Abstract

Essential oils such as thymol are added to food packaging film to obtain active films with antimicrobial and antioxidant properties. However, thymol is insoluble in water, and release rate of thymol is usually too fast. Therefore, a need exists to increase thymol solubility and to deliver thymol in a controlled manner from film matrix to food surface. In this study, spray dried inclusion complexes of β-cyclodextrin/thymol (1:1 molar ratio) was incorporated into gelatin solution to obtain active gelatin films. Both inclusion complexes and active films showed sustained release of thymol. Physical properties and thymol release kinetics were evaluated for active films. For gelatin films with 8.25% (mass ratio) inclusion complexes, complete thymol release took 235 h, compared with 38 h for thymol release from inclusion complexes. The diffusion coefficient reached 2.04 × 10−15 m2 s−1.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Food safety is a persistent growing concern. Growth of microorganisms on food surface is one of the major causes of food spoilage. When antimicrobials (AM) are applied to food systems, they react with all kinds of food components, which lead to a gradual decrease in antimicrobial activity. The concept of active packaging with antimicrobial properties is brought up. The functions of active antimicrobial packaging include better preservation of the food properties, improvement of safety and/or sensory quality, and extension of the shelf life while maintaining the quality of foods (European FAIR-project CT 98-4170). One of the approaches to extend antimicrobial efficacy is to release AM onto the food surface in a controlled rate (Cho et al. 2010). Incorporation of different antimicrobial agents into food packaging materials have been widely studied (Gemili et al. 2010; Mastromatteo et al. 2010). The main obstacle to apply antimicrobials is that AM release is too fast. Therefore, to release antimicrobials in a controlled manner is the goal of this study.

Essential oils have attracted more attention for their application in food manufacturing and storage due to the increase of bacterial resistance to antibiotics. Essential oils are natural preservatives, and these agents possess the GRAS (generally recognized as safe) status as defined by US FDA (Food and Drug Administration). Essential oils have been proposed to incorporate into active packaging for food preservation (Maisanaba et al. 2017). Thymol (5-methyl-2-isopropylphenol) is one of the most commonly used essential oils. Thymol is the major constituent of herb thyme (Thymus vulgaris), which has long been used as inhibitor of Aspergillus spp., Alternaria spp., Fusarium spp., and Penicillium spp.; these are some of the most important microorganisms causing food-borne diseases and/or spoilage molds. Thymol exhibits strong antimicrobial and antioxidant activity against those spoilage microorganisms.

In previous studies, thymol has been applied in food packaging in mainly two approaches. First, thymol is incorporated into zein film directly (Del Nobile et al. 2008; Li et al. 2012) since thymol and zein both solubilize well in ethanol, but it pose a problem to apply thymol in water-soluble packaging materials. Second, thymol is blended in petroleum-based polymer matrix using casting or extrusion technology (Ramos et al. 2014). Under this approach, thymol will degrade or lose its effectiveness resulting from volatility during processing, especially if the process involves high temperature and shear energy, as occurs during extrusion process.

