Abstract

The present work involves the adoption of an integrated approach for the purification of lactoperoxidase from milk whey by coupling aqueous two-phase extraction (ATPE) with ultrasound-assisted ultrafiltration. The effect of system parameters of ATPE such as type of phase system, polyethylene glycol (PEG) molecular mass, system pH, tie line length and phase volume ratio was evaluated so as to obtain differential partitioning of contaminant proteins and lactoperoxidase in top and bottom phases, respectively. PEG 6000-potassium phosphate system was found to be suitable for the maximum activity recovery of lactoperoxidase 150.70% leading to 2.31-fold purity. Further, concentration and purification of enzyme was attempted using ultrafiltration. The activity recovery and purification factor achieved after ultrafiltration were 149.85% and 3.53-fold, respectively. To optimise productivity and cost-effectiveness of integrated process, influence of ultrasound for the enhancement of permeate flux during ultrafiltration was also investigated. Intermittent use of ultrasound along with stirring (2 min acoustic and 2 min stirring) resulted in increased permeate flux from 0.94 to 2.18 l/m2 h in comparison to the ultrafiltration without ultrasound. The use of ultrasound during ultrafiltration resulted in increase in flux, but there was no significant change in activity recovery and purification factor. The integrated approach involving ATPE and ultrafiltration may prove to be a feasible method for the downstream processing of lactoperoxidase from milk whey.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lactoperoxidase (LPO, EC 1.11.1.7) is a member of the peroxidase family, a group of natural enzymes, found in animals and milk whey. LPO has the ability to catalyse the thiocyanate in presence of hydrogen peroxide to form potent oxidant and bactericidal agents. In bovine milk, LPO is one of the most abundant enzymes. Its concentration is around 30 mg/l, constituting about 0.5% of the whey proteins. Whey, the by-product in cheese making, is a worldwide, not fully utilised, source of interesting proteins with high nutritional value. LPO is one of the whey proteins with interesting biological properties having a commercial potential as a value-added product. It is a basic protein with isoelectric point of 8.0 to 8.5 consisting of single polypeptide chain of molecular weight of about 80–85 kDa. The anti-bacterial properties of LPO and it is generally recognised as safe status has been published in literature demonstrating its potential to be used as a natural food preservative [1–5]. The most widely recommended industrial application of the lactoperoxidase system in food processing is in the dairy industry. Extraction of proteins from dairy wastes by techniques such as chromatography, precipitation and membrane adsorption has been extensively studied over the last few decades. Since then, various chromatographic techniques, based on ion-exchange procedures have been employed. However, most of these conventional multi-step techniques are not suitable for large-scale as they suffer from major limitations such as time-intensive, loss of activity and high-capital cost [6–8]. Nevertheless, the recovery of this dilute protein from whey is a relatively difficult task, not only because the huge volume of whey needs to be dealt with but also the presence of major proteins results in complication in the separation process. Hence, there is a need to develop potential, efficient and economical downstream processing method for separation and purification of LPO from milk whey [9].

As an alternative to conventional techniques, aqueous biphasic systems are potentially used in the field of biotechnology for concentration and purification of biomolecules. Aqueous two-phase extraction (ATPE) consists of partitioning of biomolecule between the two-aqueous phases of a system formed by mixing either two polymers or a polymer and a salt. Polyethyleneglycol and potassium phosphate aqueous two-phase systems are being the most popularly used systems. The partition coefficient of a biomolecule in the system depends on molecular weight, charge of the partitioned particle, the type and concentration of salt, concentration and molecular weight of phase forming polymer. It offers many advantages such as biocompatible environment for the biomolecules, ease of scale-up, lower interfacial tension and scope for continuous operation [10–13].

