Abstract

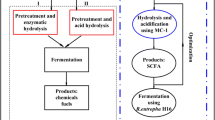

Effective pretreatment process to improve enzymatic saccharification and decrease inhibitors generation is a key operation involved in the lignocellulosic bioconversion. The pretreatment of steam explosion associated with ammonium sulfite (SEAS) process was carried out to investigate the effect on enzymatic hydrolysis and fermentation production as a combinatorial pretreatment. Results showed that after pretreatment (1.0 MPa, 30 min, 20%w/w ammonium sulfite added), the phenolic inhibitors derived from lignin significantly removed (37.8%), which transformed to chemical humic acid (humic acid and fulvic acid) mostly. Sugar conversion (glucan (77.8%) and xylan (73.3%)) and ethanol concentration (40.8 g/L) of combinatorial pretreated samples were increased by 24.7% and 33.8%, respectively, compared with steam explosion (SE) pretreated samples. FT-IR and elemental analysis results indicated that the lignin structure changed and aromatization degree increased after SEAS pretreatment. In addition, the ratio of C/N decreased and compost maturity degree increased with the holding time. The effect on the growth of wheat seedlings of soluble fulvic acid solution from combinatorial pretreatment was investigated, where below 1% (w/w) concentration did contribute to growth. Therefore, one-step chemical pretreatment process could be provided for inhibitors removal, enzymatic saccharification increase, and chemical humic acid formation as well.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lignocellulose has received extensive attention from the green industry due to its extremely rich resource reserves, renewable properties, and low cost [1,2,3]. Its dense and complex macromolecular structure makes it difficult to destroy the biomass recalcitrance during pretreatment, which affects the efficiency of subsequent enzymatic hydrolysis and inefficient adsorption of enzyme molecules [4]. Researchers have developed a variety of pretreatment methods after long time, including acid-base method, hydrothermal method, ionic liquid treatment method, and steam explosion method [1, 5, 6]. Pretreatment methods with low environmental protection and less fermentation inhibition by-products are still being explored. For example, Chen HZ et al. [5, 7, 8] invented efficient and clean component selection refining technology based on steam explosion pretreatment, which is more effective to the high value conversion of each component of the lignocellulosic materials. Our research group has done much work on steam explosion pretreatment technology for many years, and its application range has expanded from biomass to textile and food fields, etc. [9, 10]. At present, steam explosion has been applied to the lignocellulose refining demonstration industry as one mature technology. Hydrogen bond fracture, hemicellulose degradation, and the cellulase reaction site exposed through physical and chemical reaction are caused during steam explosion pretreatment, which could promote enzymatic digestibility [10, 11].

However, inhibitors derived from lignin biopolymer in the pretreatment process will seriously restrict the efficient biomass conversion [5, 11,12,13,14]. Palmqvist et al. [13] had classified inhibitors into three types, namely, weak acids, furan derivatives, and phenolic compounds, based on different inhibition mechanisms. Furan derivatives, such as furfural and 5-hydroxymethylfurfural, are more likely to form high concentrations of active-oxygen in fermentation microorganisms, resulting abnormal mutations and eventually apoptosis. Weak acid inhibitors, such as formic acid and acetic acid, mainly do a certain damage to the biomass and total amino acid contents of microbial cells, except microbial genetic activity. While phenolic compounds have been reported a higher level of toxicity than that of other two types inhibitors, with the same functional groups contained. And it acted as an electrophile to electrophilic interaction with an active substance such as proteins or enzymes in a microbial cell, finally destroying the metabolism of the normal body [14]. Overall, these substances have inhibitory effects on enzyme activity and microorganisms; weak acids and furan derivatives can be removed by physical or chemical methods, whereas lignin degradations-phenolic acid inhibitors are hard to be removed in industrial production. In consequence, how to effectively remove the phenolic inhibitors and establish a new promising pretreatment during lignocellulosic pretreatment process need to be solved urgently. Therefore, breaking the bottleneck of lignocellulose is an indispensable step.

