Abstract

Acidification is a potential solution to lignocellulose conversion. In this work, steam explosion was proposed to pretreat cornstalk and improve acidification bioconversion efficiency. Results showed that steam explosion improved the conversion ratio by 17% compared with the control group. The optimum temperature of the hydrolysis and acidification system was 50 °C and the microbial community showed higher hydrolysis and acidification efficiency at pH 8.0–9.0, which were 66.0% (pH 8.0) and 68.0% (pH 9.0), respectively. An organic nitrogen source was more preferred by the microbial community than an inorganic nitrogen source. The highest conversion ratio (67.0%) was observed when the yeast extract dose was 1.0 g/L. Steam-exploded cornstalk was degraded by the microbial community, and organic acids in hydrolysis and acidification liquid was effectively reused by R. eutropha H16 (The utilization ratios of acetic acid, propionic acid and butyric acid were 53.38, 12.27 and 20.95%, respectively.). Based on this study, steam-explosion-based conversion technology is proposed and has great potential in future application of lignocellulose conversion.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lignocellulose is the most abundant and economic reproducible resource in nature and has great applicable potential in energy, chemical and material engineering [1,2,3]. In the traditional refining procedure of lignocellulosic biomass (Fig. 1-I, 1-II), the pretreated lignocellulose is usually degraded into pentose and hexose by enzymatic or acid hydrolysis. These platform compounds could be further converted to biofuels or chemicals [4,5,6] by a purified single microbe. However, the complex structure of lignocellulose leads to nonproductive adsorption of cellulose that accounts for a large part of the total cost [1, 4]. Moreover, a purified single microbe is usually used in lignocellulose conversion which cannot make the most use of different complex components of lignocellulosic materials. Therefore, new technology must be developed for solving the problems above and realizing economic utilization of lignocellulose.

Owing to the natural recalcitrance of lignocelluloses [7], pretreatment is necessary for efficient conversion of natural biomass by destroying the natural structure and increasing the accessibility of the matrix to a biocatalyst [8, 9]. Over the past decades, steam explosion has received much attention for its merits of environmental friendliness, flexibility in scaling up and being free of additional chemicals [10, 11]. Zhang et al. [12] reported that hemicelluloses, cellulose and lignin of wheat straw could be partly degraded during the steam-explosion process. Less lignin content and more hemicellulose degradation in lignocelluloses increases its digestibility because cellulose becomes more accessible [13]. Additionally, owing to immediately discharge of high pressure, lignocelluloses are torn into small fasciculi which also contributes hydrolytic efficiency. A purified single microbe has usually been employed in traditional conversion technology, which is seriously restricted by the cultural environment. The microbial community has gradually aroused interest of scholars due to its potential in enhancing chemical diversity [14]. Strains in the microbial community cooperate to degrade substrates, which is similar to their function in nature because the microbial community could adjust to the variable environment by showing a different microbial pattern [15]. Acidification is the process by which microbial communities degrade cellulose or hemicelluloses into sugars which can be further converted into acids. No enzyme was used in this process.

A steam-explosion-based conversion technology of cornstalk was proposed based on studies in this paper. Steam explosion, acid and microwaves were employed to pretreat cornstalk and the influence on hydrolysis and acidification efficiency was investigated. The effect of process parameters including temperature, initial pH and nitrogen source on hydrolysis and acidification were also regulated. Additionally, utilization of organic acids in hydrolysis and acidification liquid by R. eutropha H16 was also investigated in order to verify the utilization feasibility of hydrolysis and acidification liquid.

Materials and Methods

Microbes and Medium

Cornstalk was harvested from the countryside of Beijing. The microbial community was screened in our previous work [16], covering various kinds of microbes such as Clostridium sp., Bacillus sp. and uncultured bacterium. R. eutropha H16 (ATCC 17699) was kindly donated by Tsinghua University, which can synthesize polyhydroxyalkanoate (PHA, a kind of biodegradable bioplastic) using short-chain fatty acids [17]. Ingredients of Luria-Bertan medium (w/v) were: 0.5% yeast extract, 1.0% peptone and 1.0% sodium chloride. Ingredients of peptone-cellulose medium (w/v) were: 0.1% yeast extract, 0.5% peptone, 0.2% sodium bicarbonate, 0.5% sodium chloride and 0.5% steam-exploded cornstalk.

