Abstract

This paper is aimed to provide a new design modeling of the gripper via using the intelligent computing model. The gripper is designed to get benefit of a symmetric structure and compliant mechanism that can manipulate the objects with a stable force. The numerically experimental samples for the gripper are built and the finite element simulations are implemented. The displacement of left hand is collected. An intelligent computing model is formulated via a hybridization of the teaching learning optimization and feed forward neural network. The teaching learning optimization algorithm is embedded into neural network to enhance the training process. The results determined that the mean square error values of the entire model, the training, the testing, and validating are about 6.04e-07, 6.11e-07, 6.50e-08, and 1.10e-06, respectively. Furthermore, the coefficient of determination value of the entire model, the training, the testing, and validating are 0.9975, 0.9970, 0.9998, and 0.9677, accordingly. In addition, the proposed intelligent predictor is outperformed other regression methods such as linear regression, full 2nd order polynomial regression, and traditional artificial neural network. Moreover, the errors among the estimated from the proposed intelligent method and the prediction errors are less than 3%. It revealed that the proposed intelligent methodology is a well-suitable predictor for modeling the behaviors of gripper. The gripper is capable of providing a displacement amplification ratio of 2.85 and a max grasping force of 145.96 N. The gripper is potential for many practical applications such as robotics and manipulators in agricultural and electrics engineering.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In robotic industry, a gripper is attached on the arm of robotics. The gripper uses the end effectors such as hands or jaws to grip the objects and release it to the desired target positions. Depending on different automatic applications, the gripper is carefully designed or selected from commercial products [1, 2]. Various types of grippers have been designed to integrate them into industrial robots. The grippers can implement various tasks in agriculture, electrics, automatic systems, etc. A robotic gripper was designed with three fingers and one actuator [3]. The developed gripper could grasp the object with dimension of 100 mm. The gripper was driven by the tendons. The enveloping angle for the tendon was minimized via genetic algorithm to improve the force efficiency. Another type, a pneumatic robot gripper was designed to manipulate eggplants [4]. In this study, the accelerometers were attached to the fingers to assess their firmness. This gripper was capable of grasping the agricultural products. For strawberry harvesting, a robotic gripper was developed and it was driven by suing cables [5]. The gripper was equipped with internal sensors which could minimize the positional errors, and it was mounted with an internal container to collect berries during operation. The position of gripper was optimally controlled via PID. A magnetorheological fluid gripper was developed for industrial robots [6]. The designed gripper could achieve a max grasping force of 50.67 N. A gripper was designed for manipulating the complex objects in industrial internet.

Over the last decades, the robotic grippers have been developed in many automatic industries. The mentioned-above grippers have still required many sensors, actuators, and controller. Their design process is still complicated. Due to attachment of many actuators and sensors, the entire weight of robotic system is relatively heavy. These robotic systems are costly.

In order to decrease the weight and cost of the robotic grippers, compliant mechanism have been discovered in designing alternative robotic grippers. The compliant robotic grippers are benefits of 3D printer [7] or monolithic machining with high precision and less assembly. A constant-force mechanism was proposed to design two jaws of a gripper which was employed to pick apples in agricultural industry [8]. This constant-force mechanism was designed via using distributed compliant mechanism. A microgripper was designed using flexure mechanism and optimized by hybridization of Taguchi method and differential evolutional algorithm [9]. Another compliant microgripper was optimized by a combination of Taguchi method and teaching learning-based optimization (TLBO) [10]. For application for DC motor, a compliant gripper was devoted and optimized by grey relational analysis [11].

In enhancement of the gripping ability of robotic grippers, many studies have applied metaheuristic algorithms. For example, grasshopper optimization algorithm was applied to optimize the stability of grip forces of two jaws of gripper. Another study focused on improving the force transmission or holding force stability of grippers using TLBO. It is noted that compliant mechanism has no joints due to it is monolithic manufactured. Therefore, mechanical behaviors and kinematics become complicated. Especially, the two behaviors are vague. On the other hand, the behaviors of compliant mechanism-based robotic grippers are difficult to analyze via analytical procedures. So, it has a need to develop alternative modeling methods which can be considered as surrogate models such as linear regression, 2nd polynomial regression, artificial neural network (ANN), and so on. Among these techniques, ANN has still a well predicting ability for nonlinear problems. Hence, metaheuristic algorithms have been attached with ANN to predict and optimize engineering problems. For instance, genetic algorithm was combined with ANN to optimize the FDM machining parameters [12]. Besides, particle swarm optimization was applied to optimize the ANN accuracy for laser metal deposition process [13] and other fields [14]. However, the existing optimization algorithms still require many tuning parameters and complex computation. In order to decrease the tuning parameters, many algorithms have been suggested such as TLBO and Rao’s algorithms [15]. Until now, there is a lack of studies which have modeled the behaviors of grippers based on metaheuristics and ANN. To get benefits of less tuning parameters, the TLBO is embedded into the feed forward ANN to enhance the prediction capacity of ANN and this hybridization is applied to analyze the displacement of gripper.

