Abstract

This study analyses energy use and CO2 emissions in the Swedish manufacturing industries between 1993 and 2008. The performance of this sector is studied in terms of CO2 emissions, energy consumption, energy intensity, energy sources, energy prices and taxes. The results show that energy consumption, energy intensity and CO2 emission intensity have reduced significantly. The decomposition analysis evidenced that decrease in the aggregate energy intensity and the aggregate CO2 emission intensity was caused by a decrease of energy intensity and substitution fuels. The factors that have influenced the results in energy intensity and CO2 emission intensity in Swedish manufacturing industries have been mainly the increase of energy price, energy taxes, investments and inter-fuel substitution.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Short Introduction

The growing population, industrialization and increasing standard of living and quality of life across the globe have substantially increased our dependence on energy. This study analyses energy use and CO2 emissions in the Swedish manufacturing industries between 1993 and 2008, where the results show that energy consumption, energy intensity and CO2 emission intensity have reduced significantly. The decomposition analysis evidenced that decrease in the aggregate energy intensity and the aggregate CO2 emission intensity was caused by a decrease of energy intensity and substitution fuels and the factors that influenced have been mainly increase of energy price, energy taxes, investments and inter-fuel substitution.

Introduction

Energy is a basic factor for production in the manufacturing industry. The growing population, industrialization and increasing standard of living and quality of life across the globe have substantially increased our dependence on energy. As a result, the development of conventional energy resources, the search for new or renewable energy sources, energy conservation (using less energy), energy efficiency (having the same service or output with less energy usage) and decreasing CO2 emissions have become unavoidable topics in global politics.

However, to improve the analysis, design and evaluation of adequate energy polices, it is necessary to achieve a better understanding of the trends in energy use, energy efficiency and CO2 emissions while considering the factors that could determine these trends. Gaining this understanding implies obtaining detailed data at various aggregation levels to apply suitable indicators and using models and methods that generate reliable and consistent information (International Energy Agency 2008a). This paper describes the trends in energy consumption and CO2 emissions in Swedish manufacturing industries between 1993 and 2008 and analyses several factors that have influenced these trends such as investments, inter-fuel substitution, energy price and energy taxes as a starting point for broader analysis.

Researchers in many fields have used various approaches to measure energy efficiency in the industrial sector with the aim of determining the specific effects of energy policies, new technologies or energy prices on energy efficiency changes and improvements, among other things. Decomposition analysis has been widely used in several studies to decompose the energy consumption and to aggregate energy intensity or CO2 emissions into the change in intensities at the disaggregated sectoral level and the impact of changes in structural composition of the industrial sector (Ang and Zhang 2000; Asia Pacific Energy Research Centre 2000; Choi and Ang 2003). For example, (Reddy and Ray 2010), in the context of Indian manufacturing industries, showed that improvements in energy efficiency are primarily achieved by structural changes. Weber (2009) analysed energy use in the US and found that improvements in energy efficiency were caused principally by structural changes in the economy. Diakoulaki and Mandaraka (2007) studied EU manufacturing industries with an emphasis on CO2 emissions and found relevant progress in the decoupling of the growth in manufacturing industries and carbon emissions.

The studies on energy efficiency and CO2 emissions in Sweden have included a variety of topics.

-

(a)

Löfgren and Muller (2010), Kander and Lindmark (2006) applied decomposition analyses to energy consumption and CO2 emissions, demonstrating that fuel substitution, improvement in the energy system and processes and changes in consumption patterns have led to the decrease in CO2 emissions in Sweden.

-

(b)

Sandberg and Söderström (2003), Svensson and Berntsson (2010) analysed the relationship between investments, CO2 emissions and energy efficiency; additionally, they demonstrated that CO2 emissions and energy efficiency influence investment decisions in Swedish industries.

-

(c)

Henriksson and Söderholm (2009), Linden and Carlsson-Kanyama (2002) studied energy policy and its effects on improvements in energy efficiency and identified several strategies such as energy prices, carbon and energy taxes, voluntary agreements, the application of energy management systems, audits and incentives for emission reductions facilitated by fuel substitutions.

