Abstract

The first successful application of the ELISA reverse method and device (ER m&d), in the context of food safety and traceability, was developed in our laboratories to detect and quantify CP4EPSPS and Cry1AB genetically modified related proteins in soy and maize samples, respectively. To prove the versatility and the transferability of the technology, the ER was here applied to assess the presence of mycotoxins in cereals. Appropriate protocols were developed to assess the presence of deoxynivalenol and ochratoxin A and the ER was tested on contaminated wheat samples. In particular, deoxynivalenol (DON) and ochratoxin A (OTA) were detected in a range of values from 430 to 5,000 µg kg−1 and from 1.7 to 10 µg kg−1, respectively. The assays were optimized to reach a limit of quantification equal to 550 and 1.8 µg kg−1 for DON and OTA, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

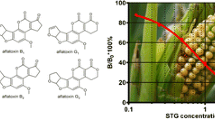

The development of innovative methods to assess the presence of contaminants in food and feed samples is strongly encouraged by the EU legislation to constantly improve food safety and traceability (AOAC International 2005; Council of Agricultural Science and Technology (CAST) 2003). Mycotoxin contamination of cereals and cereal derived products is commonly considered of high concern because of its widespread diffusion and toxic effects on both human and animal health (Ermolli et al. 2006; European 2006a). At the EU level, mycotoxin contamination has been addressed in Regulation 2006/1881/EC and in Recommendation 2006/576/EC setting the maximum levels of aflatoxins, ochratoxin A, and Fusarium toxins in foodstuffs (expressed as microgram of mycotoxin on kilogram of foodstuff, micrograms per kilogram) (European 2006b) and feedstuffs (milligrams per kilogram relative to a feedingstuff with a moisture content of 12%) (European 2006c), respectively. Recently, new thresholds were set for deoxynivalenol, zearalenone and fumonisins in maize food products by Regulation 2007/1126/EC (European 2007). Currently, mycotoxins are detected by classical analytical methods based on liquid (HPLC) or gas chromatography as well as by several commercial immunoassays in industrial and official laboratories for routine analysis mainly thanks to their rapid applicability and cost effectiveness (Findlay and Dillard 2007). Some commercial kits (for example, for aflatoxins, deoxynivalenol, and T-2 toxin) have also been standardized by regulatory bodies such as the AOAC International (United Nations 2004) and USDA/GIPSA (http://www.gipsa.usda.gov). The advantages of immunoassays in terms of sensitivity, specificity, assay time and cost-effectiveness are extensively described by other authors (Goryacheva et al. 2007; Kraska et al. 2001; Krska and Molinelli 2007). The applicability of the commercial enzyme-linked immunosorbent assay (ELISA) kits has been achieved mainly thanks to their practical commercial formats. They allow the detection of many samples distributed in the 96-well microplates and offer the possibility to store the plates for months at 4 °C. Assay time may vary from several hours to several minutes in the particular case of direct competitive ELISA. For mycotoxin direct competitive ELISA, the antigen is conjugated to a detection enzyme (mostly horseradish peroxidase) and competes with the free analyte to bind the primary antibody coated onto the surface of the microplate. Finally, the measured absorbance values are inversely related to the concentration of target analyte in the sample.

