Abstract

We describe a modified glassy carbon electrode (GCE) for the sensitive determination of nitrite in waste water samples. The GCE was modified by electrodeposition of cobalt oxide nanoparticles on multi-walled carbon nanotubes (MWCNTs) deposited on a conventional GCE. Scanning electron microscopy and electrochemical techniques were used for the characterization of the composite material which is very uniform and forms a kind of nanoporous structure. Electrochemical experiments showed that the modified electrode exhibited excellent electrocatalytic properties for nitrite. Amperometry revealed a good linear relationship between peak current and nitrate concentration in the 0.5 to 250 μM range with a detection limit of 0.3 μM (S/N = 3). The method has been applied to the amperometric detection of nitrite. The modified electrode displays good storage stability, reproducibility, and selectivity for a promising practical application.

The dense and entangled CoOx/MWCNTs nanocomposite showed a three-dimensional nanoporous structure. The three-dimensional nanoporous structure provided ample space to allow fast mass transport of ions through the electrolyte/electrode interface as well as a conductive network for enhancing electronic conductivity which was favorable to the catalytic application of CoOx.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nitrite is ubiquitous within environmental, food and life science and can interact with amines to form carcinogenic nitrosamines [1]. Hence, it is necessary to develop a reliable and sensitive sensor to detect nitrite in food, drinking water and environmental samples. Several techniques, including spectrophotometry [2], chemiluminescence [3], chromatography [4], and capillary zone electrophoresis [5], have been developed. However, it must be pointed out that most of the above methods involve time-consuming and tedious procedures. Owing to the rapid response, cheaper, safer and simple use, electrochemical methods have often been employed for the detection of nitrite [6–10]. For example, Badea [11] presented an amperometric procedure for nitrite determination in cured meat using a carbon paste electrode covered with a cellulose acetate membrane. This probe turned out to be free from interferences by ascorbic acid as present in meat samples. Zhao et al [12] constructed a biosensor for nitrite by immobilization of hemoglobin and a room temperature ionic liquid on a multi-walled carbon nanotubes modified glass carbon electrode. The biosensor has been successfully applied to the determination of nitrite in water samples. Lu et al [13] made use of the synergetic effect of Pd–Fe nanoclusters to investigate the electrocatalysis of nitrite. This modified electrode exhibited excellent stability and high catalytic activity towards nitrite reduction. Gu et al. [14] have described an electrochemical activity towards the reduction of nitrite using a nanometer-sized gold colloid attached to an ethylenediamine monolayer modified electrochemically pretreated glassy carbon electrode.

Cobalt oxide-based materials have been widely used for energy storage system [15], electrochromic thin films [16], magnetoresistive devices [17] and heterogeneous catalysis [18]. Cobalt oxides continue to attract considerable attention, mainly due to their excellent electrocatalytic activity toward various compounds, such as glucose, glutathione, carbohydrate, thiol, hydrogen peroxide, arsenic(III) and methanol [19–24]. Several methods have been developed for the preparation of cobalt oxide including solvothermal process [25], solution spray pyrolysis technique [26] and electrochemical method [27]. Among these techniques, the electrochemical method is an attractive and promising method. Casella et al. have prepared cobalt oxide or oxyhydroxide layers on the surface of gold [28] and glassy carbon electrode [29, 30] by electrodeposition technique. In addition, the electrochemical properties of cobalt oxide films deposited anodically or cathodically at conductive boron doped diamond (BDD) or glassy carbon electrodes have been investigated [31, 32].

In this study, cyclic voltammetry was used to form cobalt oxide film on the surface of MWCNTs/GCE. The electrocatalytic activity, stability, pH effect and kinetic parameters of modified electrode were evaluated by electrochemical techniques. The modified electrode for oxidation of nitrite has also been investigated. To evaluate the possible analytical application of the modified electrode, it has been used for amperometric detection of nitrite.

Experimental

Apparatus

A Model CHI660A Electrochemistry Workstation (Chenhua Instruments Co. Ltd., Shanghai, China, chi.instrument.com.cn) was employed for all the electrochemical techniques. A three-electrode system was used, where a standard saturated calomel electrode (SCE) served as the reference electrode, a platinum wire electrode as the auxiliary electrode, and a modified glassy carbon electrode (GCE, Φ = 3 mm) as the working electrode. All the electrochemical experiments were conducted at room temperature (25°C). Scanning electron microscopic (SEM) measurements were carried out with a JSM-6700F scanning electron microscope (Japan Electron Company, Japan, www.jeol.co.jp).