-

(d)

Other studies have analysed barriers to the implementation of energy efficiency measures and the effects of some energy programs on small and medium-sized enterprises (Thollander et al. 2007).

However, despite the important results of the previous analyses, these studies have not assessed the specific effects of energy efficiency on energy consumption and CO2 emissions over time, nor have they analysed other variables that could determine the trends of these variables. Therefore, the main contribution of this study is an analysis of the role of energy efficiency in the trends in energy use and CO2 emissions in the Swedish manufacturing industries that have demonstrated important improvements in energy efficiency, which should allow for the establishment of adequate strategies in the design of effective energy policy.

The results of this study show that Swedish manufacturing industries improved their energy efficiency during the sample period and that output growth has not required higher energy consumption. This led to a decrease in CO2 emission intensity. The factors that influenced these results were mainly the increase in energy prices, energy taxes, investments and inter-fuel substitution, indicating the importance of a suitable energy policy that strengthens sustainable development in this industrial sector.

The remainder of this paper is organised as follows: third section describes the Methods and Data used in this study; section Results and Discussion the results are shown and discussed; the Conclusions are stated in last section.

Methods and Data

In this analysis, energy and CO2 emission intensity are defined as the energy used or CO2 emissions generated per unit of economic production, respectively. In this study, value added is used to measure economic production to analyse trends in these indicators for Swedish manufacturing industries. Moreover, we use decomposition analysis at the manufacturing industry level to estimate and evaluate energy use and CO2 emissions. This method examines several factors, such as the activity, structure, energy intensity and energy carbon index, which have influenced the trends in energy use and CO2 emissions with respect to production value. This technique involves the division and decomposition of energy and emissions in the explanatory variables from aggregate data (Ang and Zhang 2000; Asia Pacific Energy Research Centre 2000).

The technique applied is the Multiplicative Log-Mean Divisia Method explained by Ang and Liu (2001), which allows an adequate decomposition at different levels of aggregation. This method is used to determine the effects of a structural change in manufacturing industrial production on total energy consumption, which can establish several causes of a change in energy use in this sector.

Two approaches are used in this analysis: energy intensity and CO2 emissions. The relative changes (L) are explained using the log percentage change where Ln(x,y) is the logarithmic mean of two positive numbers, i.e., L = Ln(x,y) = (y − x)/Ln(y/x) (Tornqvist and Vartia 1985). These two approaches are:

The energy intensity method: In this approach, the total change in aggregate energy intensity is decomposed into a structural effect (S) representing manufacturing industrial composition, and an intensity effect representing changes in the sector’s energy intensity (EI) [for more details see Ang and Zhang (2000)].

Note: EI agg : aggregate energy intensity, F tot : Total change in aggregate energy intensity, F str : structural effects, F int: Intensity effects, w x : energy share of sector i in year t.

The CO 2 emission method: This method explains changes in the level of CO2 emissions through three factors: activity as measured in terms of production, structure and the energy carbon index [for more details see Ausubel (1995) and Lise (2006)].

Note: COI agg : aggregate CO2 emission intensity, TC tot : Total change in aggregate CO2 emission intensity, F str : structural effects, F ce : Energy carbon index changes, CE: energy carbon index effect, y x : CO2 emissions share of sector i in year t.

The main limitation of this study is the degree of analysis (aggregate manufacturing sub-sectors) because it is only for one country and is insufficient for a full examination of the changes that took place into each Swedish sub-sector separately.

Database

Data to conduct the analysis are provided by SCB (Statistics Sweden) through the Swedish Environmental Accounts and Statistical database. These organizations use data at 2-digit levels of disaggregation, according to International Standard Economic Classification (ISEC). All monetary data are converted to 2000 euro values. The time period selected in this analysis is determined by the availability of data for the inter-sectoral Swedish manufacturing industries over the period 1993–2008.

Results and Discussion

Energy Intensity and CO2 Emission Intensity in Swedish Manufacturing Industries

The trends in energy intensity and CO2 emission intensity are shown in the Fig. 39.1; both indicators display the same tendencies. Energy intensity and CO2 emission intensity have decreased by 28 and 29 %, respectively as average of whole manufacturing industries. All Swedish manufacturing industries have decreased these indicators, especially in the last few years.