Research reported that sulfite could react with the aromatic compounds inhibitors mostly derived from lignin, which would perform a certain role in improving enzymatic hydrolysis yields and fermentation yields [15,16,17,18]. The mechanism of sulfonation reaction is to introduce SO32− and lignin to form water-soluble lignosulfonates. The sulfonation reaction of lignin occurs only in the structural unit of the phenol type and the reaction proceeds slowly. The initial delignification stage begins with sulfonation reaction, and the phenolic β-aryl ether bonds would be broken down by SO32− introduction, furtherly α-, β-disulfonic acid was formed, while it performs stably for the non-phenolic lignin structural unit [19]. As a consequence, the combination of the advantages of steam explosion and ammonium sulfite pretreatment of lignocellulose could achieve degradation and removal of lignin components.

Humic acid is a mixture of acyl, acids, and benzene cluster acid groups, formed by linkage of chlorine bonds, which could improve certain enzyme activities of seeds, maintain membrane integrity, and thus to promote the stress conditions of seeds in drought, saline, and alkali [20]. Natural humic acid is mainly derived from weathered coal and lignite, etc., while biological humic acid is mainly produced by plant residues, such as rice straw, wood chips and bean cypress, and various auxiliary materials, which are fermented by various microorganisms under certain conditions [21, 22]. Haider and Martin [23] had discovered that humic acid formed from the phenols synthesized from the fungus Epicocium nigrum at pH 6. According to the different solubility and color of humic acid in the solvent, humic acid is divided into three kinds of fulvic acid, brown humic acid, and black humic acid. As one water-soluble humic acid, fulvic acid is often used as a drought-resistant agent in agricultural production practices, which is mainly extracted from weathered coal with a low molecular weight and complex compositions. It contains carbon, chlorine and oxygen, sulfur, nitrogen and other elements, and a variety of reactive groups. Fulvic acid has been often used as anti-transpiration agents to regulate plant growth and development, with advantages of much more efficiency, wide application, and non-pollution to the environment [24]. While after the steam explosion pretreatment, the lignin degradation material such as acetosyringone and vanillin [25] could provide a new route for the source of humic acid.

The inhibitors produced from the pretreatment of lignocellulose will inhibit the enzymatic fermentation [1, 14]. For this reason, it is especially important to establish a pretreatment technique for inhibitors removal and comprehensively utilization of lignocellulose. In the present work, a new one-step method-SEAS pretreatment to realize the utilization of lignocellulose biorefineries was put forward in this research. The structure and aromatization degree of lignin after SEAS treatment were characterized by FT-IR and elemental analysis. And the effect on the growth of wheat seedlings with fulvic acid derived from lignin was investigated. The principal study objectives were to testify the feasibility of the comprehensive utilization of lignocellulose and the conversion of chemical humic acid in this new process of biomass refining.

Materials and Methods

Raw Materials Resource

Corn straw provided by Chinese Academy of Agricultural Sciences in Beijing, China, was cleaned, dried, and shredded into about 1–3 cm length pieces, then stored in a dark and ventilated place.

Steam Explosion Associated with Ammonium Sulfite (SEAS) Pretreatment

The 2-L steam explosion tank was independently developed by our research group. Each time 100 g of corn straw was placed in a steam explosion tank, the steam explosion conditions were steam pressure of 1.0 MPa, and the pressure time was 20 min. The amount of neutral ammonium sulfite added was 20% of the weight of corn straw, where adjusting pH to 9–10 with 3% aqua ammonia. In order to reduce the operational error, the steam hot tank is pre-passed, and the steam explosion process is repeated three times under the above conditions.

Enzymatic Hydrolysis and Fermentation

Cellulase (Cellic CTec2) was provided by Novozymes (China) investment Co., Ltd. (Beijing, China) and its filter paper activity was 120 FPU/mL.

The enzymatic hydrolysis process was tested in a 50-mL Erlenmeyer flask with pretreated substance washed by running water exhaustively and buffer (100 mM sodium acetate with acetic acid, pH adjusted to 4.8), where 0.02% (w/v) sodium azide was added to inhibit microbial growth. Saccharomyces cerevisiae IPE 003 was stored in our lab for previous study, which can co-ferment glucose and xylose.

Seed liquid preparation process

The dry yeast is inoculated into YPD medium (20 g/L glucose, 20 g/L peptone, and 10 g/L yeast powder), and cultured at 30 °C, 200 rpm for 12 h.

Simultaneous saccharification and fermentation of ethanol by pre-enzymatic hydrolysate

The above-mentioned pre-enzymatically hydrolyzed for 8 h was placed in an anaerobic incubator, then simultaneous enzymatic hydrolysis for 96 h.