Preparation and Hydrolysis of Cornstalk with Different Pretreatment Strategies

Steam-explosion pretreatment: steam explosion was conducted in a 4.5-L steam-explosion tank designed by our laboratory. Cornstalk was cut into 3–5 cm and put into the tank, followed by inletting saturated steam and maintaining pressure at 1.5 Mpa for 5 min. Then, pressure was immediately discharged and steam-exploded cornstalk was collected and dried naturally. Dilute acid pretreatment: naturally dried cornstalk was added into 1% sulfuric acid (w/v) at the ratio of 1:20 (w/v), followed by autoclave treatment at 100 °C for 30 min. The solid phase was washed using water and adjusted to a neutral pH with alkali. Finally, the solid was dried at 60 °C and smashed to 20 meshes for further analysis. Microwave treatment: naturally dried cornstalk was added into a waster at a ratio of 1:20 (w/v), followed by microwave treatment at 800 W for 30 min. The solid phase was dried at 60 °C and smashed into 20 meshes for further analysis. Compositions of the raw cornstalk and steam-exploded cornstalk were determined according to Scarlata et al. [18].

The microbial community (10%) was incubated into the steam-exploded cornstalk, dilute sulfuric acid-pretreated cornstalk, microwave-pretreated cornstalk and raw cornstalk, respectively. Residual solid was measured after 7 days of fermentation at 50 °C. The conversion ratio of the cornstalk was characterized by weight loss and detailed information is presented in the Analytical Methods section.

Regulation of Hydrolysis and the Acidification Process of Steam-Exploded Cornstalk

For temperature regulation, the microbial community was incubated into peptone-cellulose medium containing 1% steam-exploded cornstalk, and cultivated at 30, 40, 50 and 60 °C. To investigate the effect of initial pH on hydrolysis and acidification, the microbial community was incubated into the same culture medium with initial pH adjustment to 6.0, 7.0, 8.0, 9.0 and 10.0, followed by cultivation at 50 °C. For nitrogen source regulation, the microbial community was incubated into peptone-cellulose medium in which the nitrogen source was replaced by 1% yeast extract, urea, ammonium nitrate and ammonium sulfate. In addition, the microbial community was incubated into peptone-cellulose containing different concentrations of yeast extract. All the mixtures were cultivated for 7 days and residual solid was measured at the end of fermentation while main organic acids were detected every 24 h. The yield was calculated with the equation \( yield=\frac{weight\ of\ total\ main\ organic\ acids\ }{weight\ of\ initial\ biomass} \).

Cultivating R. eutropha H16 Using Organic Acids and Hydrolysis and Acidification Liquid

Acetic acid, propionic acid and butyric acid were added into Luria-Bertan medium respectively with the concentrations of 5, 8, 15, 20 and 30 g/L. Then, the medium was sterilized in an autoclave at 121 °C for 20 min after adjusting pH to 7.0–7.2. The prepared R. eutropha H16 was incubated into the sterilized medium at a ratio of 5% (v/v) and a 50-mL working volume in a 250-mL flask was cultivated at 30 °C and 200 r/min for 48 h. Residual organic acid and cell dry weight were detected.