The goal of this paper is to propose an intelligent approach in modeling and analyzing the behaviors of a gripper for advanced manufacturing application. The other parts of this paper are arranged as follows. The related work is provided in Sect. 2. A description of gripper and methodology are presented in Sect. 3. And then, Sect. 4 provides the results and discussion. Section 5 gives the comparative validation. Section 6 draws the conclusions.

2 Related work

In modeling behaviors of compliant mechanisms with flexure hinges, Ling et al. [16] summarized the analytical methods, such as pseudo-rigid-body model, Castigliano’s second theorem, compliance matrix method, elastic beam theory, two-port dynamic stiffness model, Ryu’s method, and beam constraint model. The mathematical explicit methods have significantly contributed in advancing compliant mechanisms, especially in modeling simple structures. Nevertheless, these methods are still challenging in modeling of more complex structures and high-nonlinear behaviors, so-called large deflection.

In addition, plenty of modeling techniques for the robotic grippers have been developed. A robotic gripper was modeled via establishing kinematic chain and Lagrange-based dynamics [17]. A Cosserat theory was suggested to establish the grasping force model for a soft robotic gripper [18]. A microgripper was designed for picking micropins and it was modeled via beam theory [19]. A two degrees of freedom constant-force gripper was modeled by using pseudo-rigid-body model [20]. For the gripper with a simple mechanism, the mentioned analytical methodologies can be effectively employed. However, they are still difficultly challenging for complex gripper mechanisms.

In enhancing the performances of engineering structures, machining process, as well as compliant mechanisms, the heuristic optimization algorithms are often utilized. There are popular optimization methods, including the Taguchi technique and metaheuristic method. The surface roughness of β phase titanium alloy was optimized via the Taguchi to improve the machining surface quality [21]. The electrical discharge machining quality of on pearlitic spheroidal graphite was enhanced by the grey-fuzzy method [22]. Besides, the particle swarm optimization (PSO) and with firefly algorithm were utilized to optimize the magnetic abrasive machining [23]. The Taguchi was employed to optimize the dimensional accuracy of titanium alloy [24]. In real world, multi-criteria are required for designing a product. For instance, non-dominated sorting genetic algorithm II was applied to optimize the spatial precision tilting manipulator [25]. Multi-objective genetic algorithm was applied to optimize the structural reliability [26]. The drilling parameters for orthopaedic implants were optimized via using the Taguchi-grey relational analysis method [27]. Considering the metaheuristic methods, a few optimizers were introduced for various engineering applications, e.g., particle swarm optimization, cuckoo search, bat algorithm, grey wolf, cat swarm algorithm, and grasshopper algorithm [28]. The flower pollination algorithm was used for multi-area interconnected power system [29] and wireless sensor networks [30].

Nowadays, the metaheuristic methods have been combined with ANN in many studies. ANN was coupled with PSO to solve the big data problems [31] and multistoried RC buildings [32]. Besides, genetic algorithm, grey wolf optimization and whale optimization algorithm were hybridized with ANN to estimate the pan evaporation [33]. Genetic algorithm was used to optimize the ANN [34].

Although there have been many modeling procedures for modeling the robotic grippers; however, there is no a couple of TLBO to improve the ANN ability for modeling the gripper. So, this paper presents a hybridization of TLBO and feed forward ANN. The gripper is a case study.