Analytical Methods and Calculations

Cellulose, hemicellulose, and lignin contents of corn straw were determined according to the standard procedure developed by NREL. Sugars including glucose, xylose arabinose, and ethanol were detected by a high-performance liquid chromatography system (HPLC, Agilent Technologies, USA) equipped with a refractive index detector and a Bio-Rad Aminex HPX-87H column (Bio-Rad, Hercules, CA, USA). Inhibitors including varieties phenols derived from hemicellulose and lignin were analyzed by HPLC with C18 column.

Fourier infrared spectroscopy (FI-IR) was used to characterize the lignin structure changes

The vacuum-dried lignin (before and after pretreatment) was ground and analyzed by infrared absorption spectroscopy. Infrared spectroscopy was carried out on a Fourier transform infrared spectrometer. The sample was prepared by potassium bromide mixed tableting method. The scanning range was 4000–500 cm−1, the resolution was 4 cm−1, and the scanning was performed 40 times for spectral accumulation. The ambient atmosphere was air.

Plant growth experimental design

The effect of generation and growth of wheat seeds and seedlings was tested with different concentrations of soluble fulvic acid solution (0.1%, 0.5%, 1%, and 2% (w/w)), where distilled water was added in the control group. The germination rate and seed vigor index of wheat seeds (constant temperature incubator at 25 °C, relative humidity of 85%) were calculated based on the data of 100 grains of seed, then the height measurement of seeds after 1 week.

Chemical humic acid (HA) extraction

The procedure described by the International Humic Substances Society [26] was used in the isolation and purification of the chemical humic acid from combinatorial pretreated corn straw with 8%, 13%, and 20% (w/w) of ammonium sulfite added. Elemental analysis (C, H, O, and N) was performed on freeze-dried samples of HA (1–3 mg) using an elemental analyzer (Elementar Vario EL, Germany).

Data Analysis

Three replicate groups were tested and the mean values with standard deviation are presented on dry weight basis. SAS statistical software package (SAS, 2003) was applied for data analysis, and Least Significant Difference Test at 5% probability was tested for differences between individual means.

Results and Discussion

Component Analysis of Corn Straw Before and After Steam Explosion/Ammonium Sulfite Pretreatment

The relative content of cellulose, hemicellulose, lignin, and ash of corn straw under different conditions was shown in Fig. 1. As a result of the removal of hemicellulose by steam explosion, the content of xylan and arabinan decreased significantly after steam explosion of straw, while the content of cellulose and lignin increased correspondingly. When 20% (w/w) ammonium sulfite was added for coupling pretreatment of SEAS, the pH gradually decreased from the initial 10 to the end 3, and lignin was linked to the introduced sulfonic acid group to cause lingo-sulfonation reaction. At the same time, hemicellulose was hydrolyzed in a large amount under acidic conditions, which was reduced by 49.08%, and the relative content of Klason lignin was significantly increased to 30.5%. As a result, it can be clearly found that the SEAS pretreatment process could significantly remove the lignin content during sulfonation reaction [27, 28], which was beneficial to increase the concentration of lignin in the extract and prepare for subsequent comprehensive utilization.

FT-IR Analysis

The corn straw pretreated with different conditions was analyzed by infrared (Fig. 2) to determine the influence of SEAS pretreatment conditions on the structure of lignin. And the most basic absorption peaks of lignin components were showed from the map [29]: vibration absorption caused by alcohol hydroxyl or phenolic hydroxyl group at 3388 cm−1; vibrational absorption peak of methyl and methylene at 2850 cm−1, strong absorption peak of benzene ring skeleton of 1598 cm−1 and 1503 cm−1, and absorption peak of 1180 cm−1 of lilac ring C=O and that of guaiac wood ring is 1208 cm−1, and absorption peak of 1018 cm−1 associated with S=O stretching was gained in –SO3H group [30, 31]. From the FT-IR spectroscopy results, the lignin component could be removed by sulfonation in the SEAS pretreatment process.