Generally, protein-based film has good mechanical, optical, and barrier properties (Li and Ye 2017; Han 2014). Protein-based films or coating are widely used in meat and meat product (Umaraw and Verma 2017), fruit and vegetables (Otoni et al. 2017), seafood (Dehghani et al. 2018), and deep fried and frozen foods (Kurek et al. 2017; Akcan et al. 2017). Gelatin is unique among proteins in forming thermo-reversible with a melting point close to the body temperature (Achet and He 1995). Gelatin is commonly used as a gelling agent of food dispersion systems, drug encapsulation, pharmaceutical and cosmetic products, and mainly in the formulation of edible packaging (Mastromatteo et al. 2009). Modification of gelatin-based film to enhance its physical properties or to make the film active by incorporating bioactive agents has been the subject of much research (Arvanitoyannis et al. 1998; De Carvalho and Grosso 2004; Hoque et al. 2011; Kanmani and Rhim 2014). Due to thymol insolubility in water, thymol cannot be directly applied to gelatin solution to prepare food films/films using casting technology. One way to stabilize and decrease thymol loss and mask its strong odor is by inclusion in suitable host molecules such as cyclodextrins (CDs). CDs are a family of cyclic oligosaccharides that are composed of α-(1, 4)-linked glucopyranose subunits. CDs have unique structure property; their polar, hydrophobic, internal cavity can entrap guest molecules by non-covalent interactions, such as hydrogen bonds, van der Waals, or hydrophobic interactions (Singh et al. 2002). Guest molecules can be beneficially modified with their physicochemical properties including stabilization of light- or oxygen-sensitive substances, fixation of very volatile substances, and a marked increase of water solubility (Cevallos et al. 2010). Thymol encapsulated in CDs can increase thymol solubility and stability (Cevallos et al. 2010). The most successfully used molecular encapsulates are β-CDs because of the low cost, non-toxicity (GRAS), biocompatibility, and effective degradation; thymol, carvacrol, and eugenol were successfully incorporated in β-CD (Zhang et al. 2015). Barba et al. (2015) found β-CD showed a higher retention than α- and γ-CD for eugenol/carvacrol. Saturated solution method to prepare β-CD inclusion is the most common method and followed by freezing drying to acquire solid-state β-CD inclusion (Cevallos et al. 2010). Spray drying is rarely reported but is low-cost and time-saving; therefore, spray drying was used in this study.

In this study, β-CD-thymol inclusion was prepared first and the inclusion was added into gelatin solution to acquire active gelatin packaging film. The physical and thermal properties of gelatin active packaging film and thymol diffusion kinetics were evaluated. Compared to freeze or vacuum drying, spray drying is easier to apply in industrial settings. Results of physical properties and DSC analysis can be used for process and quality control in large-scale production of gelatin-active packaging film. With isooctane as food simulant system to test thymol release, the active gelatin packaging film was designed to be applied to fat rich foods such as cheese. Since gelatin is widely used as excipient/capsule in pharmaceutical industry, the controlled release system may also be extended for pharmaceutical uses.

Materials and Method

Materials

Food-grade bovine gelatin was purchased from Sangon Biotech (Shanghai, China). Analytical grade chemicals including thymol, β-CD, glycerol, and sodium bromide were purchased from Sino Pharm Chemical Co., Ltd., Shanghai, China. HPLC-grade isooctane was purchased from APS Chemicals Ltd., Australia.

Preparation of Inclusion Complexes (β-CD-Thymol)

Saturated solution method and spray drying were used to prepare β-CD-thymol. Beta-CD saturated solution was prepared at 60 °C. Thymol (molar ratio of β-CD to thymol was 1:1) was added into the solution slowly. The solution was stirred in a sealed vessel for 24 h and then spray-dried using a B-290 mini spray dryer (Mini Spray Dryer B-290, BuCHI Labortechnik AG, Flawil, Switzerland). Spray drying conditions included an inlet temperature of 150 °C, a compressed air pressure of 500 kPa, an air flow rate of 20 m3/h, and a feed rate of 1.2 mL/min. The powders were collected and stored in a desiccator at 20 °C until use. The inclusion recovery and inclusion ratio were calculated using Eqs. (1) and (2) listed below.

Preparation of Active Gelatin Films

Gelatin solution was prepared, using a concentration of 8% (w/v) by hydrating gelatin powder with distilled water for 2 h at 60 °C until complete dissolution. After that, glycerol (mass ratio of gelatin to glycerol was 4:1) was added as the plasticizer. After thoroughly mixing gelatin and glycerol, different amounts (0.1, 0.3, and 0.5 g, equivalent 6.25, 18.75, and 31.25% of gelatin powder in mass ratio) of inclusion complexes were added. Gelatin-based films were prepared by casting 20-g film-forming solutions into propylene plates (12 cm in diameter) and drying at room temperature for 48 h. The obtained films were peeled off from the plate and conditioned in desiccators over saturated sodium bromide (NaBr) solution at room temperature. Conditioning was performed for 2 days for films under different treatments to reach equilibrium moisture content. After conditioning, films were subjected for determination of physical and thermal properties and thymol release kinetics.