3 Description of gripper and proposed methodology

3.1 Mechanical design of gripper

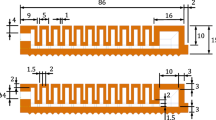

A gripper is designed to manipulate/grasp and release a variety of different objects such as cylinder, square and irregular shapes. As illustrated in Fig. 1a, the proposed gripper includes three main parts. The first part is input port where an input load is acted by translation actuators, e.g., piezoelectric actuator or other actuators (voice coil motor, or magnetic actuator). The second part comprises elastic beams which are used transfer the translation from the actuator to the output port. Particularly, the elastic beams can be considered as virtual joints with unstable rotation center. The third part consists of two hands to grip the object. The thickness of gripper is 12 mm, as depicted in Fig. 1b. By exerting the input load at the A point along the vertical direction, the left hand and the right hand are moved along the horizontal direction. The gripper is acted to open the jaws toward the object. And then, it closes the jaws to hold the object. The holding reaction forces of the object are based on the elastic energy of the beams. Due to there is no kinematic joints, the mechanical behaviors and kinematic behaviors of the gripper are vague. Therefore, the behaviors of gripper are complex and difficult to exactly analyze by analytical approaches. It is noted that one of the largest contributions of the gripper is the output displacement of hands which affected by deformations of the beams with thicknesses T1, T2, and T3. The motion principle, the motion transfer and the displacement amplification of the presented flexure-based microgripper is described as follows: The input load or input displacement from the piezoelectric actuator is acted on the input port. Then, the motion is transferred to the foldable elements, and these flexure elements are deformed. The foldable elements/flexure hinges can generate a large displacement. The output displacement of the foldable elements is transferred to the rigid link AB. Then, the motion of link AB is moved to the rigid links C1 and C2. The flexure hinges are connected to the links C1 and C2. Based on the deformation of the flexure hinges, the motion is transferred to the left and the right hands of gripper. The displacement amplification is generated by the foldable flexure elements.

3.2 Proposed methodology

As above discussed, the behaviors of gripper are relatively complex. It needs to build the surrogate models. Popularly, there are some common surrogate models such as polynomial regression, linear regression, artificial neural network (ANN), etc. In this study, a feed forward neural network [35] is chosen to model the behaviors of gripper because it is simple in use with a few tuned parameters, as shown in Fig. 2a. It comprises the input nodes (x1, x2, x3,…, xn), hidden nodes inside hidden layer, and output node (y).

Besides, the prediction accuracy of the ANN can be enhanced by using metaheuristic algorithms, e.g., GA, PSO and so forth. To get benefit of less tuning parameters, the TLBO optimizer is utilized to optimize the weight and bias of the ANN, as given in Fig. 2b. The TLBO is a teaching process with two main phases, comprising the teaching and learning phases. More details of the TLBO can be found in Ref. [36].

In this study, the proposed methodology is done by stepwise procedure, as demonstrated in Fig. 2c. It includes the following steps:

-

Generation of datasets via finite element simulations.

-

Initialization of feed forward neural network.

-

Division of dataset comprises the training, testing, and validating sets.

-

The feed forward neural network is optimized by using TLBO.

-

Establishment of the optimal ANN with best weights and biases.

-

Prediction of the behavior of gripper hand by the optimal ANN.

Three design variables (T1, T2, T3) are three inputs of the feed forward ANN and the displacement of left hand is selected as the outcome. The number of hidden nodes can be computed as follows.

where Nh is the number of hidden nodes, Ni is the number of inputs, and No is the number of outputs.

The mean square error of the feed forward ANN is considered as the objective function in the TLBO algorithm. The MSE indicator can be calculated by.

where z is the simulated value and \(\hat{z}\) is the estimated value, and k is input size.

In order to prove the robustness of the proposed method, the TLBO-hybrid feed forward ANN is compared with other regression techniques through two other indicators. The root mean squared error (RMSE) value is computed by

The coefficient of determination (R2) is calculated by.

where z is the simulated value and \(\hat{z}\) is the estimated value,\(\overline{z}\) is the average value and k is input size.

4 Results and discussion

4.1 Simulations

The designed gripper is fixed by screws at the holes, as in Fig. 1. For the simulation, an input displacement of 0.4 mm is acted along the vertical direction from the input port. The output displacements of left hand and right hand are measured along the horizontal direction. The gripper is meshed via BEAM188 elements. The fine meshes are applied for the elastic beams while the 0 meshes are employed for rigid link (see in Fig. 3a). The number of nodes and elements are 26,012 nodes and 14,389 elements, respectively. The beams/flexures are refined with fine mesh to ensure the accuracy of FEA because the deformation of gripper is mainly focused on the flexure beams. Meanwhile, the coarse mesh is applied for rigid links. In this work, the nonlinear FEA is applied for simulating the gripper. The simulated results found that the maximum stress is appeared at the beams where undergo a large deformation during the gripper operation, as given in Fig. 3b. In this paper, material Al 6082 is used for the gripper. Its yield strength is about 276 MPa, Poisson ratio is 0.33, density is 2770 kg/m3, and Young’s modulus is 69000 MPa.

