Abstract

This paper analyses the trends in energy consumption and CO2 emissions as a result of energy efficiency improvements in Swedish manufacturing industries between 1993 and 2008. Using data at the two-digit level, the performance of this sector is studied in terms of CO2 emissions, energy consumption, energy efficiency measured as energy intensity, value of production, fuel sources, energy prices and energy taxes. It was found that energy consumption, energy intensity and CO2 emission intensity, measured as production values, have decreased significantly in the Swedish manufacturing industries during the period studied. The results of the decomposition analysis show that output growth has not required higher energy consumption, leading to a reduction in both energy and CO2 emission intensities. The role of structural changes has been minor, and the trends of energy efficiency and CO2 emissions have been similar during the sample period. A stochastic frontier model was used to determine possible factors that may have influenced these trends. The results demonstrate that high energy prices, energy taxes, investments and electricity consumption have influenced the reduction of energy and CO2 emission intensities, indicating that Sweden has applied an adequate and effective energy policy. The study confirms that it is possible to achieve economic growth and sustainable development whilst also reducing the pressure on resources and energy consumption and promoting the shift towards a low-carbon economy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Energy is an important factor in the production of goods and services, and socioeconomic development in general. As a result, the levels of energy consumption, especially electricity, have been often used as indicators of progress and economic development. More recently, increasing awareness about the impacts of energy harnessing and use, as well as the scarcity of resources, has led to efforts to reduce energy dependency and shift economies towards low-carbon options. Many of these efforts are translated into energy policies to motivate and accelerate changes in the patterns of energy generation and use—an important move towards sustainability. This includes major efforts to increase energy efficiency in industries and other sectors of the economy.

Energy efficiency improvements are expected to reduce demand and, consequently, the need for new investments in energy infrastructure. In addition, it will help reduce energy factors in production, and minimize environmental impacts, whilst also guaranteeing continued welfare improvements. However, several researchers have demonstrated that increased energy efficiency has led to increased productivity and economic growth, but not necessarily to a reduction of energy consumption, because energy efficiency only plays a limited role in determining total energy consumption (Smil 2005; IEA 2008a, b; Tsao et al. 2010). In other words, an industry may save energy, but this does not necessarily help reduce total energy consumption because increased energy efficiency improvements may occur simultaneously with increased production, which, in turn, leads to an increase in the total energy consumption. This so-called rebound effect has been discussed by Bentzen (2004) and Allan et al. (2007) in the context of manufacturing industries; Schipper and Groub (2000) and Sorrell (2007) regarding the link between energy consumption and economic growth; and Dimitropoulos (2007) and Schettkat (2009) in relation to economic theory, among others.

Studies on energy efficiency in industries have mainly focused on energy-intensive sectors and, in particular, on the specific effects of energy policy, new technologies or energy prices on energy efficiency variations and improvements. Different methods of analysis have been used, including decomposition analysis and econometric models. Decomposition analysis has been applied in studies on energy demand and gas emissions using several methods as Laspeyres and logarithmic mean Divisia methods.Footnote 1 In studies on energy demand, e.g. Reddy and Ray (2010), in the context of Indian manufacturing industries, showed that improvements in energy efficiency are achieved mainly by structural changes; Weber (2009), in the USA, found that improvements in energy efficiency were caused mainly by structural changes in the economy; and Unander (2007), in manufacturing industries of ten IEA countries, showed that structural changes have determined shifts in energy use and efficiency. In studies on gas emissions, e.g. Diakoulaki and Mandaraka (2007) studied EU manufacturing industries finding relevant progress in decoupling the growth of manufacturing industries and carbon emissions; Bhattacharyya and Matsumura (2010) analysed the reduction in greenhouse gas emissions in 15 countries of the European Union finding that emission intensity has reduced significantly due mainly to changes in the energy mix and a reduction in energy intensity, and Sheinbaum et al. (2010) examined energy-related CO2 emissions in Latin America, demonstrating that the reduction of CO2 emissions in these countries has not been significant due to an increased dependence on fossil fuels in their energy mix. The Laspeyres method has been applied by Taylor et al. (2010) in IEA countries, demonstrating that energy efficiency has played a role in shaping trends in final energy use, and Cahill and Gallachoir (2010) monitored energy efficiency trends in European industry using this method, among other studies. The logarithmic mean Divisia method has been applied by, among others, Lee and Oh (2006) in APEC countries to analyse CO2 emissions, finding that efficiency gains in energy and fuel substitution contributed to decreased CO2 emissions, and Hammond and Norman (2011) in UK manufacturing who studied energy-related carbon emissions and demonstrated that the decrease in emissions was caused by a reduction in energy intensity studies.

Econometric models have been applied using various concepts, including production functions, energy demand models or general equilibrium analysis. Pardo Martinez (2010) studied the effects of investments on energy efficiency in Colombian manufacturing industries, demonstrating the positive relationship of these two variables. Sands and Schumacher (2009) used a computable general equilibrium model, which indicated that improvements in energy efficiency contribute to reduced CO2 emissions. Wei (2007) applied the Cobb–Douglas production function and found that higher energy efficiency leads to expanded production and also higher energy consumption, and measures encouraging energy use efficiency are better than those encouraging energy production efficiency if the aim is to limit total energy use.

However, despite the valuable contributions of previous studies, the effects of energy efficiency on energy consumption and CO2 emissions in Swedish manufacturing industries have not been analysed. To improve energy policies aimed at increasing energy efficiency and reducing greenhouse gas emissions in industry, better understanding is needed about the patterns of energy use, energy efficiency and CO2 emissions, and the factors that determine trends in the various industries. To perform such an analysis, we need, on the one hand, detailed data at various aggregation levels and the application of models and methods that can generate reliable and consistent information to support policy design (IEA 2008a, b). On the other hand, it is also important to understand the nature of the industry and its transformation over time. Many industries are global in nature, so national analysis needs to be complemented with an overall analysis of the global trends within each specific industry so that energy efficiency improvements can be pursued globally over the medium and long terms. This study is limited to manufacturing industries in the Swedish context and can be seen as a starting point for broader analysis.

