Abstract

A novel ferric oxide/multi-walled carbon nanotubes (\(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs)-modified glassy carbon electrode (GCE) was prepared by drop casting \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs onto the surface of GCE. Scanning electron microscopy (SEM) image shows that the \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs has a nanostructure. Cyclic voltammetry (CV) results show that the \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs-modified GCE presents excellent electrochemical activity in the presence of 1 mM nitrite in a 0.1 M phosphate-buffered saline (PBS) to compare the \(\hbox {Fe}_{2}\hbox {O}_{3}\) and MWCNTs-modified GCE. Differential pulse voltammetry (DPV) results also show that the \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs has excellent electrocatalytic performance to nitrite in a pH 7.0 PBS. The amperometric response result shows that the \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs-modified GCE can be used to detect nitrite concentration in a wide linear range of \(10\textendash 1000\, \upmu \hbox {M}\) with a detection limit of \(0.1\, \upmu \hbox {M}\).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

As is known to all that nitrite is universally found within the live process and environment and is generally used as a corrosion inhibitor or additive in some foods [1, 2]. However, carcinogenic nitrosamines can be formed by nitrite when interact with amines [3]. Therefore, it is critical and necessary to carry out the detection of nitrite in practical analysis. In recent years, many methods were developed for the determination of nitrite [4]. Among them, electrochemical techniques were widely adopted because of their properties with simple use and rapid response [5]. Generally, the electrochemical analysis of the nitrite can be completed based on the electrochemical reduction or oxidation of nitrite. However, it should be indicated that the reduction potential is extremely negative for nitrite, and it is difficult to use its reduction behaviour to detect nitrite directly. Therefore, many catalysts are used to promote the electroreduction of nitrite [6]. Recently, Zhao et al [7] prepared the sensor based on palladium-nanoparticle-functionalized multi-walled carbon nanotubes (MWCNTs) for electrochemical detection of the oxidation of \(\hbox {NO}_{2}\). Liu et al [8] reported nitrogen and phosphorus co-doped graphene quantum dots for electroanalysis of \(\hbox {NO}_{2}\). Though their work showed high sensitivity, however, their work also showed some disadvantages, such as high cost and complicated material preparation process. Therefore, the electrochemical detection of nitrite with high selectivity and sensitivity is still challenging, although the electro-catalysis of nitrite was enhanced greatly. Recently, more efforts are being made to improve the selectivity and sensitivity.

At present, the electrochemical sensor preparation from nanocomposites-modified electrodes was recognized increasingly. Recently, iron oxide nanomaterials have attracted tremendous attention in the areas of electrochemical sensors and nanotechnology, because of their excellent catalytic properties and interesting electron transport behaviour [9,10,11,12,13]. Hematite (\(\upalpha \hbox {-Fe}_{2}\hbox {O}_{3})\), maghemite (\(\upgamma \hbox {-Fe}_{2}\hbox {O}_{3})\) and magnetite (\(\hbox {Fe}_{3}\hbox {O}_{4})\) are probably the most general oxides of many oxide modalities in which oxides of iron exist in nature. In particular, \(\upalpha \hbox {-Fe}_{2}\hbox {O}_{3 }\) nanomaterials were of technological and scientific interest due to their biocompatibility, low toxicity and magnetic properties in physiological environments. It is used in many fields, such as magnetically assisted drug delivery, magnetic resonance imaging (MRI), information storage, wave adsorption and anode material [14]. Recently, \(\hbox {Fe}_{2}\hbox {O}_{3}\) was tentatively found as a potential activity and explored as an electrocatalyst towards hydrogen peroxide, glucose and reduced nicotinamide cofactors.

Carbon nanotubes have drawn more attention due to their high mechanical strength, excellent electrical conductivity, high surface area and chemical stability [15]. Recently, nanocomposites containing polythionine CNTs [16], carbon nanotubes–ionic liquids [17], CNTs–cobalt nanoparticles [18], catalase–CNTs [19], CNTs ionic liquids–Pt–Au alloy nanoparticles [20], vanadium shiefbase–CNTs [21], CNTs–iron porphyrin [22], silica–cerium mixed oxide carbon paste [23] and CNTs–poly thiophene [24] were used for the electrochemical detection of nitrite. Although all these chemical sensors are favourable for nitrite detection, some of them give relatively poor selectivity and repeatability, low sensitivity and reproducibility with short-time stability under complicated multi-step preparation methods and physiological condition. In addition, the electrocatalytic behaviour of the modified electrode was restricted only for oxidation or reduction of the nitrite. Wang et al [25] reported an efficient method of using Pt nanoparticles to decorate CNx nanotubes. It is mentioned in the report that using metal/metal oxide to decorate CNT surfaces effectively improves the emission-site density, and the work is of great importance for future electronic display devices.