Decomposition Analysis

To estimate and analyze the trends in energy use and CO2 emissions in the Swedish manufacturing industries, we apply the Multiplicative Log-Mean Divisia Method I explained in the section Methods and data. The results of the decomposition analysis are shown in Figs. 39.2 and 39.3 where a value of one indicates that the variable had no effect on aggregate intensity, energy consumption or CO2 emissions and values greater than one indicate a contribution to greater aggregate intensity, energy consumption or CO2 emissions, whereas values less than one indicated a decrease, which implies an increase in energy efficiency and a decrease in CO2 emission intensity.

The results of the decomposition analysis of CO2 emissions for the Swedish manufacturing industries (structural effects (Fstr), energy carbon index changes (FCE), aggregate CO2 emission intensity (COIagg), energy consumption (Econsumption), electricity consumption (Eleconsumption) and fossil fuel consumption (FFconsumption))

Energy intensity approach. Figure 39.2 shows the results for the decomposition of aggregate energy intensity, electricity intensity and fossil fuel intensity, where value added is the economic measures of output in the Swedish manufacturing industries. The aggregate of the energy intensity decreased considerably during the sample period. Structural and intensity effects show similar trends, indicating that both contributed to the decrease in aggregate energy intensity. However, intensity effects dominated structural effects, signifying that the decrease in aggregate energy intensity was primarily caused by a decrease in the energy intensity, which could be due to changes or improvements in technology.

The results should also demonstrate that the decrease in fossil fuel consumption has improved energy efficiency and decreased energy consumption through fuel substitution or a change in the mixture of fuels from inefficient, dirty or fossil fuels with a high carbon content (such as coal or several petroleum products) towards more efficient, clean or non-fossil fuels with a low carbon content (such as natural gas or hydroelectric energy); these trends are required for sustainable development. Moreover, achieving adequate fuel substitution to decrease the CO2 emissions and energy consumption implies a change in economic conditions (fuel prices), a technological change (new technologies and innovation with adequate cost-benefits) and regulations that promote energy efficiency and clean production through the use of technologies that require less energy consumption and fewer pollutant-generating fuels (Hoeller and Wallin 1991; Steinbuks 2010).

CO2emissions approach. Figure 39.3 depicts the results of decomposition analysis from the CO2 emissions approach. The results are similar to those obtained from the previous method, indicating the close relationship between the improvements in energy efficiency and the decrease of CO2 emission intensity, which is consistent with several studies that have identified energy efficiency as a major energy issue because it is the most cost effective way of improving energy use and increasing both energy security and productivity and plays a role in the achievement of a carbon emission reduction target (Boyd and Pan 2000; United Nations Foundation 2007).

The results of the decomposition analysis from this approach indicate that the decrease in energy consumption has contributed to a lower aggregate CO2 intensity. Similarly, structural and intensity effects had a minor role in the decrease in CO2 emission intensity. These results highlight the fact that the Swedish manufacturing industry has increased its output while decreasing energy consumption, maintaining its production structure and decreasing its effects on climate change. Therefore, the results have demonstrated that clean production is possible within the framework of sustainable development.

Discussion of Results

Thus far, the results show that the Swedish manufacturing industries have decreased their energy consumption and output growth has not required higher energy consumption, making it possible to decrease energy and CO2 emission intensity. The role of structural changes has been minor, and the trends of energy efficiency and CO2 emissions were similar during the sample period. To understand the possible factors that have influenced these trends, we analyse the following issues: investments, inter-fuel substitution, energy price and energy taxes.