In the Swedish context, studies on energy efficiency and CO2 emissions have included several topics. (1) Decomposition analyses of energy consumption and CO2 emissions have showed that fuel substitution, improvement and transformation of the energy system and processes, as well as changes in consumption patterns, have led to the reduction of CO2 emissions (Löfgren and Muller 2010; Kander and Lindmark 2006). (2) Studies on the relationship between investments, CO2 emissions and energy efficiency have demonstrated that CO2 emissions and energy efficiency have influenced investment decisions. Energy price levels and research and development expenditures determine the investment size in this field. These studies identified the need for adequate and reliable methods to support the decision-making process (Sandberg and Söderström 2003; Svensson and Berntsson 2010; Hammar and Löfgren 2010). (3) Analyses of the effects of energy policies on improvements in energy efficiency identified several effective strategies to enhance energy efficiency, including energy prices, carbon and energy taxes, voluntary agreements, the application of energy management systems, audits and incentives for emissions reductions through fuel substitution (Johansson 2006; Henriksson and Söderholm 2009; Linden and Carlsson-Kanyama 2002). Other studies have analysed the barriers to the implementation of energy efficiency measures and the effects of some energy programmes on small and medium enterprises (Rohdin and Thollander 2006; Thollander et al. 2007; Thollander and Dotzauer 2010). However, these studies have not included an analysis of the specific effects of energy efficiency improvements on energy consumption and CO2 emissions over time, nor have they used empirical analysis to evaluate other variables such as energy prices and taxes, kind of fuels and investments with their respective trends. The main contribution of this study is the analysis of the role of energy efficiency on energy use and CO2 emissions using a decomposition analysis and a production frontier model to determine the impact of various instruments of energy policy used in the Swedish manufacturing industries. Moreover, this study is supported by the importance that is placed on improvements in energy use and the reduction of greenhouse emissions where energy efficiency has become a crucial strategy for sustainable economic development and climate stabilisation today and in the near future to migrate towards a low-carbon economy.

The objective of this paper was to study and analyse the effects of energy efficiency improvements and other variables on energy consumption and CO2 emissions in Swedish manufacturing industries. For that, we use decomposition analysis and a production frontier model, as explained in detail in “Methodology and data analyses”. “The Swedish manufacturing industries—features and trends” provides an overview of Swedish manufacturing industries. “Energy intensity and CO2 emission intensity in Swedish manufacturing industries” describes the trends in energy intensity and CO2 emission intensity in Swedish manufacturing industries. “Results and discussion” presents and discusses the results, and “Conclusions” closes with the major conclusions.

Methodology and data analyses

Decomposition analysis

The first method used in this study is decomposition analysis at the manufacturing industry level to estimate and evaluate energy use and CO2 emissions. This method examines several factors such as the activity, structure and intensity which influence trends in energy consumption, energy intensity and CO2 emissions with respect to the production value. Moreover, the concept of energy from “efficiency” has the following perspectives, according to Thomas (2009): In the macroeconomic aggregated perspective, energy efficiency is either denoted as energy intensity (energy input is related to monetary output parameters) or reciprocally as energy productivity (the ratio of production is related to energy consumed); the efficiency of energy conversion (the ratio of generated end-use energy to primary energy or to secondary energy used); and the energy end-use efficiency (the proportion of amount of energy used for the satisfaction of personal needs and energy use for non-personal demands). In this study, we used the concept of energy intensity.Footnote 2

The decomposition analysis involves the division and decomposition of energy and emissions in explanatory variables from the aggregate data. Ang and Zhang (2000) described various methodologies for applying this technique. We selected the multiplicative log-mean Divisia method explained by Ang and Liu (2001), which allows an adequate decomposition at different levels of aggregation. This method is used to determine the effects of structural change in manufacturing production on the total energy consumption. It also allows the identification of the various causes of changes observed in energy use within the manufacturing industries.

In this study, the relative changes are explained using the log percentage change (Ln%) instead of ordinary percentages because this last method has asymmetric and non-additive properties. Following the method of Tornqvist and Vartia (1985), where the relative changes of two numbers x and y are described as Ln% = Ln(y/x) × 100 = [(y − x)/Ln(y,x)] × 100, signifying that the log difference is literally a relative difference with respect to the logarithm mean. Ln% is symmetric,Footnote 3 additiveFootnote 4 and normed, which is desirable for assessing relative changes.

Three indicators have been used in this study: (1) energy intensity, (2) energy consumption and (3) CO 2 emissions. These indicators are applied using the equations below where (1) and (2) follow Ang and Zhang (2000) and (3) follows Ausubel (1995) and Lise (2006).

-

1.

Energy intensity: the total change in aggregate energy intensity (EIagg) is decomposed into a structural effect (F str) that is associated with the manufacturing industrial composition of the sector and an intensity effect (F int) that is related to changes in the sector’s energy intensity.

$$ {{\text EI}_{{agg}}} = \sum\nolimits_i {{S_{{i,t}}} \times E{I_{{i,t}}}} $$(1)- EI agg :

-

Aggregate energy intensity

- S i,t :

-

Production share of sector i in year t (=Y i,t /Y t )

- EI it :

-

Energy intensity of sector i in year t (=) E i,t /Y i,t

- E i,t :

-

Energy consumption of sector i in year t

- Y i,t :

-

Unit of activity or production of sector i in year t

- Y t :

-

Total manufacturing industrial production in year t

$$ {F_{{totEI}}} = {{\text EI}_t}/{{\text EI}_0} = {F_{{str}}} \times {F_{{int}}} $$(2)- F totEI :

-

Total change in aggregate energy intensity

- F str :

-

Structural effects

- F int :

-

Intensity effects

$$ {F_{{str}}} = \exp \left\{ {\sum\nolimits_i {\frac{{{\text Ln} \left( {{\omega_{{i,t}}}{\omega_{{i,0}}}} \right)}}{{\sum\nolimits_i {{\text Ln} \left( {{\omega_{{i,t}}}{\omega_{{i,0}}}} \right)} }}} 1{\text{n}}\left( {\frac{{{S_{{i,t}}}}}{{{S_{{i,0}}}}}} \right)} \right\} $$(3)$$ {F_{{str}}} = \exp \left\{ {\sum\nolimits_i {\frac{{{\text Ln} \left( {{\omega_{{i,t}}}{\omega_{{i,0}}}} \right)}}{{\sum\nolimits_i {{\text Ln} \left( {{\omega_{{i,t}}}{\omega_{{i,0}}}} \right)} }}} 1{\text{n}}\left( {\frac{{{{{\text EI} }_{{i,t}}}}}{{{{{\text EI} }_{{i,0}}}}}} \right)} \right\} $$(4)- ω i :

-

Energy share of sector i in year t (=E i,t /E t )

- E t :

-

Total energy consumption in year t

- t :

-

0, the base year (1993)

where Ln(x, y) = (y − x)/1ny/x

-

2.

Energy consumption (EC): this explains the change in energy use in absolute terms based on the inclusion of a production effect (F pdn) that is related to changes in the production levels in the entire industrial sector.

$$ {E_t} = \sum\nolimits_i {Y \times {S_i} \times {{{\text EI} }_i}} $$(5)$$ {F_{{totEC}}} = {E_t}/{E_0} = {F_{{pdn}}} \times {F_{{str}}} \times {F_{{int}}} $$(6)$$ {F_{{{\text pdn} }}} = \exp \left\{ {\sum\nolimits_i {\frac{{{\text Ln} \left( {{\omega_{{i,t}}},{\omega_{{i,0}}}} \right)}}{{\sum\nolimits_i {{\text Ln} \left( {{\omega_{{i,t}}},{\omega_{{i,0}}}} \right)} }}} 1{\text{n}}\left( {\frac{{{Y_t}}}{{{Y_0}}}} \right)} \right\} $$(7)- F pdn :

-

Production effects

- F totEC :

-

Total change in aggregate energy consumption

-

3.