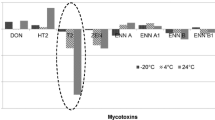

To our knowledge, only dedicated assays are available, therefore the challenge in mycotoxin quantitative analysis is the development of rapid multi-target assays in response to the urgent need of assessing the co-occurrence of several mycotoxins in one single analysis. Indeed, cereal samples are frequently simultaneously contaminated by aflatoxin B1, zearalenone, fumonisin B1, and other Fusarium mycotoxins as reported in scientific literature (Ono et al. 2001; Park et al. 2002; Schneider et al. 2004). The need of simultaneous multi-analyte detection systems is also clearly expressed in Commission Recommendation 2006/576/EC concerning the threshold limits for mycotoxins in cereals and cereal products intended for animal feeding (European 2006c). In particular, the 2006/576/EC recommends the simultaneous analysis of the presence of deoxynivalenol (DON), zearalenone, ochratoxin A (OTA), T-2 and HT-2 toxins, and fumonisins B1 and B2 in order to assess the extent of mycotoxin co-occurrence. Moreover, the same Recommendation requires that the Member States ensure that feed business operators use these values in their Hazard Analysis and Critical Control Points system. According to these thresholds, at the critical control points, food/feed products should be evaluated and classified as acceptable or unacceptable. Rapid yes/no decisions along with the food/feed production chain have to be taken, thus the availability of rapid and simple methods assumes an even greater significance.

In the present study, a first attempt to perform a direct competitive ELISA allowing the detection and quantification of two mycotoxins is reported. A test to detect DON and OTA in wheat flour was developed on the solid phase of the ELISA reverse method and device (ER m&d) which was specifically designed to be directly immersed into liquid samples. ER m&d was previously applied to assess the presence of Cry1Ab and CP4EPSPS genetically modified proteins as described by Ermolli et al. (2006) (Shephard 2008). The solid phase of the ER consists of polystyrene pins protruding from a rod and positioned at modular distance as showed in Fig. 1. Shape and features of the device make it suitable to be directly immersed into tubes collecting samples. Alternatively, sample aliquots can be distributed in microplate wells. Consequently, the incubation step is performed in tubes or into the microplate wells (Figs. 1, 2). Each pin can be sensitized with a different catcher to perform a multi-target assay. After the incubation step, washing steps and others incubation steps are carried out in presence of conjugate(s) and chromogenic substrate in pre-filled microplates wells (Figs. 1, 2 and “Materials and Methods”). In the present application, all the steps (device sensitization, device incubation with sample and mycotoxin conjugate, washing and color development) were performed into wells of microplates in which all the reagents were previously dispensed and the outcomes were measured by conventional microplate readers. Further developments of the test could foresee the simultaneous detection of an increased number of targets since each pin could be dedicated to a specific target sensitizing the pin with an appropriate monoclonal antibody.

Materials and Methods

Reagents

Matrix reference materials for mycotoxins, namely naturally contaminated wheat flours with certified content of deoxynivalenol (Cat. No. BRM 003004) and OTA (Cat. No. BRM 003006), were purchased from Biopure (Austria). Certified Reference Materials BCR-396 and BCR-471 to be used as analytical blanks were prepared by IRMM (Geel, Belgium). Pure DON (Cat. No. BRM 002009), OTA (Cat. No. BRM 002023) were purchased from Biopure (Austria). Monoclonal antibodies (mouse IgG1), against DON, OTA as well as horseradish peroxidase conjugated mycotoxins (DON-HRP, OTA-HRP) were kindly provided by Romer Labs (Austria). Antibody cross-reactivity certificates were also provided by Romer Labs. In particular, DON IgG1 performed as follows: DON: 100%; 3-Acetyl DON: >100%; 15-Acetyl DON: 103%; T-2: 0%; Nivalenol: 0%; Fus-X:0%; DON -3-glycoside 4.8%. The concentration of the monoclonal antibodies was determined by conventional Bradford assay (Bio-Rad Laboratories, CA) and the purity was assessed by SDS-PAGE. 3,3′, 5,5′ tetramethylbenzidine (TMB) ready-to-use liquid substrate system for ELISA (Cat. No. T0440) was purchased from Sigma Aldrich (Milan, Italy). Prototypes of polystyrene activated devices HB10 with four pins (Fig. 1) were produced by Biomat snc (Rovereto, Italy) while low binding microplates were purchased from Thermo Electron Corporation (Finland).

Commercial kits used to evaluate the ER performance were AgraQuant® Deoxinivalenol Assay 0.25/5.0 and AgraQuant® Ochratoxin Assay 2/40 from Romer Labs (Austria).