In this work, we report a facile composition of MWCNTs/\(\hbox {Fe}_{2}\hbox {O}_{3}\) nanocomposites, and its application to the electrochemical detection of nitrite. Electrochemical studies showed that the composite exhibited a low detection limit and a wide linear range to nitrite with a fast current response. In addition, the modified electrode showed long-term stability and excellent reproducibility. The fabricated electrochemical sensor displayed significant selectivity, sensitivity and it was also used to real sample analysis.

2 Experimental

2.1 Materials

MWCNTs, potassium ferricyanide (\(\hbox {K}_{3}[\hbox {Fe(CN)}_{6}\)]), sodium nitrite (\(\hbox {NaNO}_{2}\)), \(0.1\, \hbox {mol l}^{-1}\) phosphate buffer solution (PBS) is made up of disodium hydrogen phosphate (\(\hbox {Na}_{2}\hbox {HPO}_{4})\) and two hydrated sodium dihydrogen phosphate (\(\hbox {NaH}_{2}\hbox {PO}_{4}\cdot 2\hbox {H}_{2}\hbox {O}\)), hydrochloric acid (HCl), sodium hydroxide (NaOH) and dimethyl formamide (DMF). All other reagents were of analytical grade and were used as received without further treatment.

2.2 Apparatus

Electrochemical experiment technology including chronoamperometry (CA), differential pulse voltammetry (DPV) and cyclic voltammetry (CV) were carried out on CHI660 electrochemical work station (Chenhua, Shanghai, China) with traditional three-electrode system, among them, the platinum electrode as the counter electrode, Ag/AgCl ((sat) KCl) electrode as the reference electrode, and glassy carbon electrode (GCE) and its modified electrode as working electrodes. The morphologies and structures of samples were carried out by a Hitachi S-4700 SEM (scanning voltages was 15 kV). Powder X-ray diffraction (XRD) was performed using a Thermo ARL SCINTAG X’TRA X-ray diffractometer with \(\hbox {CuK}\!\upalpha \) radiation (\(\lambda = 0.154056\, \hbox {nm}\)) in the \(2 \theta \) range of \(20\textendash 70^{\circ }\).

2.3 Synthesis of \(\hbox {Fe}_{2}\hbox {O}_{3}\) /MWCNTs nanocomposite

\(\hbox {Fe}_{2}\hbox {O}_{3}\) was synthesized through a hydrothermal method, which was reported previously [26]. In a typical preparation of \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs, \(197.6\, \hbox {mg K}_{3}[\hbox {Fe(CN})_{6}\)] was dissolved in 40 ml of distilled water with pH of 12, and then, 60.0 mg of the MWCNTs were added into the solution. Next, the homogeneous solution was poured into a 50 ml Teflon-lined autoclave and held at \(160^{\circ }\hbox {C}\) for 24 h. Then, the reddish brown precipitate was collected by centrifugation, which was washed three times with ethanol and distilled water, and then dried in the oven at \(60^{\circ }\hbox {C}\) for 12 h. As a control experiment, \(\hbox {Fe}_{2}\hbox {O}_{3}\) nanometre material was prepared without adding MWCNTs under the same conditions.

2.4 Preparation of the modified electrode

Prior to modification, a 3 mm diameter GCE was polished with alumina slurry of 3 and \(0.5\, \upmu \!\hbox {M}\) on polishing cloth with water, respectively, and then thoroughly rinsed with anhydrous ethanol and sonicated in ultrapure water bath for 5 min before use. For preparation of the electrochemical sensor, 5 mg samples and 5 ml dimethyl formamide (DMF) were dispersed by ultrasonication for 25 min to gain a homogeneous suspension (\(1.0\, \hbox {mg ml}^{-1})\). Then, \(5\, \upmu \hbox {l}\) of the suspension was dropped onto the surface of GCE and was dried at room temperature.