Characterization of Active Gelatin Packaging Films

Mechanical Properties

Tensile strength (TS) and elongation at break (EB) of the films were determined using a texturometer TA.XT2i—Stable Micro Systems (Surrey, England) equipped with a tension grip system A/TG, according to the standard testing method ASTM D638-01 (2001). The measurements were made at 20 °C and 65% RH in a controlled room. A minimum of six strips (5 cm in length and 1 cm in width) were obtained from each film for the test. The initial grip separation and velocity were fixed at 30 mm and 1 mm/s, respectively. The curves of force (N) as a function of deformation (mm) were recorded by the Texture Expert Exceed Software. Tensile properties were calculated from the plot of stress (tensile force/initial cross-sectional area) versus strain (extension as a fraction of the original length) (Masamba et al. 2016a). Tensile strength was calculated by dividing the required force for film rupture by the area of the transverse section, and elongation at break was calculated from the ratio of the increase in length to the original length, expressed in percentage (Chen et al. 2013). The reported values corresponded at least to five determinations.

Thickness

Thickness was acquired by averaging the thickness measurements of 10 randomly different locations using a dial gauge with a sensitivity of 0.001 mm (Chen et al. 2013).

Water Vapor Barrier Property

Water vapor permeability (WVP, gm−1 s−1 Pa−1) tests were performed according to ASTM method E96 (1995) with some modifications. The films were sealed with rubber band on glass cups (diameter 30 mm, height 60 mm) filled with silicon gel. All cups were placed in desiccators containing saturated bromide solution (60% RH). The desiccators were maintained at 25 °C until the weights of the cup became constant (± 0.0001 g). Water vapor permeability was calculated with Eq. (3) (Fabra et al. 2013).

where W is weight difference, T is the time required for the weights to become constant, X is the average thickness of film. A is the permeation area (7.065 cm2), and (P2-P1) is the difference of partial vapor pressure of the atmosphere with silica gel and distilled water (3169 Pa, 25 °C). After steady-state conditions were reached, eight weight measurements were performed. The reported values corresponded to the average of at least three determinations.

Thermal Properties

Thermal properties were characterized by differential scanning calorimeter (DSC). DSC analysis was performed with NETZSCH DSC 200F3. Thymol, β-CD, β-CD-thymol complexes, and gelatin film without and with incorporation of inclusion complexes were analyzed. Samples were heated from − 50 to 250 °C at a rate of 10 °C/min under a dry nitrogen purge. The sample amounts used were approximately 10 mg.

Quantification of Thymol Release from β-CD-Thymol Inclusion Complexes and Active Gelatin Packaging Films

The total amounts of thymol in β-CD-thymol complexes and gelatin film were determined by gas chromatography (GC). The procedures were as follows: for inclusion complexes, 0.5 g β-CD-thymol complexes was extracted by Soxhlet extraction using 100 mL of isooctane until the extraction was exhausted. For active film, the whole films were immersed into 50-mL isooctane until all of the thymol migrated into the isooctane. A 10-μL aliquot was subjected to GC. A Shimadzu GC 2010 equipped with a fused silica capillary column DB-5 (30 m* 0.25 mm i.d., film thickness 0.25 mm, J &W Scientific, USA) was used. The following conditions were applied: sample volume, 1.0 mL; non-split model, initial column temperature, 80 °C held for 2 min; heating rate, 20 °C min−1 to 160 °C, 5 °C min−1 to 160 °C, then held for 5 min more; injector temperature, 250 °C; FID detector temperature, 300 °C; and carrier gas, nitrogen. Thymol amounts were calculated from prepared standard curves. Thymol retention and thymol inclusion efficiency were calculated according to Eqs. (4) and (5).

Diffusion Experiments in Food Simulant System

Dainelli et al. (2008) suggested a relatively rapid and convenient method to determine diffusivity of species in AM films by immersion in food simulants such as distilled water, buffer solution, isooctane, ethanol, acetic acid, and rectified olive oil (Sung et al. 2013; Arcan and Yemeniciogglu 2014). Gelatin-active film was designed to film fat-rich foods such as cheese; therefore, isooctane was chosen as the food simulant. Diffusion experiments were performed in closed flasks and stored at 25 °C in an incubation shaker (Innova-4230, New Brunswick Scientific, U.S.A.) with a continuously rotating speed of 30 rpm (Janjarasskul and Krochta 2010). Such mild agitation condition simulates agitation during storage and transportation and a steady-state transfer of antimicrobial agents from the inclusion complexes and films to the simulant (Hou et al. 2016).