The microbial community [inoculation ratio 1:10 (v/v)] was incubated into peptone-cellulose medium containing 10% steam-exploded cornstalk and 1.0 g/L of yeast extract. Then, the pH of the mixed system was adjusted to 9.0 and cultivated at 50 °C for 3 days. The hydrolysis and acidification liquid was centrifuged at 3000 rpm for 20 min. The centrifuged supernatant was concentrated to one-third volume (33 mL) at 75–80 °C in a rotary evaporator. pH was adjusted to 3.0 so as to turn the acetate, propionate and butyrate into free organic acids. The treated hydrolysis and acidification liquid was used to cultivate R. eutropha H16 with an initial inoculation amount of 5%. R. eutropha H16 was cultivated at 30 °C and 200 rpm for 48 h. Residual organic acid and dry cell weight were detected.

Analytical Methods

The conversion ratio of cornstalk was calculated according to weight loss of substrate which was determined as follows. The fermented substrate was centrifuged at 4 °C and 10,000 rpm for 15 min. Sediment was suspended in 50 ml of water and heated at 100 °C for 30 min to break the flocculation and separate the biological cells from the sediment. Solid residue was filtered and washed for three times. After that, the residual solids were dried at 60 °C and finally weighed. The conversion ratio was the portion of substrate weight loss.

Determination of the main organic acids and cell weight was carried out as follows. Broth was centrifuged at 3000 rpm for 10 min, and the supernatant was used for the main organic acids determination by high-performance liquid chromatography (HPLC, Agilent 1200, Agilent Technologies, USA), with an Aminex HPX-87H column (300 × 7.8 mm, Bio-Rad Laboratories Inc.) and a refractive index detector. H2SO4 (0.5 mM) was used as mobile phase with a flow rate of 0.6 ml. min−1 and the column temperature was set at 35 °C. Acetic acid in pretreated cornstalk was deducted from total acetic acid in the fermentation system when calculating acetic acid yield in hydrolysis and acidification of cornstalk. The precipitation was washed and freeze-dried for cell weight determination.

Results and Discussion

Enhancing Hydrolysis and Acidification Efficiency of Cornstalk by Steam Explosion

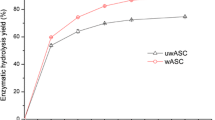

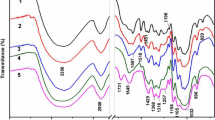

The composition of cornstalk greatly affects its conversion. The composition of cornstalk with different pretreatment strategies was analyzed. Results showed that after steam-explosion pretreatment, cellulose and lignin in cornstalk increased by 13.9 and 16.9%, respectively, while hemicelluloses decreased by 39.0%. However, for dilute acid-pretreated and microwave-pretreated cornstalk, they are 11.6, 23.5and 49.0% and 5.9, 1.5 and 5.8%, respectively (Table 1). During steam explosion, acetyl in cornstalk was removed and converted into acetic acid which degraded hemicelluloses into xylose and other small molecules. Additionally, the cornstalk was mechanically torn due to immediate pressure release. The physicochemical changes of the cornstalk were beneficial for further hydrolysis of cornstalk because cellulose and hemicelluloses exposed lager accessible area and increased the accessibility to enzymes or microbes, which may increase the conversion efficiency of cornstalk [19, 20]. It was verified by our experimental results (Fig. 2) that the conversion ratio of steam-exploded cornstalk was 64%, showing a better conversion performance than that of dilute acid-pretreated (48%) and microwave-pretreated cornstalk (49%). Additionally, solid yields and chemical compositions of steam-explosion cornstalk and dilute acid-treated cornstalk were similar (Table 1). According to our previous work [20, 21], the porosity and penetrability of steam-exploded cornstalk were greatly enhanced, which promoted saturation of the matrix with water within a short time. In other words, the changed cornstalk structure improved mass transfer during the biodegradation process. Besides, generation and immediate consumption by the microbial community occurred simultaneously, which reduced inhibition during the degradation process and finally increased the conversion efficiency of steam-exploded cornstalk. There were also differences in metabolite patterns. The proportion of acetic acid among the total main organic acid (TMOA) was 0.62 when untreated cornstalk was used and it increased to 14.8% when steam-exploded cornstalk was used. It was reported that acids with shorter chains are preferred by microbes [22]. Therefore, taking the conversion ratio and further microbials into consideration, steam explosion is more acceptable for cornstalk pretreatment.