With three main design variables (T1, T2, T3) and two displacements of the left hand and right hand, the datasets are established through central composite design. The fifteen samples are made and the results are retrieved, as provided in Table 1.

The results of Table 1 indicated that the displacement of left hand is equal to the displacement of the right hand. It means that the gripper can operate with a stable gripping force. The results noted that the maximum displacement of hands is 2.85 times more than the input displacement (0.4 mm). It can conclude that the displacement is amplified about 2.85 through the elastic beam systems. This ensures a wide workspace of the gripper so that it can handle many dimensions of objects.

4.2 Establishment of intelligent model and prediction

The results showed that the displacements of two hands are almost the same. Hence, the displacement of left hand is selected as the datasets (Table 1). In order to formulate a well-train predictor, the TLBO is embedded into the feed forward ANN. The goal of established intelligent model is to map the design variables and the displacement of gripper. To do this, the TLBO is initialized an initial population of 50 and a max termination condition of 500. By using the Eq. (1), the hidden nodes are equal to 7. The MSE of the feed forward ANN is chosen as the fitness function for the TLBO.

The training results found that the correlation coefficients are close to 1, as depicted in Fig. 4.

Figure 5 demonstrates the best validation performance of the proposed intelligent predictor. It showed that the MSE value of the training is decreased at the 3rd epoch. Lastly, the training state is illustrated in Fig. 6.

The modeling results from Figs. (4, 5 and 6) showed that the optimal results found that the performance indicators of the proposed intelligent predictor are relatively well. Especially, the MSE values of the entire model, the training, the testing, and validating are approximately 6.04e-07, 6.11e-07, 6.50e-08, and 1.10e-06, respectively. Meanwhile, the RMSE values are about 0.000778, 0.000782, 0.000255, and 0.001051 for the entire model, the training, the testing, and validating, respectively. The R2 value of the model, the training, the testing, and validating are about 0.9975, 0.9970, 0.9998, and 0.9677, accordingly. It can conclude that the proposed intelligent model is well-suitable predictor for modeling and predicting the behavior of gripper.

5 Comparison and validation

In demonstrating the robustness, feasibility, and effectiveness of the proposed intelligent method, a few popular regression techniques are utilized for comparing purpose. The used regression models comprise the linear regression, the full 2nd order polynomial regression, and the conventional ANN. Three metric indicators (MSE, RMSE, and R2) are computed by using Eqs. (2–4). It is noted that the smaller values of MSE and RMSE provide a better predictor. Meanwhile, the higher R2 value shows a greater predictor.

The comparing results are collected in Table 2. The performance criteria for the model, training, testing, and validating are utilized for the comparison purpose. The R2 values of the proposed method are close to one. This proved that the built predictor can well-predict the behavior of the gripper. The results revealed that the suggested intelligent method is better than the conventional ANN and other regression methods. The linear regression is the worst predictor for the gripper. To sum up, the proposed intelligent method is the best predictor for the gripper because the entire indicators are very well.

Figure 7 illustrates the comparing correlation of the observed displacement of hand and predicted values from the TLBO-coupled ANN. The correlation determined by the suggested method is better than the linear regression.

In addition, the accuracy and robustness of the proposed intelligent model is verified through numerical experimentations. To do this, a few random values of design variables are arranged into ten numerically experimental samples. The ten prototypes of the developed gripper with material Al 6082 are built, and then they are determined by finite element analysis (FEA) software ANSYS 2019R1. The displacement of the left hand is measured. The results are provided in Table 3. The predicted displacement and the measured one deviate lower than 3%. This shows that the devoted intelligent method is considered as an efficient predictor for the gripper.

To sum up, when an input displacement of 0.4 mm acts to the A point from an outer actuator (e.g., piezoelectric actuator), the max output displacement is found about 1.14. It means that the gripper can achieve a displacement amplification ratio of 2.85. In addition, the developed gripper can provide a max gripping force of the jaw/hand is about 145.96 N.