Inclusion complexes (0.5 g) and whole pieces of active films were immersed in 50-mL isooctane solution, and samples were sampled at various times (3, 18, 38, 65, 89, 114, 137, 162, 186, 210, 234, and 270 h). Experiments were performed in triplicates. The amount of thymol was determined using GC as described in “Quantification of thymol release from β-CD-thymol inclusion complexes and active gelatin packaging films.”

Release Kinetics Analysis

Thymol release kinetics was evaluated by fitting general law of diffusion (Crank 1979) first. The diffusion coefficients D (m2 s−1) of thymol were later calculated using the half-time method given in Eq. (6) (Masamba et al. 2016b; Barnes et al. 2006).

where L is the thickness of the film, and t0.5 is the time required for 50% of the migrating species to be released into the simulant (i.e., when Mt = 0.5 M∞) (Suppakul et al. 2011; Ouattara et al. 2000).

Statistical Analysis

Thymol release kinetics, mechanical properties, thickness and water vapor permeability were subjected to analysis of variance using one-way factorial ANOVA procedure. To this aim, procedures were performed with SPSS 12.0 for Windows. Mean comparisons were performed using the Duncan’s test to examine if differences were significant at P < 0.05.

Results and Discussion

Inclusion Performance

Various known methods used for the formation of the inclusion complexes like co-precipitation, neutralization, kneading, spray drying, freeze-drying, and solvent evaporation, and ball-milling and sealed-heating in the laboratory have been widely reported (Yamada et al. 2000). Saturated solution method followed by spray drying is a low-cost and simple method. Beta-CD-thymol inclusion mass yield reached 55.52 ± 1.23% with an inclusion ratio of 8.67 ± 0.79%. Thymol retention in β-CD-thymol inclusion was 0.91 ± 0.05%. Thymol inclusion efficiency was 7.80 ± 1.22%. The formation of β-CD-thymol inclusion complexes was confirmed by DSC. DSC thermograms are discussed in “DCS Thermograms.” Spray drying is widely used in food and pharmacy industry for its low-cost and time-saving characteristics. However, large sums of produce adhere to the drying chamber leading to mass yield loss, which led to inclusion mass yield of only 55%. Similar low yields of inclusion complexes were reported as 51% in Bruschi et al. (2003) and as < 50% in Barba et al. (2015). Operating conditions (wall material concentration, solid to liquid ratio, inlet temperature, air and feed rates) can affect mass yield (Al-Nasiri et al. 2018). The addition of drying aids (silicon dioxide, sodium chloride, and gum Arabic) can reduce or eliminate adhesion problems (Souza and Oliveira 2006; Tontul and Topuz 2017; Mahdavi et al. 2016). To make spray drying economically viable for producing β-CD-thymol inclusion, further work should be optimizing operating conditions and adding drying aid materials to improve mass yield.

Physical Properties and Release Kinetics

Pure gelatin film as control and active gelatin films incorporated with different amounts of β-CD-thymol inclusion were uniform, homogeneous, thin, and easy to handle. The films were removed without difficulty from polypropylene plates with thickness ranging between 280 and 330 μm. As shown in Table 1, tensile strength decreased from 17 to 14% and elongation decreased from 28 to 11% with increased addition of inclusion complexes. The values of tensile strength and elongation were similar to what has been reported for typical gelatin-based films decreased from 17 to 14%. The trend that these two parameters decreased with increasing amount of β-CD-thymol inclusion is also consistent with previous research (Ahmad et al. 2012; Hoque et al. 2011; Arfat et al. 2014). Thickness and water vapor permeability increased with the inclusion content increased. Similar phenomena were found in other studies when incorporating bioactives containing hydroxyl group (–OH) into active films (Hoque et al. 2011; Suppakul et al. 2011). For instance, increasing addition of plasticizer increased thickness and lowered the tensile strength and elongation (Hoque et al. 2011). In the case of adding inclusion complexes, more inclusion complexes addition means increasing hydroxyl group interaction with water since each β-CD molecule has 14 external hydroxyl group (–OH). Therefore, water vapor permeability increased. Gelatin film with an inclusion loading of 18.75% exhibited significantly lowered tensile strength and elongation and higher water vapor permeability. These changes are caused by the less dense network which resulted from the extra particles adding into the gelatin polymeric matrix. The polymeric network became looser with higher amount of inclusion complexes.

