Abstract

Wood is considered an important renewable energy resource with a variable elemental chemical composition, which may change according to environmental conditions (e.g., temperature, precipitation, altitude). In this study, we evaluated how heating value (HV), elemental chemical composition, and main thermoenergetic parameters of Abies religiosa wood change along an altitudinal gradient. To evaluate these parameters, wood samples were collected from six independent trees in an altitudinal gradient (3000–3500 masl) every 100 m of altitude (36 trees) and their respective HV (higher and low), thermogravimetric and immediate analysis, specific carbon energy (SCE), and fuel value index (FVI) were determined. We found that the higher and lower heating values, elemental chemical composition and the majority of the studied parameters were significantly different (p < 0.05) between altitudes. Our results suggest that A. religiosa wood from 3300 masl has more energy content than wood from 3200 and 3500 masl. Additionally, FVI showed that wood from 3500 masl is the best feedstock in order to use as a solid biofuel. Finally, the results suggest that the altitude at which A. religiosa is grown significantly affects the energetic content of their wood and throughput as a solid biofuel.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Since the origin of humanity, wood has been an important energy reserve for emergency cases such as natural disasters, fossil fuel shortages, and is used as a primary fuel source for those in extreme poverty. Its demand is still increasing because this fuel source is mainly used for heating and food preparation [1, 2]. Globally, the bioenergy potential of wood has been estimated to be 1700 × 1018 J/year, making it an important renewable resource due to its availability [3]. However, the use of wood as an energy resource has been associated with problems of pollution, deforestation, and desertification [1]. To mitigate these negative impacts, a sustainable forest ecosystem management approach should be included as part of a strategy for climate change mitigation [4, 5].

In the sustainability use of biomass, characterization of raw materials is crucial to understand how to transform them to biofuels. Therefore, it is necessary to evaluate and characterize the main chemical and thermoenergetic properties of woody biomass [3]. One of the most important parameters to characterize a material as a potential fuel is its heating value, since this is the absolute value of thermal energy released in the combustion process [6, 7].

Other important parameters are the percentages of humidity, volatile material, fixed carbon, and ash content, which are determined by immediate analysis. From these parameters, it is possible to find the fractions of material in which the chemical energy is stored (volatile compounds and fixed carbon) and to identify the inert fractions (moisture and ash) too [6, 8,9,10].

In many countries, including Mexico, conifers are the forestry resource with the most economic importance [11, 12]. They belong to the softwoods and are more recalcitrant than hardwoods, as solid fuels, due to that the first of both usually have a higher lignin and carbon content (the primary energy source of wood) which gives the softwoods a higher heating value (HHV) than hardwoods [8, 13,14,15,16]. Within the conifers, the genus Abies (Firs) is an abundant taxa of the mountain forests of Mexico and Central America [17], which has not been sufficiently studied.

Particularly, Abies religiosa (Kuntch) Schldl. et Cham (Sacred fir) is a specie relatively common from the Trans-Mexican Volcanic Belt, which develops under very particular geographical, climatic, and ecological conditions, confined in high mountain areas in altitudinal gradients from 2400 to 3600 masl, in Mexico, this conifer has been found in locations like: the Mexico valley, the Pico de Orizaba, Cofre de Perote, and Nevado de Toluca mountains, among others (these areas represent approximately 0.16% of the vegetative cover in the country) [17, 18]. This species contains on average 46.5% of carbon [5]. However, it is unknown whether its carbon content is modified along an altitudinal gradient as it occurs in other species of the same genus [19, 20], or whether the altitude has an effect on its respective heating value as well as in other parameters of the wood [21].

The question that we address in this study was as follows: Does the heating value, elemental chemical composition, and the main parameters of thermal degradation process of Abies religiosa wood change because of growing up in different altitudes? The hypothesis was the following: If the elemental chemical composition, particularly carbon content, changes along the altitudinal gradient in A. religiosa wood as it occurs in other species, then the heating value and other thermoenergetic parameters of wood also could change and affect its solid biofuel throughput. We expect to find the most contrasting changes in energy content, elemental chemical composition and other parameters of thermal degradation of wood at the lowest and highest level (3000–3500 masl) of the altitudinal gradient because they have conditions that limit physically and biologically the distribution of A. religiosa.

Materials and Methods

Study Site

Wood from A. religiosa was obtained from the National Park Cofre de Perote (19° 31.908′ N and 97° 09.246′), specifically from “El Conejo,” Perote, Veracruz, Mexico. The climate is temperate cold-sub-humid, with a range of temperatures ranging from − 5 to 22 °C and a rainfall regime in summer, ranging between 1200 and 1500 mm annually [18, 21]. A. religiosa forest develops only along the altitudinal gradient from 3000 to 3500 m at the study site [22].

Sampling

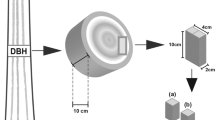

Samples of A. religiosa wood were collected along an altitudinal gradient (AG) of 500 m in August 2014. AG was divided into six altitudinal levels with a distance of 100 m from each other (3000, 3100, 3200, 3300, 3400, and 3500 masl). At each of these levels, wood samples from six trees were collected at a trunk height of 1.3 m according to the methodology developed by Musule et al. [23]. A total of 36 trees were sampled. The chemical composition of A. religiosa wood was 54.81 ± 2.20% cellulose, 12.37 ± 1.33% hemicellulose, and 24.68 ± 1.16% of insoluble lignin [21].