Reagents

MWCNTs (~95% purity) were purchased from Shenzhen Nanotech. Port. Co., Ltd. (Shenzhen, China, http://www.nanotubes.com.cn/doce/default.html). CoCl2 was purchased from Tianjin Kermel Chemical Reagent Co., Ltd. (Tianjin, China, http://kermel.b2b.hc360.com). All other reagents were of analytical grade, and all solutions were prepared with water purified in a Milli-Q Millipore system throughout.

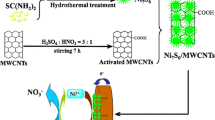

Preparation of the modified electrodes

GCE was polished before each experiment with 0.3, and 0.05 μm α-alumina powders (CHI Instrument, Shanghai, China, chi.instrument.com.cn) in sequence, rinsed thoroughly with doubly distilled water between each polishing step, ultrasonicated in 1:1 HNO3, ethanol, and doubly distilled water, and allowed to dry at room temperature. Then 3.0 mg MWCNTs functionalized with carboxylic acid groups was dispersed in 1.0 mL of N,N-Dimethylformamide (DMF). GCEs were modified by a 5.0 μl drop of MWCNTs-DMF solution and dried in air. Cobalt oxide was electrodeposited on the surface of electrodes from 1 mM cobalt chloride in pH 6.76 phosphate buffer solution, using repetitive potential cycling between 0.5 and −1.1 V [33]. The cycles for the electrodeposition of CoOx nanoparticals had been optimized. The results were shown in Fig. S1 in Supplementary Section. The peak current changed with cycles. At 35 cycles the peak current reached its maximum. Thus, the optimum cycles for further studies was set in 35 cycles at 100 mV s−1. Modified electrode was eventually washed with double distilled water and stored at ambient temperature (25°C) before being used in experiments.

Experimental procedures

Cyclic voltammetric and amperometric measurements were performed in a cell containing 20 mL 0.1 M phosphate buffer solution at room temperature. All solutions were deoxygenated by bubbling highly pure nitrogen for at least 20 min and maintained under nitrogen atmosphere during measurements. The amperometric experiments were carried out with applied potential at +0.75 V for nitrite on a stirred cell at room temperature.

Results and discussions

Characterization of CoOx/MWCNTs composite

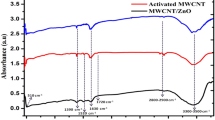

In order to investigate the formation of the CoOx, the electrode surface was observed by SEM (Fig. 1). The MWCNTs’ tangled ropes with a smooth surface were shown in Fig. 1a. After electrodeposition of CoOx onto the surface of the MWCNTs/GCE, a dense and entangled CoOx/MWCNTs hybrid nanostructure with a three-dimensional network structure was obtained (Fig. 1b). Due to its high surface-to-volume ratio, the three-dimensional nanoporous structure provided ample space to allow fast mass transport of ions through the electrolyte/electrode interface as well as a conductive network for enhancing electronic conductivity which was favorable to the catalytic application of CoOx [34]. The possible mechanism of the growing process was that the Co2+ ions can get selectively adsorbed onto the surface of MWCNTs, and this heterogeneous nucleation process may mainly take place on the surface of CNT.

Figure 2 shows the cyclic voltammograms for the CoOx/MWCNTs/GCE in pH 6.76 phosphate buffer solution in absence (b) and presence of 1.0 mM NO −2 (a). For comparison, this figure also presents the behavior of bare GCE (d) and GCE modified with MWCNTs only (c) both in presence of NO −2 . As can be seen, the best response was obtained with the GCE modified with CoOx/MWCNTs nanocomposite (Fig. 2a). This modified electrode presented higher peak current and lower oxidation potential for NO −2 than the bare GC and MWCNTs modified electrodes. This behavior suggests that the cobalt oxide and MWCNTs can cause a synergic enhancement effect for nitrite oxidation on the sensor surface.

Electrocatalytic behavior of nitrite on CoOx/MWCNTs modified electrode

In order to evaluate the electrocatalytic activity of cobalt oxide film, the cyclic voltammograms of the modified electrode in the presence of different concentrations of nitrite were recorded (Fig. 3). As was shown, with increasing nitrite concentration, the anodic peak currents increased and cathodic peaks decreased due to catalytic oxidation of nitrite. The increased peak current of nitrite oxidation confirmed that cobalt oxide nanoparticles had high catalytic ability for nitrite oxidation. The anodic peak currents of nitrite increased linearly with the increase in nitrite concentrations from 0.25 mM to 1.5 mM. The linear regression equation was obtained as \( {I_{\text{p}}}(\mu {\text{A}}) = 32.76 + 25.90c\,({\text{mM}})\,({R^2} = 0.9960) \).