Device Pins Coating Step

The solid phase was immersed into 100 µL of phosphate buffered saline (PBS) containing 1 μg of primary antibody and incubated at room temperature for 2 h. Coupled pins were washed four times with phosphate buffered saline-TRIS-NaCl buffer (PBS-TBN; PBS 10 mM, pH 7.4, 0.02% Tween-20, 0.1% BSA and 0.05% sodium azide) and incubated in PBS-TBN for 30 min at room temperature (blocking step). Devices could then be stored over night at 4 °C into PBS-TBN or immediately used after four washing steps into PBST (PBS, pH 7.4, 0.05% Tween-20). After each washing step pins were dried on absorbent paper.

Preparation of Mycotoxin Standard Solutions and Samples

Pure mycotoxin solutions were prepared in PBS (10 mM, pH 8) to final concentrations of 0, 10, 20, 50, 100, 200 ng mL−1 for DON and of 0, 0.1, 0.2, 0.4, 1, 2 ng mL−1 for OTA to construct the assay dose-response curves.

Three extracts of each target were prepared from the same batch of certified naturally contaminated flour as indicated in the sample preparation/extraction procedure of Agraquant® kits. Briefly, wheat flour containing 1,062 ± 110 μg kg−1 of DON (Biopure, BRM 003004) was thoroughly mixed before taking sub-samples of 10 g each. Samples were extracted in a ratio of 1:5 (w/v) of sample to distilled water and vigorously shaken for 3 min. After settling, the top layers of the extracts were filtered through a Whatman #1 filter. Sample extracts were verified to have a pH of 6.0–8.0, then diluted 1:5 with distilled water and analyzed as described below. An extraction in methanol 70% was carried out to evaluate the possibility of applying the same extraction protocol to both deoxynivalenol and ochratoxin A. In such samples, the final methanol concentration was equal to 23%. Samples from wheat flour containing 2.7 ± 1 μg kg−1 of ochratoxin A (Biopure, BRM 003006) were extracted in a ratio of 1:5 (w/v) of sample to methanol 70% and filtered without further dilutions. Wheat flour containing <50 μg kg−1 of DON (IRMM, BCR-396) and wheat flour containing <0.6 μg kg−1 of OTA (IRMM, BCR-471) were used as analytical blanks to investigate the limit of detection (LOD) and limit of quantification (LOQ) of assays. Extracts from such certified reference materials were prepared and analyzed essentially as previously described and following the specifications provided in the certificate of analysis issued by the IRMM. Mycotoxin concentration in the extracts was calculated from the standard curve and compared to the certified value.

Assay

One hundred microliters of standards or samples were distributed into microplate wells and 200 µL of horseradish peroxidase conjugated mycotoxins were added (final concentration of 1.67 µg mL−1 for DON-HRP and 0.35 µg mL−1 for OTA-HRP). After mixing, 200 µL of the sample-conjugate solution were transferred into a new well. The coupled devices were immersed into the wells containing 200 µL of sample-conjugate solution and incubated for 15 min at room temperature. Devices were removed, washed four times into PBST (PBS 10 mM, pH 7.4, 0.05% Tween-20), dried on absorbent paper and finally incubated for 15 min into 100 µL of TMB. Devices were removed from TMB containing wells and the reaction was stopped by adding 100 µL of 0.5 M sulphuric acid into the same wells. Absorbance values were read at 450 nm using a Bio-Rad Model 550 microplate reader (Bio-Rad). Both the competition and incubation steps into TMB were carried out with gentle shaking.

Calibration curve

The quantification of mycotoxin in the sample was achieved as a result of the competition between the free mycotoxin and the enzyme labeled mycotoxin for the binding to antibodies immobilized on the pins of the devices. Accordingly, the maximum absorbance values were read when the concentration of free mycotoxin is zero (zero standard or blank) decreasing as the concentration increased.