Effects of Steam Explosion/Ammonium Sulfite Pretreatment on Enzymatic Hydrolysis and Fermentation

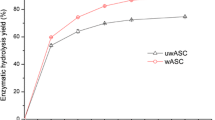

Unlike cellulose and hemicellulose polymerized from monosaccharides, lignin is polymerized from a phenylpropane structural monomer [32]. Thus, pretreated straw could not be directly utilized in the enzymatic hydrolysis and fermentation process, owing to the physical barrier and unproductively binding to enzymes of lignin on the cellulose would lead inefficient adsorption to cellulase and low level of enzymatic efficiency [4, 33]. As a result, delignification is an important step to improve the efficiency of enzymatic hydrolysis furtherly. Table 1 shows the inhibitors changes of SEAS pretreatment and after water-washing substance of corn straw, where the contents of inhibitors all decreased, and the total phenols decreased about 37.8%. The results showed that most of the phenolic acid inhibitors have been removed, which possibly on account of the sulfonation reaction of lignin during the SEAS pretreatment process and lignosulphonates removal by water-washing [20, 34]. Even though the hydrolysate toxicity mostly depends on the microorganism, about 1 g/L of furfural could be considered inhibitory to yeast [1]. Figures 3 and 4 showed the comparison of total sugar concentration and ethanol production with solid-liquid ratio1:4, enzyme loading 20 FPU/g after pretreatment. Liquefaction phenomenon of SEAS pretreated substances was showed during 3 h, and the enzymatic hydrolysis efficiency was reached 60% at 4 h. After 6 h, the raw material was almost completely converted from solid to liquid phase, and the total sugar concentration reached about 117.23 g/L. Compared with steam explosion pretreatment, the increase was 24.7% and the concentration of ethanol produced was 40.8 g/L, which was 33.8% higher than that of steam explosion pretreatment. The experimental results showed the 77.8% and 73.3% of glucan and xylan conversion respectively in enzymatic hydrolysis at 20% solid loading, which indicated a significant effect on inhibitors removal to ethanol simultaneous fermentation of with SEAS pretreatment. Different from nitrogen content increased by ammonium chloride preimpregnation pretreatment [35], almost no ammonium salts remained in the hydrolysis substances washed thoroughly, which indicated that this pretreatment method could effectively promote the enzymatic hydrolysis and fermentation process of lignocellulose. Research reported that 20% (w/w) ammonium sulfite and 4% (based on ammonium sulfite dosage) sodium carbonate at 180 °C for 1 h caused about 82.6% acid insoluble lignin removal and 48.6% total sugar concentration increased [20].

Comparison analysis of enzymatic hydrolysis process of steam explosion/ammonium sulfite pretreated corn straw. Note: control, without pretreatment; SE, steam explosion pretreated corn straw; SEAS, steam explosion/ammonium sulfite (20% (w/w) ammonium sulfite added) pretreated corn straw. (A), the total sugar concentration of the enzymatic hydrolysis system; (B), the changes of substrates during enzymatic hydrolysis

Total sugar utilization and ethanol production during fermentation. Note: control, without pretreatment; SE, steam explosion pretreated corn straw; SEAS, steam explosion/ammonium sulfite (20% (w/w) ammonium sulfite added) pretreated corn straw. “—” represented the sugar concentration; “- - -” represented the ethanol concentration

In the substrate after SEAS pretreatment, only a small amount of macromolecules of lignin depolymerization and repolymerization existed, which promotes the enzymatic efficiency at low concentration [36]. Actually, as the most important linkage in the lignin macromolecular structure, aryl ether bond is relatively fragile and easy to be broken under high temperature acid-base conditions [37,38,39,40]. As high concentration of lignin depolymerization macromolecules impaired enzymatic hydrolysis, many chemical and thermochemical processes have been developed, which would lead to inhibitors generation and high cost [36, 40, 41]. Thus, inducing sulfonation was often used to decrease lignin depolymerization in industrial pulping. Thus, the separation of lignin could not only reduce the inhibition of cellulolytic hydrolysis of ethanol, but also at the same time obtaining the dispersibility and cohesive lignin component of the macromolecular polymer with both hydrophilic and hydrophobic groups, and realizing the biosynthesis of straw lignocellulose system.

Chemical Humic Acid Formed from Steam Explosion/Ammonium Sulfite–Pretreated Corn Straw

During the pretreatment, the polysaccharide and the lignin depolymerization structure were combined together, deposited as droplets and microspheres on the surface of biomass residue, and also exhibited lignin-like properties, which was known as pseudo-lignins and/or humins [33]. It was found that after 30-min coupling pretreatment, the chemical humic acid obtained includes 12.8% humic acid and 17.2% fulvic acid. Compared with the humic acid extracted from municipal solid waste, the elemental analysis showed that the C/N ratio decreased with the increase of pretreatment holding time, indicating that the degree of compost maturity increased [42, 43]. The elemental components and atomic ratios of humic acid produced from SEAS-pretreated corn straw were determined as shown in Tables 2 and 3. Under the same pretreatment condition, the ratio of C/N decreased in the range of 2–4% with the increase additions of ammonium sulfite. While as the SEAS pretreatment time increased, the percentage of C decreased within the range of 1.6–6.9%, and the percentages of N and S both increased in the range of 0.3–1.3% and 0.8–1.8%, respectively, with the holding time increased [44].