CO 2 emission intensity: this explains changes in the level of CO2 emissions through three factors: activity, structure and intensity.

$$ {{\text COI}_{{agg}}} = \sum {_i{S_{{i,t}}} \times {{{\text COI} }_{{i,t}}}} $$(8)- COIagg :

-

Aggregate CO2 emission intensity

- COI i,t :

-

CO2 emission intensity of sector i in year t (=CO i,t /Y i,t )

- CO i,t :

-

CO2 emissions of sector i in year t

- TCtot :

-

\( \frac{{{\text{CO}}{{\text{I}}_t}}}{{{\text{CO}}{{\text{I}}_0}}} = {F_{{pdn}}} \times {F_{{str}}} \times {F_{{int}}} \)

- TCtot :

-

Total change aggregate CO2 emission intensity

$$ {F_{{str}}} = \exp \left\{ {\sum {_i\frac{{{\text Ln} \left( {{\psi_{{i,t}}},{\psi_{{i,0}}}} \right)}}{{\sum {_i{\text Ln} \left( {{\psi_{{i,t}}},{\psi_{{i,0}}}} \right)} }}\ln \left( {\frac{{{S_{{i,t}}}}}{{{S_{{i,0}}}}}} \right)} } \right\} $$(9)$$ {F_{{int}}} = \exp \left\{ {\sum {_i\frac{{{\text Ln} \left( {{\psi_{{i,t}}},{\psi_{{i,0}}}} \right)}}{{\sum {_i{\text Ln} \left( {{\psi_{{i,t}}},{\psi_{{i,0}}}} \right)} }}\ln \left( {\frac{{{{{\text COI} }_{{i,t}}}}}{{{{{\text COI} }_{{i,0}}}}}} \right)} } \right\} $$(10)- ψ i :

-

CO2 emissions share of sector i in year t (=COI i,t /CO t )

- CO i,t :

-

CO2 emissions associated to the energy consumption of sector i in year t

- CO t :

-

Total CO2 emissions in year t

Econometric model

The second method in this study follows the works of Stern (2010) and Greene (2011). The selected econometric model is a production frontier model estimated for the period 1993–2008 using a set of data at the two-digit level of statistical aggregation for the Swedish manufacturing industry (ISEC 15-36).Footnote 5 This model describes the variations in energy intensity and CO2 emission intensity across Swedish manufacturing industries based on the levels of capital, labour and a residual term, u, that characterises the state of energy efficiency determined by a manufacturing industry according to its technology level. These values are estimated using a panel data stochastic frontier model developed by Battese and Coelli (1992, 1995) in which the effects of the variables on energy intensity and CO2 emission intensity are the opposite of their effects on the distance of frontier. The models for energy intensity and CO2 emission intensity are as follows:

Note that α, δ, β are the regression-type coefficients estimated with the maximum likelihood technique that makes distributional assumptions of u it and v it (Kumbhakar and Lovell 2000; Hadri et al. 2003). Y is the gross production in euros; E is the final energy consumption, CO is dioxide carbon emissions, K is the capital stock of the industries, L is the employment level in the industries, FF and Ele are fossil fuel and electricity consumption, respectively, and INV is the investments for every manufacturing industry i in each year t.

In Eqs. 11 and 12, E it /Y it Footnote 6 and CO it /Y it are the dependent variables (Y is measured as the production value). From the estimation, we define the algebraic signs of the coefficients which are determined for every variable whether there is a positive or negative effect on energy efficiency and CO2 emission intensity. In other words, the positive sign indicates direct influence (e.g. the most capital-intensive sectors are also the more energy-intensive) and the negative sign reflects inverse influence (e.g. sectors with high investments are expected to be low energy-intensive).

v is a normally distributed random error term supposed to characterise the measurement error. u is the state of energy efficiency in manufacturing industry i. The logarithm of u is a random variable that can only take non-negative values which is modelled as the non-negative part of a normal distribution with mean Γ′z i . z i is a vector of the following additional variables that explain the differences in energy efficiency and CO2 emission intensity across Swedish manufacturing industries: lnEP is the log of energy prices and lnCO2tax and lnEtax the log of the CO2 emission tax expenditures and the log of the energy tax expenditures for every manufacturing industry i in each year t, respectively.

Following Stern and Jotzo (2010), the total factor of productivity in each year in every Swedish manufacturing industry can be calculated as follows. A residual series is computed according to

where the measurement error, v i , is estimated via the maximum likelihood procedure.

Data analyses

Data necessary to conduct the econometric analysis were provided by SCB (Statistics Sweden) through the Swedish Environmental Accounts and Statistical database. These organisations use data at two-digit levels of disaggregation according to the International Standard Economic Classification (ISEC Rev. 3.1). ISEC defines the manufacturing sector as an agglomeration of units engaged in the physical or chemical transformation of materials, substances or components into new products. The specific sectors for Sweden, retrieved from Statistics Sweden, are listed in the Appendix. All monetary data were converted to 2000 euro values. The time period selected in this analysis was determined by the availability of detailed data for the intersectoral Swedish manufacturing industries over the period 1993–2008. The data used in this study are as follows:

-

Y is the output measured as gross production in euros. Several studies have indicated that the production value is a better reference than the value added for energy intensity analysis. When used as the output measure, the value added tends to exaggerate changes in efficiency and is, thus, relatively more vulnerable to economic change than the production value (Freeman et al. 1997; Pardo Martinez 2009).

-

E is energy measured as the final energy consumption in terajoules.

-

CO is dioxide carbon emissions measured as tonnes of CO2total.

-

K is the capital stock of the industries in euros.

-

L is the employment level in every Swedish manufacturing industry.

-

FF is the consumption of fossil fuels measured in terajoules. We expected that a higher consumption of fossil fuels generates higher energy intensity and CO2 emission intensity.

-

Ele is the electricity consumption measured in terajoules. We would expect a higher electricity consumption to be associated with more energy efficiency.

-

INV is the investments measured in euros. We would expect higher investments to associate positively with energy efficiency.

-

EP is the energy prices measured in euros. We would expect a direct relationship between energy prices and the energy price because higher energy prices, for example, ought to encourage more rapid adoption of energy-saving technologies and thus lead to faster energy efficiency growth (Worrel and Galitsky 2008).

-

E tax and CO2 tax are the energy and CO2 emission tax expenditures measured in euros, respectively. We would expect higher values of these variables to associate positively with energy efficiency.