The present study involves integration of two different processes such as aqueous two-phase extraction and ultrafiltration (membrane process) for the purification and concentration of lactoperoxidase. Further ultrasound was applied to improve the performance of the ultrafiltration process. After successful partitioning of biomolecule to one of the phases, it can be concentrated and purified using membrane processes such as ultrafiltration. The separations involving membranes do not require additives and can be performed at low temperatures with less energy consumption in comparison to other separation processes. Due to the unique properties of membranes, their integration with other separation or reaction processes is easy. One of the critical issues in the performance of ultrafiltration is the decline in permeate flux that occurs as a result of both concentration polarisation and membrane fouling. Recently, a number of other researchers have demonstrated the use of ultrasound to enhance the permeate flux. Ultrasound techniques provide an attractive alternative to the control of membrane fouling [14–19].

In the present study, the main objectives of the study are (a) to study the partitioning behaviour and effect of various process parameters on purification of lactoperoxidase (b) integration of ATPE with ultrasound-assisted ultrafiltration and to enhance the overall productivity of the process.

Materials and Methods

Fresh unpasteurised cow milk sample was collected from a local dairy. The cow milk contained approximately 3.2% protein and 3.7% fat.

Polyethylene glycol (MW 1,500, 4,000, 6,000 and 20,000) and BSA were procured from Sisco Research Laboratories, Mumbai, India. Di-potassium hydrogen orthophosphate (K2HPO4), potassium di-hydrogen orthophosphate (KH2PO4), magnesium sulphate (MgSO4), ammonium sulphate (NH4)2SO4, tri-sodium citrate dihydrate (C6H5Na3O7.2H2O), sodium sulphate (Na2SO4), of AR grade were procured from Ranbaxy Chemicals, Mumbai, India. O-Methylphenol catechol monomethylether (guaiacol) was purchased from HiMedia Laboratories Pvt. Ltd., Mumbai, India. Hydrogen peroxide was obtained from Merck Pvt. Ltd., Mumbai, India. Molecular marker for sodium dodecyl sulphate polyacrylamide gel electrophoresis (SDS–PAGE) was from Sigma Chemicals Co, St. Louis, MO, USA.

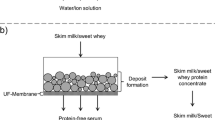

Preparation of Milk Whey

Milk whey was prepared as per the procedure detailed by Nandini and Rastogi [9]. Skim milk was prepared by centrifugation of milk at 8,000 rpm for 20 min, which was acidified to pH 4.2 to 4.6 by adding 2 N HCl to coagulate casein. The casein was separated by filtration using double-layered cheese cloth. The clear whey, thus obtained, was neutralised to pH 6.0 using 2 N NaOH and centrifuged at 8,000 rpm for 15 min. The supernatant obtained was stored at 4°C, referred as milk whey and used for further experiments [9]. LPO activity in unpasteurised milk and whey were found to be 3.82 and 3.59 U/ml, respectively.

Aqueous Two-Phase Extraction

Aqueous two-phase systems were prepared at room temperature by adding PEG (14%) and salts (14%) such as magnesium sulphate, sodium sulphate, potassium phosphate, sodium citrate or sodium carbonate to the whey making the total weight of the system 100 g [20, 21]. The pH of the aqueous two phase systems were found to be 4.3, 5.0, 7.0, 8.0 and 12.0, respectively. The amount of PEG and salt resulted in volume ratio close to 1.0 [22]. The contents of the aqueous two-phase system were mixed for about an hour for equilibration and allowed for phase separation. LPO activity and total protein concentration in both the phases were estimated as per the procedure reported in the following sections.

Ultrafiltration

Bottom phase (salt phase) rich in lactoperoxidase was subjected to ultrafiltration in a stirred cell (Amicon 8060, capacity of 50 ml). The membrane discs (45 mm diameter) of polysulphone and 50 kDa molecular weight cut-off procured from M/s Permionics, Baroda, India was used. The ultrafiltration experiments were carried out by maintaining the applied pressure, stirring speed, temperature and ultrasonic frequency constant throughout the experiment as one atmosphere, 250 rpm, 25 ± 2°C and 35 kHz, respectively for 4 h. The pressure was applied using N2 gas. Transmembrane flux was calculated based on the average flux for every 30 min. Lactoperoxidase activity and protein concentration were measured at the end of the process after 4 h.