Process Regulation of Hydrolysis and Acidification of Steam-Exploded Cornstalk by a Microbial Community

Regulation of Temperature in the Hydrolysis and Acidification Process of Steam-Exploded Cornstalk

Therefore, hydrolysis and acidification efficiency of steam-exploded cornstalk at the temperature of 30-60 °C was investigated. Results showed that the microbial community showed hydrolysis and acidification capability at the rage of 30–60 °C, but with differences. As shown in Fig. 3, the conversion ratio of steam-exploded cornstalk reached up to 69.0% at 50 °C, while 34.0, 64.0 and 53.0% were observed at 30, 40 and 60 °C, respectively. In addition, the results also showed that acetic acid, propionic acid and butyric acid were main products of the hydrolysis and acidification system. TMOA (2.41 g/L) was obtained at 50 °C after fermentation and the yield was 0.241 g /g biomass. Therefore, 50 °C was chosen in our further assays.

Variation and Regulation of pH during Hydrolysis and Acidification of Steam-Exploded Cornstalk

pH is an important factor which affects metabolism processes of microbes and finally affects the hydrolysis and acidification efficiency. The effect of initial pH on hydrolysis and acidification efficiency and main products was investigated in this part. As shown in Fig. 4a, pH changed during the hydrolysis and acidification process, to 7.0–7.6 on the first day of hydrolysis and acidification. Then the pH went up stably along with the hydrolysis and acidification process. However, it was beyond the self-adjustment capability of the microbial community when pH was adjusted to 10 and no pH variation was observed. Therefore, it is speculated that pH variation could reflect maintaining the capability of the microbial community for hydrolysis and acidification. The conversion ratio and distribution of TMOA at different initial pH are shown in Fig. 4b. The microbial community showed high hydrolysis and acidification efficiency at pH 6.0–9.0, but not at pH 10.0. The conversion ratio was 68.0% at pH 9.0, while 54.0, 58.0 and 66.0% were observed at pH 6.0, pH 7.0 and pH 8.0, respectively. Even so, hydrolysis and acidification efficiency was affected by initial pH, and a higher conversion ratio was observed at pH 8.0–9.0. Acetic acid and propionic acetic were the two main products in these hydrolysis and acidification systems. TMOA yield reached 0.268 g/g biomass and the concentration was 2.68 g/L at pH 9.0 which was 1.68, 1.64 and 0.44 g/L higher than that at pH 6.0, pH 7.0 and pH 8.0, respectively. Hence, a pH of 9 was favorable for hydrolysis and acidification of steam-exploded cornstalk.

Variation and adjustment of pH during hydrolysis and acidification of steam-exploded cornstalk: a. pH variation during hydrolysis and acidification process; b. effect of initial pH on total main organic acid (TMOA) concentration and conversion ratio of steam-exploded cornstalk; bars represent TMOA concentration; lines represent conversion ratio; reaction conditions: 50 °C

According to research results above, the microbial community showed a better hydrolysis and acidification capability in a wide range of pH. Therefore, it can be concluded that the microbial community had great pH tolerance and self-adjustment capability. The variably dominant strains at different stages of hydrolysis and acidification may be responsible for this [15, 16]. Strains in the microbial community could adapt to the shifting environment without affecting the hydrolysis and acidification process. In addition, acetic acid and propionic acetic were two main products during the hydrolysis and acidification process. This could be explained by the strains altering the metabolic pathways to release a small number of protons in order to maintain intracellular pH under higher pH environment [23] and retain the relatively stable potential of the cells. During this process, butyric acid was converted into acetic acid and ethanol further, resulting in a relatively low concentration of butyric acid.