The Swedish manufacturing industries—features and trends

Swedish manufacturing industries are recognised worldwide as the most automated ones. They have also gone through a transformation from traditional, labour-intensive industries to a knowledge-based service industry generating sustained economic growth with a wide range of developments in technology, research and development, clean production and innovation (Lundquist et al. 2008; Schön 2007).

In 2008, there were around 61681 manufacturing companies in Sweden, consuming approximately 1,485 PJ, or 45 % of the energy consumed by industrial activities in the country (Statistics Sweden). Swedish manufacturing industries represent 36 % of the total production value, 25 % of the total value added and 22 % of the total employment in the national economy. Figure 1 shows trends in energy consumption, CO2 emissions, production value, value added and employment in this segment of industries for the study period (1993–2008). Energy consumption and employment decreased by 1.5 and 0.7 %, respectively, whilst production value, value added and CO2 emissions increased by 82, 88 and 8 %, respectively, during the period. These results indicate that, whereas Swedish manufacturing industries have generally increased production, they have reduced energy consumption at the cost of some minor increase in CO2 emissions. This achievement demonstrates that it is possible to produce sustained economic growth whilst using less energy resources and controlling the amount of CO2 emissions, which is consistent with sustainable development.

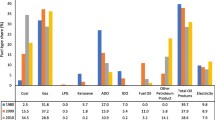

Figure 2 shows trends in energy consumption by the kind of fuel used by Swedish manufacturing industries such as electricity, fossil fuels and biofuels. Whereas electricity consumption increased, the use of other fuels decreased, summing up to a small reduction in the total energy consumption in these industries. In particular, there has been a shift away from fossil fuels in line with the shifts made in the structure of energy types used by the industry. This relates also to the move made in Sweden away from low efficiency or more polluting fuels such as coal and petroleum products to cleaner and more efficient fuels such as electricity and biofuels. This trend and consequent achievement is consistent with UNEP (1976) and Pardo Martinez’s (2011) analysis in the context of manufacturing industries. However, it should also be pointed out that inefficiencies have been moved to the supply side. Although the total Swedish energy consumption has remained rather unchanged since 1970, the total supply increased by 1.43 % per year on average as a result of the increasing use of nuclear power in the Swedish energy matrix.

Energy intensity and CO2 emission intensity in Swedish manufacturing industries

Energy intensity and CO2 emission intensity are defined as the energy used or CO2 emissions generated per unit of economic production, respectively. In this study, the production value is used to measure economic production and analyse trends in Swedish manufacturing industries. Figure 3 shows trends in energy intensity and CO2 emission intensity. Both indicators display the same tendencies. Energy intensity and CO2 emission intensity have decreased by 46 and 41 %, respectively, in relation to production values. In fact, all Swedish manufacturing industries have presented a downtrend of these indicators in the period analysed, especially after 2000.

Results and discussion

Results of the decomposition analysis

To estimate and analyse the trends in energy use and CO2 emissions in the Swedish manufacturing industries, we apply the multiplicative log-mean Divisia method I, as explained in the “Methodology and data analyses”. The results of the decomposition analysis are shown in Tables 1 and 2. Notice that a value of 1 indicates that the variable had no effect on the aggregate intensity, energy consumption or CO2 emissions. Values >1 indicate a contribution to greater aggregate intensity, energy consumption or CO2 emissions, whereas values lower than 1 imply an increase in energy efficiency and a decrease in CO2 emission intensity.

Results for the decomposition of energy intensity

Table 1 shows the results for the decomposition of aggregate energy intensity, electricity intensity and fossil fuel intensity, with production value as the economic measure of output in the Swedish manufacturing industries. The aggregate of energy intensity in manufacturing industries decreased considerably during the sample period. Structural changes and energy intensity effects show similar trends, indicating that both contributed to lower the aggregate energy intensity in the economy. When it comes to structural changes, the energy-intensive sectors decreased production at an average of 2 % during the sample period, whereas non-energy-intensive sectors increased production at an average of 6 %. Intensity effects dominated over structural effects, indicating that the decrease in aggregate energy intensity was primarily caused by a decrease in the intensity, which could be due to changes or improvements in technology.

Results for the decomposition of energy consumption

The results of the energy consumption analysing the aggregate energy intensity and production effects for energy, electricity and fossil fuel consumption are shown in Table 1. In the Swedish manufacturing industries, growth in production did not lead to increases in the aggregate energy intensity, indicating that this sector produced more with less energy. This is a sign that improvements in technology and production standards actually took place, which led to higher productivity and lower energy use in manufacturing industries. This is certainly a positive result for Sweden and indicates the efficiency of Swedish energy policies in pursuing sustainable development according to national, regional and global agenda.

The results also demonstrate that the decrease in fossil fuel consumption has improved energy efficiency and reduced energy consumption. This has been partly achieved through fuel substitution and a change in the mixture of fuels from inefficient, dirty or fossil fuels with high carbon content, such as coal and petroleum products, towards more efficient, clean or non-fossil fuels with low carbon content, such as natural gas and biomass. In addition, there has been an ambitious attempt to address sustainable development in a context of improved energy security, technological deployment and restructuring of energy markets in Sweden (Silveira 2001). Certainly, achieving adequate fuel substitution to reduce CO2 emissions and energy consumption, and economic growth at the same time, often requires shifts in relative economic conditions (fuel prices), technological innovation (with adequate competitiveness) and regulations to promote energy efficiency, clean production and markets for clean fuels (Hoeller and Wallin 1991; Steinbuks 2010; Pacini and Silveira 2010).

Results for the decomposition of the CO2 emissions

Table 2 depicts the results of decomposition analysis using the CO2 emissions indicator. The results are similar to those obtained from the two previous methods, indicating the close relationship between the improvements in energy efficiency and the reduction of CO2 emission intensity in the Swedish case. Also, these results are consistent with several studies that have identified energy efficiency as the most cost-effective way of improving energy use patterns and increasing both energy security and productivity whilst also achieving carbon emission reduction targets (Capros et al. 1998; Boyd and Pan 2000; UNF 2007).

The results of the decomposition analysis using this indicator show that the reduction in energy consumption has contributed to a lower aggregate CO2 intensity. Similarly, structural effect had a minor role in the reduction of CO2 emission intensity. These results highlight the fact that the Swedish manufacturing industry has increased its output whilst reducing energy consumption, maintaining its production structure and reducing the effects on climate change. Therefore, the results of the Swedish experience demonstrate that clean production paves the way to sustainable development.

Results of econometric model

Thus far, the results of the study show that the Swedish manufacturing industries have reduced their energy consumption by 1.5 % in a 16-year period (1993–2008) and that output growth has not required higher energy consumption. This led to a decrease in energy intensity and CO2 emission intensity. The trends of energy efficiency and CO2 emissions have been similar during the sample period. To understand the possible factors that have influenced these trends, we applied the production frontier model explained in “Econometric model”, where energy intensity and CO2 emission intensity are the dependent variables and the production factors, kinds of fuels, investments, energy prices and taxes are the independent variables (see Tables 3 and 4).