The release of a low molecular weight compound migrating from a swelling homogeneous polymeric network can be viewed as a result of the following phenomena: (1) solvent diffusion from the outer solvent solution into the polymeric matrix; (2) macromolecular matrix relaxation; (3) counter diffusion of the active compound from the swollen polymeric network into the outer solvent solution (Mastromatteo et al. 2009). In this study, thymol first diffused from inclusion complexes, second migrated into the gelatin polymeric matrix, and diffused into the isooctane simulant until a thermodynamic equilibrium between the two phases was reached. Figure 1 shows the release rate of thymol from inclusion complexes, and active gelatin films incorporated with 6.25, 18.75, and 31.25% inclusion complexes. Thymol completely migrated from inclusion complexes (0.5 g) into isooctane in 38 h (no significant differences for thymol release between 38 and 65 h), while active film containing inclusion complexes (0.5 g) had a sustained release for 235 h (no significant differences for thymol release between 235 and 270 h). Release kinetics showed that thymol release is more sustained when incorporating the inclusion into gelatin packaging compared to adding it directly into food simulant system. However, with increasing incorporation of inclusion complexes in active films, diffusion coefficients dropped significantly (Table 1). By adjusting the amount of inclusion complexes incorporated in gelatin film, thymol release rate can be easily controlled.

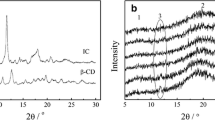

DSC Thermograms

DSC is commonly used to confirm the complexes formation in the solid state (Karathanos et al. 2007); disappearance of thermal events (melting point) corresponding to guest molecules is generally taken as an evidence (Pralhad and Rajendrakumar 2004). Thymol shows an exothermal peak at 50 °C (Fig. 2a), which is in accordance with its melting point. The β-CD thermogram (Fig. 2b) showed a baseline decreasing from close to 90 °C with a peak above 150 °C, which is similar to the previous research by Cevallos et al. (2010). In Fig. 2c, there was no endothermic peak at around 50 °C in β-CD-thymol inclusion complexes, indicating that thymol is forming inclusion complexes with β-CD. For gelatin film thermograms, two peaks at lower temperatures (70 and 120 °C) are caused by the devitrification of blocks rich in α-amino acids, and the high one (180 °C) is attributed to the devitrification of blocks rich in amino acids such as proline and hydroxyproline (Zheng et al. 2002). It is noteworthy that the melting point of β-CD-thymol inclusion complexes (Fig. 2c) starts at 137 °C, while the melting point of gelatin film without and with inclusion complexes (31.65%) (Fig. 2d, e) started at around 180 °C. Thymol was stabilized in β-CD-thymol inclusion complexes and additionally stabilized by incorporating β-CD-thymol inclusion complexes in gelatin films.

Conclusion

In this work, saturation method and spray drying proved to be an efficient method to prepare β-CD-thymol inclusion complexes. Controlled release system based on gelatin packaging film was prepared by incorporating β-CD-thymol inclusion complexes into gelatin film-forming solution. Tensile strength and elongation decreased while water vapor permeability increased with increasing amount of inclusion in the gelatin films, which is expected. Sustained release (38 h) of thymol is obtained with β-CD-thymol inclusion complexes, and additionally, sustained release (235 h) of thymol is achieved by incorporating inclusion complexes into gelatin films.

References

Achet, D., & He, X. (1995). Determination of the renaturation level in gelatin films. Polymer, 36(4), 787–791.

Ahmad, M., Benjakul, S., Prodpran, T., & Agustini, T. W. (2012). Physico-mechanical and antimicrobial properties of gelatin film from the skin of unicorn leatherjacket incorporated with essential oils. Food Hydrocolloids, 28(1), 189–199. https://doi.org/10.1016/j.foodhyd.2011.12.003.