Pretreatment of Samples

Wood samples (20 ± 0.03 g) were dried (105 ± 5 °C for 24 h) in a force convection furnace according to the Technical Association of the Pulp and Paper Industry (TAPPI) standards (T 264cm-07, Preparation of Wood for Chemical Analysis) [24]. Samples were then ground with a Cyclotec 1093 (Foss Tecator, Hamburg, Germany) laboratory grinder equipped with a 1 mm mesh, aiming to produce materials with uniform characteristics (1 mm), for further analysis.

Higher Heating Value Determination

HHV of wood samples were calculated using an adiabatic oxygen bomb calorimeter (Parr 6400, Parr Instrument Company, IL, USA). Benzoic acid (NIST Thermochemical Standard 39j, 26,434 ± 3 J g−1) was used as standard to calibrate the instrument. One gram of A. religiosa wood pellets were placed into nickel crucibles and burned within the instrument, starting the ignition with pure cotton thread [25]. HHV was determined in triplicate, and the average value was reported for each sample in MJ/kg.

Elemental Analysis (EA)

Nitrogen (N), carbon (C), hydrogen (H), and sulfur (S) contents were evaluated through the elemental analyzer (Eurovector EA 3000, Milano, IT) and 1.5 mg of dry sample was used for each determination. The oxygen content (O) was estimated by difference (100% − %C − %N − %H − %S − %ash) [26]. EA was carried out by duplicate, and average value was reported for each element. A Van Krevelen diagram was used to compare atomic rates: H/C and O/C [27, 28].

Thermogravimetric and Immediate Analysis

Thermogravimetric analysis (TGA) was performed by a TGA/DSC analyzer (Perkin Elmen STA 6000, EEUU) under constant flow of nitrogen (40 mL/min) in a range of temperatures from 25 to 950 °C. The TGA was heated from 25 to 120 °C with a heating rate of 50 °C/min; then, temperature was maintained at 120 °C for 3 min, heating from 120 to 950 °C at 100 °C/min, and cooling from 950 to 450 °C at 100 °C/min. Then, a change from nitrogen to oxygen at 40 mL/min flow was done; heating from 450 to 800 °C at 100 °C/min and finally an isotherm of 800 °C for 3 min (adopted method for immediate analysis). Approximately 10 mg of wood sample was used. Data processing and DTG curves (first derivate from TGA curves, lost weight rate dm/dT) were made using the Pyris software (Perkin Elmer).

Parameters of immediate analysis

Percentage humidity (Hum), volatile material (VM), and fixed carbon (FC) were obtained by TGA analysis. Duplicates of the percentage of ash were determined by direct incineration of 1 g of dry wood by sample in a muffle, using the methodology described by Sluiter et al. [29]. Additionally, a ternary diagram (VM, FC, and ash percentage) was used to compare the immediate composition of A. religiosa wood in different altitudes transforming and normalizing percentages of this parameters to the value of 1.

Low Heating Value, Specific Carbon Energy, and Fuel Value Index Estimations

Low heating value (LHV, dry base, expressed in MJ/kg) of samples was estimated using Eq. 1 [7]. Furthermore, the parameter specific carbon energy (SCE) was calculated (kJ/% dry base) [30]. Moreover, fuel value index (FVI) was estimated using Eq. 2 (taking into account humidity percentage in field) [31, 32] and Eq. 3 (without considering humidity percentage in field) [31, 33, 34]. A. religiosa wood density (g/cm3) was calculated using the empiric method described in previous reports [35]. Humidity percentage of wood in field (%) was calculated by gravimetric dehydration of wood in a drying oven for 24 h at 105 ± 5 °C.

Statistical Analysis

One-way ANOVAs were carried out considering altitudinal gradient as factor while dependent variables were as follows: (I) higher heating value (II) percentages of EA and their respective atomic rates (%C, %H, %O, H/C, and O/C)c (III) parameters obtained by TGA and immediate analysis (%Hum, %VM, %FC, and %ash), and (IV) calculated values for LHV, SCE, and FVIs. Additionally, a post hoc Tukey test was performed in order to make multiple comparisons.

In all cases, the dependent variables that did not fulfill the assumptions of a normal distribution were transformed into ranks suitable for parametric statistical analysis [36]. In ANOVAs, wood samples of each tree were considered as a sampling unit with six replicates per level (altitudinal level). A trust rate of 95% was analyzed (P < 0.05) using R statistical free software (2.14.2 version). Graphs were drawn with GraphPad Prism 6 and XLSTAT software.

Results and Discussion

Higher Heating Value Determination

The average HHV (36 trees studied) of A. religiosa wood was 18.8 ± 0.23 MJ/kg. Significant differences (p = 1.39 × 10–5***) were observed in the HHV in relation to the altitude (Fig. 1), with an upper HHV in wood developed at altitudes of 3300, 3400, and 3100, in contrast with lower HHV in the wood that grew up at 3200 and 3500 masl.