The ultrasound experiments for evaluation of enhancement of permeate flux were conducted by subjecting the ultrafiltration unit to the sonication bath (Model UCB 40, 35 kHz). Experiments were conducted up to 4 h by combining ultrasound and stirring (Mode I stirring for 2 min and ultrasound for 2, 5 or 10 min; Mode II ultrasound for 2 min and stirring for 2, 5 or 10 min). The transmembrane flux was measured after every cycle consisting of a step of stirring followed by ultrasound at a regular interval and expressed in l m−2 h−1. The temperature of the ultrasonication bath was maintained at 25 ± 2°C throughout the experiment.

Enzyme Assay and Protein Estimation

Lactoperoxidase activity was measured using spectrophotometric method using O-methylphenol catechol monomethylether (guaiacol) as substrate in presence of H2O2 as H+ donor. The substrate solution contained 2.99 ml of 33 mM guaiacol in 0.1 M phosphate buffer of pH 7.4 and 0.01 ml of 0.3 mM hydrogen peroxide. The reaction was initiated with 0.05 ml of whey followed by immediate mixing at room temperature. The absorbance was recorded at 470 nm for every 30 s using UV-Visible spectrophotometer (Shimadzu, Model UV-200 S, Japan). The rate of oxidation of guaiacol in presence of hydrogen peroxidise to release a blue coloured product tetra-guaiacol was monitored. The amount of enzyme that catalyses the oxidation of 1 μmol of guaiacol per minute at 25°C is defined as 1 U/ml [23]. Lactoperoxidase activity was calculated as follows:

Where, ΔA 470/min is the change in absorbance per min at 470 nm; V t is the total volume of reaction mixture (ml); D F is the dilution factor; V s is the sample volume (ml); ε is the molar extinction coefficient of tetra-Guaiacol (i.e. 26.6 mM−1 cm−1).

The protein concentration was determined using Bradford dye-binding method [24]. Bradford reagent was prepared by dissolving 100 mg of Coomasie brilliant blue G 250 in 50 mL of 95% ethanol. After the dye was completely dissolved, 100 mL of 85% phosphoric acid was added and the volume was made up to 1000 mL using double distilled water. Protein was estimated by adding 100 μl sample containing enzyme to 2 mL of Bradford reagent and the volume was made up to 3.0 mL with distilled water. Absorbance was measured at 595 nm. The protein content was inferred from the standard graph of bovine serum albumin.

Estimation of Parameters and Terms Involved in ATPS

Partition Coefficient, Phase Volume Ratio and Tie Line Length

Partition coefficient of total protein (K TP) is the ratio of equilibrium concentration of protein in the top phase to the bottom phase, and it was calculated as follows.

where C t and C b are equilibrium concentrations of the partitioned protein in the polymer rich top phase and salt rich bottom phase, respectively.

Phase volume ratio (R) is defined as volume ratio of top phase to the bottom phase:

where V t and V b stand for the volume of the top phase and the bottom phase, respectively.

Tie line length (TLL) is one of the ways of characterising an ATPS. It is a measure of the difference in composition between the top and bottom phases of a defined ATPS. TLL is a square root of the sum of the square of the difference in PEG and salt concentrations between the top and bottom phases [25]. The TLL of aqueous two-phase system was calculated from its reported phase diagram [20] according to the following equation:

Where C pt and C pb are the PEG concentrations (% w/w) in top and bottom phases, respectively, and C st and C sb are the salt concentrations (% w/w) in top and bottom phases, respectively.

Activity Recovery of Lactoperoxidase and Purification Factor

Activity recovery of lactoperoxidase A R was determined in terms of enzyme activity recovered by the salt rich bottom phase because enzyme was preferentially partitioned to the salt phase. The activity recovery (%) was calculated as the ratio of percentage lactoperoxidase activity found in the bottom phase at the end of ATPE to the initial lactoperoxidase activity.

where, L i and L b are the lactoperoxidase activities (U/mL) in acid whey and bottom phase, respectively; V i and V b are the corresponding volumes.