The influence of the solution pH in the electrochemical response of the nitrite using 0.1 M phosphate buffer solution at pH 3–10 were shown in Fig. S2 in Supplementary Section. The peak current changed with pH in the range from 3.14 up to 6.76. At pH 6.76 the peak current reached its maximum. A decrease in the current was observed when the solution pH was higher than 6.76. Thus, the optimum pH for further studies was set in 6.76.

Additional information about NO −2 oxidation on the modified electrode surface was obtained by using the catalytic current from cyclic voltammograms. According to the theoretical model of Andrieux [35], the catalytic current I p depends on the potential scan rates ν, as is shown in the Eq. 1:

where C o is the substrate concentration, D o the diffusion coefficient of the substrate, F the Faraday constant, R and T the gas constant and temperature respectively [35, 36]. Firstly, the anodic peak currents of nitrite were proportional to the square root of scan rate in the range of 20–180 mV s−1 in pH 6.76 phosphate buffer solution, \( {I_{\text{p}}}(\mu {\text{A}}) = 16.13 + 62.96\,{v^{{{{1} \left/ {2} \right.}}}}({\text{m}}{{\text{V}}^{{{{1} \left/ {2} \right.}}}}{{\text{s}}^{{ - {{1} \left/ {2} \right.}}}})\,(r = 0.9980) \) (Fig. 5a), suggesting that the process was controlled by diffusion as expected for a catalytic system. Second, a plot of the sweep rate-normalized current density I p / ν 1/2 versus the sweep rate (Fig. 5b) exhibited the characteristic shape of a typical EC’ catalytic process [37].

As can be seen in Fig. 4, nitrite oxidation was an irreversible process. Thus, the number of electrons, n, involved in the overall reaction could be obtained from the slope of the I p versus ν 1/2 plot according to the equation for a totally irreversible process controlled by diffusion [36]:

where α is the electron transfer coefficient, n a the number of electrons involved in the rate-determining step, D o (cm2 s−1) the diffusion coefficient of the electroactive species and C ∗o (mol cm−3) the concentration of the electroactive species. Other terms and their meanings were mentioned before. In the present study, the values of the concentration and diffusion coefficient used for NO −2 in aqueous solution were 0.5 M and 2.1 × 10-5 cm2 s−1 [38] respectively. In addition, considering the fact that the (1−α)n a value has to be known, one approach was employed for the NO −2 oxidation reaction based on its dependence on the difference between the peak potential E p and the potential of the half peak current E p/2 given by the equation [36]:

The value of (1–α) n a was estimated as 0.50. Thus, using its value in the Eq. (2) and the slope of the plot was 62.96 μA / (V s−1)1/2 extracted from Fig. 5a, the value of n was calculated to be 1.8, suggesting two electrons in the oxidation mechanism of nitrite. Hence, the NO −3 ion was the main product of the reaction, which is in agreement with other works based on the catalytic oxidation of NO −2 [39, 40]. Therefore, the following mechanism could be suited for the system:

Amperometric detection of nitrite

Figure 5 displays the typical steady-state catalytic current time response of CoOx/MWCNTs/GCE with successive injection of nitrite at an applied potential 0.75 V. A well-defined response was observed under the successive addition of 0.5 μM, 2.5 μM and 25 μM of NO −2 , which suggested a stable and efficient catalytic property through the CoOx/MWCNTs composite film. The oxidation currents at the modified electrode were proportional to the concentration of nitrite in the range of 0.5–249 μM. The linear regression equation was obtained as \( {I_{\text{p}}}(\mu {\text{A}}) = 0.3145 + 56.19 \times {10^{{ - 3}}}C\,(\mu {\text{M}})\,({R^2} = 0.9963) \) with the detection limit of 0.3 μM (S/N = 3).

The comparisons of the parameters of NO −2 detection by use of various chemically modified electrodes are listed in Table 1, from which, it can be seen that the detection limit of the method is lower than previously reported [12–14, 41–47]. Meanwhile, the linear ranges of the method for the determination of nitrite are similar to previous methods listed in Table 1. So we think the method has its advantages for the detection of nitrite.