The HHV of A. religiosa wood was found within the reported range for different types of biomass (14–23 MJ/kg dry matter) [16]. However, it was lower than the general HHV of softwoods (20.08 MJ/kg) [7]. Compared to other species of the genus Abies, it had also a lower value. For example, the HHV found for A. concolor, A. pindrow, and A. spectabilis were 19.9 MJ/kg for the first [37] and 21.2 MJ/kg for the latter two [33]. This can be attributed to the intrinsic differences of woods between species [3, 38]. Lima reported a HHV of A. religiosa wood of 18.1 MJ/kg [39], a very similar value to the one found in the present study, which suggests the presence of small changes in HHV intraspecies (within the same species), possibly associated to multiple variables, for example different ecological conditions in relation to the respective geographical areas from growth, among other. Moreover, HHV of A. religiosa wood is similar to the reported value for “Douglas Fir” (Pseudotsuga menziesii) (18.88 MJ/kg), a wood species widely researched for bioenergy purposes [40].

Significant differences in HHV of A. religiosa wood from different altitudes suggests the presence of changes in other parameters widely related to HHV, such as the elemental and immediate composition of wood [28, 41, 42]. In this sense, the main causes of HHV modification are carbon content (main energy source) and changes in mineral content (percentage ash) [16]. However, there are other factors that can also change the HHV, for example the proportions of the elements H and O [41, 42].

Elemental Analysis

EA results of A. religiosa wood showed 46.17 ± 3.35% of carbon content, 47.70 ± 3.08% of oxygen, and a hydrogen content of 6.12 ± 0.35%. Nitrogen and sulfur were not detected by EA in wood samples. These results suggest that both elements could be present in very small amounts, under the detection limit of the instrument used in the present study (0.1%). Significant differences in the percentages of three analyzed elements (C, H, and O) in relation to altitude (p < 0.05) were found. Carbon content was higher in 3300 and 3400 masl and lower in 3000 masl (Table 1) while oxygen content had an opposite pattern (lower in 3300 and 3400 masl and higher in 3000 masl); finally, hydrogen percentage was higher in 3000 masl and lower when altitude increased in the highest altitudinal levels (3400 and 3500 masl).

The general elemental composition of wood is 50% carbon, 44% oxygen, 6% hydrogen, and 0.1% nitrogen [43], and our results showed that average elemental composition of A. religiosa wood presents variations with respect to general reported values, mainly in a higher oxygen content and in a lower carbon content, in contrast to other kinds of wood [8, 30, 44]. On the other hand, the virtual absence of N and S in A. religiosa wood suggests that during combustion, it will produce a low concentration of NOx and SO2 [40] which contribute to environmental problems such as acid rain and smog [3, 45]. Thus, this wood could be considered less polluting than others woody biomass with more content of N and S.

When the elemental composition of A. religiosa is compared with the reported percentages for other species into the same genus (51.23% carbon, 42.29% oxygen, 5.98% hydrogen, 0.06% nitrogen, and 0.03% sulfur) [3], a lower carbon content and a higher percentage of oxygen are found also. Additionally, a variation in elemental composition is also observed for A. amabilis (48.55% carbon and 8.1% hydrogen, in Canada), A. balsamea (50.08% carbon and 7.69% hydrogen, in Canada) [15], A. concolor (49% carbon, 45% oxygen, 5.98% hydrogen, 0.05% nitrogen, and 0.01% sulfur, in the USA) [37], and A. bornmulleriana (47.2% carbon, 4xygen, 6.1% hydrogen, 0.3% nitrogen, and 0.03% sulfur, in Turkey) [46]. These data suggest an important variation in elemental content between species from the genus Abies.

With respect to the carbon content and its storage in trees, the generic value of carbon in wood is 50%; this percent may lead to a sub- or overestimation of carbon storage, because the concentration of this element varies depending on the species in a range of around 47–59% [15, 47]. The results found in this study indicate that the use of 50% of carbon for A. religiosa wood would imply an overestimation in the generation of the models to estimate its carbon storage. Moreover, it is important to emphasize that changes can also occur in the intraspecies content of carbon, as can be seen from the data reported for A. balsamea (50.08–51.8%) [15, 48] and on the results of the present study.

Changes in carbon content have been associated with environmental factors too, such as different growth sites and their respective climatic conditions [49, 50]. Regarding altitude, in the A. georgei wood, significant changes were reported in carbon concentration along an altitudinal gradient (46.7–48%) decreasing with altitude [19]. In this study, we found that carbon content of A. religiosa wood also changed significantly with altitude, from 41.23 ± 0.79% for the lowest part of the altitudinal gradient (3000 masl) to 49.18 ± 1.14% at the altitude of 3300 masl, which suggests different responses of variation of the carbon content related to the altitude in these species. A recent study (using a meta-analysis) highlighted the influence of altitude in relation to carbon content in forest foliage, reporting a 2.1% increase in carbon content per 1000 m of altitude [51]. Therefore, depending on the species, the anatomical fraction studied and the climatic conditions, different patterns of variation of the carbon content in relation to the altitude could be expected, which also can lead to changes in the quality of wood and be closely related to the different forms of carbon flows and cycles in forest ecosystems.

