Abstract

Ion Mobility Spectroscopy (IMS) is commonly used for in-situ rapid online detection of trace substances at atmospheric pressure. By selecting four types of Phthalic acid Ester (PAE) compounds as the quantitative research objects, studying the effects of the temperature of the mobility tube, the temperature of the sample desorbed heater and the electric field strength of the mobility region on the detection, analysing the microscopic process of ion reaction after the addition of reagent molecules using the Rectilinear Ion Trap Mass Spectrometer (RIT-MS), the paper preliminary studies the product ions of phthalic acid ester, and establish a method for rapid measurement of phthalic acid ester-like environmental hormones with ion mobility spectrometry. With the addition of ammonia reagent molecules, the detection limits of dimethyl phthalate, diethyl phthalate, dibutyl phthalate and butyl benzyl phthalate were 0.08 and 0.1, 0.09, 0.70 ng, respectively, and relative standard deviation RSD of 6 parallel measurements <6.3%. When used for the detection of phthalates in plastics, this method can quickly and easily screen products containing trace PAE-like contaminants.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Phthalic acid Esters (PAEs), which are widely used as plasticizers, can contaminate food by migrating and dissolving into food, thereby threatening human life safety [1,2,3]. With an increasing amount of PAEs used, the contamination caused by PAEs cannot be ignored [4, 5]. Therefore, To better study the contamination status of PAEs, strengthen the control of PAEs and ensure the life safety of people, it is urgent to develop a technique for accurate and efficient detection of PAEs. This technique has certain practical application significance [6].

According to existing reports, the analytical methods for PAEs include: liquid chromatography-mass spectrometry (LC-MS), gas chromatography, gas chromatography-mass spectrometry (GC-MS), thin-layer chromatography, etc. [7,8,9]. At present, it is generally accepted that the gas chromatography-mass spectrometry technique is widely used to detect PAEs. For example, the standards of the American Materials and Testing Association, EU standards, and the official testing methods of the US Consumer Product Safety Commission consistently adopt GC/MS as the testing method [10,11,12], while China establishes corresponding national standards according to the characteristics of different industries based on GC-MS [13, 14]. However, GC / MS equipment is expensive and complicated to operate. A technique capable of accurately and efficiently detecting PAEs is expected to be developed to meet the development needs.

The principle of ion mobility spectrometry (IMS) is based on the differences in gaseous ion mobilities of samples, so as to complete the detection of different samples. In situ rapid detection of trace substances often uses the ion mobility spectroscopy technique [15, 16]. At present, this technical method is widely used, and has been reported in fast online monitoring of biomolecules, environments, hazardous chemicals etc. [17, 18] .It needs to improve the selectivity when analyzing complex samples. The major methods include: combining with the GC or adding reagent molecules to the system. To achieve rapid detection, the addition of reagent molecules is undoubtedly the best solution. Puton et al. [19] reviewed the effects of the addition of reagent molecule on the ion mobility spectrometry: adding an appropriate amount of acetone or ammonia as a reagent molecules in a positive ion mode, and adding a halogenated hydrocarbon as reagent molecules in a negative ion mode can significantly improve the selective detection of ion mobility spectrometry, thus avoiding interference from impurities.

The paper intends to examine the effects of instrument parameters on detection based on independently developed ion mobility spectrometry and further analyzes the microscopic process of ion reactions after the addition of the ammonia reagent molecules using a self-made miniaturized rectilinear ion trap mass spectrometer. The results have shown that using ammonia as reagent molecules helps improve the recognition accuracy of various types of PAEs. Under these conditions, a rapid screening method for PAE-like environmental hormones was established.

Experimental section

Apparatuses

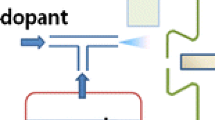

The ion mobility spectrometer used in the paper was independently developed by the laboratory, as shown in Fig. 1. It includes a thermal desorber, 0.5-GBq radioactive 63Ni foil ion source, a Bradbury–Nielsen (BN) gate, a drift region, a Faraday plate and an amplifier. The IMS was operated in the positive ion mode, and the operating parameters are listed in Table 1. The IMS was equipped with thermal desorption (TD) inlet assembly in the present study, which is also shown in Fig. 1. The TD inlet consisted of two parts: the upper part of the thermal desorption and the lower part of the transmission mechanism. Once the sample swipe was inserted, the solenoid valve was closed and sealed. The analyte on the sampling swipe was rapidly vaporized in the high-temperature thermal desorption chamber (180 °C), and introduced as neutrals into the reaction region by carrier gas. The thermal desorption chamber was temperature-controlled by using a rod heater and with a thermal resistor.