According to Ling et al. [16], the analytical methods (e.g., pseudo-rigid-body model, Castigliano’s second theorem, compliance matrix method, elastic beam theory, two-port dynamic stiffness model, Ryu’s method, and beam constraint model) showed a significant advance in the field. But, these methods are still difficult to build the concise mathematic equations for complex structures and large deflection for the gripper. Meanwhile, the current study proposed a new intelligent modeling method to solve the complex behavior of the gripper. The current study suggested a data-driven technique in order to overcome the disadvantages in physic-based methods. The proposed method would be interesting in predicting the kinetostatic and dynamics of others mechanisms. It could be considered as artificial intelligence technique for modeling, optimization and synthesis of general compliant mechanisms.

In real word, pneumatic robot or manipulator are often used to handle objects in industry. Unlike the existing robotics, the advantage of the proposed gripper consisted of lightweight, low cost, high precision, free joints and lubricants. At the beginning of contacting, the proposed gripper is flexible to handle the object based on the elastic deformations of flexure beams. This can help to avoid the breakout the targeted object. In addition, the gripper is symmetrically designed and a large thickness to prevent in the out-of-plane (z-axis) to prevent the rotation.

6 Conclusions

This paper presented a new design modeling of the gripper via using the elastic beams. To get benefit of a symmetric structure, the jaws of gripper can manipulate the objects with a stable force. The holding reaction force of the left hand is similar to that of right hand. The displacement of left hand is chosen to analyzed. An intelligent model is established via a hybridization of the teaching learning optimization and feed forward neural network. The proposed intelligent method is employed to predict the displacement. The achieved results were summarized as follows.

-

The results found that the MSE values of the entire model, the training, the testing, and validating are 6.04e-07, 6.11e-07, 6.50e-08, and 1.10e-06, respectively. Furthermore, the RMSE values are 0.000778, 0.000782, 0.000255, and 0.001051 for the entire model, the training, the testing, and validating, respectively.

-

The R2 value of the model, the training, the testing, and validating are 0.9975, 0.9970, 0.9998, and 0.9677, accordingly.

-

Besides, the proposed intelligent predictor is superior to other regression methods (linear regression, full 2nd order polynomial regression, and traditional ANN).

-

Moreover, the deviation errors among the estimated from the proposed intelligent method and the FEA results are very small. It revealed that the proposed intelligent model is well-suitable predictor for modeling the behaviors of gripper.

-

Finally, the designed gripper can provide a max displacement amplification ratio of 2.85 and a max grasping force of 145.96 N.

Although the proposed intelligent approach is effective for modeling the gripper but it still has some drawbacks. Particularly, the computation becomes more complicated when the number of hidden layers is increased. It needs a large computational effort of computer and human work. Therefore, the computing modeling process should increase the speed the computation with a less time as well as achieve a higher precise predictor. These works can be done by enhancing the TLBO algorithm and feed forward ANN. In future work, the prototype of gripper is manufactured via wire electrical discharged machining, and the experimental verifications are performed. Then, the gripper has a largely potential for many practical applications such as robotics and manipulators in agricultural engineering and electrics.

References

Nguyen, P., Ho, V.A.: Grasping interface with wet adhesion and patterned morphology: case of thin shell. IEEE Robot. Autom. Lett. 4, 792–799 (2019). https://doi.org/10.1109/LRA.2019.2893401

Nguyen Van, P., Bui, T.H., Ho, V.A.: (2021) Towards safely grasping group objects by hybrid robot hand. 2021 4th Int Conf Robot Control Autom Eng RCAE 2021 1:389–393. https://doi.org/10.1109/RCAE53607.2021.9638841

Dong, H., Asadi, E., Qiu, C., et al.: Geometric design optimization of an under-actuated tendon-driven robotic gripper. Robot. Comput. Integr. Manuf. 50, 80–89 (2018). https://doi.org/10.1016/j.rcim.2017.09.012

Blanes, C., Ortiz, C., Mellado, M., Beltrán, P.: Assessment of eggplant firmness with accelerometers on a pneumatic robot gripper. Comput Electron. Agric. 113, 44–50 (2015). https://doi.org/10.1016/j.compag.2015.01.013