The energy intensity model

Table 3 shows the results of the stochastic frontier model for energy intensity. Capital and fossil fuel consumption have a significant positive influence on energy intensity, that is, in a context of increased amount of fixed assets and higher fossil fuel consumption, energy intensity increases. Electricity consumption, investments, total factor of productivity, energy prices, energy and CO2 taxes have a significant negative influence on energy intensity, indicating that increasing these variables serves as an incentive to lower energy intensity, thus leading to higher energy efficiency.

The results of the production factors indicate that Swedish manufacturing industries are more capital-intensive than labour-intensive, which demonstrates that the segment has developed and applied innovative technologies towards a greater level of automation. Changes from labour-intensive production to medium- and high-technology-intensive production can induce labour-saving technical progress and increased output. In fact, this has been observed in the context of medium- and high-technology industries in developed countries (Morrison and Siegel 2001; Yun 2008).

The results pertaining to the kinds of fuels demonstrate that increases in electricity consumption generate reduction in energy intensity, whereas decreases in fossil fuel consumption lead to higher energy efficiency in the Swedish manufacturing industries. The use of oil has decreased significantly in the last decades, in parallel with increased electricity consumption and achievements in energy efficiency. This inter-fuel substitution began with the oil price shocks of the 1970s, when governments and enterprises started searching for alternative fuels to reduce oil consumption and dependency. In 1970, the shares of oil and electricity consumption in Swedish industries were 48 and 21 %, respectively, whereas currently, the proportions are 12 and 36 %, respectively, indicating that oil has been replaced by other kinds of fuels such as electricity, gas, heat or biomass (Swedish Energy Agency 2009a).

The influence of investments on energy efficiency is positive, meaning that higher investments generate higher energy efficiency, or reduced energy intensity in the manufacturing industries. Currently, investments in energy efficiency and clean energy are triggered by regulatory requirements, on the one hand, and the need to increase productivity and reduce production costs, on the other hand (EPA 2007). The patterns of investments are, in fact, consistent with several programmes being implemented in Sweden to promote energy efficiency improvements. The Swedish long-term agreement programme for energy efficiency in energy-intensive industries (PFE), for example, includes standardised energy management systems, energy audits and identification of measures to reduce energy demand and intensity. It was launched in January 2005 and has become a successful voluntary programme. It has achieved an annual reduction of 2,909.33 TJ in energy use through the application of 872 measures and new investments made by companies (Ottosson and Petersson 2007; Stenqvist et al. 2009).

In addition, the investments in the manufacturing industries have been motivated by several subsidies, which have included payments from the Swedish government to producers aimed at shifting the kinds of fuels and improving energy use patterns. Figure 4 shows the trend in these subsidies between 2000 and 2008 and the relationship between subsidies, energy intensity and energy consumption in the Swedish manufacturing industry. As shown here, there is close relationship between investments on technology and the improvements achieved in energy use patterns. A joint effort of the stakeholders, especially in the industrial sector and the government, has led to reduced energy consumption and increased energy efficiency through the application of adequate top-down and bottom-up instruments with a sustainable development approach.

Energy prices have a significant negative coefficient, indicating that higher energy prices promote energy efficiency and conservation. These results are consistent with energy price trends in Sweden where oil prices increased by 70 % on average between 2000 and 2008, and electricity prices for the industrial sector almost doubled during the same period (Swedish Energy Agency 2010). This strategy has apparently worked to promote energy efficiency. However, increases in energy prices are not sufficient to achieve energy efficiency. Therefore, it is important to simultaneously create policies to encourage industries to invest in energy efficiency technologies and incentive good practices in energy use so that they can save energy and reduce energy costs and environmental impacts whilst maintaining competitiveness (SME 2009; Henning and Trygg 2008; Johansson et al. 2007; Thollander et al. 2005, 2007).

Another factor analysed here was the energy and CO2 taxes, which have had a significant impact on energy intensity, demonstrated by substantial improvements in energy efficiency. Energy taxes have been used in Sweden both as a fiscal tax source and as a policy instrument to motivate and strengthen energy-saving actions. Taxes are also designed to favour low-carbon fuels.Footnote 7 These taxes have been integrated with a variety of instruments and mechanisms not only to ensure their effectiveness as energy and climate policy but also to maintain the competitiveness of the Swedish manufacturing industries. A permanent dialogue among all stakeholders has generated higher applicability and effectiveness of the measures for society (Fouquet and Johansson 2008; Price et al. 2008; Ptak 2010).

The CO2 emission intensity model

The results of the CO2 emission intensity study using the stochastic frontier model are shown in Table 4. The results are similar with respect to the previous model, which again demonstrates the close relationship between improvements in energy efficiency and the reduction of CO2 emission intensity. Labour, capital and fossil fuel consumption have a positive influence, and capital and fossil fuel consumption are significant on CO2 emission intensity, indicating that increasing these variables leads to a higher CO2 emission intensity. On the other hand, electricity consumption, investments, total factor of productivity, energy prices, energy taxes and CO2 taxes have a significant negative effect on CO2 emission intensity, indicating that increasing these variables leads to a lower CO2 emission intensity.

Capital and labour have a positive relationship with CO2 emission intensity, but only capital is significant, indicating that the most capital-intensive sectors are also the most CO2-intensive. These results concur with theory. More capital-intensive economies should be less energy- and carbon-intensive due to substitution between capital and energy (Koetse et al. 2008; Stern 2010).

The results of the kinds of fuels show that increases in electrical consumption and a decrease in fossil fuel consumption have led to a lower CO2 emission intensity. These results are consistent with increases in the consumption of renewable energy sources. However, Sweden has also made major investments and additions of power capacity from nuclear power, which largely explains why the rapid increase in electricity demand could take place without major increases in CO2 emissions. Whilst the results are consistent with long-term energy policies that prioritize low-carbon alternatives, the nuclear path is still a debatable question in Sweden and elsewhere when it comes to long-term sustainability (IEA 2008a, b; Swedish Energy Agency 2009b; IAEA 2009; Wolde-Rufael and Menyah 2010; WNA 2011).

Investments in Swedish manufacturing industries show that higher investments lead to lower CO2 emission intensity. Several programmes have motivated environmental investment in manufacturing industries, especially in energy-intensive industries. Among these programmes, we can mention the Climate Investment Programmes (KlimpFootnote 8) and the voluntary programme for energy efficiency in energy-intensive industries (Swedish Energy Agency 2009a). Furthermore, the Swedish government has offered increasing emission reduction subsidies (see Fig. 5). As a result of these efforts, investments in clean technologies have grown significantly, mainly in renewable electricity production, biofuels and techniques for increasing energy efficiency (Swedish Energy Agency 2009b). CO2 emissions and CO2 emission intensity have, in fact, decreased (see Fig. 5). This also demonstrates that an adequate energy and climate change policy requires both government support and the industrial sector to improve environmental performance and reduce carbon emissions, in line with increased productivity and economic growth.