The soluble fulvic acid was formulated into different proportions of solutions, and the effects of soaking seeds with fulvic acid solution on the germination rate, vigor index, and plant height of wheat seedlings were investigated as shown in Table 3. The results have showed that when the concentration of fulvic acid increased to 0.5% (w/w), the germination rate, seed vigor index, and plant height of wheat seeds were significantly increased (Table 4). When the concentration of fulvic acid was higher than 1% (w/w), the germination rate, seed vigor index, and plant height were decreased. It indicated that fulvic acid from SEAS pretreatment presented a trend of promotion in low concentration and inhibition in high concentration on the germination and growth of plants [42].

Conclusion

Through the study of SEAS-pretreated corn straw, a new one-step method for biomass refining of lignocellulose was proposed. Compared with FT-IR and elemental analysis of SEAS pretreatment and SE pretreatment, chemical humic acid formed by the phenolic substances derived from the depolymerization of lignin was identified. The results of enzymatic hydrolysis and fermentation experiments further gave eloquent proof of a higher content of total sugar concentration and ethanol production with SEAS-pretreated substances than SE-pretreated. In addition, the chemical fulvic acid could effectively increase the chlorophyll content of wheat seedlings. Based on the above results, the feasibility of this one-step process of combinatorial pretreatment of SEAS was fully proved, which could provide theoretical basis for comprehensive utilization of lignocellulose.

References

Jönsson, L. J., & Martín, C. (2016). Pretreatment of lignocellulose: formation of inhibitory by-products and strategies for minimizing their effects. Bioresource Technology, 199, 103–112.

Arevalo-Gallegos, A., Ahmad, Z., Asgher, M., Parra-Saldivar, R., & Iqbal, H. M. (2017). Lignocellulose: a sustainable material to produce value-added products with a zero waste approach—a review. International Journal of Biological Macromolecules, 99, 308–318.

Chen, H., Liu, J., Chang, X., Chen, D., Xue, Y., Liu, P., Lin, H. L., & Han, S. (2017). A review on the pretreatment of lignocellulose for high-value chemicals. Fuel Processing Technology, 160, 196–206.

Sindhu, R., Binod, P., & Pandey, A. (2016). Biological pretreatment of lignocellulosic biomass—an overview. Bioresource Technology, 199, 76–82.

Chen, H. Z. (2015). Gas explosion technology and biomass refinery. Netherlands: Springer.

de Souza Moretti, M. M., Perrone, O. M., Nunes, C. D. C. C., Taboga, S., Boscolo, M., da Silva, R., & Gomes, E. (2016). Effect of pretreatment and enzymatic hydrolysis on the physical-chemical composition and morphologic structure of sugarcane bagasse and sugarcane straw. Bioresource Technology, 219(219), 773–777.

Chen, H. (2015). Lignocellulose biorefinery engineering: principles and applications (No. 74). Woodhead Publishing.

Chen, H., & Wang, L. (2016). Technologies for biochemical conversion of biomass. Academic Press.

Grous, W. R., Converse, A. O., & Grethlein, H. E. (1986). Effect of steam explosion pretreatment on pore size and enzymatic hydrolysis of poplar. Enzyme and Microbial Technology, 8(5), 274–280.

Brownell, H. H., Yu, E. K. C., & Saddler, J. N. (1986). Steam-explosion pretreatment of wood: effect of chip size, acid, moisture content and pressure drop. Biotechnology and Bioengineering, 28(6), 792–801.

Hull, W., Smith, B., Hull, J., & Holzer, W. (1954). Staff-industry collaborative report ammonia base sulfite pulping. Industrial and Engineering Chemistry, 46(8), 1546–1557.

Qiu, W., & Chen, H. Z. (2012). Enhanced the enzymatic hydrolysis efficiency of wheat straw after combined steam explosion and laccase pretreatment. Bioresource Technology, 118(4), 8–12.