3 Results and discussion

Figure 1a represents SEM pattern of the \(\hbox {Fe}_{2}\hbox {O}_{3}/\hbox {MWCNTs}\) nanocomposite. SEM image of the composite displayed almost uniform sized \(\hbox {Fe}_{2}\hbox {O}_{3}\) nanoparticles, which were dispersed on the MWCNTs surface. The successful synthesis of \(\hbox {Fe}_{2}\hbox {O}_{3}/\hbox {MWCNTs}\) nanocomposites was further confirmed. Figure 1b shows the transmission electron microscopy (TEM) images of \(\hbox {Fe}_{2}\hbox {O}_{3}/\hbox {MWCNTs}\) nanocomposite. The TEM images show that the \(\hbox {Fe}_{2}\hbox {O}_{3}\) nanoparticles are doped with MWCNTs. In addition, a high-resolution TEM (HRTEM) image of \(\hbox {Fe}_{2}\hbox {O}_{3}/\hbox {MWCNTs}\) nanocomposite is shown in figure 1c. The clear lattice fringes (\(d = 0.344\, \hbox {nm}\)) observed in the HRTEM image agree well with the (002) lattice planes of MWCNTs, and the lattice fringes of (104) planes (\(d = 0.271\, \hbox {nm}\)) are assigned to \(\hbox {Fe}_{2}\hbox {O}_{3}\). Figure 1d illustrates the elemental composition of the electrode surface. The energy dispersive X-ray analysis (EDX) spectrum confirms the existence of C, Fe and O on the electrode surface. Figure 2 illustrates the XRD image of the \(\hbox {Fe}_{2}\hbox {O}_{3}/\hbox {MWCNTs}\) nanocomposite. The MWCNTs exhibited one significant diffraction peak at \(2\theta = 26\), attributed to the (0 0 2) reflections of carbon nanotubes. In addition, the nanocomposite exhibited nine obvious diffraction peaks, and which were indexed to the (0 1 2), (1 0 4), (1 1 0), (1 1 3), (0 2 4), (1 1 6), (0 1 8), (2 1 4) and (3 0 0) planes of the pure \(\hbox {Fe}_{2}\hbox {O}_{3}\). The narrow and sharp peaks indicate that these \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs nanocomposite are well-crystallized. These results proved the existence of both MWCNTs and \(\hbox {Fe}_{2}\hbox {O}_{3}\) in the as-synthesized composite.

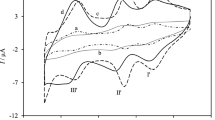

Figure 3 shows the CVs of the bare GCE, \(\hbox {Fe}_{2}\hbox {O}_{3}\)/GCE, MWCNTs/GCE and \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs/GCE in the presence of 1 mM nitrite in a 0.1 M PBS (pH 7.0) at a scan rate of \(100\, \hbox {mV s}^{-1}\). The anodic peak current of the MWCNTs/GCE is greater than that of the bare GCE, which can be attributed to that the large specific surface area of MWCNTs. The background current of the \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs/GCE was much larger than the \(\hbox {Fe}_{2}\hbox {O}_{3}\)/GCE and bare GCE, which may be due to the synergy of ferric oxide and carbon nanotubes. Different mass ratio of composites make different electrochemical behaviours of nitrite detection. To explore the best proportion, we created different mass ratios of composite materials towards nitrite detection through CV. CVs (figure 4) were recorded to understand the electrochemical behaviour of \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs composites with different proportions modified electrode in a 0.1 M PBS solution in the presence of nitrite. It can be seen, when the mass ratio for 5:6 than catalytic peak is the largest, which may be at the time of the proportion, the synergy is of best. Hence, the electrode material was made according to the optimal proportion.

(a) DPVs of \(\hbox {Na}\hbox {NO}_{2}\) at \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs/GCE in pH 7.0 PBS. \(\hbox {Na}\hbox {NO}_{2}\) concentrations: 0, 20, 40, 60, 80, 100, 120, 140, 160, 180 and \(200\, \upmu \hbox {M}\). (b) Linear relationship between peak current and the concentration of \(\hbox {Na}\hbox {NO}_{2}\).