The interference effect of potentially interfering ions on the determination of nitrite was examined by adding various ions into the phosphate buffer solution (pH 6.76) containing 1.0 mM nitrite and the results showed that most of the ions, such as NH +4 , Cs+, Ag+, Mg2+, Ca2+, Sr2+, Zn2+, Cd2+, Ni2+, F−, Cl−, NO −3 , SO 2−4 did not interfere the determination. The interference of some oxidable species was also studied. We found that 50-fold amount of Br−, 20-fold amount of S2O 2−3 , and 5-fold amount of I− showed serious interference. As can be verified, this study reveals that the developed sensor can tolerate a high concentration of interfering ions and, therefore, can be stated as selective over the commonly present interfering ions.

Stability and reproducibility of the CoOx/MWCNTs/GCE

In order to investigate the stability of the CoOx/MWCNTs/GCE, the currents of cyclic voltammograms for 1.0 mM nitrite in 0.1 M phosphate buffer solution (pH6.76) was recorded at an interval of every 3 min. It was found that the oxidation current of nitrite remained almost unchanged with a relative standard deviation of 1.6% for 25-time repetitive measurements, indicating that this electrode had a good reproducibility. After voltammetric measurements, this electrode was kept at room temperature. The current response decreased about 2.3% in one week and 3.7% in about two weeks. The above results showed that the present modified electrode was stable and reproducible towards the oxidation of nitrite.

Determination of nitrite in real samples

To examine the possible use of the electrode in practical application, experiments were conducted in samples of waste water for the determination of nitrite. The nitrite concentration was determined. Recovery studies were carried out in waste water samples by using the standard addition method. An appropriate volume of the sample was placed in an electrochemical cell for the determination of nitrite by amperometric determination. From the results listed in Table 2, it can be seen that the method can be successfully applied for the detection of nitrite in real samples.

Conclusions

In this work, a novel sensor for determination of nitrite, which based on cobalt oxide nanoparticles deposited on the surface of MWCNTs/GCE, was successfully constructed. The CoOx/MWCNTs/GCE exhibited good electrocatalytic activity towards the oxidation of nitrite. Compared with previous reports for nitrite response, the method for nitrite determination displayed a lower detection limit of 0.3 μM (S/N = 3). The main reason was ascribed to the large surface area and good conductivity of CoOx/MWCNTs composite, which can enhance the efficiency of the electron transfer between the modified electrode and nitrite. The CoOx/MWCNTs/GCE showed high stability, excellent selectivity, good sensitivity and reproducibility and has been applied to the determination of nitrite in waste water. The reliability and stability gave a good possibility for applying the technique to routine analysis of nitrite in other samples.

References

Lijinsky W, Epstein SS (1970) Nitrosamines as environmental carcinogens. Nature 225:21–23

Al-Okab RA, Syed AA (2007) Novel reactions for simple and sensitive spectrophotometric determination of nitrite. Talanta 72:1239–1247

Kodamatani H, Yamazaki S, Saito K, Tomiyasu T, Komatsu Y (2009) Selective determination method for measurement of nitrite and nitrate in water samples using high-performance liquid chromatography with post-column photochemical reaction and chemiluminescence detection. J Chromatogr A 1216:3163–3167

Jedličková V, Paluch Z, Š Alušík (2002) Determination of nitrate and nitrite by high-performance liquid chromatography in human plasma. J Chromatogr B 780:193–197

Merusi C, Corradini C, Cavazza A, Borromei C, Salvadeo P (2010) Determination of nitrates, nitrites and oxalates in food products by capillary electrophoresis with pH-dependent electroosmotic flow reversal. Food Chem 120:615–620

Chen XW, Wang F, Chen ZL (2008) An electropolymerized Nile blue sensing film-based nitrite sensor and application in food analysis. Anal Chim Acta 623:213–220

Biagiotti V, Valentini F, Tamburri E, Terranova ML, Moscone D, Palleschi G (2007) Synthesis and characterization of polymeric films and nanotubule nets used to assemble selective sensors for nitrite detection in drinking water. Sens Actuators B 122:236–242

Ammam M, Keita B, Nadjo L, Fransaer J (2010) Nitrite sensor based on multilayer film of Dawson-type tungstophosphate α-K7[H4PW18O62]·18H2O immobilized on glassy carbon. Talanta 80:2132–2140

Liu TS, Kang TF, Lu LP, Zhang Y, Cheng SY (2009) Au-Fe(III) nanoparticle modified glassy carbon electrode for electrochemical nitrite sensor. J Electroanal Chem 632:197–200