To describe the ER dose-response curve the four-parameter logistic model (4-PL) was applied (Turner et al. 2009). The equation describing the 4-PL model is as follows:

where y is the response, d is the response at infinite analyte concentration, a is the response at zero analyte concentration, x is the analyte concentration, C is the inflation point on the curve, and b is a slope factor. Based on fitting criteria by (Turner et al. 2009), parameter values were calibrated against measured ER values by using the Microsoft® Office Excel 2003 solver to minimize the square error of estimation.

Statistical analysis

Univariate analysis of variance (ANOVA) was used for analyzing experimental data (absorbance values) produced under conditions identified by three classification factors: experiment, device and sensitization. The procedure GLM of SAS/STAT (version 9, SAS Institute Inc, Gary, NC, version) was used to construct tests to determine the significance of each classification effect and interaction effects in a combined model with fixed and random factors. The random statement in the GLM procedure specified the random portion of the ANOVA model, i.e., the effect of repeated experiments, and computed the variance components for each effect. Ryan-Einot-Gabriel-Welch multiple range test (REGWQ) was used for post-hoc comparisons.

A similar approach was also applied to test the effect of the extraction methods on the calculated concentrations of mycotoxins. In this case, planned orthogonal contrasts (statement contrast) were used where water against methanol-based extracts were compared.

Results and Discussion

Monoclonal antibodies recognizing DON and OTA were successfully coupled to the solid phase of the ER device through simple antibody polystyrene absorption in phosphate buffer. In the first stage of the study, tests were carried out on mycotoxin solutions (PBS 10 mM, pH 8) at six different concentration levels (see “Materials and Methods”) in order to determine the quantification range of each assay. For each target two devices were used thus six absorbance values were obtained. In all tests, three pins of each device were coupled to antibody recognizing the same target while the fourth one was left uncoated. The fourth pin was meant as negative control of the sensitization step to detect potential background signals derived from unspecific bindings. As expected, significant differences in the absorbance values (p < 0.05) between sensitized and unsensitized pins were found. Although differences linked to the device were generally observed (p < 0.01) post-hoc tests proved that different devices under the same experimental conditions belonged to the same group of mean absorbance separation. Therefore, the outcomes were treated as homogeneous (Fig. 3).

Mean absorbance values calculated for each device. Couples of devices 1–2, 3–4, 5–6, 7–8, 9–10, 11–12 were tested at the same concentration level (expressed as ng mL−1 and reported in italic above the x-axis of each graph) for DON and OTA. Couples of devices were verified to belong to the same group of mean separation by means of REGW post-hoc test

The dynamic range of the ER method for DON was comparable with those described by the technical bulletin of commercial ELISA kits (0–200 ng mL−1) such as EuroClone ELISA Kit for DON, MycoMonitor™ Deoxynivalenol Assay and AgraQuant® Deoxynivalenol Test Kit (Fig. 4a). With regards to the ochratoxin A the newly developed test responded with a drastic drop off in absorbance (B/B 0 = 0.3) which was observed in the range of values from 0 to 0.4 ng mL−1. Appropriate quantification curves were obtained in the range 0.1–2 ng mL−1 (Fig. 4b). Compared to the commercial kits the assay was therefore more sensitive although the dynamic range was not as wide, being 0–8 ng mL−1 for commercial kits.