Figure 5a presents the CVs of the \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs/GCE in pH 7.0 PBS containing 1.0 mM nitrite at different scan rates. From this figure, we can see a positive shift in the peak potential and an augment in the anodic peak current as scan rate increases. The positive change of potential may be attributed to the dynamic control of the redox reaction between the \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs and the nitrite. This reaction is irreversible, and the \(E_{\mathrm{pa}}\) obeys the Laviron’s equation. Figure 5b shows that the catalytic peak of nitrite is proportional to the square root of scan rate (v) in the range of \(20\textendash 260\, \hbox {mV s}^{-1}\), and the linear equation can be exhibited by \(I_{\mathrm{pa}}\, \hbox {(mA)} = 10.08948 + 2.8075 \hbox {v}^{1/2}\) with \(R = 0.99211\). These results demonstrated that the electrocatalytic oxidation behaviour of nitrite was a diffusion-controlled process.

In general, the type of the solution, pH value and supporting electrolyte are essential factors to the electrochemical reaction. In comparison with the reaction of nitrite in B–R buffer solution and acetum buffer solution, a more sensitive catalytic peak of \(\hbox {NO}_{2}^{-}\) with more desirable peak shape was acquired in PBS buffer solution (results not shown). Therefore, PBS was chosen for the investigation of this experiment [7]. The effect of buffer solution pH value on the electrochemical response of 1.0 mM \(\hbox {NO}_{2}^{-}\) was explored in the range of 3.0–9.0 in PBS. As shown in figure 6, the anodic peak current of \(\hbox {NO}_{2}^{-}\) was influenced by pH value greatly. When pH was \({<}7.0\), with the decrease in pH the catalytic peak decreased. To the best of our knowledge, in strong acidic medium, nitrites were not stable and could undergo the following conversion:

The decrease in anodic peak current at lower pH value (\(\mathrm{<}7.0\)) may be attributed to the transformation of nitrite to nitric oxide and nitrate [27, 28]. On the other hand, due to the pKa of nitrous acid, which was 3.3, most \(\hbox {NO}_{2}^{-}\) was protonated in acidic solution. Protonation was proved to refer to the catalytic oxidation process, and the active substance should be nitrous acid instead of nitrite [29,30,31,32]. When pH was \({>}7.0\), the electrocatalytic oxidation of \(\hbox {NO}_{2}^{-}\) became more difficult, and may be attributed to the shortage of proton [33,34,35,36]. Hence, with the increase in buffer solution pH, the catalytic peak decreased. The maximal anodic peak current was obtained at pH 7.0, which was employed as the optimum pH in our experiments.

Under the optimum conditions, the catalytic peak of different nitrite concentrations at the \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs/GCE were recorded by DPV in static solutions. As shown in figure 7a, the anodic peak current was proportional to the concentration of \(\hbox {NO}_{2}^{-}\) in the range of 2.0 \(\times \) 10\(^{-5}\) to 2.0 \(\times 10^{-4}\, \hbox {M}\). The linear relationship between peak current and the concentration of \(\hbox {Na}\hbox {NO}_{2}\) was showed in figure 7b. The linear regression equation can be expressed by \(I_{\mathrm{pa}}(\upmu \hbox {A}) = 0.1674\,\hbox {C} (10^{-5 }\hbox {M}) + 1.4023 ({n} = 10, {R} = 0.9992)\), and showed a low detection limit of \(2.0 \times 10^{-7}\, \hbox {M (S/N} = 3)\).

Figure 8a presents the amperometric response of the \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs/GCE to successive additions of nitrite in 0.1 M PBS. An obvious increase in anodic peak current was obtained when nitrite was drip into the stirred PBS. The \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs/GCE electrode responded rapidly to the \(\hbox {NO}_{2}^{-}\), reaching a plateau within 4 s. Figure 8b shows the relationship between the peak current of the \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs/GCE and the concentration of nitrite. The catalytic peak at the \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs/GCE are proportional to the various concentrations of \(\hbox {NO}_{2}^{-}\) in the range of \(10\textendash 1000 \,\upmu \hbox {M}\). The linear regression equation can be expressed by \(I_{\mathrm{pa}}(\upmu \hbox {A}) = 0.9013\hbox {C}\, (10^{-5 }\hbox {M}) + 0.52571 ({R} = 0.9988)\). The limit of detection was \(0.1\, \upmu \hbox {M}\), which is about three order of the magnitude lower than the tap water limit quantity postulated by the WHO (\(43\, \upmu \hbox {M}\)). To evaluate the activity of the proposed nitrite sensor, other nitrite modified electrodes were listed in table 1 for comparison. Clearly, this nitrite sensor exhibits a comparable activity to others reported previously. Therefore, the \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs/GCE can be used for the preparation of a nitrite sensor with a low limit, and a wide linear range.