The O/C and H/C atomic rates in A. religiosa wood collected at different altitudes were significantly different (p < 0.05) (Table 1). It was noted that for O/C rate, 3000 and 3100 masl ˃ 3200 masl ˃ 3500 masl ˃ 3300 masl, and for the rate H/C, 3000 and 3100 masl ˃ 3200, 3300, 3500, and 3400 masl. By means of average atomic O/C and H/C rates of the different altitudes, a Van Krevelen diagram was constructed (Fig. 2), where the following descending order was observed: 3300, 3400, 3500, 3200, 3100, and 3000 masl. This suggests that as the elemental composition of the wood changes with respect to the altitude, its respective HHV is modified also, the reason why the wood must vary its content of compounds with carbonyl groups and unsaturations in relation to the altitude, increasing the HHV in woods with a higher amount of C-C bounds and lower C-O and C-H bounds [27, 28]. Additionally, a high content of carbon and hydrogen and low oxygen (degree of oxygenation) are associated with an increase in the HHV [8, 52].

Contrasting the results obtained in the HHV experimental determination with the results of the EA, actually a higher HHV was found in the wood of the altitudinal levels of 3300 and 3400 masl, which have the largest amounts of carbon. However, it was found that HHV was also high in the wood of 3100 masl, despite not containing a high carbon content and located with a higher O/C ratio as shown on the Van Krevelen diagram. The wood with a lower HHV were those of the altitudes of 3200 and 3500 masl and not at 3000 masl (Fig. 2), which could imply that in addition to the elemental composition, there are other factors that could be affecting the variation of HHV in the A. religiosa wood.

Thermogravimetric (TGA) and Immediate Analysis

Weight loss curves (%) according to temperature (Fig. 3a) and the respective derivatives of TG curves (dweight/dT mg/°C) (Fig. 3b) were obtained by TGA of A. religiosa wood. Initially, a small weight loss was observed between 100 and 120 °C which was related to the evaporation of remaining water (% humidity) into the wood [53]. Then, a further thermic degradation process of wood occurred in a range from 320 to 400 °C, and it was characterized by an important weight loss (70.79 ± 1.53%) which may be mainly related to depolimerization process of hemicelluloses and cellulose from wood [53, 54]. On the other hand, thermograms of A. religiosa wood (Fig. 3a) did not show the slight shoulder-shaped peak around 300 °C that is typical in many kinds of wood [53, 54]. This shoulder-shaped peak is related to degradation of hemicelluloses [53] so its absence can be explained because of a lower concentration of this biopolymer in A. religiosa wood [21]. Also, this peak has not been observed in TGA of wood from another species of fir (A. alba) [54] which could be a common feature of thermograms of wood from genus Abies, so it is relevant to extend the database of TGA obtained from this kind of wood.

Additionally, four parameters of thermic degradation process (Table 2) were obtained from DTG curves (around 380–400 °C): initial temperature (T0), maximum thermic degradation temperature (Tm), final temperature (Tf), and weight loss (%). Significant differences (p < 0.05) in Tm and Tf were found showing different levels of thermic stability in wood at 3500 masl in contrast to wood at 3200 and 3000 masl. Wood samples from 3200 and 3000 masl were less stable to temperature than wood samples from 3500 masl. These variations can be explained by changes in chemical composition. For example, it is reported that a higher lignin content is related to a higher thermic stability [53] which is consistent with the found results by our research group in a previous study about changes in chemical composition of A. religiosa wood [21]. Furthermore, thermic degradation of a chemical compound of wood may accelerate the degradation of other components into the same wood [53] which suggests that this could be occurring during the thermic degradation degree in wood from 3000 and 3200 masl.

Parameters of average immediate analysis of A. religiosa wood were 5.88 ± 0.77% of humidity, 76.09 ± 1.63% of volatile material, 17.30 ± 1.30% of fixed carbon, and 0.82 ± 0.31% of ash. Significant differences (p < 0.05) in humidity and ash percentage in relation to altitude were found (Table 1). Humidity was higher in upper altitudinal levels (3400 and 3500 masl) in contrast to the lowest altitudinal level (3000 masl). Moreover, ash percentage was higher in lower altitudinal levels (3000 and 3200 masl) than in upper altitudinal levels (3500 and 3400 masl). Results suggest that A. religiosa could have a lower access to mineral material and consequently to a lower accumulation of minerals in its wood at upper altitudinal levels in contrast to the lowest altitudinal level, which is in agreement with previous studies in which it has been observed a relation of nutrient deficiency and decrease of minerals in soils and plants respect to an increase of altitude [55,56,57]. Besides, a higher ash percentage is associated to a decrease in HHV [6, 28, 42] which is consistent with the observed data in wood from 3000 and 3200 masl. However, wood from the uppermost altitudinal level (3500 masl) showed the lowest ash percentage and a low HHV which suggests that also other factors can affect the decrease in this parameter. Percentages of VM and FC did not show significant differences in relation to altitude (p < 0.05).