Investments. Multiple studies have demonstrated that higher investments generate higher energy efficiency or decrease energy intensity. Currently, investments in energy efficiency and clean energy are necessarily business decisions, and the greatest investment priorities are, in this case, based on regulatory requirements, decreased production costs or increases in productivity while maintaining or increasing product quality (Environmental Protection Agency 2007; Ramos and Ortege 2003). Moreover, the results of this study are consistent with several programs of the Swedish Energy Agency (SEA), which promotes investments to improve energy efficiency through standardised energy management systems and energy audits and identifies measures to decrease energy use and energy intensity. The Swedish long-term agreement program for energy efficiency in energy intensive industries (PFE), launched by the Swedish government in January 2005 and implemented and operated by the Swedish Energy Agency, has become a successful voluntary program. It has achieved an annual reduction in energy use of 2.909.33 TJ and a 2.5 % increase in electricity intensity through the application of 872 measures and increased investments by companies (Ottosson and Petersson 2007; Stenqvist et al. 2009). Moreover, investments in clean technologies have grown significantly in the Swedish manufacturing industries, mainly in renewable electricity production, bio-fuels and techniques for increasing energy efficiency supported by different emission-reducing subsidies from the Swedish government (Stenqvist et al. 2009). This demonstrates that an adequate energy and climate change policy require government support and the interest of the industrial sector in improving environmental performance, pursuing increased productivity and economic growth with a goal of clean production with low carbon emissions.

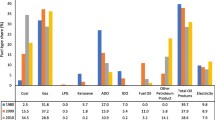

Inter-fuel substitution. During the sample period, the manufacturing sector in Sweden increased its use of electricity and bio-fuels, whereas the use of other fuels has decreased (see Fig. 39.4), indicating that, in this sector, electricity consumption has grown at a higher rate. However, fossil fuels declined during the sample period, demonstrating a shift in the structure of energy sources from lower efficiency or more polluting fuels (e.g., coal or petroleum products) to greater efficiency or cleaner fuels (e.g., electricity or bio-fuels). This is consistent with other studies (Pardo Martinez 2011) in the context of manufacturing industries. Moreover, the decline in the energy intensity in the manufacturing industries has been due to the ability to expand the use of higher quality fuels (Swedish Energy Agency 2009).

Energy prices. In the literature, it is accepted that energy efficiency becomes important during periods of high energy prices from a cost minimisation of outputs perspective. This may encourage improvements in the process and appropriate substitution of other inputs for energy (Mukherjee 2008). Hence, increases in the prices of fossil fuels generated the substitution of these fuels for electricity and bio-fuels. Moreover, energy prices influenced energy efficiency results because decreases in aggregate energy intensity occurred during the years in which energy prices increased e.g., from 2000, Swedish manufacturing industries decreased the aggregate energy intensity while energy prices increased (see Figs. 39.2 and 39.5). Therefore, an increase in energy prices over time leads to a decrease in energy intensity, which concurs with (Holdren 2001; Cornillie and Fankhauser 2002; Pardo Martínez 2009).

Energy Taxes. Another factor analysed were the taxes, represented by energy and CO2 taxes. This mechanism has been used in Sweden as both a fiscal tax source and as a policy instrument to motivate and strengthen incentives to save energy by increasing energy prices and carbon taxes. The taxes also make lower-carbon fuels substitutes. These taxes have been integrated with a variety of instruments and mechanisms that were designed to make them effective and maintain the competitiveness of Swedish manufacturing industries. A permanent substantial dialogue between all of the stakeholders, but mainly with industry, has generated higher applicability and effectiveness (Price et al. 2008; Ptak 2010). Moreover, results from decomposition analysis may demonstrate that adequate energy taxation reduces CO2 emissions, improves the efficiency of energy use, promotes renewable energy production and use and provides incentives for sustainable development established by the green tax shift. Therefore, higher taxes should be applied to environmentally harmful activities to generate an increase in the use of biomass in district heating systems, investments in new technologies and the application of energy management systems and audits (Fouquet and Johansson 2005; International Energy Agency 2008a, b).

Conclusions

This study analyses the trends in energy consumption and CO2 emissions in Swedish manufacturing industries between 1993 and 2008. This sector has achieved important advances in energy use, simultaneously increasing its output while decreasing its energy consumption. Similarly, energy and CO2 emission intensity decreased during the sample period, demonstrating that it is possible to produce economic growth while using fewer energy resources and controlling the amount of CO2 emissions.

The results of the decomposition analysis showed a decrease in aggregate energy intensity and aggregate CO2 emission intensity, which was caused by a decrease in energy intensity and substitution fuels; the role of structural changes has been minor. Moreover, the growth in production did not lead to increases in aggregate energy intensity and CO2 emission intensity, indicating that this sector produced more with less energy consumption and fewer emissions.

