Abstract

In this study, as a first step toward the development of novel candidate for absorbable suture materials based on poly(glycolide-co-ɛ-caprolactone), we synthesized a poly(glycolide-co-ɛ-caprolactone-co-l-lactide) block copolymer with ABA block structure via a two-step polymerization process and prepared the final PGCLA suture using a pilot-scale melt spinning machine. Then, to understand the mechanism on the early degradation stage of the PGCLA suture, we systematically investigated the mechanical, morphological properties and microstructural changes of the PGCLA suture through in vitro degradation. As a result, it was observed that, during the in vitro degradation process, the mechanical properties of PGCLA sutures exhibited an overall linear decrease and retained only 32% of its initial strength at 2 weeks of degradation. In addition, it was confirmed that, from FE-SEM analysis, internal degradation and structural changes, including longitudinal cracks on the suture surface, were noticeably appeared at 2 weeks of degradation. Interestingly, the results obtained from 1H-NMR and WAXS analyses exhibited clearly that PGCLA sutures undergo simultaneous degradation of glycolide units and l-lactide units present in the amorphous region during in vitro degradation. Therefore, based on these findings, we concluded that in the early stage of in vitro degradation of PGCLA suture, simultaneous degradation of glycolide units and l-lactide units in the amorphous region occurs, leading to chemical and structural changes such as erosion and cracking of the suture, as well as a decrease in its mechanical properties.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Absorbable medical sutures based on biodegradable polymers degrade naturally in vivo without causing long-term foreign body reactions and do not require removal after surgery [1,2,3]. Over the past few decades, various types of biodegradable sutures have been developed, ranging from those that degrade rapidly in the body to those that degrade more slowly [4,5,6,7,8,9,10]. From this perspective, poly(glycolide-co-ɛ-caprolactone) (PGCL) is still undoubtedly one of the most widely used biodegradable polymers used to create suture materials for medical application [11, 12] and it would be very attractive to develop various suture materials based on this PGCL polymer by utilizing previously known suture materials or monomers. However, in order to develop PGCL-based suture material, it is necessary to understand the synthesis process of conventional PGCL polymers.

In general, it is known that the PGCL polymers for suture materials are manufactured in the form of block copolymers through a two-step polymerization process [13, 14]. In the first step, a random PGCL prepolymer (B block) is prepared by copolymerizing glycolide and ε-caprolactone used as monomers (glycolide:ε-caprolactone, 55:45). In the second step, glycolide (A block) is added to finally prepare a PGCL block copolymer with an ABA-type block structure (glycolide:ε-caprolactone, 75:25). The random PGCL prepolymer obtained from the first step mainly acts as an amorphous component providing flexibility to the final PGCL block copolymer. In addition, the A block composed mainly of glycolide serves as a crystalline component and influences various properties, such as in vitro degradation, mechanical and thermal properties, of the final PGCL block copolymer and its suture.

From previous research, we have discovered that introducing l-lactide as a comonomer into the existing PGCL polymerization process can alter in a variable manner the microstructure of PGCL block copolymers [15]. Especially, we observed that the introduction of l-lactide in the first step of the polymerization process had a significant effect on the microstructure of the random PGCL prepolymer (B block) as well as the final PGCL block copolymers (ABA block). For instance, it was found that there is a relatively large difference in the average sequence length of glycolide segments in the final PGCL block copolymers. As a result, these microstructural changes of the PGCL prepolymer originated from the l-lactide comonomer affected significantly the thermal properties and in vitro degradation properties on the final PGCL block copolymers.

Considering the results of the study so far, we believe that the introduction of l-lactide as a new monomer into the existing PGCL block copolymer has successfully demonstrated its potential to be a candidate for the preparation of various PGCL-based polymers and suture materials. Therefore, from now on, efforts are required to utilize the poly(glycolide-co-ɛ-caprolactone-co- l-lactide) (PGCLA) block copolymer as suture materials. For example, since absorbable sutures are necessarily accompanied by mechanical property degradation upon degradation, it would be of great academic and industrial significance to clearly investigate the structure–property correlation during early degradation for PGCLA sutures through this study. This is because the PGCLA material used in this study is itself a block copolymer synthesized by a two-step polymerization using three monomers, making it a very complex system compared to typical homopolymers, which are composed of a single monomer or a single repeating unit.