Ternary diagram of VM, FC, and ash percentage (Fig. 4) showed that the analyzed samples (into the altitudinal range from 3000 to 3500 masl) of A. religiosa wood are very similar between them and only a small separation is observed in the marks from wood at 3200 and 3500 masl. Taking into account the EA, TGA, and immediate analysis results obtained in this study, we conclude that distribution of chemical components of A. religiosa wood change slightly in relation to altitude, mainly at 3200 and 3500 masl where more meaningful differences are observed. In addition, their respective chemical compositions could be decreasing their HHV in both altitudes due to different factors, probably related to each altitudinal level.

Low Heating Value, Specific Carbon Energy, and Fuel Value Index Estimations

The average LHV for A. religiosa wood was 17.46 0.23 MJ/kg. This value was lower than the value for A. concolor (18.6 MJ/kg) [37] but higher than the reported data for other tree species [7]. On the other hand, significant differences (p = 0.001**) in LHV in relation to altitude were found with a higher energy content in wood from 3300 masl with respect to wood from 3200 and 3500 masl. The last was similar to the found data in HHV. However, in contrast to results of HHV, the amount of net energy of wood from 3500 masl was not significantly different to wood from 3400 and 3100 masl. This is because of the respective element concentrations of elements (O and H percentages in wood samples) in each altitudinal level.

Moreover, the average SCE for A. religiosa wood was 408.36 ± 31.37 kJ/% which is consistent with the reported value for biomass from forest origin (396 kJ/%) [29]. SCE showed highly significant differences (p = 1.8 × 10–11***) in relation to altitude (Table 1). It was found that SCE of A. religiosa wood had the next pattern: 3000 masl > 3200 masl > 3300, 3400, and 350 masl. The last means that this parameter increased at the lowest altitudinal level, then at 3200 masl and decreased in upper altitudinal levels. These results again suggest that carbon could be found in different kinds of sp3, sp2, or sp hybridized carbon atoms and in different functional groups which could influence SCE values. Additionally, oxidation state of carbon also could affect the relation between HHV and SCE, particularly in carbon content [30].

Average density of A. religiosa wood was 0.32 ± 0.04 g/cm3. This result was lower than the previous reported value for the same species (0.36–0.38 g/cm3) [58, 59] which suggests an intra species variation. Density of A. religiosa wood may be considered low in comparison to other kinds of wood from the same genus such as A. pindrow and A. spectabilis (0.81 g cm−3 for both) [33] and also in other conifer woods (0.51 g/cm3 as average) [59]. According to our results, density of A. religiosa wood did not show significant differences (p < 0.05) in relation to altitude (Table 1). On the other hand, humidity in field of A. religiosa wood was 0.52 ± 0.04% showing significant differences (p < 0.15*) with respect to altitude (Table 1) in the next order: 3000 masl > 3400 and 3500 masl; the last means that upper altitudinal levels showed a lower amount of water. However, it is important to highlight that humidity in field is a nonintrinsic parameter of wood from a particular species and its value may vary in a short period of time [33].

Fuel value indexes FVI1 and FVI2 for A. religiosa wood had an average value of 441.29 ± 172.65 and 873.23 ± 389.52, respectively (Table 1). FVI1 of A. religiosa wood was lower than the reported value for other kinds of wood [31] which could be related to the relatively high percentages of humidity in field and the low density of A. religiosa wood. On the other hand, FVI2 was higher than in other species such as Lannea grandis, Lagerstroemia flos-reginae, Pinus roxburghii, and many others [31, 33, 34]. The last could be due to the fact that A. religiosa has low ash percentages in its wood which improves FVI2. Additionally, FVI2 for A. religiosa is close to FVI2 for A. pindrow and A. spectabilis (903.8 for both) [33].

Significant differences (p < 0.05) in FVI1 and FVI2 in relation to altitude were found (Table 1). Results showed a relevant association of altitude with both indexes which is explained by a significant association between altitude and HHV, humidity in field, and ash percentage, so FVIs are very sensible to altitude. Both indexes indicate that quality of wood as a fuel is higher in upper altitudinal levels (3500 and 3400 masl) than in the lowest altitudinal level (3000 masl) because in this altitudinal level, wood has higher percentages of ash and humidity in field. In addition, a low value of standard deviation was observed between the FVIs data of samples obtained at 3200 masl which could indicate homogeneity conditions in A. religiosa wood at this altitude.

Conclusions

In this study, the quality of A. religiosa wood as solid biofuel changes significantly in relation to altitude. Significant differences in energy content, elemental content, and other important thermoenergetic parameters of A. religiosa wood were found at the different altitudes where samples were collected. Our data indicate that wood from 3300 masl had a higher energy content (HHV and LHV) and was characterized by a higher carbon content and lower O/C and H/C atomic rates. Furthermore, wood from 3200 and 3500 masl had a lower energy content. Taking into account our data, the decrease of energy content in wood from 3200 and 3500 masl could be due to several possible factors such as different elemental content, variable hybridation and oxidation state of carbon, differences in their thermic stability, and ash percentages.