Palmqvist, E., & Hahn-Hägerdal, B. (2000). Fermentation of lignocellulosic hydrolysates. II: inhibitors and mechanisms of inhibition. Bioresource Technology, 74(1), 25–33.

Jönsson, L. J., Alriksson, B., & Nilvebrant, N. O. (2013). Bioconversion of lignocellulose: inhibitors and detoxification. Biotechnology for Biofuels, 6(1), 16.

Han, X., Liu, G., Song, W., Qin, Y., & Qu, Y. (2017). Continuous feeding of spent ammonium sulphite liquor improves the production and saccharification performance of cellulase by Penicillium oxalicum. Bioresource Technology, 245, 984–992.

Alriksson, B., Cavka, A., & Jönsson, L. J. (2011). Improving the fermentability of enzymatic hydrolysates of lignocellulose through chemical in-situ detoxification with reducing agents. Bioresource Technology, 102(2), 1254–1263.

Cavka, A., Alriksson, B., Ahnlund, M., & Jönsson, L. J. (2011). Effect of sulfur oxyanions on lignocellulose-derived fermentation inhibitors. Biotechnology and Bioengineering, 108(11), 2592–2599.

Cavka, A., & Jönsson, L. J. (2013). Detoxification of lignocellulosic hydrolysates using sodium borohydride. Bioresource Technology, 136, 368–376.

Zhang, H., Bai, Y., Zhou, W., & Chen, F. (2017). Color reduction of sulfonated eucalyptus kraft lignin. International Journal of Biological Macromolecules, 97, 201–208.

Qi, G., Xiong, L., Tian, L., Luo, M., Chen, X., Huang, C., Li, H. L., & Chen, X. (2018). Ammonium sulfite pretreatment of wheat straw for efficient enzymatic saccharification. Sustainable Energy Technologies and Assessments, 29, 12–18.

Wu, H., Lai, C., Zeng, G., Liang, J., Chen, J., Xu, J., Dai, J. J., Li, X. D., Liu, J. F., Chen, M., Lu, L. H., Hu, L., & Wan, J. (2017). The interactions of composting and biochar and their implications for soil amendment and pollution remediation: a review. Critical Reviews in Biotechnology, 37(6), 754–764.

de Melo, B. A. G., Motta, F. L., & Santana, M. H. A. (2016). Humic acids: structural properties and multiple functionalities for novel technological developments. Materials Science and Engineering: C, 62, 967–974.

Haider, K., & Martin, J. P. (1967). Synthesis and transformation of phenolic compounds by Epicoccum nigrum in relation to humic acid formation 1. Soil Science Society of America Journal, 31(6), 766–772.

Lipczynska-Kochany, E. (2018). Humic substances, their microbial interactions and effects on biological transformations of organic pollutants in water and soil: a review. Chemosphere, 202, 420–437.

Qiu, W., Zhang, W., & Chen, H. (2014). Natural laccase mediators separated from water-washed solution of steam exploded corn straw by nanofiltration and organic solvent fractionation. Bioresource Technology, 156, 368–371.

Kuwatsuka, S., Watanabe, A., Itoh, K., & Arai, S. (1992). Comparison of two methods of preparation of humic and fulvic acids, IHSS method and NAGOYA method. Soil Science and Plant Nutrition, 38(1), 23–30.

Huang, C., Ragauskas, A. J., Wu, X., Huang, Y., Zhou, X., He, J., Huang, C. X., Lai, C. H., Li, X., & Yong, Q. (2018). Co-production of bio-ethanol, xylonic acid and slow-release nitrogen fertilizer from low-cost straw pulping solid residue. Bioresource Technology, 250, 365–373.

Wang, G. S., Pan, X. J., Zhu, J. Y., Gleisner, R., & Rockwood, D. (2009). Sulfite pretreatment to overcome recalcitrance of lignocellulose (SPORL) for robust enzymatic saccharification of hardwoods. Biotechnology Progress, 25(4), 1086–1093.

Roopan, S. M. (2017). An overview of natural renewable bio-polymer lignin towards nano and biotechnological applications. International Journal of Biological Macromolecules, 103, 508–514.

Faix, O., Meier, D., & Beinhoff, O. (1989). Analysis of lignocelluloses and lignins from Arundo donax L. and Miscanthus sinensis Anderss., and hydroliquefaction of Miscanthus. Biomass, 18(2), 109–126.