Xiong, Y., Peng, C., Grimstad, L., et al.: Development and field evaluation of a strawberry harvesting robot with a cable-driven gripper. Comput. Electron. Agric 157, 392–402 (2019). https://doi.org/10.1016/j.compag.2019.01.009

Nishida, T., Okatani, Y., Tadakuma, K.: Development of universal robot gripper using MR α Fluid. Int. J. Humanoid Robot 13, 1–13 (2016). https://doi.org/10.1142/S0219843616500171

Sandhu, K., Singh, G., Singh, S., et al.: Surface characteristics of machined polystyrene with 3D printed thermoplastic tool. Materials (Basel) 13, 1–16 (2020). https://doi.org/10.3390/ma13122729

Miao, Y., Zheng, J.: Optimization design of compliant constant-force mechanism for apple picking actuator. Comput. Electron. Agric. 170, 105232 (2020). https://doi.org/10.1016/j.compag.2020.105232

Dao, T.: Robust parameter design for a compliant microgripper based on hybrid Taguchi-differential evolution algorithm. Microsyst. Technol. (2017). https://doi.org/10.1007/s00542-017-3534-2

Le Chau, N., Ho, N.L., Tran, N.T., Dao, T.-P.: Analytical model and computing optimization of a compliant gripper for the assembly system of mini direct-current motor. Int. J. Ambient Comput. Intell. (2021). https://doi.org/10.4018/ijaci.2021010101

Le Chau, N., Ho, N.L., Vinh Chung, T.T., et al.: Computing optimization of a parallel structure-based monolithic gripper for manipulation using weight method-based grey relational analysis. Int. J. Ambient Comput. Intell. 12, 39–74 (2021). https://doi.org/10.4018/IJACI.2021070103

Deshwal, S., Kumar, A., Chhabra, D.: Exercising hybrid statistical tools GA-RSM, GA-ANN and GA-ANFIS to optimize FDM process parameters for tensile strength improvement. CIRP J. Manuf. Sci. Technol. 31, 189–199 (2020). https://doi.org/10.1016/j.cirpj.2020.05.009

Pant, P., Chatterjee, D.: Prediction of clad characteristics using ANN and combined PSO-ANN algorithms in laser metal deposition process. Surf. Interfaces 21, 100699 (2020). https://doi.org/10.1016/j.surfin.2020.100699

Prakash, C., Singh, S., Singh, M., et al.: Multi-objective parametric appraisal of pulsed current gas tungsten arc welding process by using hybrid optimization algorithms. Int. J. Adv. Manuf. Technol. 101, 1107–1123 (2019). https://doi.org/10.1007/s00170-018-3017-3

Rao, R.V., Singh, H.: Rao algorithms for multi - objective optimization of selected thermodynamic cycles. Eng. Comput. (2020). https://doi.org/10.1007/s00366-020-01008-9

Ling, M., Howell, L.L., Cao, J., Chen, G.: Kinetostatic and dynamic modeling of flexure-based compliant mechanisms: a survey. Appl. Mech. Rev. (2020). https://doi.org/10.1115/1.4045679

Hassan, A., Abomoharam, M.: Modeling and design optimization of a robot gripper mechanism. Robot Comput. Integr. Manuf. 46, 94–103 (2017). https://doi.org/10.1016/j.rcim.2016.12.012

Haibin, Y., Cheng, K., Junfeng, L., Guilin, Y.: Modeling of grasping force for a soft robotic gripper with variable stiffness. Mech. Mach. Theory 128, 254–274 (2018). https://doi.org/10.1016/j.mechmachtheory.2018.05.005

Jain, R.K., Majumder, S., Ghosh, B., Saha, S.: Design and manufacturing of mobile micro manipulation system with a compliant piezoelectric actuator based micro gripper. J. Manuf. Syst. 35, 76–91 (2015). https://doi.org/10.1016/j.jmsy.2014.12.001

Zhang, X., Xu, Q.: Design and testing of a novel 2-DOF compound constant-force parallel gripper. Precis Eng. (2019). https://doi.org/10.1016/j.precisioneng.2018.09.004

Wandra, R., Prakash, C., Singh, S.: Experimental investigation and optimization of surface roughness of β-Phase titanium alloy by ball burnishing assisted electrical discharge cladding for implant applications. Mater. Today Proc 48, 975–980 (2021). https://doi.org/10.1016/j.matpr.2021.06.070