Akcan, T., Estevez, M., & Serdaroglu, M. (2017). Antioxidant protection of cooked meatballs during frozen storage by whey protein edible films with phytochemicals from Laurus nobilis L. and Salvia officinalis. LWT - Food Science and Technology, 77, 323–331.

Al-Nasiri, G., Cran, M. J., Smallridge, A. J., & Bigger, S. W. (2018). Optimisation of β-cyclodextrin inclusion complexes with natural antimicrobial agents: thymol, carvacrol and linalool. Journal of Microencapsulation, 35(1), 26–35.

Arcan, I., & Yemeniciogglu, A. (2014). Controlled release properties of zein–fatty acid blend films for multiple bioactive compounds. Journal of Agricultural and Food Chemistry, 62(32), 8238–8246.

Arfat, Y. A., Benjakul, S., Prodpran, T., Sumpavapol, P., & Songtipya, P. (2014). Properties and antimicrobial activity of fish protein isolate/fish skin gelatin film containing basil leaf essential oil and zinc oxide nanoparticles. Food Hydrocolloids, 41, 265–273. https://doi.org/10.1016/j.foodhyd.2014.04.023.

Arvanitoyannis, I., Nakayama, A., & Aiba, S.-i. (1998). Edible films made from hydroxypropyl starch and gelatin and plasticized by polyols and water. Carbohydrate Polymers, 36(2–3), 105–119.

Barba, C., Eguinoa, A., & Mate, J. I. (2015). Preparation and characterization of β-cyclodextrin inclusion complexes as a tool of a controlled antimicrobial release in whey protein edible films. LWT - Food Science and Technology, 64(2), 1362–1369. https://doi.org/10.1016/j.lwt.2015.07.060.

Barnes, K., Sinclair, R., & Watson, D. (2006). Chemical migration and food contact materials. Woodhead Publishing.

Bruschi, M. L., Cardoso, M. L. C., Lucchesi, M. B., & Gremiao, M. P. D. (2003). Gelatin microparticles containing propolis obtained by spray-drying technique: preparation and characterization. International Journal of Pharmaceutics, 264(1), 45–55. https://doi.org/10.1016/S0378-5173(03)00386-7.

Cevallos, P. A. P., Buera, M. P., & Elizalde, B. E. (2010). Encapsulation of cinnamon and thyme essential oils components (cinnamaldehyde and thymol) in β-cyclodextrin: effect of interactions with water on complex stability. Journal of Food Engineering, 99(1), 70–75.

Chen, Y., Ye, R., Li, X., & Wang, J. (2013). Preparation and characterization of extruded thermoplastic zein–poly (propylene carbonate) film. Industrial Crops and Products, 49, 81–87.

Cho, S. Y., Lee, S. Y., & Rhee, C. (2010). Edible oxygen barrier bilayer film pouches from corn zein and soy protein isolate for olive oil packaging. LWT - Food Science and Technology, 43(8), 1234–1239.

Crank, J. (1979). The mathematics of diffusion (2nd ed.). Oxford: Oxford University Press.

Dainelli, D., Gontard, N., Spyropoulos, D., Zondervan-van den Beuken, E., & Tobback, P. (2008). Active and intelligent food packaging: legal aspects and safety concerns. Trends in Food Science & Technology, 19(Supplement 1), S103–S112. https://doi.org/10.1016/j.tifs.2008.09.011.

De Carvalho, R. A., & Grosso, C. R. F. (2004). Characterization of gelatin based films modified with transglutaminase, glyoxal and formaldehyde. Food Hydrocolloids, 18(5), 717–726. https://doi.org/10.1016/j.foodhyd.2003.10.005.

Dehghani, S., Hosseini, S. V., & Regenstein, J. M. (2018). Edible films and coatings in seafood preservation: a review. Food Chemistry, 240, 505–513.

Del Nobile, M. A., Conte, A., Incoronato, A. L., & Panza, O. (2008). Antimicrobial efficacy and release kinetics of thymol from zein films. Journal of Food Engineering, 89(1), 57–63. https://doi.org/10.1016/j.jfoodeng.2008.04.004.