The reagent molecules vapor was carried into the reaction region via the carrier gas to form reagent ions. The reagent molecular ions produced by the reagent molecules that have been ionized in the 63Ni ionization source reacted with the analytes that entered the IMS reaction region after being thermally decomposed and vaporized by a thermal desorber to form product ions. Under the action of ion gate pulses, product ions entered the IMS mobility region and drifted and were detected by the detector. The air was dried by a molecular sieve and activated carbon and acted as carrier gas and drift gas [20], with its flow rate set to 200 mL / min.

A miniaturized rectilinear ion trap mass spectrometer (RIT-MS) developed by the laboratory [21], combined with a 63Ni ionization source and a thermal desorber, was used for the identification of PAEs product ions. A mass spectrometer using a rectilinear ion trap as an analyzer was composed of two pairs of orthogonal electrodes (on the x and y axes) and a pair of z-axis electrodes. The gaseous sample molecules that had been thermally resolved by the sample thermal desorber were purged with 500 mL / min carrier gas (purified air) and ionized in a 63Ni ion source. The ions to be measured entered the RIT-MS through a stainless-steel capillary tube with an inner diameter of 0.5 mm. By scanning the amplitude of the high-frequency voltage, the ions enclosed in the ion trap exited the trap in order from small to large as per m/z, which were detected by a converted dynode electron multiplier detector (Model 397, Detector Technology, Inc., Palmer, MA).

Sample preparation and methods

Dimethyl phthalate (DMP), Diethyl Phthalate (DEP), Dibutyl phthalate (DBP), butyl benzyl phthalate Benzyl butyl phthalate (BBP) were all of the analytical grade and purchased from Kermel Chemicals CO. Ltd., Tianjin, China; PAE standard solutions of different concentrations were obtained by stepwise diluting the 100 ng / μL mother liquor; ammonia and the solvent used were analytical grade and purchased from Kermel Chemicals CO. Ltd., Tianjin, China. The actual samples (plastic packaging materials) involved in the experiment were purchased from supermarkets.

Concerning the sample pretreatment method of phthalate in the food plastic packaging materials [14], the simple sample pretreatment method of solvent extraction was developed. The plastic products were cleaned and dried and cut into 0.5 cm*0.5 cm fragments. The plastic samples of 0.5 g were accurately weighed and placed in test tubes. After analytical pure organic solvent (10 ml ethanol) was added, the test tubes were ultrasonic extracted with 10 min. Finally, 5 μl extract could be directly used for detection and analysis.

Sample detection

The analytical process of detecting PAEs using the ion mobility spectrometer is as follows: first, the sample solution with injected 5 μL was placed in the middle of the preceding of a sampling swipe, which made of PTFE could endure high temperature, and then inserted into the opening of the thermal desorption chamber after the solvent was vaporized. The most maximum intensity plot of peak height of interested the (product ions peak) PIP was determined as the characteristic intensity. PAE-containing samples were quickly gasified by a built-in thermal analyzer, and the temperature of the thermal analysis was controllable. The sample gas obtained by the thermal analysis was carried by the carrier gas into the ionization region of the ion mobility spectrometer. The sample was ionized into positive ions in the ionization region and detected according to the difference in mobility. The drift time was found for the most intense peak at the peak maximum. The IMS spectrum was recorded after averaged 20 times.

Reduced mobility calculation method

The calculation of the reduced mobility (K0) of the unknown peak was derived from the reduced mobility of the known standard substance [22]:

In the above formula, tdstandard: the mobility time of the standard substance; K0standard: the reduced mobility of the standard substance; tdunknown refers to the mobility time of the ions of the sample to be analyzed. Dimethyl methylphosphonate (DMMP) was used as the standard substance with K0 of 1.40 cm2V−1 s−1 in positive ion detection mode.

Results and discussion

Effects of instrument parameters on PAE detection

Mobility tube temperature

In the paper, the effects of mobility tube temperatures (60, 80, 100, 120, and 140 °C) on the response strength of four typical methyl phthalates were examined, as shown in Fig. 2. As the temperature of the mobility tube increased from 60 °C to 100 °C, the mobility time of the characteristic ion peaks of the four types of PAEs showed a decreasing trend, that is, the mobility gradually increased, while the sensitivity improved correspondingly, presenting as an increase in the product ions peak (PIP) intensity. However, higher temperatures of the mobility tube are not necessarily beneficial. Taking into account the heat resistance, air tightness, and working stability of the mobility tube materials, we took 120 °C as the optimal temperature for the mobility tube.

Electric field intensity in the mobility region

The electric field intensity of the mobility tube was optimized under the conditions of the mobility tube temperature of 120 °C and the sample thermal desorber temperature of 180 °C. In the paper, effects of different electric field intensities (180, 200, 220, 240 V/cm) on the response intensities of four typical PAEs were investigated, as shown in Fig. 3. It can be seen that as the electric field intensity increases, the peak height of the characteristic ion peak of PAEs increases accordingly. Considering the effects of signal intensity and resolution, PAE compounds were determined under the electric field intensity of 240 V/cm.