Sharma, A., Kumar, V., Babbar, A., et al.: Experimental investigation and optimization of electric discharge machining process parameters using grey-fuzzy-based hybrid techniques. Materials (Basel) (2021). https://doi.org/10.3390/ma14195820

Babbar, A., Prakash, C., Singh, S., et al.: Application of hybrid nature-inspired algorithm: single and bi-objective constrained optimization of magnetic abrasive finishing process parameters. J. Mater. Res. Technol. 9, 7961–7974 (2020). https://doi.org/10.1016/j.jmrt.2020.05.003

Pramanik, A., Islam, M.N., Basak, A.K., et al.: Optimizing dimensional accuracy of titanium alloy features produced by wire electrical discharge machining. Mater. Manuf. Process 34, 1083–1090 (2019). https://doi.org/10.1080/10426914.2019.1628259

Ling, M., Song, D., Zhang, X., et al.: Analysis and design of spatial compliant mechanisms using a 3-D dynamic stiffness model. Mech. Mach. Theory 168, 104581 (2022). https://doi.org/10.1016/j.mechmachtheory.2021.104581

Konak, A., Coit, D.W., Smith, A.E.: Multi-objective optimization using genetic algorithms: a tutorial. Reliab Eng Syst Saf 91, 992–1007 (2006). https://doi.org/10.1016/j.ress.2005.11.018

Antil, P., Kumar Antil, S., Prakash, C., et al.: Multi-objective optimization of drilling parameters for orthopaedic implants. Meas Control (United Kingdom) 53, 1902–1910 (2020). https://doi.org/10.1177/0020294020947126

Nilanjan, D., Ashour, A.S., Bhattacharyya, S.: Applied nature-inspired computing: algorithms and case studies. Springer Singapore (2020). https://springerlink.bibliotecabuap.elogim.com/book/10.1007/978-981-13-9263-4?noAccess=true

Jagatheesan, K., Anand, B., Samanta, S., et al.: Application of flower pollination algorithm in load frequency control of multi-area interconnected power system with nonlinearity. Neural Comput. Appl. 28, 475–488 (2017). https://doi.org/10.1007/s00521-016-2361-1

Binh, H.T.T., Hanh, N.T., Van Quan, L., Dey, N.: Improved cuckoo search and chaotic flower pollination optimization algorithm for maximizing area coverage in wireless sensor networks. Neural Comput. Appl. 30, 2305–2317 (2018). https://doi.org/10.1007/s00521-016-2823-5

Cao, J., Cui, H., Shi, H., Jiao, L.: Big data: a parallel particle swarm optimization-back-propagation neural network algorithm based on MapReduce. PLoS ONE 11, 1–17 (2016). https://doi.org/10.1371/journal.pone.0157551

Chatterjee, S., Sarkar, S., Hore, S., et al.: Particle swarm optimization trained neural network for structural failure prediction of multistoried RC buildings. Neural Comput. Appl. 28, 2005–2016 (2017). https://doi.org/10.1007/s00521-016-2190-2

Seifi, A., Soroush, F.: Pan evaporation estimation and derivation of explicit optimized equations by novel hybrid meta-heuristic ANN based methods in different climates of Iran. Comput. Electron. Agric. (2020). https://doi.org/10.1016/j.compag.2020.105418

Hore, S., Chatterjee, S., Santhi, V., et al.: Optimized Neural Networks. 139–151 (2017) https://doi.org/10.1007/978-3-319-38771-0

Cappelli, L., Balokas, G., Montemurro, M., et al.: Multi-scale identification of the elastic properties variability for composite materials through a hybrid optimisation strategy. Compos. Part B Eng. (2019). https://doi.org/10.1016/j.compositesb.2019.107193

Rao, R.V., Savsani, V.J., Vakharia, D.P.: Teaching-learning-based optimization: an optimization method for continuous non-linear large scale problems. Inf. Sci. (Ny) 183, 1–15 (2012). https://doi.org/10.1016/j.ins.2011.08.006

Acknowledgements

This research is supported by Industrial University of Ho Chi Minh City (IUH) under grant number 01/HD-DHCN.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nguyen, D.N., Dang, M.P., Nguyen, T.T. et al. Intelligent computation modeling and analysis of a gripper for advanced manufacturing application. Int J Interact Des Manuf 17, 2185–2195 (2023). https://doi.org/10.1007/s12008-022-00885-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-022-00885-2