Fabra, M. J., Lopez-Rubio, A., & Lagaron, J. M. (2013). High barrier polyhydroxyalcanoate food packaging film by means of nanostructured electrospun interlayers of zein. Food Hydrocolloids, 32(1), 106–114.

Gemili, S., Yemenicioglu, A., & Altınkaya, S. A. (2010). Development of antioxidant food packaging materials with controlled release properties. Journal of Food Engineering, 96(3), 325–332.

Han, J. H. (2014). Edible films and coatings: a review. In J. H. Han (Ed.), Innovations in food packaging, (2nd ed., pp. 213–255). Elsevier.

Hoque, M. S., Benjakul, S., & Prodpran, T. (2011). Effects of partial hydrolysis and plasticizer content on the properties of film from cuttlefish (Sepia pharaonis) skin gelatin. Food Hydrocolloids, 25(1), 82–90.

Hou, L., Johnson, J. A., & Wang, S. (2016). Radio frequency heating for postharvest control of pests in agricultural products: a review. Postharvest Biology and Technology, 113, 106–118.

Janjarasskul, T., & Krochta, J. M. (2010). Edible packaging materials. Annual Review of Food Science and Technology, 1(1), 415–448.

Kanmani, P., & Rhim, J.-W. (2014). Physical, mechanical and antimicrobial properties of gelatin based active nanocomposite films containing AgNPs and nanoclay. Food Hydrocolloids, 35, 644–652.

Karathanos, V. T., Mourtzinos, I., Yannakopoulou, K., & Andrikopoulos, N. K. (2007). Study of the solubility, antioxidant activity and structure of inclusion complex of vanillin with β-cyclodextrin. Food Chemistry, 101(2), 652–658.

Kurek, M., Scetar, M., & Galic, K. (2017). Edible coatings minimize fat uptake in deep fat fried products: a review. Food Hydrocolloids, 71, 225–235.

Li, M., & Ye, R. (2017). Edible active packaging for food application: materials and technology. In M. A. Masuelli (Ed.), Biopackaging (1st ed., p. 1). Boca Raton: CRC Press.

Li, K.-K., Yin, S.-W., Yang, X.-Q., Tang, C.-H., & Wei, Z.-H. (2012). Fabrication and characterization of novel antimicrobial films derived from thymol-loaded zein–sodium caseinate (SC) nanoparticles. Journal of Agricultural and Food Chemistry, 60(46), 11592–11600.

Mahdavi, S. A., Jafari, S. M., Assadpoor, E., & Dehnad, D. (2016). Microencapsulation optimization of natural anthocyanins with maltodextrin, gum Arabic and gelatin. International Journal of Biological Macromolecules, 85, 379–385.

Maisanaba, S., Llana-Ruiz-Cabello, M., Gutierrez-Praena, D., Pichardo, S., Puerto, M., Prieto, A., et al. (2017). New advances in active packaging incorporated with essential oils or their main components for food preservation. Food Reviews International, 33(5), 447–515.

Masamba, K., Li, Y., Hategekimana, J., Liu, F., Ma, J., & Zhong, F. (2016a). Effect of type of plasticizers on mechanical and water barrier properties of transglutaminase cross–linked zein–oleic acid composite films. International Journal of Food Engineering, 12(4), 365–376.

Masamba, K., Li, Y., Hategekimana, J., Zehadi, M., Ma, J., & Zhong, F. (2016b). Evaluation of mechanical and water barrier properties of transglutaminase crosslinked zein films incorporated with oleic acid. International Journal of Food Science and Technology.

Mastromatteo, M., Barbuzzi, G., Conte, A., & Del Nobile, M. (2009). Controlled release of thymol from zein based film. Innovative Food Science & Emerging Technologies, 10(2), 222–227.

Mastromatteo, M., Mastromatteo, M., Conte, A., & Del Nobile, M. A. (2010). Advances in controlled release devices for food packaging applications. Trends in Food Science & Technology, 21(12), 591–598.