These trends could be explained by the energy policies and strategies applied in Sweden that include energy prices, energy taxes and technological change that encourage investments in new technologies, encourage fuel substitution and energy management in the manufacturing industries.

The findings of this study indicate that it is possible to achieve improvements in energy efficiency and decrease CO2 emissions while increasing production and competitiveness through a suitable energy policy that encourages the importance of energy efficiency in the manufacturing process through technological change and policy strategies.

The results found in this analysis are a valuable source of information because they suggest several strategies to make significant improvements in the energy efficiency of manufacturing industries, especially in developing countries where it is very important to increase the efforts of industry and policy makers to achieve energy savings that contribute significantly to the reduction of greenhouse gas emissions.

Finally, the results of this study are particularly relevant for the formulation, development and strengthening of energy policies for manufacturing industries that are based on Swedish experience, where economic instruments (energy prices and energy taxes) and technical instruments have driven substantial improvements in energy efficiency and decreases in CO2 emissions through clean technology investments and fuel substitution. These results demonstrate that it is possible to achieve economic growth and sustainable development through a steady advancement towards a low-carbon economy. Future research should scrutinise data on other sectors, countries and aggregation levels to improve the understanding of the trends of energy efficiency and CO2 emissions.

References

Ang BW, Liu FL (2001) A new energy decomposition method: perfect in decomposition and consistent in aggregation. Energy 26(6):537–548

Ang BW, Zhang FQ (2000) Survey of index decomposition analysis in energy and environmental studies. Energy 25(12):1149–1176

Asia Pacific Energy Research Centre (APERC) (2000) Energy efficiency indicators, A study of energy efficiency indicators for industry in APEC Economies, APEC # 00-RE-0.1.7

Ausubel J (1995) Technical progress and climate change. Energy Policy 23(4–5):411–416

Boyd G, Pan J (2000) Estimating the linkage between energy efficiency and productivity. Energ policy 28(5):289–296

Choi K, Ang BW (2003) Decomposition of aggregate energy intensity changes in two measures: ratio and difference. Energ Econ 25(6):615–624

Cornillie J, Fankhauser S (2002) The energy intensity of transition countries, working paper No. 72, European Bank, Available at www.ebrd.com/downloads/research/economics/working papers/wp0072.pdf

Diakoulaki D, Mandaraka M (2007) Decomposition analysis for assessing the progress in decoupling industrial growth from CO2 emissions in the EU manufacturing sector. Energ Econ 29(4):636–664

Environmental Protection Agency (EPA) (2007) Energy trends in selected manufacturing sectors: opportunities and challenges for environmentally preferable energy outcomes, Final Report Available at www.epa.gov/sectors/pdf/energy/report.pdf

Fouquet D, Johansson T (2005) Energy and environmental tax models from Europe and their link to other instruments for sustainability: policy evaluation and dynamics of regional integration. Presentation at the 8th Senior Energy Advisory Council Meeting, Beijing, China

Henriksson E, Söderholm P (2009) The cost-effectiveness of voluntary energy efficiency programs. Energ Sustain Dev 13(4):235–243

Hoeller P, Wallin M (1991) Energy prices, taxes and carbon dioxide emissions, OECD Economic Studies, Paris No 17

Holdren P (2001) Searching for a National energy policy. Issues Sci Technol 17 43–51 (No Spring 2001)

International Energy Agency (IEA) (2008a) Worldwide trends in energy use and efficiency”, key insights from IEA indicator analysis Available at http://www.iea.org/papers/2008/indicators_2008.pdf

International Energy Agency (IEA) (2008b) Energy policies of IEA Countries, Sweden, Available at http://www.iea.org/textbase/nppdf/free/2008/sweden2008.pdf

Kander A, Lindmark M (2006) Foreign trade and declining pollution in Sweden: a decomposition analysis of long-term structural and technological effects. Energ Policy 34(13):1590–1599

Linden A, Carlsson-Kanyama A (2002) Voluntary agreements -a measure for energy-efficiency in industry? Lessons from a Swedish programme. Energ Policy 30(10):897–905