Energy prices also have contributed to the reduced CO2 emission intensity in Sweden, suggesting that with high energy and carbon prices, CO2 emission intensity tends to fall. The trends in CO2 emissions are sensitive to the relative prices of energy. This means that when energy prices fall, the CO2 emission intensity tends to increase because there is less incentive to improve or invest in energy savings or low-carbon emission technologies and innovations (Bowen et al. 2009). For this reason, it is important to adopt an adequate energy price policy that encourages lower energy consumption and the use of clean and low-carbon technologies.

The application of energy and CO2 taxes has been effective at reducing CO2 emission intensity; according to empirical results, these two variables are statistically significant, leading to positive environmental effects. This demonstrates that higher energy taxation reduces CO2 emissions, improves efficient energy use, promotes renewable energy production and use, and provides incentives for sustainable development.

Conclusions

The results of the decomposition analysis showed a decrease in the aggregate energy intensity and the aggregate CO2 emission intensity, which was caused by a decrease of energy intensity and fuel substitution, whereas the role of structural changes has been minor. Moreover, the growth in production did not lead to increases in the aggregate energy intensity and CO2 emission intensity, indicating that this sector produced more with less energy consumption and fewer emissions.

The results of the stochastic frontier model for energy efficiency and CO2 emission intensity indicate that capital and fossil fuel consumption influence energy and CO2 emission intensities. Thus, the most capital-intensive sectors are also the most energy- and CO2-intensive. Higher fossil fuel consumption leads to increases in energy and CO2 emission intensities. Electricity consumption, investments, total factor of productivity, energy prices, and energy and CO2 taxes have a significant and negative influence on energy and CO2 emission intensities, implying that increasing these variables leads to lower energy intensity and higher energy efficiency. This phenomenon indicates that increased energy efficiency and decreased CO2 emission intensity can be achieved through changes in economic conditions (energy prices and taxes), incentives for investments in clean or low-carbon technologies and adequate energy policy instruments. However, despite important achievements in energy use and emission reductions in Swedish manufacturing industries, it is now important to also encourage energy efficiency in other industries, particularly the rapidly growing sectors in which energy consumption is increasing and could result in higher CO2 emissions in the medium and long terms. Future studies could also examine trends in energy and CO2 emissions in specific sectors and use physical indicator to determine how economic shocks and other factors influence the results of energy efficiency and decrease of CO2 emissions.

The Swedish experience offers relevant information for the formulation, development and strengthening of energy policies in manufacturing industries elsewhere. As shown, economic instruments (e.g. energy prices and energy taxes) and technical instruments have driven fuel substitution, investments in clean technologies and, consequently, substantial improvements in energy efficiency and reduction in CO2 emissions. These results demonstrate that it is possible to achieve economic growth and sustainable development through steady advancement towards a low-carbon economy.

Notes

For more details, see a survey of index decomposition analysis (Ang and Zhang 2000).

‘Energy intensity’ refers to the amount of energy used to obtain one unit of production, whereas ‘CO2 emission intensity’ is the amount of CO2 emissions generated to obtain one unit of production.

It is independent of the point which is taken as the point of comparison.

Successively relative changes can be added.

A list of the sectors is shown in the Appendix.

Energy efficiency is commonly defined as energy intensity, that is, the quantity of energy required per unit of output or activity. This definition implies that when the relationship between energy and production decreases over time, energy efficiency has improved.

According to the Swedish Ministry of the Environment, the total revenue from environment-related taxes and fees amounted to roughly 7 billion euros per year, with higher taxes on non-eco-friendly consumption, primarily energy and carbon dioxide (www.sweden.gov.se/sb/d/5400/a/43594).

References

Allan, G., Hanley, N., McGregor, P., Swales, K., & Turner, K. (2007). The impact of increased efficiency in the industrial use of energy: a computable general equilibrium analysis for the United Kingdom. Energy Economics, 29, 779–798.

Ang, B. W., & Liu, F. L. (2001). A new energy decomposition method: perfect in decomposition and consistent in aggregation. Energy, 26, 537–548.

Ang, B. W., & Zhang, F. Q. (2000). Survey of index decomposition analysis in energy and environmental studies. Energy, 25, 1149–1176.

Ausubel, J. (1995). Technical progress and climate change. Energy Policy, 23, 411–416.

Battese, G., & Coelli, T. (1992). Frontier production functions, technical efficiency and panel data: with application to paddy farmers in India. Journal of Econometrics, 38, 387–399.

Battese, G., & Coelli, T. (1995). A model for technical inefficiency effects in a stochastic frontier production function for panel data. Empirical Economics, 20, 325–332.

Bentzen, J. (2004). Estimating the rebound effect in US manufacturing energy consumption. Energy Economics, 26, 123–134.

Bhattacharyya, S., & Matsumura, W. (2010). Changes in the GHG emission intensity in EU-15: lessons from a decomposition analysis. Energy, 35, 3315–3322.

Bowen, A., Forster, P., Gouldson, A., Hubacek, K., Martin, R., O’Neill, D., Rap, A., & Rydge, J. (2009). The implications of the economic slowdown for greenhouse gas emissions and targets. Policy paper. Centre for Climate Change Economics and Policy. Retrieved from www.cccep.ac.uk/Publications/Policy/docs/PPBowenetc-economic-slowdown-emissions.pdf

Boyd, G., & Pan, J. (2000). Estimating the linkage between energy efficiency and productivity. Energy Policy, 28, 289–296.

Cahill, C., & Gallachoir, B. (2010). Monitoring energy efficiency trends in European industry: which top-down method should be used? Energy Policy, 38, 6910–6918.

Capros, P., Georgakopoulos, T., & Mantzos, L. (1998). Economic and energy system implications of European CO2 mitigation strategy for 2010: a model based analysis. International Journal of Environment and Pollution, 10(3–4), 403–427.

Diakoulaki, D., & Mandaraka, M. (2007). Decomposition analysis for assessing the progress in decoupling industrial growth from CO2 emissions in the EU manufacturing sector. Energy Economics, 29, 636–664.

Dimitropoulos, J. (2007). Energy productivity improvements and the rebound effect: an overview of the state of knowledge. Energy Policy, 35, 6354–6363.

Fouquet, D., & Johansson, T. (2008). European renewable energy policy at crossroads—focus on electricity support mechanisms. Energy Policy, 36, 4079–4092.

Freeman, S. L., Niefer, M. J., & Roop, J. M. (1997). Measuring industrial energy intensity: practical issues and problems. Energy Policy, 25, 703–714.

Greene, W. (2011). Econometric analysis. Pearson Education; global edition of the 7th revised edition.