Nitrogen Source Regulation of the Hydrolysis and Acidification System of Steam-Exploded Cornstalk

Owing to the low nitrogen content of cornstalk, an additional nitrogen source was required by the microbial community to ensure stable microbial metabolism. Ammonium nitrate, ammonium sulfate, yeast extract and urea were investigated for selection of a suitable nitrogen source. Figure 5a shows the conversion ratio of steam-exploded cornstalk with different nitrogen sources. A higher conversion ratio was observed when an organic nitrogen source (yeast extract 67.0%, urea 61.0%) was used compared with that of inorganic sources (ammonium nitrate 44.0%, ammonium sulfate 38.0%), indicating that an organic nitrogen source was more preferred by the microbial community.

Besides, the carbon-to-nitrogen ratio (C/N) is a controllable factor which could alter the fermentation pattern by inducing enrichment of different strains in the microbial community. The metabolic pathway can be shifted by adjusting the carbon-to-nitrogen ratio [24]. Therefore, the dose of yeast extract was optimized. Results showed (Fig. 5b) that the highest conversion ratio (66.0%) was observed when the dose of yeast extract was 1.0 g/L, followed by 64.0 (2.0 g/L), 53.0 (5.0 g/L) and 44.0% (0.5 g/L). Moreover, acetic acid and propionic acid were the main products of hydrolysis and acidification when the doses of yeast extract were 0.5 and 1 g/L, which account for 88.6 and 94.2%, respectively. Interestingly, butyric acid became one of the main products with increased yeast extract. When the doses of yeast extract were 5 and 10 g/L, butyric acid accounted for 23.8 and 27.6% of the TMOA, respectively. This may be explained by the changed fermentation pattern of the microbial community which demands further investigation. The highest concentration of TMOA was 3.65 g/L and the yield was 0.365 g/g biomass when the dose of yeast extract was 1 g/L. However, in order to make most use of steam-exploded cornstalk and save total cost, 1 g/L of yeast extract was chosen for further study.

Feasibility Analysis of Organic Acids as Nutrients in Cultivating R. eutropha H16

Organic acids were the main products of hydrolysis and acidification. Those acids can be used for synthesis of high-value products such as polyhydroxyalkanoate (PHA) and biohydrogen [25,26,27]. In this part, acetic acid, propionic acid, butyric acid and hydrolysis and acidification liquid were studied to investigate the feasibility when used as carbon sources for R. eutropha H16 cultivation.

Table 2 shows differences in utilization ratio of acetic acid, propionic acid and butyric acid with different concentrations. The dry cell weight was 4.0 g/L when acetic acid concentration was less than 15.0 g /L and decreased with additional amounts of acetic acid. The highest dry cell content of 2.5 g/L was observed when the propionic acid was 5.0 g/L, while a dry cell weight of 3.5 g/L was observed when butyric acid was less than 20.0 g/L. R. eutropha H16 showed a higher utilization ratio when acetic acid was used as the carbon source, followed by butyric acid and propionic acid. The results showed that acetic acid is beneficial to cell growth because the shorter chain is more easily used [22]. For organic acids in hydrolysis and acidification liquid utilization, volatilization during the concentration process led to different concentration multiples (Table 3). Butyric acid resulted in the highest concentration multiple (21.15) due to its longer chain, which reduced the volatilization. A larger amount of acetic acid in hydrolysis and acidification liquid was consumed by R. eutropha H16, followed by butyric acid and propionic acid, which is consistent with previous work. The utilization ratios of acetic acid, butyric acid and propionic acid were 53.80, 20.95 and 12.27%, respectively, and the dry cell weight was 3.5 g/L after 48 h fermentation. This result showed that acetic acid is favored by R. eutropha H16, followed by butyric acid and propionic acid. Additionally, organic acids in hydrolysis and acidification liquid of steam-exploded cornstalk could be used by R. eutropha H16 effectively and 3.5 g/L cell was obtained; this is comparable with the work of Fukui et al. [28] who obtained a dry cell weight of 3.7 g/L using fructose as the substrate. Therefore, it is feasible to employ hydrolysis and acidification liquid of steam-exploded cornstalk for cultivating R. eutropha H16.