The purification factor of lactoperoxidase is defined as the ratio of specific activity of lactoperoxidase in bottom phase after extraction to that of acid whey and can be calculated as per the following equation:

where L i and L b are the lactoperoxidase activity in the acid whey and bottom phases after extraction, respectively; P i and P b are the corresponding protein concentrations.

Statistical Analysis

Significant difference between means was determined by t test using Microsoft Excel. The significance of differences was defined at p ≤ 0.05. All the experiments were performed in triplicates and average values were reported.

Gel Electrophoresis

SDS–PAGE was performed using electrophoresis unit (Genei, Bangalore, India) by following the method as described in Methods in Enzymology [26]. Electrophoresis was conducted at 50 V, 12.5 mA, for about 3 to 4 h. The gel was stained with 0.05% (w/v) Coomassie brilliant blue R-250 prepared in a mixed solvent system containing methanol, distilled water and acetic acid in the proportion 5:4:1. The gel was destained using the same solvent system without Coomassie brilliant blue.

Results and Discussion

Lactoperoxidase was extracted from unpasteurized milk by acid coagulation procedure. LPO activities in milk and whey were found to be 3.82 and 3.59 U/ml, respectively, which indicated the 94% of extraction of LPO in whey. The development of a purification procedure using ATPS involves the variation of several factors to ensure differential partitioning of the target protein to bottom phase and the contaminants to the top phase. After partitioning of LPO to bottom phase, ultrasound-assisted ultrafiltration was attempted for further concentration and purification.

Aqueous Two-Phase Extraction

Effect of Phase Forming Salts

In order to select the suitable ATPS, PEG 1500 and different salt systems (magnesium sulphate, sodium sulphate, potassium phosphate, sodium citrate and sodium carbonate) were evaluated for partitioning behaviour of LPO and contaminant proteins. ATPS composed of 14/14 (%, w/w) PEG 1,500/salt concentration and the results are summarised in Fig. 1. Lactoperoxidase in milk whey was preferentially partitioned to the bottom phase. Activity recovery (71.34%) and purification factor (1.21-fold) was found to be maximum in case of PEG/potassium phosphate (K2HPO4 and KH2PO4) in comparison to other phase systems. Same aqueous two-phase system was found to be most effective and used by the different research group for separation of α-lactalbumin and β-lactalbumin [27], cheese whey proteins [28] and differential partitioning of fat and protein from cheese whey [29]. Based on the preliminary results, PEG/potassium phosphate system was used for further studies.

Effect of phase forming salts on extraction of lactoperoxidase phase system: PEG 1,500/Different salts (14/14% w/w), at 25 ± 2°C. 1 magnesium sulphate, 2 sodium sulphate, 3 potassium phosphate, 4 sodium citrate, 5 Sodium carbonate; AR activity recovery, PF purification factor, K TP partition coefficient of total protein

Effect of PEG Molecular Weight

The influence of polymer molecular weight on the partitioning and purification of lactoperoxidase was investigated using different PEG molecular weights (1,500, 4,000, 6,000, 8,000 and 20,000) in PEG-potassium phosphate system (K2HPO4, KH2PO4 in the ratio of 1.82:1.0). The activity recovery and purification factor were found to increase with an increase in PEG molecular weight up to 6,000 and beyond which the values were found to decrease (p ≤ 0.05). Maximum activity recovery (88.17%) and purification factor (1.44-fold) were observed when the PEG of molecular weight 6,000 was taken. With the increase in PEG molecular weight from 1,500 to 20,000, the partition coefficient of total protein was found to decrease from 0.8 to 0.44 (Fig. 2, p ≤ 0.05). The decreasing trend of partition coefficient of total protein beyond PEG molecular weight 6000 is due to volume exclusion effect of the polymer rich (top) phase. Increase in the polymer molecular weight results in the reduction of free volume of the top phase, which in turn results in partition of biomolecules in the salt rich (bottom) phase leading to decrease in partition coefficient [25, 30]. Due to volume exclusion effect, the contaminant proteins partitioning to the bottom phase with the increase in PEG molecular weight beyond PEG 6000, which resulted in the decrease in purification factor of lactoperoxidase. Based on above studies, PEG 6000 was considered as the suitable phase forming polymer and chosen for the subsequent studies.