Wang F, Hu SS (2009) Electrochemical sensors based on metal and semiconductor nanoparticles. Microchim Acta 165:1–22

Badea M, Amine A, Benzine M, Curulli A, Moscone D, Lupu A, Volpe G, Palleschi G (2004) Rapid and selective electrochemical determination of nitrite in cured meat in the presence of ascorbic acid. Microchim Acta 147:51–58

Wei W, Jin HH, Zhao GC (2009) A reagentless nitrite biosensor based on direct electron transfer of hemoglobin on a room temperature ionic liquid/carbon nanotube-modified electrode. Microchim Acta 164:167–171

Lu LP, Wang SQ, Kang TF, Xu WW (2008) Synergetic effect of Pd-Fe nanoclusters: electrocatalysis of nitrite oxidation. Microchim Acta 162:81–85

Liu Y, Gu HY (2008) Amperometric detection of nitrite using a nanometer-sized gold colloid modified pretreated glassy carbon electrode. Microchim Acta 162:101–106

Kandalkar SG, Dhawale DS, Kim CK, Lokhande CD (2010) Chemical synthesis of cobalt oxide thin film electrode for supercapacitor application. Synth Met 160:1299–1302

Yoshino T, Baba N (1995) Characterization and properties of electrochromic cobalt oxide thin film prepared by electrodeposition. Sol Energ Mat Sol C 39:391–397

Okabe H, Akimitsu J, Kubodera T, Matoba M, Kyomen T, Itoh M (2006) Low-temperature magnetoresistance of layered cobalt oxides NaxCoO2. Phys B Condens Matter 378–380:863–864

Rashkova V, Kitora S, Konstantinov I, Vitahov T (2002) Vacuum evaporated thin films of mixed cobalt and nickel oxides as electrocatalyst for oxygen evolution and reduction. Electrochim Acta 47:1555–1560

Ding Y, Wang Y, Su L, Bellagamba M, Zhang H, Lei Y (2010) Electrospun Co3O4 nanofibers for sensitive and selective glucose detection. Biosens Bioelectron 26:542–548

Buratti S, Brunetti B, Mannino S (2008) Amperometric detection of carbohydrates and thiols by using a glassy carbon electrode coated with Co oxide/multi-wall carbon nanotubes catalytic system. Talanta 76:454–457

Xia YS, Dai HX, Jiang HY, Zhang L (2010) Three-dimensional ordered mesoporous cobalt oxides: Highly active catalysts for the oxidation of toluene and methanol. Catal Commun 11:1171–1175

Hou Y, Ndamanisha JC, Guo LP, Peng XJ, Bai J (2009) Synthesis of ordered mesoporous carbon/cobalt oxide nanocomposite for determination of glutathione. Electrochim Acta 54:6166–6171

Salimi A, Hallaj R, Soltanian S, Mamkhezri H (2007) Nanomolar detection of hydrogen peroxide on glassy carbon electrode modified with electrodeposited cobalt oxide nanoparticles. Anal Chim Acta 594:24–31

Salimi A, Mamkhezri H, Hallaj R, Soltanian S (2008) Electrochemical detection of trace amount of arsenic(III) at glassy carbon electrode modified with cobalt oxide nanoparticles. Sens Actuators B 129:246–254

Qi YC, Zhao YB, Wu ZS (2008) Preparation of cobalt oxide nanoparticles and cobalt powders by solvothermal process and their characterization. Mater Chem Phys 110:457–462

Shinde VR, Mahadik SB, Gujar TP, Lokhande CD (2006) Supercapacitive cobalt oxide (Co3O4) thin films by spray pyrolysis. Appl Surf Sci 252:7487–7492

Xia XH, Tu JP, Xiang JY, Huang XH, Wang XL, Zhao XB (2010) Hierarchical porous cobalt oxide array films prepared by electrodeposition through polystyrene sphere template and their applications for lithium ion batteries. J Power Sources 195:2014–2022

Casella IG, Guascito MR (1999) Anodic electrodeposition of conducting cobalt oxyhydroxide films on a gold surface. XPS study and electrochemical behaviour in neutral and alkaline solution. J Electroanal Chem 476:54–63

Casella IG, Gatta M (2002) Study of the electrochemical deposition and properties of cobalt oxide species in citrate alkaline solutions. J Electroanal Chem 534:31–38

Casella IG (2002) Electrodeposition of cobalt oxide films from carbonate solutions containing Co(II)–tartrate complexes. J Electroanal Chem 520:119–125