To gain a deeper understanding of the structure–property correlation of absorbable medical sutures based on biodegradable polymers, our study focused on preparing PGCLA monofilament sutures through a pilot-scale melt spinning machine and systematically investigating their mechanical, morphological properties, and microstructural changes during in vitro degradation. To the best of our knowledge, we have not found any studies that have synthesized PGCLA block copolymers by introducing l-lactide comonomers in the first step of the polymerization process of conventional two-step PGCL block copolymers and used them to manufacture PGCLA sutures to evaluate various properties. We believe that the results of our study will provide valuable information on the structure–property correlation of PGCLA sutures and offer insight into the role that each monomer plays in determining the microstructure and properties of these sutures.

2 Experimental

2.1 Materials

In this study, glycolide, ε-caprolactone, and l-lactide, which are medical grade products from Boehringer-Ingelheim and Daicel, respectively, were purchased and used in the experiments as monomers for the preparation of the PGCLA prepolymer and block copolymer. Stannous octoate (Sigma-Aldrich, ≥ 99.0%) and diethylene glycol (DEG) (Sigma-Aldrich, 95.0%) were used as a catalyst and initiator, respectively, in the experiments. Deuterated dimethyl sulfoxide-d6 (DMSO-d6) was used as a solvent for an 1H-NMR analysis. In addition, all reagents used in this study were conducted without further purification.

2.2 Synthesis of PGCLA Block Copolymer

The PGCLA block copolymer used in this study contains 6.3 mol% l-lactide as a third comonomer in addition to the conventional glycolide and ɛ-caprolactone, and the synthesis of this block copolymer was performed by the same two-step polymerization method described in our previous study [15]. The detailed polymerization process is shown in Scheme 1. In this study, the polymerization was carried out using a pilot-scale polymerization reactor with a capacity of 30 L to consider the preparation of the final PGCLA suture. As reported in the previous study and shown in Scheme 1, in the first step process, glycolide, ɛ-caprolactone and l-lactide monomers were added in a molar ratio of 55/33.7/11.3, respectively, and stannous octoate dispersed in toluene and DEG were added to proceed with the reaction. In the first step reaction, the above three monomers were introduced into the reactor in the specified order and content, and the reaction time was set to 6 h based on the target reaction temperature of 190 °C to proceed with the polymerization. In the second step reaction, additional glycolide was added to adjust the molar ratio of the final block copolymer to be 75/18.7/6.3 and the reaction was carried out at 210 °C for 3 h. Finally, the synthesized PGCLA block copolymer was pushed out using a nitrogen gas flow from the reactor to a cooling water bath and was cut into chips. The chips were then air-dried at room temperature for 24 h and then further dried in a vacuum chamber at 120 °C for additional 24 h to remove residual moisture. The composition ratio of the final PGCLA block copolymer was confirmed through 1H-NMR analysis, which showed that the glycolide units, caprolactone units, and l-lactide units had molar ratios of 74.6, 19.0, and 6.3, respectively.

2.3 Preparation of PGCLA Monofilament Suture

The final PGCLA suture, using the synthesized PGCLA block copolymer, was manufactured on a pilot-scale melt-spinning machine rather than at a laboratory scale. The spinning process conditions were carefully controlled to ensure that the final PGCLA suture met USP 1 size (0.400 mm–0.499 mm) requirements. Scheme 2 shows a schematic illustration of the spinning process, which consists of an extruder, gear pump, water bath, roller zone, chamber for heat-treatment, and winder. The following are the detailed conditions, including temperature and roller speed, set at each stage: the extruder, gear pump, and heat-treatment chamber were set to a temperature range of 210–230 °C, 225–230 °C, and 50–130 °C, respectively. The roller speeds were controlled to 6.5–7.2 m/min for roller 1, 33.5–36.0 m/min for rollers 2 and 3, and 33.0–35.0 m/min for the winder.