Effect of pH

The variation of pH on lactoperoxidase partitioning and purification was studied using pH range from 5.0 to 9.0. The appropriate concentration of KH2PO4 and K2HPO4 salts were added in order to obtain the desired pH [22]. The activity recovery, partition coefficient of total protein and purification factor was found to increase from 63.80% to 123.63%, 0.61 to 1.09 and 1.08- to 1.67-fold, respectively, with an increase in pH from 5.0 to 8.0 (p ≤ 0.05). Further increase in pH resulted in reduction in activity recovery and purification factor (Fig. 3). It has been reported that PEG behaves as positively charged and proteins above their isoelectric point acquire negative charge, prefer the polymer rich top phase in PEG-salt system. The isoelectric point of the major whey proteins such as α-lactalbumin, β-lactalbumin, immunoglobulin and BSA are 4.8, 5.15–5.41, 5.5 and 4.71–5.41, respectively. These proteins will be more negatively charged with the increase in pH and the interactions between protein and PEG subunits become stronger, which results in the migration of these proteins to the top phase [27, 28, 31, 32]. Increase in migration of contaminant proteins to the top phase results in an increase in partition coefficient of total protein which leads to an increase in purity of lactoperoxidase. Similar results involving increase in partition coefficient of total protein with the increase in pH of the phase system was observed for C-phycocyanin [33] and whey proteins [27, 28]. Based on the results obtained from the study, the system pH was kept constant at 8.0 for further experiments.

The increase in activity recovery above 100% may be attributed to the elimination of inhibiting proteins during the purification process, which enhanced the activity recovery of the enzyme. Such results have been demonstrated for the concentration and purification of enzymes in case of liquid-liquid extraction by many research groups [30, 34–36].

Effect of Tie Line Length

The effect of increasing TLL upon partition behaviour of lactoperoxidase was evaluated. For all the TLL of PEG and phosphate system, volume ratio and system pH were kept constant at 1.0 and 8.0, respectively. The concentration of phase forming components at different TLL was chosen to ensure that the volume ratios were 1 in all the experiments. The activity recovery, partition coefficient of total protein and purification factor was found to increase from 76.73% to 124%, 0.79 to 1.18 and 0.66- to 1.96-fold, respectively with the increase in TLL from 6 to 25% (Fig. 4, p ≤ 0.05). Palomares and Hernandez [28] have reported that the free volume in the bottom phase decreases with an increase in TLL. With an increase in TLL, the salt concentration in the bottom phase increases, whereas in the upper phase the salt concentration remains relatively constant and equal to its solubility limit in PEG [33, 37]. As a result, the salting out of the proteins in the bottom phase promoted the partition of the protein to the top phase until it reached its solubility limit and this in turn led to increase in partition coefficient of total protein. The increase in the activity recovery and purification factor of lactoperoxidase in the bottom phase showed that the protein partitioned to the PEG rich top phase with the increase in TLL is the contaminant proteins. Similar results of increase in partition coefficient of protein with the increase in TLL were observed for α-lactalbumin [27], whey proteins [28] and Schistosoma mansoni tegumental antigen [37]. Above 25% TLL, the protein precipitation was observed at the interface, which resulted in decrease in activity recovery and purification factor. This could be attributed to the combined influence of volume exclusion and salting out effect due to increase in concentration of the phase forming components with an increase in TLL [12, 30].