Proposition of Conversion Technology of Lignocelluloses Coupled with Steam-Explosion Pretreatment

Based on assays above, a steam-explosion-based conversion technology of lignocelluloses was proposed and shown in Fig. 1 (III). Steam explosion was employed for biomass pretreatment and to enhance the accessibility of the substrate. A microbial community was employed to enhance hydrolysis and acidification efficiency of steam-exploded cornstalk by cooperating at different stages. The metabolites in hydrolysis and acidification liquid of steam-exploded cornstalk were used for cultivating R. eutropha H16 for high-value products synthesis.

Conclusion

Steam explosion improved lignocellulose conversion performance through changing the substrate composition. The microbial community showed higher hydrolysis and acidification efficiency at 50 °C and pH 8.0–9.0. Additionally, the products of hydrolysis and acidification could be used for further fermentation by R. eutropha H16, and the utilization ratios of acetic acid, propionic acid and butyric acid were 53.38, 12.27 and 20.95%, respectively. Hence, steam-explosion-based conversion technology could realize effective utilization of cornstalk and has great potential for future application in lignocellulose bioconversion.

References

Chen HZ (2014) Biotechnology of lignocellulose. Springer, Netherlands, pp 403–510

Bosch SVD, Schutyser W, Vanholme R, Driessen T, Koelewijn SF, Renders T, Meester BD, Huijgen WJJ, Dehaen W, Courtin MC (2015) Reductive lignocellulose fractionation into soluble lignin-derived phenolic monomers and dimers and processable carbohydrate pulps. Energy Environ Sci 8(6):1748–1763

Kumar G, Bakonyi P, Periyasamy S, Kim SH, Nemestóthy N, Bélafi-Bakó K (2015) Lignocellulose biohydrogen: practical challenges and recent progress. Renew Sust Energ Rev 44:728–737

Jin MJ, Gunawan C, Uppugundla N, Balan V, Dale BE (2012) A novel integrated biological process for cellulosic ethanol production featuring high ethanol productivity, enzyme recycling and yeast cells reuse. Energy Environ Sci 5(5):7168–7175

Zheng Y, Pan Z, Zhang R, Wang D (2009) Enzymatic saccharification of dilute acid pretreated saline crops for fermentable sugar production. Appl Energy 86(11):2459–2465

Chen WH, Benli P, Yu CT, Wensong H (2011) Pretreatment efficiency and structural characterization of rice straw by an integrated process of dilute-acid and steam explosion for bioethanol production. Bioresour Technol 102(3):2916–2924

Himmel ME, Ding SY, Johnson DK, Adney WS, Nimlos MR, Brady JW, Foust TD (2007) Biomass recalcitrance: engineering plants and enzymes for biofuels production. Science 315(5813):804–807

Chen HZ, Liu ZH (2014) Multilevel composition fractionation process for high-value utilization of wheat straw cellulose. Biotechnol Biofuels 7(1):1–12

Alvira P, Tomás-Pejó E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101(13):4851–4861

Chen HZ, Liu LY (2007) Unpolluted fractionation of wheat straw by steam explosion and ethanol extraction. Bioresour Technol 98(3):666–676

Liu ZH, Qin L, Jin MJ, Pang F, Li BZ, Kang Y, Dale BE, Yuan YJ (2013) Evaluation of storage methods for the conversion of corn Stover biomass to sugars based on steam explosion pretreatment. Bioresour Technol 132(2):5–15

Zhang LH, Li D, Wang LJ, Wang TP, Zhang L, Chen XD, Mao ZH (2008) Effect of steam explosion on biodegradation of lignin in wheat straw. Bioresour Technol 99(17):8512–8515

Leu SY, Zhu JY (2013) Substrate-related factors affecting enzymatic saccharification of lignocelluloses: our recent understanding. BioEnergy Res 6(2):405–415