In the second part of the experimental design, wheat reference materials contaminated with DON (1,062 ± 110 μg kg−1) or ochratoxin A (2.7 ± 1 μg kg−1) were used to simulate unknown cereal samples. The samples were analysed by the ER assays and in parallel by the commercial kits AgraQuant® Deoxinivalenol Assay 0.25/5.0 or AgraQuant® Ochratoxin Assay 2/40, according to the nature of the target. To develop a multitarget assay the first challenging step of the procedure is the target extraction. Indeed, a unique extraction method for all targets would be the first step for improving multiple mycotoxin detection, which would be technically possible through the ER solid phase. Same protocols were applied to standard materials used to build up calibration curves. No significant shifting of calibration curves in the reported conditions was observed (data not shown). The extraction of DON is commonly performed by shaking samples in presence of acetonitrile, distilled water, water/PEG or chloroform/methanol. Extraction of OTA is matrix dependent. In case of wheat samples methanol/water or acetonitrile/water are preferably used. In particular, aqueous methanol is recommended when samples have to be analyzed by ELISA, thus we also used 70% methanol in water (v/v). Before the incubation step, extracts were mixed with conjugates. DON extractions were performed both in water and methanol as it is most frequently performed for OTA. The extraction with methanol was included in the experimental design to evaluate the possibility of applying the same extraction protocol to both DON and OTA contaminated samples. The results obtained from DON contaminated samples when two different extraction protocols were applied, showed significant differences. In fact, pre-planned orthogonal contrasts put in evidence differences (p < 0.05) between methanol-based extraction and water extractions. In the test six devices were dedicated to standards (one device for each concentration level) and two devices were dedicated to the analysis of each of the three extracts. No differences were found among replicates using the same extraction protocol for both DON and OTA (ANOVA, p > 0.05). For both DON and OTA, the method was evaluated in terms of accuracy (% bias) and precision (% repeatability standard deviation (RSDr)) as reported in Table 1. In general, the experiments showed a satisfactory repeatability with both mycotoxins (RSDr < 20%). For DON experiments, the calculated bias was relatively low (∼15%) when water was used as extraction solution (95% confidence interval 939 ± 62 µg kg−1). Accuracy was lower (bias>25%) for methanol-based DON extract due to over-estimation of the concentration (95% confidence interval of estimated concentration being 1,352 ± 141 µg kg−1 against 1,062 ± 110 µg kg−1 for the certified concentration). An even higher over-estimation was obtained by analyzing the same extracts with the commercial kit, the bias being >130%. Regarding OTA the calculated biases were higher than 25% for both the ER method and the kit. The 95% confidence interval for the concentration calculated by means of ER was equal to 3.7 ± 0.19 µg kg−1 (2.7 ± 1 µg kg−1 for the certified value), while a concentration of 2.0 ± 0.43 µg kg−1 was calculated using the commercial kit.

The ER assays LOD and LOQ were also determined for DON and OTA by analyzing certified wheat flours with a very low content of mycotoxin (analytical blanks, DON < 50 µg kg−1 and OTA < 0.6 µg kg−1 from IRMM). To be able to compare our results with the performance characteristics of commercial kits, extracts were prepared according to their recommendations (water extraction for DON, 70% methanol extraction for OTA). The LOD and LOQ, determined by the average concentration of 27 analytical blanks plus two and three standard deviations respectively, were equal to 430 and 550 µg kg−1 for DON and 1.7 and 1.8 µg kg−1 for OTA.

Conclusion

A direct competitive immunoassay protocol for mycotoxins detection and quantification has been developed using the ER m&d. The system was fine-tuned for detection of deoxynivalenol and ochratoxin A in wheat flour with limits of quantification equal to 550 and 1.8 µg kg−1, respectively. The assay could be further improved in terms of repeatability mostly through the automation of the device coating step, which was carried out here manually. The scope of the present study was to develop an immunoassay protocol for mycotoxin quantification on the innovative solid phase of ER devices as it represents a promising tool for multi-target detection in the food safety context. As general consideration, multiple screening could facilitate and speed up the full characterization of food products as well as the identification of possible contaminations. Currently, HPLC is extensively applied to detect mycotoxins in cereals. The benefits of using HPLC are mainly the high quality of separation and the low reachable limit of detection (van Egmond et al. 2007; Zheng et al. 2005; Zheng et al. 2006). Moreover, it is possible to combine HPLC to multiple detection systems (fluorescent, UV, diode array) to perform multiple detections (Zheng et al. 2005). However, all these solutions highly increase costs analyses. ER m&d does not suffer of this limitation, it does not need expensive equipments, instruments or trained personnel. Furthermore, comparable results between ELISA and HPLC have been described in the validation study of the ELISA test kit AgraQuant (Romer Labs) for OTA in several commodities (Zheng et al. 2006). Compared to the ELISA kits for single use, the ER m&d offers the possibility to perform multiple assay decreasing costs.