Hadri, K., Guermat, C., & Whittaker, J. (2003). Estimation of technical inefficiency effects using panel data and doubly heteroscedastic stochastic production frontiers. Empirical Economics, 28, 203–222.

Hammar, H., & Löfgren, Å. (2010). Explaining adoption of end of pipe solutions and clean technologies—determinants of firms’ investments for reducing emissions to air in four sectors in Sweden. Energy Policy, 38, 3644–3651.

Hammond, G., & Norman, J. (2011). Decomposition analysis of energy-related carbon emissions from UK manufacturing. Energy. doi:10.1016/j.energy.2011.06.035.

Henning, D., & Trygg, L. (2008). Reduction of electricity use in Swedish industry and its impact on national power supply and European CO2 emissions. Energy Policy, 36, 2330–2350.

Henriksson, E., & Söderholm, P. (2009). The cost-effectiveness of voluntary energy efficiency programs. Energy for Sustainable Development, 13, 235–243.

Hoeller, P., & Wallin, M. (1991). Energy prices, taxes and carbon dioxide emissions. OECD Economic Studies No. 17. Retrieved http://www.oecd.org/dataoecd/33/26/34258255.pdf. Accessed 21 May 2011.

International Atomic Energy Agency (IAEA) (2009). Country nuclear power profiles: Sweden. Retrieved from http://www.oecd-nea.org/general/profiles/sweden-annex.html.

International Energy Agency (IEA) (2008a). Worldwide trends in energy use and efficiency. Key insights from IEA indicator analysis. Retrieved from http://www.iea.org/papers/2008/indicators_2008.pdf.

International Energy Agency (IEA) (2008b). Energy policies of IEA countries. Sweden 2008 review. Retrieved from http://www.iea.org/textbase/nppdf/free/2008/sweden2008.pdf.

Johansson, B. (2006). Climate policy instruments and industry—effects and potential responses in the Swedish context. Energy Policy, 34, 2344–2360.

Johansson, B., Modig, G., & Nilsson, L., (2007). Policy instruments and industrial responses—experiences from Sweden. Proceedings of the ECEEE Summer Study on Energy Efficiency. Panel 7. Making industries more energy efficient. Retrieved from www.eceee.org/conference_proceedings/ecee/2007/Panel_7/7.048/.

Kander, A., & Lindmark, M. (2006). Foreign trade and declining pollution in Sweden: a decomposition analysis of long-term structural and technological effects. Energy Policy, 34, 1590–1599.

Koetse, M., Groot, H., & Florax, R. (2008). Capital-energy substitution and shifts in factor demand: a meta-analysis. Energy Economics, 30, 2236–2251.

Kumbhakar, S. C., & Lovell, C. A. K. (2000). Stochastic frontier analysis. Cambridge, MA: Cambridge University Press.

Lee, K., & Oh, W. (2006). Analysis of CO2 emissions in APEC countries: a time-series and a cross-sectional decomposition using the log mean Divisia method. Energy Policy, 34, 2779–2787.

Linden, A., & Carlsson-Kanyama, A. (2002). Voluntary agreements—a measure for energy-efficiency in industry? Lessons from a Swedish programme. Energy Policy, 30, 897–905.

Lise, W. (2006). Decomposition of CO2 emissions over 1980–2003 in Turkey. Energy Policy, 34, 1841–1852.

Löfgren, Å., & Muller, A. (2010). Swedish CO2 emissions 1993–2006: an application of decomposition analysis and some methodological insights. Environmental and Resource Economics, 47, 221–239.

Lundquist, K., Olander, L., & Svensson-Henning, M. (2008). Decomposing the technology shift: evidence from the Swedish manufacturing sector. Journal of Economic and Social Geography, 99, 145–159.

Morrison, C., & Siegel, D. (2001). The impacts of technology, trade and outsourcing on employment andlabour composition. The Scandinavian Journal of Economics, 103, 241–264.

Ottosson, C., & Petersson, K. (2007). First results from the Swedish LTA programme for energy efficiency in industry. ECEEE 2007 Summer Study—Saving Energy—Just Do It! Retrieved from www.eceee.org/conference_proceedings/eceee/2007/Panel_7/7.209/.

Pacini, H., & Silveira, S. (2010). Ethanol or gasoline? Consumer choice in face of different fuel pricing systems in Brazil and Sweden. Biofuels, 1(5), 685–695.

Pardo Martinez, C. (2009). Energy efficiency developments in the manufacturing industries of Germany and Colombia, 1998–2005. Energy for Sustainable Development, 13, 189–201.

Pardo Martinez, C. (2010). Investments and energy efficiency in Colombian manufacturing industries. Energy and Environment, 21, 545–562.

Pardo Martinez, C. (2011). Energy efficiency development in German and Colombian non-energy-intensive sectors: a non-parametric analysis. Energy Efficiency, 4, 115–131.

Price, L., Galitsky, C., Kramer, K., & McKane, A. (2008). International experience with key program elements of industrial energy efficiency or greenhouse gas emissions reduction target-setting programs. Ernest Orlando Lawrence Berkeley National Laboratory. Environmental Energy. Technologies Division.LBNL-63807, REV. 1.

Ptak, M. (2010). Environmentally motivated energy taxes in Scandinavian countries. Economic and Environmental Studies, 10, 255–269.

Reddy, B., & Ray, B. (2010). Decomposition of energy consumption and energy intensity in Indian manufacturing industries. Energy for Sustainable Development, 14, 35–47.

Rohdin, P., & Thollander, P. (2006). Barriers to and driving forces for energy efficiency in the non-energy intensive manufacturing industry in Sweden. Energy, 31, 1836–1844.

Sandberg, P., & Söderström, M. (2003). Industrial energy efficiency: the need for investment decision support from a manager perspective. Energy Policy, 31, 1623–1634.

Sands, R., & Schumacher, K. (2009). Economic comparison of greenhouse gas mitigation options in Germany. Energy Efficiency, 2, 17–36.

Schettkat, R. (2009). Analysing rebound effects. Wuppertal Papers No. 177. Retrieved from http://www.wupperinst.org/uploads/tx_wibeitrag/WP177.pdf.

Schipper, L., & Groub, M. (2000). On the rebound? Feedback between energy intensities and energy uses in IEA countries. Energy Policy, 28, 367–388.

Schön, L. (2007). En modern svensk ekonomisk historia—tillväxt och omvandling under två sekel. Stockholm: SNS Förlag.

Sheinbaum, C., Ruíz, B., & Ozawa, L. (2010). Energy consumption and related CO2 emissions in five Latin American countries: changes from 1990 to 2006 and perspectives. Energy, 36, 3629–3638.

Silveira, S. (2001). Building sustainable energy systems—Swedish experiences. Swedish Energy Agency.

Smil, V. (2005). Energy at the cross roads. Global perspectives and uncertainties. Massachusetts Institute of Technology.