2.4 Characterization

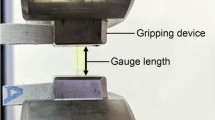

A universal tensile machine (Instron model 4467) was used to measure the tensile properties of the PGCLA suture. The tensile strength was measured at a measuring speed of 250 mm/min with a length of 200 mm between the chucks. The load cell used was 50 kgf, and five to seven measurements were taken per sample to obtain average values for strength and elongation. To observe the in vitro degradation characteristics of PGCLA suture, the prepared samples of the suture were immersed in a phosphate buffer solution with a pH of 7.4 and degraded. At this time, the temperature of the solution was 37 °C, and samples were collected according to a predetermined time, and composition analysis and tensile analysis were performed. The intrinsic viscosity of the samples was measured at a concentration of 0.1 g/dL using DMSO-d6 as a solvent in a constant temperature water bath maintained at 30 °C. The morphological features of the surface and cross section of the PGCLA sutures according to the in vitro degradation were investigated using field emission scanning electron microscopy (FE-SEM, JEOL, JSM-7000F). Specifically, to obtain cross-sectional images of PGCLA sutures, samples were immersed in liquid nitrogen and cut in the cross-sectional direction. Nuclear magnetic resonance spectroscopy (500 MHz NMR Spectroscopy, Bruker) was used to observe and analyze the changes on microstructure of the PGCLA sutures during the in vitro degradation. Information about changes in the chemical composition of PGCLA sutures using each spectral and characteristic peak obtained through 1H-NMR analysis was calculated based on our previous studies [15]. The structural analysis of PGCLA suture, such as crystallinity and crystal size upon degradation, was analyzed using wide-angle X-ray scattering (WAXS, Bruker, D8 Discover) using CuK radiation (= 1.54 Å) with an X-ray exposure time of 300 s for samples at room temperature. The information obtained by WAXS was processed with a two-dimensional detector (2-Dimensional Area Detector, Hi-Star) and represented as a 2D WAXS pattern, which was converted into equatorial scan profiles to analyze the microstructure of the PGCLA sutures.

3 Results and Discussion

3.1 Mechanical Properties

In general, the mechanical properties of absorbable sutures decrease as degradation progresses, which is attributed to a variety of factors including polymer degradation and mass loss by hydrolysis [16, 17]. These decreases in mechanical properties and the rate of degradation can be influenced by environmental factors such as pH and temperature and can also be affected by changes in the microstructure with various monomers. Figure 1 shows the change in mechanical properties upon in vitro degradation of PGCLA sutures. As shown in the figure, the mechanical properties of the PGCLA sutures show a linear decrease as the degradation progresses. Specifically, the tensile strength of the PGCLA suture decreased from 73.13 kgf/mm2 to 23.41 kgf/mm2 after 2 weeks of degradation. Furthermore, as can be seen in Table 1, in terms of breaking strength retention, which is a major concern for suture materials, it can be understood that this PGCLA suture retained 32% of its initial strength at 2 weeks after the onset of degradation. Additionally, Fig. 2 shows a rapid decrease in the intrinsic viscosity of the PGCLA suture up to 2 weeks after degradation, which likely caused the decrease in mechanical properties due to polymer chain degradation.

3.2 Morphological Observation

It is generally accepted that an erosion phenomenon of suture materials occurs in a three-step process; in the first step, water penetrates into the suture; in the second step, hydrolysis of the water and ester bonds to form a water-soluble oligomer; and in the third step, mass loss of the suture occurs. Therefore, amorphous regions in the suture materials are more susceptible to water penetration and hydrolysis due to lower intermolecular bonding, which allows molecules to move freely, and for this reason they are more likely to erode relatively faster than crystalline regions and appear as cracks. Figure 3 shows FE-SEM images of the surface morphological changes of the PGCLA sutures according to in vitro degradation. As exhibited in the figure, at the beginning of degradation (0–1 weeks, Fig. 3A, B), the PGCLA suture maintains a smooth surface morphology, but from 2 weeks of degradation, fine cracks are observed to form in the direction of the fiber axis (Fig. 3C–F). Interestingly, the surface of the suture at 2 weeks of degradation did not appear to be as damaged, or the size of the cracks formed as expected, but the degradation inside the suture was nevertheless quite large and faster than expected. Figure 4 shows the morphological changes in a cross section of the PGCLA sutures, and as can be seen this figure, there are no noticeable changes at the beginning of degradation (0–1 weeks, Fig. 4A, B). On the other hand, the 2 weeks of degradation (Fig. 4C) clearly indicate that most of the degradation has occurred inside the suture, and this significant degradation behavior is expected to have a significant impact on erosion and polymer degradation inside the suture as well as crack formation on the suture surface.