Dynamic response characteristics of PAE

Figure 4 shows the ion mobility spectra of four types of PAE compounds under the conditions of 120 °C mobility tube temperature, 240 V / cm electric field intensity, and 180 °C sample desorber temperature. With 1.20 ppm ammonia as dopant molecules added in the drift gas, the reduced mobilities K0 for DMP, DEP, DBP, and BBP were 1.60, 1.44, 1.19, and 1.12 cm2V−1 s−1, respectively. As the molecular weight increased, the mobility time of PAE compounds also increased. This method can effectively identify different types of PAE compounds.

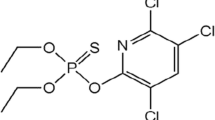

In addition, the paper also analyzed the microscopic process of the ion reaction after the addition of ammonia reagent molecules using mass spectrometry. Figure 5 shows the mass spectra of six types of PAEs in the 63Ni ion source formed in the air where ammonia was added. It can be seen that the positive ions of the products of DMP, DEP, DBP, BBP are mainly composed of [M + H]+, and the corresponding mass-to-charge ratios (M/z) are 195, 223, 279, and 313, respectively. Among them, a peak at M/z = 163 was also found in DMP, corresponding to [M − O2]+; DEP had a peak at M / z = 177, corresponding to [M − COOH]+. At the same time, a peak at M/z = 279 was found in BBP, which might cause ion collisions and chain scission to produce fragment ions with the same mass-to-charge ratio as DBP. Compared with the traditional GC-MS [15] test results, PAE ionization in GC-MS mostly generated fragment ions. For example, DEP and DBP both used M/z = 149 as the quantitative ions. In the paper, by using ammonia as the reagent molecules, the characteristic ions obtained by detecting PAE in 63Ni − IMS were all protonated molecular ion peaks ([M + H]+). This characteristic helps improve the recognition accuracy of various types of PAEs, and the addition of reagent molecules also avoids the interference from impurity peaks.

Quantitative curves

Under the above optimized conditions, Fig. 6 (a) shows the positive ion mobility spectrum of 0.1–20 ng DMP measured with ammonia as the reagent molecules. Figure 6 (b) shows the curve of the relationship between the response intensities of four types of PAEs (DMP, DEP, DBP, and BBP) and their mass (ng). The results of the quantitative analysis of the four types of PAE are summarized in Table 2.

Detection of PAE in plastic packaging

In terms of packaging of foods and daily chemicals, PAEs are particularly used as plasticizers for soft plastics and various types of plastic boxes and plastic bags contain PAEs. Therefore, it is of great significance to quickly and accurately monitor the dissolution and mobility of PAEs in actual samples.

Using methanol as the solvent, the method established above was used for the rapid detection of PAE in plastic packaging. Figure 7 shows the ion mobility spectra of PAE dissolved in plastic packaging materials (1 # —7 #). It can be observed from the figure that with methanol as the extractant, IMS pairs 4 # − 6 # plastic packaging (4 # polyethylene—fresh film, 5 # polypropylene—disposable spoon, 6 # polystyrene—fast food box), there were multiple small peaks on the mobility spectrum for detected ions, and the peak shapes of PAE were not obvious, which indicates that there are more impurities dissolved in these types of plastic products, which interfered with the detection of PAEs. The detection methods for these types of plastics need to be further optimized. In the remaining plastic packaging samples, we can clearly observe the corresponding product ion peaks of PAE.

Using the existing quantitative standard curve, we could calculate the dissolved DMP concentration of 1 # PET− mineral water bottle was about 4 mg/kg; 2 # HDPE− the dissolved DBP concentration of chewing gum bottle was about 0.4 mg / kg; 3 # PVC− the concentration of DEP dissolved out in wire sheath was about 2.4 mg / kg, and the concentration of DBP dissolved out was about 35 mg/kg. The content PAE in these plastic packaging materials are all lower than the national standard of 0.1%, and they are initially identified as qualified products.

Conclusions

The paper establishes a method for rapid screening of PAE substances based on ion mobility spectrometry. The paper examines the detection limits, linear ranges, repeatability, and the like of four typical trace (ng-level) PAE contaminants and use this method for rapid analysis of cosmetics. The method is simple to operate and responds quickly, which lays a theoretical and experimental basis for the research and development of trace PAE detection instruments. In future work, it may be combined with the sample pre-enrichment (solid phase microextraction, etc.) technique at the same time, and it is expected to play an important role in environmental analyses and online analyses of food safety.