Unfortunately, the applications of multi-target immunoassays are affected by several factors as an example the possibility to apply a unique extraction protocol for all targets. In conclusion, the ER immunoassays here described allow the detection of DON in the range 430–5,000 µg kg−1 and of OTA in the range 1.7–10 µg kg−1. Detection of higher concentrations of OTA and DON are possible through further dilution of the extract. The system allows the quantification of both targets within the maximum levels imposed by the EU regulation with the exception of baby foods (DON, 200 µg kg−1 and OTA, 0.5 µg kg−1) and bread (DON, 500 µg kg−1) as described in Table 2.

References

AOAC International (2005) Official methods of analysis of AOAC international, 18th edn. AOAC International, Gaithersburg

Council of Agricultural Science and Technology (CAST) (2003) Mycotoxins: risks in plant, animal and human systems. Task force Report No. 139. CAST, Ames, Iowa

Ermolli M, Prospero A, Balla B, Querci M, Mazzeo A, Van den Eede G (2006) Food Addit Contam 23:876–882

European Commission (2006) Commission Regulation 401/2006 Off JL 70:12–34

European Commission (2006) Commission Regulation 1881/2006 Off JL 364, 5–24

European Commission (2006) Commission Recommendation 576/2006 Off JL229, 7–9

European Commission (2007) Commission Regulation 1126/2007 Off JL 225, 14–17

Findlay JWA, Dillard RF (2007) AAPS J 9:260–267

Food and Agriculture Organization of the United Nations (2004) Worldwide regulations for mycotoxins in food and feed in 2003. FAO Food and Nutrition Paper N. 81. FAO, Rome, Italy. Available at http://www.fao.org/docrep/007/y5499e/y5499e00.HTM

Goryacheva IY, De Saeger S, Eremin SA, Van Peteghem CH (2007) Food Addit Contam 24:1169–1183

Kraska R, Baumgartner S, Josephs R (2001) Fresenius J Anal Chem 371:285–299

Krska R, Molinelli A (2007) Anal Bioanal Chem 387:145–148

Ono EYS, Ono MA, Funo FY, Medina AE, Oliveira TCRM, Kawamura O, Ueno Y, Hirooka EY (2001) Food Addit Contam 18:719–729

Park JW, Kim EK, Shon DH, Kim YB (2002) Food Addit Contam 19:1073–1080

Schneider E, Curtui V, Seidler C, Dietrich R, Usleber E, Märtlbauer E (2004) Toxicol Lett 153:113–121

Shephard GS (2008) Chem Soc Rev 37(11):2468–2477

Turner NW, Subrahmanyam S, Piletsky SA (2009) Anal Chim Acta 632:168–180

van Egmond HP, Schothorst RC, Jonker MA (2007) Anal Bioanal Chem 389:147–157

Zheng MZ, Hanneken J, Houchins D, King R, Lee P, Richard J (2005) Mycopathologia 159:265–272

Zheng MZ, Richard JL, Binder J (2006) Mycopathologia 161:261–273

Acknowledgements

The on-going collaboration between DG-Joint Research Centre (JRC) and University of Molise was enhanced by the ENEA-Innovation Relay Centre IRIDE as part of the IRC NETWORK created by the European Commission. Authors wish to acknowledge the colleagues of IRMM DG-JRC in Geel (Belgium) for valuable discussions as Community Reference Laboratory (CRL) for mycotoxins by Regulation 2006/776/EC.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Folloni, S., Bellocchi, G., Kagkli, DM. et al. Development of an ELISA Reverse-Based Assay to Assess the Presence of Mycotoxins in Cereal Flour. Food Anal. Methods 4, 221–227 (2011). https://doi.org/10.1007/s12161-010-9150-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-010-9150-8