Lise W (2006) Decomposition of CO2 emissions over 1980–2003 in Turkey. Energ Policy 34(14):1841–1852

Löfgren Å, Muller A (2010) Swedish CO2 Emissions 1993–2006: an application of decomposition analysis and some methodological insights. Environ Resource Econ 47(2):221–239

Mukherjee K (2008) Energy use efficiency in U.S. manufacturing: a nonparametric analysis. Energ Econ 30(1):76–96

Ottosson C, Petersson K (2007) First results from the Swedish LTA programme for energy efficiency in industry, ECEEE 2007 Summer study—saving energy—just do it! Available at www.eceee.org/conference_proceedings/eceee/2007/Panel_7/7.209/.2007

Pardo Martínez CI (2009) Energy efficiency developments in the manufacturing industries of Germany and Colombia, 1998–2005. Energ Sustain Dev 13(3):189–201

Pardo Martinez CI (2011) Energy efficiency development in German and Colombian non-energy-intensive sectors: a non-parametric analysis. Energ Effi 4(1):115–131

Price L, Galitsky C, Kramer K, McKane A (2008) International experience with key program elements of industrial energy efficiency or greenhouse gas emissions reduction target, Ernest Orlando Lawrence Berkeley National Laboratory, LBNL-63807 http://ies.lbl.gov/iespubs/LBNL-63807.pdf

Ptak M (2010) Environmentally motivated energy taxes in Scandinavian countries. Econ Environ Stud 10(3):255–269

Ramos J, Ortege M (2003) Non-linear relationship between energy intensity and economic growth, ESEE conference frontiers 2 Available at www.rrojasdatabank.info/thermo/PS35p.pdf

Reddy B, Ray B (2010) Decomposition of energy consumption and energy intensity in Indian manufacturing industries. Energ Sustain Dev 14(1):35–47

Sandberg P, Söderström M (2003) Industrial energy efficiency: the need for investment decision support from a manager perspective. Energ Policy 31(15):1623–1634

Steinbuks J (2010) Inter-fuel substitution and energy Use in the UK manufacturing sector, EPRG working paper 1015, Cambridge working paper in economics 1032

Stenqvist C, Nilsson L, Henriksson E, Söderholm P, Wårell L (2009) Voluntary energy efficiency programs: an interim evaluation of PFE in Sweden. In: Proceedings of the 10th IAEE European Conference: energy, policies and technologies for sustainable economies

Svensson E, Berntsson T (2010) Economy and CO2 emissions trade-off: a systematic approach for optimizing investments in process integration measures under uncertainty. Appl Therm Eng 30(1):23–29

Swedish Energy Agency (SEA) (2009) Swedish Clean tech opportunities, a market overview from the Swedish Energy Agency, Available at www.swedishenergyagency.se

Thollander P, Danestig M, Rohdin P (2007) Energy policies for increased industrial energy efficiency: evaluation of a local energy programme for manufacturing SMEs. Energ Policy 35(11):5774–5783

Tornqvist L, Vartia P (1985) How should relative changes be measured? Am Stat 39(1):43–46

United Nations Foundation (UNF) (2007), Realizing the potential of energy efficiency, targets, policies, and measures for G8 Countries, expert group on energy efficiency, expert report

Weber C (2009) Measuring structural change and energy use: decomposition of the US economy from 1997 to 2002. Energ Policy 37(4):1561–1570 www.oecd.org/dataoecd/33/26/34258255.pdf

Acknowledgments

The authors are grateful for the financial support provided by the Swedish Energy Agency and KTH for the development of this research. We also thank the support of the University of La Salle. The research has been developed independently.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Martínez, C.I.P., Silveira, S. (2013). Energy Use in Manufacturing Industries Evidence from Sweden. In: Leal Filho, W., Mannke, F., Mohee, R., Schulte, V., Surroop, D. (eds) Climate-Smart Technologies. Climate Change Management. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-37753-2_39

Download citation

DOI: https://doi.org/10.1007/978-3-642-37753-2_39

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-37752-5

Online ISBN: 978-3-642-37753-2

eBook Packages: Business and EconomicsEconomics and Finance (R0)