hybrid clones material. They gratefully acknowledge Réseau Ligniculture Québec et Le Fonds Québécois de la Recherche sur la Nature et les Technologies for their financial contribution to this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kuljich, S., Cáceres, C.B. & Hernández, R.E. Steam-bending properties of seven poplar hybrid clones. Int J Mater Form 8, 67–72 (2015). https://doi.org/10.1007/s12289-013-1148-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-013-1148-5