The stated hypothesis in this study about probable significant changes in energy content, elemental content, and other parameters of A. religiosa in relation to altitude was not rejected. With respect to wood from extreme altitudinal levels (3000 and 3500 masl), a higher energy content was not observed. However, if FVIs are considered, then wood from the uppermost altitude areas (3500 masl) is the best option to use as a solid biofuel due to its low percentage of ash and humidity.

References

Acheampong BB (2016) Biomass and bioenergy strength properties and calorific values of sawdust-briquettes as wood-residue energy generation source from tropical hardwoods of different densities. Biomass Bioenergy 85:144–152. https://doi.org/10.1016/j.biombioe.2015.12.006

Gillespie GD, Everard CD, Fagan CC, McDonnell KP (2013) Prediction of quality parameters of biomass pellets from proximate and ultimate analysis. Fuel 111:771–777. https://doi.org/10.1016/j.fuel.2013.05.002

Tao G, Lestander TA, Geladi P, Xiong S (2012) Biomass properties in association with plant species and assortments I: a synthesis based on literature data of energy properties. Renew Sust Energ Rev 16(5):3481–3506. https://doi.org/10.1016/j.rser.2012.02.039

Pineda-López MR, Ortega-Solis R, Sánchez-Velásquez LR et al (2013) Population structure of Abies religiosa (Kunth) Schltdl. et Cham., in the ejido el conejo of the national park Cofre de Perote, Veracruz, Mexico. Rev Chapingo Ser Ciencias For y del Ambient 19(3):375–385. https://doi.org/10.5154/r.rchscfa.2012.11.058

Avendaño D, Acosta M, Carrillo F, Etchevers J (2009) Estimación de la biomasa y carbono en un bosque de Abies religiosa. Rev Fitotec Mex 32:233–238

Vargas-Moreno JM, Callejón-Ferre AJ, Pérez-Alonso J, Velázquez-Martí B (2012) A review of the mathematical models for predicting the heating value of biomass materials. Renew Sust Energ Rev 16(5):3065–3083. https://doi.org/10.1016/j.rser.2012.02.054

Telmo C, Lousada J (2011) Heating values of wood pellets from different species. Biomass Bioenergy 35(7):2634–2639. https://doi.org/10.1016/j.biombioe.2011.02.043

Demirbas T, Demirbas C (2009) Fuel properties of wood species. Energy Sources Part A Recover Util Environ Eff 31(16):1464–1472. https://doi.org/10.1080/15567030802093153

Sebastián F, García-Galindo D, Rezeau A (2010) Energía de la biomasa. Primera. Universidad de zaragoza, Zaragoza

Nhuchhen DR, Abdul Salam P (2012) Estimation of higher heating value of biomass from proximate analysis: a new approach. Fuel 99:55–63. https://doi.org/10.1016/j.fuel.2012.04.015

Roy J, Smith WK, Hinckley TM (2013) Resource physiology of conifers: acquisition, allocation, and utilization. Academic Press

Martínez-Antúnez P, Hernández-Díaz JC, Wehenkel C, López-Sánchez CA (2015) Estimación de la densidad de especies de coníferas a partir de variables ambientales. Madera y bosques 21:23–33

Kumar L, Arantes V, Chandra R, Saddler J (2012) The lignin present in steam pretreated softwood binds enzymes and limits cellulose accessibility. Bioresour Technol 103(1):201–208. https://doi.org/10.1016/j.biortech.2011.09.091

Alvarez-Vasco C, Zhang X (2013) Alkaline hydrogen peroxide pretreatment of softwood: hemicellulose degradation pathways. Bioresour Technol 150:321–327. https://doi.org/10.1016/j.biortech.2013.10.020

Lamlom SH, Savidge RA (2003) A reassessment of carbon content in wood: variation within and between 41 North American species. Biomass Bioenergy 25(4):381–388. https://doi.org/10.1016/S0961-9534(03)00033-3

Gravalos I, Xyradakis P, Kateris D, Gialamas T, Bartzialis D, Giannoulis K (2016) An experimental determination of gross calorific value of different agroforestry species and bio-based industry residues. Nat Resour 7(01):57–68. https://doi.org/10.4236/nr.2016.71006

Aguirre-Planter E, Jaramillo-Correa JP, Gómez-Acevedo S, Khasa DP, Bousquet J, Le E (2012) Phylogeny, diversification rates and species boundaries of Mesoamerican firs (Abies, Pinaceae) in a genus-wide context. Mol Phylogenet Evol 62(1):263–274. https://doi.org/10.1016/j.ympev.2011.09.021

Pineda Lopez MR, Sanchez-Velasquez LR, Vazquez-Dominguez G, Rojo Alboreca A (2013) The effects of land use change on carbon content in the aerial biomass of an Abies religiosa (Kunth Schltdl. et Cham.) forest in central Veracruz, Mexico. For Syst 22(1):82. https://doi.org/10.5424/fs/2013221-02756

Wang G, Ran F, Chang R, Yang Y, Luo J, Jianrong F (2014) Variations in the live biomass and carbon pools of Abies georgei along an elevation gradient on the Tibetan Plateau, China. For Ecol Manag 329:255–263. https://doi.org/10.1016/j.foreco.2014.06.023