Sorrell, S. (2007). The rebound effect: an assessment of the evidence for economy-wide energy savings from improved energy efficiency. The UK Energy Research Centre. Retrieved from http://www.Ukerc.ac.uk/Downloads/PDF/07/0710ReboundEffect/0710ReboundEffectReport.pdf.

Steinbuks, J. (2010). Inter-fuel substitution and energy use in the UK manufacturing sector. EPRG Working Paper 1015. Cambridge Working Paper in Economics 1032.

Stenqvist, C., Nilsson, L., Henriksson, E., Söderholm, P., & Wårell, L. (2009). Voluntary energy efficiency programs: an interim evaluation of PFE in Sweden. Proceedings of the 10th IAEE European Conference: Energy, Policies and Technologies for Sustainable Economies.

Stern, D. (2010). Modeling international trends in energy efficiency and carbon emissions. Research Report No. 54. Environmental Economics Research Hub Research Reports.

Stern, D., & Jotzo, F. (2010). How ambitious are China and India’s emissions intensity targets? Energy Policy, 38, 6776–6783.

Svensson, E., & Berntsson, T. (2010). Economy and CO2 emissions trade-off: a systematic approach for optimizing investments in process integration measures under uncertainty. Applied Thermal Engineering, 30, 23–29.

Swedish Energy Agency (2009a). Energy efficiency policies and measures in Sweden. Monitoring of energy efficiency in EU 27, (ODYSSEE-MURE). Retrieved from http://www.odyssee-indicators.org/publications/PDF/sweden_nr.pdf.

Swedish Energy Agency (2009b). Swedish clean tech opportunities. A market overview from the Swedish Energy Agency. Retrieved from www.swedishenergyagency.se.

Swedish Energy Agency (2010). Energiindikatorer 2010. Uppföljning av Sveriges energipolitiska mål. Eskilstuna, Sweden. www.energimyndigheten.se.

Swedish Ministry of Environment (SME) (2009). Economic instruments. Retrieved from www.sweden.gov.se/sb/d/5400/a/43594.

Taylor, P., Ortigue, O., Francoeur, M., & Trudeau, N. (2010). Final energy use in IEA countries: the role of energy efficiency. Energy Policy, 38, 6463–6474.

Thollander, P., & Dotzauer, E. (2010). An energy efficiency program for Swedish industrial small- and medium-sized enterprises. Journal of Cleaner Production, 18, 1339–1346.

Thollander, P., Karlsson, M., Söderström, M., & Creutz, D. (2005). Reducing industrial energy costs through energy-efficiency measures in a liberalized European electricity market: case study of a Swedish iron foundry. Applied Energy, 81, 115–126.

Thollander, P., Danestig, M., & Rohdin, P. (2007). Energy policies for increased industrial energy efficiency: evaluation of a local energy programme for manufacturing SMEs. Energy Policy, 35, 5774–5783.

Thomas, S. (2009). Evaluate energy savings EU, Intelligent Energy Europe. Measuring and reporting energy savings for the Energy Services Directive—how it can be done. Results and recommendations from the EMEEES project, Wuppertal Institute. Retrieved from www.evaluateenergy-savings.eu/emeees/en/publications/reports/EMEEES_Final_Publishable_Report.pdf.

Tornqvist, L., & Vartia, P. (1985). How should relative changes be measured? The American Statistician, 39(1), 43–46.

Tsao, J., Saunders, H., Creighton, J., Coltrin, M., & Simmons, J. (2010). Solid-state lighting: an energy-economics perspective. Journal of Physics D: Applied Physics, 43, 1–17.

U.S. Environmental Protection Agency (EPA) (2007). Energy trends in selected manufacturing sectors: opportunities and challenges for environmentally preferable energy outcomes. Final Report.

Unander, F. (2007). Decomposition of manufacturing energy-use in IEA countries. How do recent developments compare with historical long-term trends? Applied Energy, 84, 771–780.

United Nations (UNEP) (1976). Increased energy economy and efficiency. A study on measures taken or which might be taken to achieve increased energy efficiency.

United Nations Foundation (UNF) (2007). Realizing the potential of energy efficiency. Targets, policies, and measures for G8 countries. Expert Group on Energy Efficiency. Expert Report.

Weber, C. (2009). Measuring structural change and energy use: decomposition of the US economy from 1997 to 2002. Energy Policy, 37, 1561–1570.

Wei, T. (2007). Impact of energy efficiency gains on output and energy use with Cobb–Douglas production function. Energy Policy, 35, 2023–2030.

Wolde-Rufael, Y., & Menyah, K. (2010). Nuclear energy consumption and economic growth in nine developed countries. Energy Economics, 32, 550–556.

World Nuclear Association (WNA) (2011). Nuclear power in Sweden. Retrieved from http://www.world-nuclear.org/info/inf42.html.

Worrel E., & Galitsky, C. (2008). Energy efficiency improvement and cost saving opportunities for cement making. Environmental energy technologies. Berkeley National Laboratory.

Yun, L. (2008). Technical progress and labour demand in Swedish manufacturing firms. Journal of Industry, Competition and Trade, 8, 147–167.

Acknowledgements

The authors are grateful for the financial support provided by the Swedish Energy Agency and KTH for the development of this research. We also thank the support of the University of La Salle. The research has been developed independently.

Author information

Authors and Affiliations

Corresponding author

Appendix. List of Swedish manufacturing industries at the two-digit level

Appendix. List of Swedish manufacturing industries at the two-digit level

In this study, the following sectors were used based on Statistics Sweden (Swedish Environmental Accounts and Statistical database):

15–16 Manufacture of food products, beverages and tobacco

17 Manufacture of textiles

18 Manufacture of wearing apparel

19 Tanning and dressing of leather

20 Manufacture of wood and wood products

21 Manufacture of paper and paper products

22 Publishing and printing

23 Manufacture of coke, refined petroleum products and nuclear fuel

24 Manufacture of chemicals and chemical products

25 Manufacture of rubber and plastics products

26 Manufacture of non-metallic mineral products

27 Manufacture of basic metals

28 Manufacture of fabricated metal products

29 Manufacture of machinery and equipment

30 Manufacture of office machinery and computers

31 Manufacture of electrical machinery and apparatus

32 Manufacture of radio, television and communication equipment

33 Manufacture of medical and optical instruments, watches and clocks

34 Manufacture of motor vehicles, trailers and semi-trailers

35 Manufacture of other transport equipment

36 Manufacture of furniture and other manufacturing

Rights and permissions

About this article

Cite this article

Pardo Martínez, C.I., Silveira, S. Energy efficiency and CO2 emissions in Swedish manufacturing industries. Energy Efficiency 6, 117–133 (2013). https://doi.org/10.1007/s12053-012-9159-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12053-012-9159-5

Keywords

- Energy efficiency

- CO2 emissions

- Decomposition analysis

- Stochastic frontier model

- Swedish manufacturing industries