Seca, A. M., Cavaleiro, J. A., Domingues, F. M., Silvestre, A. J., Evtuguin, D., & Neto, C. P. (2000). Structural characterization of the lignin from the nodes and internodes of Arundo donax reed. Journal of Agricultural and Food Chemistry, 48(3), 817–824.

Hu, J., Wu, S., Jiang, X., & Xiao, R. (2018). Structure-reactivity relationship in fast pyrolysis of lignin into monomeric phenolic compounds. Energy & Fuels, 32(2), 1843–1850.

Shinde, S. D., Meng, X., Kumar, R., & Ragauskas, A. J. (2018). Recent advances in understanding the pseudo-lignin formation in a lignocellulosic biorefinery. Green Chemistry, 20(10), 2192–2205.

Liu, H., Pang, B., Wang, H., Li, H., Lu, J., & Niu, M. (2015). Optimization of alkaline sulfite pretreatment and comparative study with sodium hydroxide pretreatment for improving enzymatic digestibility of corn stover. Journal of Agricultural and Food Chemistry, 63(12), 3229–3234.

Chen, H., Li, G., & Li, H. (2014). Novel pretreatment of steam explosion associated with ammonium chloride preimpregnation. Bioresource Technology, 153, 154–159.

Hu, F., Jung, S., & Ragauskas, A. (2012). Pseudo-lignin formation and its impact on enzymatic hydrolysis. Bioresource Technology, 117, 7–12.

van der Hage, E. R., Mulder, M. M., & Boon, J. J. (1993). Structural characterization of lignin polymers by temperature-resolved in-source pyrolysis-mass spectrometry and Curie-point pyrolysis-gas chromatography/mass spectrometry. Journal of Analytical and Applied Pyrolysis, 25, 149–183.

Pereira, J. H., Heins, R. A., Gall, D. L., McAndrew, R. P., Deng, K., Holland, K. C., Donohue, T. J., Noguera, D. R., Simmons, B. A., Sale, K. L., Ralph, J. R., & Adams, P. D. (2016). Structural and biochemical characterization of the early and late enzymes in the lignin β-aryl ether cleavage pathway from Sphingobium sp SYK-6. Journal of Biological Chemistry, jbc-M115, 291(19), 10228–10238.

Zhao, X., Li, S., Wu, R., & Liu, D. (2017). Organosolv fractionating pre-treatment of lignocellulosic biomass for efficient enzymatic saccharification: chemistry, kinetics, and substrate structures. Biofuels, Bioproducts and Biorefining, 11(3), 567–590.

Aro, T., & Fatehi, P. (2017). Production and application of lignosulfonates and sulfonated lignin. ChemSusChem, 10(9), 1861–1877.

Xie, S., Sun, Q., Pu, Y., Lin, F., Sun, S., Wang, X., Ragauskas, A. J., & Yuan, J. S. (2017). Advanced chemical design for efficient lignin bioconversion. ACS Sustainable Chemistry & Engineering, 5(3), 2215–2223.

Wang, X., Selvam, A., & Wong, J. W. (2016). Influence of lime on struvite formation and nitrogen conservation during food waste composting. Bioresource Technology, 217, 227–232.

Wu, S., Shen, Z., Yang, C., Zhou, Y., Li, X., Zeng, G., Ai, S. J., & He, H. (2017). Effects of C/N ratio and bulking agent on speciation of Zn and Cu and enzymatic activity during pig manure composting. International Biodeterioration & Biodegradation, 119, 429–436.

Yang, F., Li, G., Shi, H., & Wang, Y. (2015). Effects of phosphogypsum and superphosphate on compost maturity and gaseous emissions during kitchen waste composting. Waste Management, 36, 70–76.

Funding

This study was financially supported by the Transformational Technologies for Clean Energy and Demonstration (Strategic Priority Research Program of the Chinese Academy of Sciences, Grant No. XDA 21060300), the National Key Research and Development Program of China (Grant No. 2018YFB1501702).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

This manuscript complies with the Ethical Rules applicable for this journal.

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, Q., Wang, L. & Chen, H. Effect of Novel Pretreatment of Steam Explosion Associated with Ammonium Sulfite Process on Enzymatic Hydrolysis of Corn Straw. Appl Biochem Biotechnol 189, 485–497 (2019). https://doi.org/10.1007/s12010-019-03018-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-019-03018-w