Spataru N, Terashima C, Tokuhiro K, Sutanto I, Tryk DA, Park SM, Fujishima A (2003) Electrochemical behavior of cobalt oxide films deposited at conductive diamond electrodes. J Electrochem Soc 150:E337–334

McNally EA, Zhitomirsky I, Wilkinson DS (2005) Cathodic electrodeposition of cobalt oxide films using polyelectrolytes. Mater Chem Phys 91:391–398

Casella IG, Gatta M (2002) Study of the electrochemical deposition and properties of cobalt oxide species in citrate alkaline solutions. J Electroanal Chem 534(1):31–38

Kim IH, Kim JH, Cho BY, Lee YH, Kim KB (2006) Pseudocapacitive properties of electrochemically prepared vanadium oxide on carbon nanotube film substrate. J Electrochem Soc 153:A1451–A1458

Andrieux CP, Savéant JM (1978) Heterogeneous (chemically modified electrodes, polymer electrodes) vs. homogeneous catalysis of electrochemical reactions. J Electroanal Chem 93:163–168

Bard AJ, Faulkner LR (1980) Electrochemical methods, fundamentals and applications. Wiley, New York

Pariente F, Lorenzo E, Tobalina F, Abruna HD (1953) Aldehyde biosensor based on the determination of NADH enzymically generated by aldehyde dehydrogenase. Anal Chem 67:3936–3944

Pournaghi-Azar MH, Dastangoo H (2004) Electrocatalytic oxidation of nitrite at an aluminum electrode modified by a chemically deposited palladium pentacyanonitrosylferrate film. J Electroanal Chem 567:211–218

Santos WJR, Sousa AL, Luz RCS, Damos FS, Kubota LT, Tanaka AA, Tanaka SMCN (2006) Amperometric sensor for nitrite using a glassy carbon electrode modified with alternating layers of iron(III) tetra-(N-methyl-4-pyridyl)-porphyrin and cobalt(II) tetrasulfonated phthalocyanine. Talanta 70:588–594

Sousa AL, Santos WJR, Luz RCS, Damos FS, Kubota LT, Tanaka AA (2008) Amperometric sensor for nitrite based on copper tetrasulphonated phthalocyanine immobilized with poly-L-lysine film. Talanta 75:333–338

Huang X, Li YX, Chen YL, Wang L (2008) Electrochemical determination of nitrite and iodate by use of gold nanoparticles/poly(3-methylthiophene) composite coated glassy carbon electrode. Sens Actuators B 134:780–786

Song Y, Ma YT, Wang Y, Di JW (2010) Electrochemical deposition of gold–platinum alloy nanoparticles on an indium tin oxide electrode and their electrocatalytic applications. Electrochim Acta 55:4909–4914

Karousos N, Chong LC, Ewen C, Livingstone C, Davis J (2005) Evaluation of a multifunctional indicator for the electroanalytical determination of nitrite. Electrochim Acta 50:1879–1884

Pournaghi-Azar MH, Dastangoo H (2004) Electrocatalytic oxidation of nitrite at an aluminum electrode modified by a chemically deposited palladium pentacyanonitrosylferrate film. J Electroanal Chem 567:211–218

Kamyabi MA, Aghajanloo F (2008) Electrocatalytic oxidation and determination of nitrite on carbon paste electrode modified with oxovanadium(IV)-4-methyl salophen. J Electroanal Chem 614:157–165

Zen JM, Kumar AS, Chen HW (2001) Electrochemical behavior of stable cinder/prussian blue analogue and its mediated nitrite oxidation. Electroanalysis 13:1171–1178

Cui YP, Yang CZ, Zeng W, Oyama M, Pu WH, Zhang JD (2007) Electrochemical determination of nitrite using a gold nanoparticles-modified glassy carbon electrode prepared by the seed-mediated growth technique. Anal Sci 23:1421–1425

Acknowledgements

The authors appreciate the financial support from the National Natural Science Foundation of China (No.20875076), the Science Foundation of Northwest University (No. NF0902) and the NWU Doctorate Dissertation of Excellence Funds (No. 08YYB06).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM1

(DOC 286 kb)

Rights and permissions

About this article

Cite this article

Meng, Z., Liu, B., Zheng, J. et al. Electrodeposition of cobalt oxide nanoparticles on carbon nanotubes, and their electrocatalytic properties for nitrite electrooxidation. Microchim Acta 175, 251–257 (2011). https://doi.org/10.1007/s00604-011-0688-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00604-011-0688-y