Selectivity is an significant parameter of the nitrite electrochemical sensor. Various common ions, such as \(\hbox {Mg}^{2+},\, \hbox {NH}_{4}^{+}, \hbox {Na}^{+},\, \hbox {PO}_{4}^{3+},\, \hbox {SO}_{4}^{2-},\, \hbox {NO}_{3}^{-}\) and \(\hbox {Cl}^{-}\), did not interfere with the determination of nitrite. Figure 9 showed that no significant response currents were observed when 0.1 mM each of NaCl, \(\hbox {K}\hbox {NO}_{3}, \hbox {NH}_{4}\hbox {Cl},\, \hbox {Na}_{3}\hbox {PO}_{4}, \hbox {CuSO}_{4}\) and \(\hbox {Mg}(\hbox {NO}_{3})_{2}\) were injected at regular intervals. However, upon the addition of 0.1mM nitrite, a significant amperometric response was immediately observed, demonstrating the excellent selectivity of the \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs/GCE towards nitrite determination.

For real sample analysis, the preparative \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs/GCE sensor was used to detect nitrite levels in tap water. Tap water samples consisting of various concentrations of spiked \(\hbox {NO}_{2}^{-}\) were quantitatively analysed through a standard addition method. Before analysis, the samples were filtered by using a \(0.2\, \upmu \hbox {m}\) filter to eliminate micron-sized particles. Figure 10 is the amperometric response curve of modified electrode upon successive addition of the 10, 20 and \(30\, \upmu \hbox {M}\) nitrite spiked samples in tap water at 0.85 V. The results exhibited that the sensor was highly sensitive and selective to nitrite. The recoveries (table 2) were observed as 97.8, 99.5 and 101.2% for the 10, 20 and \(30\, \upmu \hbox {M}\) nitrite spiked samples, respectively. These results indicated that the \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs/GCE modified electrode showed excellent determination of nitrites in tap water.

4 Conclusion

In summary, it is the first time that an unprecedented nitrite sensor based on tron oxide/carbon nanotube composite materials (\(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs/GCE) was developed. The \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs/GCE-modified electrode has excellent catalytic efficiency and highly electron transfer rate constant towards the catalytic oxidation of nitrite compared to undecorated electrode. CV, DPV and CA were used to verify the electrocatalytic performance of the proposed sensor. The dynamic linear range and obtained limit of detection indicate that the sensor exhibited low detection limit and a wide linear range. The modified electrodes for various interferences such as of NaCl, \(\hbox {K}\hbox {NO}_{3}, \hbox {NH}_{4}\hbox {Cl}\) and other important cations and anions is negligible. Based on this experiment it is anticipated that proposed sensor could be used to the detection of nitrite in real sample such as tap water successfully. \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs/GCE-modified electrode can be applied as a promising candidate for determination of nitrite sensor or detector, because of its high simplicity, sensitivity, reproducibility and selectivity, low detection limit, rapid analysis procedure and long-term stability.

References

Zhao K, Song H Y, Zhuang S Q, Dai L M, He P G and Fang Y Z 2007 Electrochem. Commun. 9 65

Alonso A, Etxaniz B and Martinez M D 1992 Food Addit. Contam. 9 111

Bruning-Fann C S and Kaneene J B 1993 Vet. Hum. Toxicol. 35 521

Kamyabi M A and Aghajanloo F 2008 J. Electroanal. Chem. 614 157

Wen Z H and Kang T F 2004 Talanta 62 351

Lin A J, Wen Y, Zhang L J, Lu B, Li Y, Jiao Y Z et al 2011 Electrochim. Acta 56 1030

Thirumalraj B, Palanisamy S, Chen S M and Zhao D H 2016 J. Colloid Interface Sci. 478 413