Effect of Phase Volume Ratio

The influence of phase volume ratio on the recovery and purification of lactoperoxidase was evaluated. The volume ratio was varied along the selected tie line length of 25%, and the experiments were performed at pH 8.0. The activity recovery and purification factor was found to increase from 118.17% to 150.24% and 1.61- to 2.31-fold, respectively, with decrease in phase volume ratio from 1.27 to 0.35 (Fig. 5, p ≤ 0.05). Further decrease in phase volume ratio resulted in decrease in activity recovery and purification factor. The partition coefficient of total protein and lactoperoxidase followed the decreasing trend with decrease in phase volume ratio. The decrease in partition coefficient of total protein and lactoperoxidase indicated that the maximum protein partitioned to the bottom phase was lactoperoxidase. Higher activity recovery in the bottom phase can be attributed to the increase in extracting phase volume (salt rich bottom phase) with decrease in phase volume ratio and the enhancement of activity above 100% is due to removal of contaminant proteins, which inhibited the lactoperoxidase activity [34, 35, 38]. From the results of these experiments, it is clear that the phase volume ratio lower than one favoured activity recovery and purification factor of lactoperoxidase in the bottom phase. However, volume ratio below 0.35 resulted in decrease in activity recovery and purification factor. This could be due to partitioning of contaminant protein to the bottom phase because of reduction in the top phase volume.

PEG 6000/potassium phosphate system was found to be the suitable phase system for the aqueous two phase extraction of lactoperoxidase. The optimum conditions for the extraction of lactoperoxidase was pH 8.0, TLL 25% and 0.35 phase volume ratio which resulted in the activity recovery of 150.24% and 2.31-fold purity.

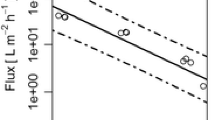

Ultrafiltration

The bottom phase rich in lactoperoxidase was subjected to ultrafiltration with and without ultrasound to investigate further purification of LPO. The lactoperoxidase activity, specific activity and purification factor after ultrafiltration was found to increase from 6.7 to 8.4 U/ml, 1.28 to 1.96 U/mg and 2.31- to 3.53-fold, respectively. The integration of ultrafiltration with ATPE resulted in further purification of lactoperoxidase by removing the contaminant proteins (Table 1). It can be observed from Fig. 6 that the permeate flux during continuous ultrasound was found to be higher as compared to stirring throughout the process. Kyllonen et al. [39] has reported that higher flux can be obtained with intermittent use of ultrasound than the continuous one. Ultrafiltration was subjected to ultrasound in combination with intermittent stirring. Hence, in one experiment (mode I) ultrasound time was kept constant (2 min) and varying stirring time (2 to 10 min, Fig. 6a). While in the other experiment (mode II), stirring time was kept constant (2 min) and varying ultrasound time (2 to 10 min, Fig. 6b). The permeate flux was found to be highest for stirring time 2 min and ultrasound for 2 min (Experiment S2:A2, Fig. 6a, b). For constant ultrasound time of 2 min, the permeate flux was found to decrease with an increase in stirring time from 2 to 10 min. However, for constant stirring time of 2 min, there was no significant change in the flux with an increase in ultrasound time from 2 to 10 min (Fig. 6a, b). It may be noted that the potential effect of increasing permeate flux due to ultrasound was observed when ultrasound was applied for minimum time of 2 min along with stirring. Probably, this time period may be just sufficient to disturb the boundary layer, thereby increasing the flux. Further increase in ultrasound period did not yield any significant increase in flux. The intermittent ultrasound has been used by many researchers for whey ultrafiltration [18], Radix astragalus extract [40] and suspended solutions [41].

Combination of ultrasound and stirring during ultrafiltration resulted in higher average permeate flux (2.18 l/m2 h) as compared to ultrafiltration alone (0.94 l/m2 h). However, no significant difference in activity recovery and purification factor was observed with ultrasound (Table 1). This indicates that the application of ultrasound can lead to significant reduction of the working volume without affecting the enzyme activity. It may be concluded that the application of ultrasound enhanced the flux, but it did not enhance the removal of protein; hence, there was no enhancement in specific activity was observed.