References

Suzuki Y, Niwa M, Yoshinaga J, Mizumoto Y (2010) Prenatal exposure to phthalate esters and PAHs and birth outcomes. Environ Int 36(7):699–704

Suzuki Y, Niwa M, Yoshinaga J, Watanabe C (2009) Exposure assessment of phthalate esters in Japanese pregnant women by using urinary metabolite analysis environ. Health Prev Med 14(3):180–187

Karpas,Zeev(2013) Applications of ion mobility spectrometry (IMS) in the field of foodomics. Food Res Int 54(1): 1146–1151

Fischer CJ, Graz MB, Muehlethaler V, Palmero D, Tolsa JF (2013) Phthalates in the NICU: is it safe? Aust Paediatr J 49(9):E413–E419

Heudorf U, Mersch-Sundermann V, Angerer E (2007) Phthalates: toxicology and exposure Int. J Hyg Environ Health 210(5):623–634

Du L (2016) P, Ma L J, Qiao Y, Lu Y, Xiao D G. Food Chem 197:1200–1206

Yan HY, Liu BM, Du JJ, Row KH (2010) Simultaneous determination of four phthalate esters in bottled water using ultrasound-assisted dispersive liquid-liquid microextraction followed by. GC-FID detection Analyst 135(10):2585–2590

Manz C, Pagel K (2018) Glycan analysis by ion mobility-mass spectrometry and gas-phase spectroscopy. Curr Opin Chem Biol 42:16–24

Ebrahim K, Poursafa P, Amin MM (2017) Development of a simple and valid method for the trace determination of phthalate esters in human plasma using dispersive liquid–liquid microex-traction coupled with gas chromatography–mass spectrometry. J Sep Sci 40(22):4403–4410

BS EN l5777:2009. Textiles-Test Method for Phthalates[S]. European Committee for Standardization, Brussels

CPSC-CH-C1001–09. Standard Operating Procedure for Determination of Phthalates[Z]. United States Consumer Product Safety Commission Directorate for Laboratory Sciences Division of Chemistry

CPSC-CH-C1001–09.2. Standard Operating Procedure for Determination of Phthalates[Z]. United States Consumer Product Safety Commission Directorate for Laboratory Sciences Division of Chemistry

GB/T 22931–2008. Leather and Fur—Chemical Tests—Determination of Plasticizers. National Standards of the People's Republic of China

GB/T 21928–2008. Determination of Phthalate Esters in Food Plastic Packaging Materials. National Standards of the People's Republic of China

Villeneuve J, Chaussidon M, Marrocchi Y, Deng ZB, Watson EB (2019) High-precision in situ silicon isotopic analyses by multi-collector secondary ion mass spectrometry in olivine and low-calcium pyroxene. Rapid Commun Mass Spectrom 33(20):1589–1597

Parchami R, Tabrizchi M, Shahraki H (2020) Rapid analysis of lithium in serum samples by thermal ionization ion mobility spectrometry. Int J Ion Mobil Spec. https://doi.org/10.1007/s12127-020-00264-1

Fowler PE, Tarassov A, Lee G, Pasupuleti D, Ray A, Eiceman GA (2020) Stable compensation voltages in differential mobility spectra by separating neutral vapors from ions in sample flow. Int. J. Ion Mobil. Spec. 23(1):9–17

Mirzaei F, Fakhari AR, Hashemzadeh A, Amini MM (2020) Sensitive determination of ketamine, methylphenidate, and tramadol in urine and wastewater samples by porous aromatic Framework-48 assisted electromembrane extraction coupled with ion mobility spectrometer. Int. J. Ion Mobil. Spec. 23(1):29–37

Puton J, Nousiainen M, Sillanpaa M (2008) Ion mobility spectrometers with doped gases. Talanta 76(5):978–987

Liang X, Wang X, Wang W, Zhou Q (2014) Sensitive detection of black powder by stand-alone ion mobility spectrometer with chlorinated hydrocarbon modifiers in drift gas. Talanta 121:215–219

Liang X, Zhou Q, Wang W, Wang X (2013) Sensitive detection of black powder by a stand-alone ion mobility spectrometer with an embedded titration region. Anal Chem 2013(85):4849–4852

Chernyshev DM, Frolov IS, Frolov AS, Mukhanov MS, Sysoev AA (2011) Measurements of reduced mobility of standard compounds by high resolving power ion mobility spectrometer in remote laboratories. J. Anal. Chem. 66(13):1253–1257

Acknowledgments

This work is supported by Doctoral Start-up Foundation of Liaoning Province (CN) (Grant 20170520231).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liao, S., Liang, X. Rapid measurement of Phthalic acid Ester environmental hormones using ion mobility spectrometry. Int. J. Ion Mobil. Spec. 23, 97–103 (2020). https://doi.org/10.1007/s12127-020-00268-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12127-020-00268-x