Marmann A, Aly AH, Lin W, Wang B, Proksch P (2014) Co-cultivation--a powerful emerging tool for enhancing the chemical diversity of microorganisms. Mar Drugs 12(2):1043

Horiuchi JI, Shimizu T, Tada K, Kanno T, Kobayashi M (2002) Selective production of organic acids in anaerobic acid reactor by pH control. Bioresour Technol 82(3):209

Zhang X, Qiu WH, Chen HZ (2012) Enhancing the hydrolysis and acidification of steam-exploded cornstalks by intermittent pH adjustment with an enriched microbial community. Bioresour Technol 123(123):30

Fernándezdacosta C, Posada JA, Kleerebezem R, Cuellar MC, Ramirez A (2015) Microbial community-based polyhydroxyalkanoates (PHAs) production from wastewater: techno-economic analysis and ex-ante environmental assessment. Bioresour Technol 185:368–377

Scarlata C, Sluiter J, Templeton D, Crocker D (2011) Determination of structural carbohydrates and lignin in biomass. National Renewable Energy Laboratory-NREL/TP-510-42618 Laboratory Analytical Procedure (LAP) Golden, CO

Mood SH, Golfeshan AH, Tabatabaei M, Jouzani GS, Najafi GH, Gholami M, Ardjmand M (2013) Lignocellulosic biomass to bioethanol, a comprehensive review with a focus on pretreatment. Renew Sust Energ Rev 27(6):77–93

Chen HZ (2013) Technology of steam explosion and biorefining. Springer, Netherlands, pp 35–37

Zhao JY, Chen HZ (2013) Correlation of porous structure, mass transfer and enzymatic hydrolysis of steam exploded corn Stover. Chem Eng Sci 104(50):1036–1044

Lee S, Yu J (1997) Production of biodegradable thermoplastics from municipal sludge by a two-stage bioprocess. Resour Conserv Recycl 19(3):151–164

Temudo MF, Kleerebezem R, Loosdrecht MV (2007) Influence of the pH on (open) mixed culture fermentation of glucose: a chemostat study. Biotechnol Bioeng 98(1):69

Lin CY, Lay CH (2004) Carbon/nitrogen-ratio effect on fermentative hydrogen production by mixed microflora. Int J Hydrog Energy 29(1):41–45

Wang Y, Wang H, Feng XQ, Wang XF, Huang JX (2010) Biohydrogen production from cornstalk wastes by anaerobic fermentation with activated sludge. Int J Hydrog Energy 35(7):3092–3099

Steinbüchel A, Schlegel HG (1991) Physiology and molecular genetics of poly(beta-hydroxy-alkanoic acid) synthesis in Alcaligenes eutrophus. Mol Microbiol 5(3):535–542

Yang YH, Brigham CJ, Budde CF, Boccazzi P, Willis LB, Hassan MA, Yusof ZAM, Rha C, Sinskey AJ (2010) Optimization of growth media components for polyhydroxyalkanoate (PHA) production from organic acids by Ralstonia eutropha. Appl Microbiol Biotechnol 87(6):2037–2045

Fukui T, Chou K, Harada K, Orita I, Nakayama Y, Bamba T, Nakamura S, Fukusaki E (2014) Metabolite profiles of polyhydroxyalkanoate-producing Ralstonia eutropha H16. Metabolomics 10(2):190–202

Acknowledgements

The authors gratefully acknowledge the financial support from the Transformational Technologies for Clean Energy and Demonstration (Strategic Priority Research Program of the Chinese Academy of Sciences, grant no. XDA 21060300), the Special Project of Cultivation and Development of Innovation Base of Beijing (grant no. Z171100002217003), and the Equipment Project of the State Key Laboratory of Biochemical Engineering (grant no. Y826051101) in this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, L., Liu, Y. & Chen, H. A Steam-Explosion-Based Hydrolysis and Acidification Technology for Cornstalk Bioconversion. Bioenerg. Res. 12, 103–111 (2019). https://doi.org/10.1007/s12155-018-9945-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-018-9945-9