SDS–PAGE Analysis

The purity of lactoperoxidase after integrated approach was ascertained using SDS–PAGE profiles, which indicated molecular weight markers (Lane 1), milk whey (Lane 2), lactoperoxidase (standard) from Sigma (Lane 3), lactoperoxidase after ATPE (Lane 4) and lactoperoxidase after integrated process (Lane 5) in Fig. 7. Milk whey showed large number of bands. The reduction in the number of bands indicated the purification of lactoperoxidase using integrated approach. The band obtained lies close to the reported range of the molecular weight of lactoperoxidase (85 kDa). The existence of the second band even after purification may be due to presence of other biomolecules having similar charge and size such as lactoferrin [9].

Conclusion

The partitioning behaviour of LPO in PEG 6000-potassium phosphate aqueous two-phase system indicated that the enzyme can be extracted to the salt-rich bottom phase with an activity recovery and purification factor of 150.24% and 2.31-fold, respectively. Further, concentration and purification of enzyme using ultrafiltration of lactoperoxidase-rich salt phase resulted in higher purification factor (3.53-fold); however, no change in activity recovery was observed. The applications of ultrasound for the possible enhancement of permeate flux during ultrafiltration resulted in higher permeate flux from 0.94 to 2.18 l/m2 h as compared to control. The integration of ultrafiltration with aqueous two-phase extraction was demonstrated to be an attractive scheme of downstream processing of lactoperoxidase from milk. Further, use of ultrasound improved the performance of ultrafiltration by increasing the transmembrane flux. However, there was no significant improvement in activity recovery and purification factor.

References

Kussendrager, K. D., & Hooijdonk, A. C. M. (2000). Br J Nutr, 84, 19–25.

Elliot, R. M., McLay, J. C., Kennedy, M. J., & Simmond, R. S. (2004). Int J Food Microbiol, 91, 73–81.

Touch, V., Hayakawa, S., Yamada, S., & Kaneko, S. (2004). Int J Food Microbiol, 93, 175–183.

Andersson, J., & Mattiasson, B. (2006). J Chromatogr A, 1107, 88–95.

Min, S., Krochta, J. M., & Rumsey, T. R. (2007). J Food Eng, 80, 1116–1124.

Ozdemir, H., Aygul, I., & Küfrevioglu, O. I. (2001). Prep Biochem Biotechnol, 31, 125–134.

Doultani, S., Turhan, K. N., & Etzel, M. R. (2004). Process Biochem, 39, 1737–1743.

Billakanti, J. M., & Fee, C. J. (2009). Biotechnol Bioeng, 103, 1155–1163.

Nandini, K. E., & Rastogi, N. K. (2010). Biotechnology Progress, 26, 763–771.

Souza, R. L. D., Barbosa, J. M. P., Zanin, G. M., Lobão, M. W. N., Soares, C. M. F., & Lima, Á. S. (2010). Applied Biochemistry and Biotechnology, 161, 288–300. doi:10.1007/s12010-010-8907-2.

Rajni, H. K. (2000). Aqueous two phase systems methods and protocols. Hoboken: Humana.

Nandini, K. E., & Rastogi, N. K. (2009). Process Biochem, 44, 1172–1176.

Raghavarao, K. S. M. S., Rastogi, N. K., Gowathman, M. K., & Karanth, N. G. (1995). Advances in applied microbiology, vol 41 (pp. 97–172). New York: Academic.

Simon, A., Penpenic, L., Gondrexon, N., Taha, S., & Dorange, G. (2000). Ultrason Sonochem, 7, 183–186.

Smythe, M. C., & Wakeman, R. J. (2000). Ultrasonics, 38, 657–661.

Saxena, A., Tripathi, B. P., Kumar, M., & Shahi, V. K. (2009). Adv Colloid Interface Sci, 145, 1–22.

Muthukumaran, S., Kentish, S. E., Ashokkumar, M., & Stevens, G. W. (2005). J Membr Sci, 258, 106–114.

Chen, D., Weavers, L. K., Walker, H. W., & Lenhart, J. J. (2006). J Membr Sci, 276, 135–144.