Xu G, Jiang H, Zhang Y, Korpelainen H, Li C (2013) Effect of warming on extracted soil carbon pools of Abies faxoniana forest at two elevations. For Ecol Manag 310:357–365. https://doi.org/10.1016/j.foreco.2013.08.038

Musule R, Alarcón-Gutiérrez E, Houbron EP, Bárcenas-Pazos GM, del Rosario Pineda-López M, Domínguez Z, Sánchez-Velásquez LR (2016) Chemical composition of lignocellulosic biomass in the wood of Abies religiosa across an altitudinal gradient. J Wood Sci 62(6):537–547. https://doi.org/10.1007/s10086-016-1585-0

Narave Flores H (1985) La vegetacion de Cofre de Perote, Veracruz, Mexico. Veg Cofre Perote Veracruz Mex Biot 10:35–64

Musule R, Bárcenas-Pazos G, Pineda-López MR et al (2017) Development and evaluation of a rational and nondestructive sampling methodology for softwoods used in chemical analyses. Madera y Bosques. http://dx.doi.org/10.21829/myb.2018.2411427

TAPPI (2007) TAPPI T 264 cm-07. Preparation of wood for chemical analysis

Yang I, Kim S, Sagong M, Han GS (2016) Fuel characteristics of agropellets fabricated with rice straw and husk. Korean J Chem Eng 33(3):851–857. https://doi.org/10.1007/s11814-015-0210-z

Muñoz R, Navia R, Ciudad G, Tessini C, Jeison D, Mella R, Rabert C, Azócar L (2015) Preliminary biorefinery process proposal for protein and biofuels recovery from microalgae. Fuel 150:425–433. https://doi.org/10.1016/j.fuel.2015.02.004

Nanda S, Mohanty P, Pant KK, Naik S, Kozinski JA, Dalai AK (2013) Characterization of North American lignocellulosic biomass and biochars in terms of their candidacy for alternate renewable fuels. Bioenergy Res 6(2):663–677. https://doi.org/10.1007/s12155-012-9281-4

McKendry P (2002) Energy production from biomass (part 1): overview of biomass. Bioresour Technol 83(1):37–46. https://doi.org/10.1016/S0960-8524(01)00118-3

Sluiter A, Hames B, Ruiz R et al (2008) Determination of ash in biomass. Laboratory Analytical Procedure: Technical Report NREL/TP-510-42622. National Renewable Energy Laboratory, Golden

Toscano G, Riva G, Foppa Pedretti E, Duca D (2013) Effect of the carbon oxidation state of biomass compounds on the relationship between GCV and carbon content. Biomass Bioenergy 48:231–238. https://doi.org/10.1016/j.biombioe.2012.11.002

Deka D, Saikia P, Konwer D (2007) Ranking of fuelwood species by fuel value index. Energy Sources 29(16):1499–1506. https://doi.org/10.1080/15567030600820476

Cardoso MB, Ladio AH, Dutrus SM, Lozada M (2015) Biomass and bioenergy preference and calorific value of fuelwood species in rural populations in northwestern Patagonia. Biomass Bioenergy 81:514–520. https://doi.org/10.1016/j.biombioe.2015.08.003

Bhatt BP, Todaria NP (1992) Firewood characteristics of some mountain trees and shrubs. Commonw For Rev 71:183–185

Bhatt BP, Sarangi SK, De LC (2010) Fuelwood characteristics of some firewood trees and shrubs of eastern Himalaya, India. Energy Sources,Part A Recover Util Environ Eff 32(5):469–474. https://doi.org/10.1080/15567030802612408

Valencia MS, Vargas JH (1997) Método empírico para estimar la densidad básica en muestras pequeñas de madera. Madera y Bosques 3:81–87

Conover WJ, Iman RL (1981) Rank transformations as a bridge between parametric and nonparametric statistics. Am Stat 35:124–129

Nielsen J, Diebold J, Walton T, Boyle M, Walt R (2011) Converting riparian restoration waste to energy: testing tamarisk (Tamarix spp.) woody biomass as fuel for downdraft gasification. Ecol Restor 29(3):270–278. https://doi.org/10.3368/er.29.3.270

Vassilev SV, Baxter D, Andersen LK, Vassileva CG, Morgan TJ (2012) An overview of the organic and inorganic phase composition of biomass. Fuel 94:1–33. https://doi.org/10.1016/j.fuel.2011.09.030

Lima Rojas L (2013) Evaluación de la composición química y propiedades físicas de madera y corteza de cuatro coníferas para la producción de bioenergía. Dissertation, Universidad Autónoma de Nuevo León, Nuevo Leon

Ren S, Lei H, Wang L, Bu Q, Wei Y, Liang J, Liu Y, Julson J, Chen S, Wu J, Ruan R (2012) Microwave torrefaction of douglas fir sawdust pellets. Energy Fuels 26(9):5936–5943. https://doi.org/10.1021/ef300633c