Otoni, C. G., Avena-Bustillos, R. J., Azeredo, H., Lorevice, M. V., Moura, M. R., Mattoso, L. H., et al. (2017). Recent advances on edible films based on fruits and vegetables—a review. Comprehensive Reviews in Food Science and Food Safety, 16(5), 1151–1169.

Ouattara, B., Simard, R. E., Piette, G., Bégin, A., & Holley, R. A. (2000). Diffusion of acetic and propionic acids from chitosan-based antimicrobial packaging films. Journal of Food Science, 65(5), 768–773. https://doi.org/10.1111/j.1365-2621.2000.tb13584.x.

Pralhad, T., & Rajendrakumar, K. (2004). Study of freeze-dried quercetin–cyclodextrin binary systems by DSC, FT-IR, X-ray diffraction and SEM analysis. Journal of Pharmaceutical and Biomedical Analysis, 34(2), 333–339.

Ramos, M., Beltran, A., Peltzer, M., Valente, A. J. M., & Garrigos, M. d. C. (2014). Release and antioxidant activity of carvacrol and thymol from polypropylene active packaging films. LWT - Food Science and Technology, 58(2), 470–477. https://doi.org/10.1016/j.lwt.2014.04.019.

Singh, M., Sharma, R., & Banerjee, U. C. (2002). Biotechnological applications of cyclodextrins. Biotechnology Advances, 20(5–6), 341–359. https://doi.org/10.1016/S0734-9750(02)00020-4.

Souza, C. R., & Oliveira, W. P. (2006). Powder properties and system behavior during spray drying of Bauhinia forficata link extract. Drying Technology, 24(6), 735–749.

Sung, S.-Y., Sin, L. T., Tee, T.-T., Bee, S.-T., Rahmat, A. R., Rahman, W. A. W. A., Tan, A. C., & Vikhraman, M. (2013). Antimicrobial agents for food packaging applications. Trends in Food Science & Technology, 33(2), 110–123. https://doi.org/10.1016/j.tifs.2013.08.001.

Suppakul, P., Sonneveld, K., Bigger, S. W., & Miltz, J. (2011). Diffusion of linalool and methylchavicol from polyethylene-based antimicrobial packaging films. LWT - Food Science and Technology, 44(9), 1888–1893.

Tontul, I., & Topuz, A. (2017). Spray-drying of fruit and vegetable juices: effect of drying conditions on the product yield and physical properties. Trends in Food Science & Technology, 63, 91–102.

Umaraw, P., & Verma, A. K. (2017). Comprehensive review on application of edible film on meat and meat products: an eco-friendly approach. Critical Reviews in Food Science and Nutrition, 57(6), 1270–1279.

Yamada, T., Imai, T., Ouchi, K., Otagiri, M., Hirayama, F., & Uekama, K. (2000). Inclusion complex of 3, 9-bis (N,N-dimethylcarbamoloxy)-5H-benzofuro [3, 2-c] quinoline-6-one (KCA-098) with Heptakis (2, 6-di-O-methyl)-b-cyclodextrin: interaction and dissolution properties. Chemical and Pharmaceutical Bulletin, 48(9), 1264–1269.

Zhang, Y., Cui, L., Che, X., Zhang, H., Shi, N., Li, C., Chen, Y., & Kong, W. (2015). Zein-based films and their usage for controlled delivery: origin, classes and current landscape. Journal of Controlled Release, 206, 206–219.

Zheng, J. P., Li, P., Ma, Y. L., & Yao, K. D. (2002). Gelatin/montmorillonite hybrid nanocomposite. I. Preparation and properties. Journal of Applied Polymer Science, 86(5), 1189–1194.

Funding

This work was supported by National Key Technologies R&D Program (Grant No. 2016YFD0400800).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, M., Zhang, F., Liu, Z. et al. Controlled Release System by Active Gelatin Film Incorporated with β-Cyclodextrin-Thymol Inclusion Complexes. Food Bioprocess Technol 11, 1695–1702 (2018). https://doi.org/10.1007/s11947-018-2134-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-018-2134-1

), gelatin films incorporated with 6.25% (

), gelatin films incorporated with 6.25% ( ), 18.75% (

), 18.75% ( ), 31.25% (

), 31.25% ( ) inclusion complexes

) inclusion complexes