Teng, M. Y., Lin, S. H., Wu, C. Y., & Juang, R. S. (2006). J Membr Sci, 281, 103–110.

Albertson, P. Å. (1986). Partition of Cell Particles and Macromolecules (3rd ed.). New York: Wiley.

Zaslavsky, B. Y. (1995). Aqueous two-phase partitioning, physical chemistry and bioanalytical applications. New York: Marcel Dekker.

Nandini, K. E., & Rastogi, N. K. (2009). Food and Bioprocess Technology, doi: 10.1007/s11947-008-0160-0.

Morrison, M. (1970). In H. Tabor & C. Tabor (Eds.), Methods in Enzymology (pp. 653–657). New York: Academic.

Bradford, M. M. (1976). Anal Biochem, 72, 248–254.

Marcos, J. C., Fonseca, L. P., Ramalho, M. T., & Cabral, J. M. S. (1999). J Chromatogr B, 734, 15–22.

Deuscher, M. (1990). Electrophoretic Methods, 182, 425–488.

Chen, J. P. (1992). J Ferment Bioeng, 73, 140–147.

Palomares, M., & Hernandez, M. (1998). J Chromatogr B, 711, 81–90.

Anandharamakrishna, C., Raghavendra, S. N., Barhate, R. S., Hanumesh, U., & Raghavarao, K. S. M. S. (2005). Food Bioprod Process, 83, 191–197.

Babu, B. R., Rastogi, N. K., & Raghavarao, K. S. M. S. (2008). Chem Eng Process, 47, 83–89.

Fuda, E., Jauregi, P., & Pyle, D. L. (2004). Biotechnol Prog, 20, 514–525.

Nielsen, A. H., Justesen, S. F. L., & Thomas, O. R. T. (2004). J Biotechnol, 113, 247–262.

Benavides, J., & Palomares, M. (2004). J Chromatogr B, 807, 33–38.

Mayerhoff, Z. D. V. L., Roberto, I. C., & Franco, T. T. (2004). Biochem Eng J, 18, 217–223.

Porto, T. S., Silva, M. G. M., Porto, C. S., Cavalcanti, M. T. H., Neto, B. B., Lima, F. J. L., et al. (2008). Chem Eng Process, 47, 716–721.

Cavalcanti, M. T. H., Porto, T. S., Neto, B. B., Lima, F. J. L., Porto, A. L. F., & Pessoa, J. A. (2006). Journal of Chromatogrphy B, 833, 135–140.

Chaves, A. C., Silva, L. N., Abath, F. G. C., Pereira, V. R. A., Filho, J. L. L., Porto, A. L. F., et al. (2000). Bioprocess Eng, 23, 435–438.

Chethana, S., Nayak, C. A., & Raghavarao, K. S. M. S. (2007). J Food Eng, 81, 679–687.

Kyllonen, H. M., Pirkonen, P., & Nystrom, M. (2007). Desalination, 181, 319–335.

Cai, M., Wang, S., Zheng, Y., & Liang, H. (2009). Effects of ultrasound on ultrafiltration of Radix astragalus extract and cleaning of fouled membrane. Sep Purif Technol, 68, 351–356.

Juang, R. S., & Lin, K. H. (2004). J Membr Sci, 243, 115–124.

Acknowledgement

Authors thank Dr. V. Prakash, Director, CFTRI, Mysore for encouragement. Authors thank Dr. K.S.M.S. Raghavarao, Head, Department of Food Engineering for valuable suggestions. The author Nandini expresses her gratitude and sincere thanks to the Council of Scientific and Industrial Research (CSIR), New Delhi, India for providing senior research fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nandini, K.E., Rastogi, N.K. Integrated Downstream Processing of Lactoperoxidase from Milk Whey Involving Aqueous Two-Phase Extraction and Ultrasound-Assisted Ultrafiltration. Appl Biochem Biotechnol 163, 173–185 (2011). https://doi.org/10.1007/s12010-010-9026-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-010-9026-9