3.3 Microstructure Analysis and Degradation Mechanism

3.3.1 1H-NMR

1H-NMR analysis was adopted to observe the changes in composition and chemical structures of PGCLA sutures during in vitro degradation. Figure 5 shows the 1H-NMR spectra of PGCLA sutures as a function of degradation time, and the results of the structural analysis, including changes in the chemical composition of each sample calculated based on the analysis results, are summarized in Table 2. The first noticeable changes upon degradation are the development of new peaks around 4.54 ppm and 4.81 ppm, which is expected to be due to the decomposition of the [CGG + GGC] peak produced by the primary transesterification. In other words, the oligomeric end-groups created by the cleavage of glycolidyl units by hydrolysis are seen to be responsible for the new peak. Also, as shown in Table 2, it was observed an overall decrease in the content of glycolidyl units and lactidyl units in the early stages of degradation. Figure 6 shows the changes in the composition of each monomer unit according to the in vitro degradation in the PGCLA suture. As can be seen in the figure, the composition ratio of the initial PGCLA suture before degradation test was 76.2, 16.3, and 7.5 for glycolide units, ɛ-caprolactone units, and l-lactide units, respectively. However, it was confirmed that as degradation progresses, the composition ratio of glycolide and l-lactide units decreases, while ɛ-caprolactone units increase relatively. Based on the results, it can be concluded that PGCLA sutures undergo simultaneous degradation of glycolide and l-lactide units at the beginning of degradation. Meanwhile, as mentioned in the experimental part, it is observed that the composition ratio of the final PGCLA block copolymer is 74.6/19.0/6.3, while the composition of the PGCLA suture is somewhat different (76.2/16.3/7.5). This suggests that the high temperature applied during the melt spinning process may have triggered additional reactions or thermal degradation, and we believe that further research is needed to correlate microstructure changes with spinning conditions to derive optimal melt spinning conditions for PGCLA sutures in future.

3.3.2 WAXS

The crystal structure of PGCLA sutures was analyzed using WAXS to observe crystal structure changes upon in vitro degradation. In general, the crystals of polymers act as a physical barrier during degradation, making it difficult for water to penetrate and hydrolysis to occur. This is why it is meaningful to observe crystal structure changes using WAXS, as the 1H-NMR analysis discussed earlier is limited in providing information about the crystalline and non-crystalline regions of the polymer. In other words, while we know from 1H-NMR that glycolide and l-lactide units are degraded simultaneously, it is not easy to estimate their exact location within the microstructure of a PGCLA suture. In this sense, we can derive more meaningful information about the microstructure of PGCLA sutures from the combination of 1H-NMR and WAXS analysis. Figure 7 shows two-dimensional (2D) images of the PGCLA suture with increasing degradation time, and diffraction patterns of (110) and (020) planes induced from glycolide units (or polyglycolide, PGA) are observed. Furthermore, as shown in Fig. 7, an increase in the intensity of both diffraction patterns is observed with increasing degradation time, which can be understood as a result of the relative increase in crystalline regions as the amorphous regions of the PGCLA suture are reduced by degradation. Figure 8 shows the equatorial 1D WAXS profile with increasing degradation time, where a strong peak in the (110) plane and a weak peak in the (020) plane are observed at 21.8° and 29°, respectively. It can also be observed that the intensity of the peaks in the (110) and (020) planes increases as the degradation progresses. Nevertheless, the characteristic peaks of polycaprolactone (PCL), which are typically observed at 21.2° and 23.6°, and polylactide (PLA), which appear at 17.1°, 28.7°, and 29.4°, are not observed in this study. The ɛ-caprolactone units and l-lactide units inside the PGCLA suture do not have sufficient block length and content to form crystals and therefore are unlikely to form crystalline peaks, so it seems unlikely that the characteristic peaks of PCL and PLA were superimposed on those of PGA. Figure 9 shows the change in crystallinity and apparent crystallite size (ACS) of PGCLA sutures with degradation time, and it is observed that both crystallinity and ACS increase continuously from the beginning of degradation. This can be attributed to the preferential degradation of glycolide units present in the amorphous region at the beginning of the degradation and is in good agreement with the results of the previous 1H-NMR structure analysis. In addition, since the l-lactide in this study was introduced in the first step of the polymerization process that imparts flexibility to the PGCLA block copolymer, it is highly unlikely that it exists in the crystalline region. Therefore, based on the results of 1H-NMR and WAXS analyses, it can be concluded that PGCLA sutures undergo simultaneous degradation of glycolide units and l-lactide units present in the amorphous region in the microstructure of the suture during in vitro degradation. Furthermore, ɛ-caprolactone units can be considered to have little effect on the initial in vitro degradation behavior of PGCLA sutures.