García R, Pizarro C, Lavín AG, Bueno JL (2014) Spanish biofuels heating value estimation. Part I: ultimate analysis data. Fuel 117:1130–1138. https://doi.org/10.1016/j.fuel.2013.08.048

García R, Pizarro C, Lavín AG, Bueno JL (2014) Spanish biofuels heating value estimation. Part II: Proximate analysis data. Fuel 117:1139–1147. https://doi.org/10.1016/j.fuel.2013.08.049

Barton GM (1984) Definition of biomass samples involving wood, bark and foliage. Biomass 4(4):311–314. https://doi.org/10.1016/0144-4565(84)90044-1

Vassilev SV, Baxter D, Andersen LK, Vassileva CG (2010) An overview of the chemical composition of biomass. Fuel 89(5):913–933. https://doi.org/10.1016/j.fuel.2009.10.022

González JF, González-García CM, Ramiro A et al (2004) Combustion optimisation of biomass residue pellets for domestic heating with a mural boiler. Biomass Bioenergy 27(2):145–154. https://doi.org/10.1016/j.biombioe.2004.01.004

Dumanli AG, Taş S, Yürüm Y (2011) Co-firing of biomass with coals: part 1. Thermogravimetric kinetic analysis of combustion of fir (abies bornmulleriana) wood. J Therm Anal Calorim 103(3):925–933. https://doi.org/10.1007/s10973-010-1126-9

Thomas SC, Martin AR (2012) Carbon content of tree tissues: a synthesis. Forests 3(4):332–352. https://doi.org/10.3390/f3020332

Xing Z, Bourque CP, Swift DE et al (2005) Carbon and biomass partitioning in balsam fir (Abies balsamea). Tree Physiol 25(9):1207–1217. https://doi.org/10.1093/treephys/25.9.1207

Yuan F, Arain MA, Barr AG et al (2008) Modeling analysis of primary controls on net ecosystem productivity of seven boreal and temperate coniferous forests across a continental transect. Glob Chang Biol 14(8):1765–1784. https://doi.org/10.1111/j.1365-2486.2008.01612.x

Peri PL, Gargaglione V, Martínez Pastur G, Lencinas MV (2010) Carbon accumulation along a stand development sequence of Nothofagus antarctica forests across a gradient in site quality in Southern Patagonia. For Ecol Manag 260(2):229–237. https://doi.org/10.1016/j.foreco.2010.04.027

Tashi S, Singh B, Keitel C, Adams M (2016) Soil carbon and nitrogen stocks in forests along an altitudinal gradient in the eastern Himalayas and a meta-analysis of global data. Glob Chang Biol 22(6):2255–2268. https://doi.org/10.1111/gcb.13234

Saidur R, Abdelaziz EA, Demirbas A, Hossain MS, Mekhilef S (2011) A review on biomass as a fuel for boilers. Renew Sust Energ Rev 15(5):2262–2289. https://doi.org/10.1016/j.rser.2011.02.015

Poletto M, Zattera AJ, Santana RMC (2012) Structural differences between wood species: evidence from chemical composition, FTIR spectroscopy, and thermogravimetric analysis. J Appl Polym Sci 126(S1):E337–E344. https://doi.org/10.1002/app.36991

Popescu MC, Popescu CM, Lisa G, Sakata Y (2011) Evaluation of morphological and chemical aspects of different wood species by spectroscopy and thermal methods. J Mol Struct 988(1-3):65–72. https://doi.org/10.1016/j.molstruc.2010.12.004

Soethe N, Wilcke W, Homeier J, et al (2008) Plant growth along the altitudinal gradient—role of plant nutritional status, fine root activity, and soil properties. In: Gradients a trop. Mt. Ecosyst. Ecuador. Springer, pp 259–266

Benner J, Vitousek PM, Ostertag R (2010) Nutrient cycling and nutrient limitation in tropical montane cloud forests. In: Bruijnzeel LA, Scatena FN, Hamilton LS (eds) Tropical montane cloud forests: science for conservation and management. Cambridge University Press, London

Singh B, Bhatt BP, Prasad P (2010) Altitudinal variation in nutritive value of adult-juvenile foliage of Celtis australis L.: a promising fodder tree species of Central Himalaya, India. J Am Sci 6:108–112

Rosa AB (2001) Variación de las propiedades físicas de la madera en un árbol de Abies religiosa y de Pinus ayacahuite var. veitchii. Rev Chapingo Ser Ciencias For y del Ambient 6:83–92

Ordoñez Diaz JAB, Galicia Naranjo A, Venegas Mancera NJ et al (2015) Densidad de las maderas mexicanas. Madera y Bosques 21:77–126

Acknowledgments

We thank to the Universidad Veracruzana because of the support given to do a research stay in the Universidad de Concepción, Chile. Ricardo Musule thanks to National Council of Science and Technology (CONACyT) because of the given postgraduate scholarship number 344898 and the mixed scholarship for international research.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflicts of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Musule, R., Acuña, E., Romero-Hermoso Osorio, L.S. et al. Growing up at Different Altitudes: Changes in Energy Content of the Abies religiosa Wood. Bioenerg. Res. 11, 209–218 (2018). https://doi.org/10.1007/s12155-017-9889-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-017-9889-5