Liu R G, Zhao J J, Huang Z R, Zhang L L, Zou M B, Shi B F et al 2017 Sens. Actuators B 240 604

Mimica D, Zagal J H and Bedioui F 2001 J. Electroanal. Chem. 497 106

Adekunle A S and Ozoemena K I 2010 J. Electrochem. Sci. 5 1726

Zhang Y P, Chu Y and Dong L H 2007 Nanotechnology 18 435608

Neri G, Bonavita A, Galvagno S, Siciliano P and Capone S 2002 Sens. Actuators B 82 40

Mitra S, Das S, Mandal K and Chuadhari S 2007 Nanotechnology 18 275608

He Y, Zeng K, Zhang X, Gurung A, Baloda M, Xu H et al 2010 Electrochem. Commun. 12 985

Mou F Z, Guan J G, Xiao Z D, Sun Z G, Shi W D and Fan X A 2011 J. Mater. Chem. 21 5414

Yonezawa T, Onoue S and Kimizuka N 2001 Adv. Mater. 13 140

Deng C, Chen J, Nie Z, Yang M and Si S 2012 Thin Solid Films 520 7026

Xiao F, Li L, Li J, Zeng J and Zeng B 2008 Electroanalysis 20 2047

Adekunle A S, Pillay J and Ozoemena K I 2010 Electrochim. Acta 55 4319

Salimi A, Mamkhezri H and Mohhebbi S 2006 Electrochem. Commun. 8 688

Xiao F, Mo Z, Zhao F and Zeng B 2008 Electrochem. Commun. 10 1740

Salimi A, Noorbakhsh A and Ghadermazi M 2007 Sens. Actuators B 123 530

Turdean G L, Popescu I C, Curulli A and Palleschi G 2006 Electrochim. Acta 51 6435

Morais A D, Villis P C M, Maroneze C M, Gushikem Y, Lucho A M S and Pissetti F L 2012 J. Colloid Interface Sci. 369 302

Ghosh K, Kumar M, Wang H F, Maruyama T and Ando Y 2010 J. Phys. Chem. C 114 5107

Lin C Y, Vasantha S V and Ho K C 2010 Sens. Actuators B 18 51

Zhang X L, Sui C H, Gong J, Su Z M and Qu L Y 2007 J. Phys. Chem. C 111 9049

Wang P, Mai Z B, Dai Z, Li Y X and Zou X Y 2009 Biosens. Bioelectron. 24 3242

Piela B and Wrona P K 2002 J. Electrochem. Soc. 149 E55

Xing X and Scherson D A 1988 Anal. Chem. 60 1468

Mani V, Periasamy A P and Chen S M 2012 Electrochem. Commun. 17 75

Yang G, Yang Y, Wang Y, Yu L, Zhou D and Jia J 2012 Electrochim. Acta 78 200

Unnikrishnan B, Ru P L, Chen S M and Mani V 2013 Sens. Actuators B 177 887

Silveria G, Morais A, Villis P C M, Maroneze C M, Gushikem Y, Lucho A M S et al 2012 J. Colloid Interface Sci. 369 302

Kozub B R, Rees N and Compton R G 2010 Sens. Actuators B 143 539

Meng Z, Liu B and Zheng J 2011 Microchim. Acta 175 251

Ma Y, Song X Y, Ge X, Zhang H M, Wang G Z and Zhang Y X 2017 J. Mater. Chem. A 5 4726

Haldorai Y, Kimb J Y, Viliana A T, Heo N S, Huh Y S and Han Y K 2016 Sens. Actuators B 227 92

Kung C W, Chang T H, Chou L Y, Hupp J T, Farha O K and Ho K C 2015 Electrochem. Commun. 58 51

Yadav D K, Ganesan V, Sonkar P K, Gupta R and Rastogi P K 2016 Electrochim. Acta 200 276

Yang J H, Yang H T, Liu S H and Mao L Q 2015 Sens. Actuators B 220 652

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, X.R., Zheng, Y.F. & Song, X.C. \(\hbox {Fe}_{2}\hbox {O}_{3}\)/MWCNTs nanocomposite decorated glassy carbon electrode for the determination of nitrite. Bull Mater Sci 41, 35 (2018). https://doi.org/10.1007/s12034-018-1553-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-018-1553-y