4 Conclusion

The aim of this study is to understand the mechanism for the early degradation stage of PGCLA sutures, which are composed of three monomers: glycolide, ε-caprolactone and l-lactide. To achieve this, we synthesized PGCLA block copolymers having ABA block structure via a two-step polymerization process and prepared PGCLA sutures through a pilot-scale melt-spinning machine. Then, mechanical, morphological properties and microstructural changes of the PGCLA sutures during in vitro degradation were systematically investigated and discussed, and the following results were obtained. During the in vitro degradation process, the mechanical properties of PGCLA suture show an overall linear decrease. For instance, the strength of the PGCLA suture before degradation is 73.13 kgf/mm2, while after 2 weeks of degradation, it is 23.41 kgf/mm2. FE-SEM analysis showed visible internal degradation and structural changes, including longitudinal cracks on the suture surface at 2 weeks of degradation, suggesting that water infiltrated through the suture surface and rapidly diffused into the interior, rapidly promoting hydrolysis and physical erosion of the suture interior. The results obtained by 1H-NMR analysis exhibited that the composition ratio of glycolide and l-lactide decreased and caprolactone increased relatively as the in vitro degradation progressed, which can be attributed to the degradation of glycolide and l-lactide units. In addition, the WAXS analysis also clearly shows an increase in the intensity of crystalline diffraction peaks associated with glycolide units as the in vitro degradation progresses, which clearly implies degradation of glycolide units present in the amorphous region. Based on these results, we concluded that in the early stage of in vitro degradation of PGCLA sutures, the glycolide units and l-lactide units present in the amorphous region are degraded simultaneously, and that these chemical changes cause structural changes such as erosion and cracking of the suture, as well as a decrease in its mechanical properties.

Data Availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

C.K.S. Pillai, C.P. Sharma, J. Biomater. Appl. 25, 291 (2010)

J.P. Singhal, H. Singh, A.R. Ray, Polym. Rev. 28, 475 (1988)

K. Syamala Devi, P. Vasudevan, J. Macromol. Sci. C 25, 315 (1985)

A.C. Vieira, J.C. Vieira, R.M. Guedes, A.T. Marques, Mater. Sci. Forum 636–637, 825 (2010)

A. Pandey, G.C. Pandey, P.B. Aswath, J. Mech. Behav. Biomed. Mater. 1, 227 (2008)

H. Bramfeldt, P. Sarazin, P. Vermette, J. Biomed. Mater. Res. A 83, 503 (2007)

K. Tomihata, M. Suzuki, N. Tomita, Bio-Med. Mater. Eng. 15, 381 (2005)

E.K. Odermatt, L. Funk, R. Bargon, D.P. Martin, S. Rizk, S.F. Williams, Int. J. Polym. Sci. 2012, 216137 (2012)

Y. Baimark, R. Molloy, N. Molloy, J. Siripitayananon, W. Punyodom, M. Sriyai, J. Mater. Sci. Mater. Med. 16, 699 (2005)

D.K. Gilding, A.M. Reed, Polymer 20, 1459 (1979)

R.S. Bezwada, D.D. Jamiolkowski, I.Y. Lee, V. Agarwal, J. Persivale, S. Trenka-Benthin, M. Erneta, J. Suryadevara, A. Yang, S. Liu, Biomaterials 16, 1141 (1995)

Y.J. Low, M.I. Kittur, A. Andriyana, B.C. Ang, N.I.Z. Abidin, J. Mech. Behav. Biomed. Mater. 140, 105723 (2023)

R.S. Bezwada, D.D. Jamiolkowski, and S.W. Shalaby, US Pantent. 5,133,739 (1992)

D.D. Jamiolkowski and S.W. Shalaby, US Patent. 4,700,704 (1987)

M.H. Jee, J.H. Park, S.Y. Choi, D.H. Baik, Fiber. Polym. 63, 280 (2022)

K. Tomihata, M. Suzuki, Y. Ikada, J. Biomed. Mater. Res. 58, 511 (2001)

C.P. Ooi, R.E. Cameron, J. Biomed. Mater. Res. 63, 280 (2002)

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interests regarding the publication of this article.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jee, M.H., Choi, S.Y., Kang, C.S. et al. Mechanical Properties, Morphological Characteristics and Microstructural Changes of Poly(glycolide-co-ε-caprolactone-co-l-lactide) Suture during In Vitro Degradation. Fibers Polym 24, 3037–3045 (2023). https://doi.org/10.1007/s12221-023-00284-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-023-00284-8