Abstract

Antimicrobial activity is an attractive property for packaging materials which can extend the shelf life of products and provide microbial safety for consumers. The study aimed to analyze the physicochemical and antimicrobial properties of gelatin-based edible films containing trans-anethole as the active additive. Encapsulation with β-cyclodextrin was used as an effective way to introduce trans-anethole into gelatin matrix. The results showed that the trans-anethole/β-cyclodextrin inclusion complex could be evenly dispersed in the gelatin-based edible films with appropriate addition. The incorporation of trans-anethole conferred the edible films with good antimicrobial activity as expected, which increased with the content of trans-anethole increasing. Moreover, the addition of inclusion complex improved the tensile strength and surface hydrophobicity and reduced the moisture content of the edible films. It was interesting that the edible films presented great UV light barrier property and it was increased by the addition of inclusion complex. Overall, the antimicrobial gelatin-based edible films showed great potential as bioactive packaging materials to extend food shelf life.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, biodegradable and biobased packaging materials have obtained a widespread interest due to the limited natural resources, food safety, and environmental problems caused by the use of petrochemical-based plastics (Sun et al. 2017). Among them, proteins are good options because of their favorable structural and mechanical characteristics. Gelatin is a biodegradable polymer with the protein nature that is obtained by changing the thermal nature or chemical and physical degradation of collagen (Guo et al. 2013). Gelatin has been widely introduced into food, pharmaceutical, cosmetic, and photographic industries, owing to its unique functional and technological properties (Karim and Bhat 2009). However, the application of gelatin as packaging material is limited to its poor barrier ability against water vapor, poor mechanical property, and thermal stability. Particularly, the perishable property of gelatin packaging material is one of its main defects since microbial spoilage is a major problem affecting food quality. Therefore, antimicrobial activity has been an attractive property for gelatin packaging materials which can extend the shelf life of products and provide microbial safety for consumers (Otero et al. 2014).

To date, many antimicrobial agents have been incorporated into packaging materials for antimicrobial activity such as silver nanoparticles and plant essential oils (Shankar and Rhim 2016). In this context, plant essential oils and their main components are gaining a wide interest as they are generally recognized as safe (Kavoosi et al. 2014). Moreover, incorporation of essential oils in packaging materials may not only enhance the antimicrobial properties but also reduce water solubility, vapor permeability, and slow lipid oxidation of the product (Hafsa et al. 2016). Bergamot (Sánchez-González et al. 2011), garlic oil (Pranoto et al. 2005), rosemary (Gómez-Estaca et al. 2009), thyme oil (Pires et al. 2013), and some other essential oils from plants have been used to improve antimicrobial capacity of gelatin edible films.

Trans-anethole (1-methoxy-4-(1-propenyl) benzene, ANE) is the major component in essential oil of several plants such as anise (Kosalec et al. 2005), star anise (Padmashree et al. 2007), and fennels (Przygodzka et al. 2013). ANE was reported to possess antimicrobial, estrogenic, and antithrombotic effects (Gharib et al. 2016). It is effective against bacteria, yeast, and fungal strains and has wide applications in food preservation (De et al. 2002; Singh et al. 2006). However, ANE presents some disadvantages as a functional additive such as poor water solubility, high volatility, and low physicochemical stability (Gharib et al. 2016). Encapsulation in cyclodextrins is one of the most applied technologies to protect guests and design controlled release systems (Barba et al. 2015). In the previous works, the aqueous solubility and physicochemical stability of ANE could be increased to a large scale by being included in β-cyclodextrin (β-CD) (Zhang et al. 2015). The release behavior of ANE from the inclusion complex was well controlled (Zhang et al. 2015; Kfoury et al. 2016). Therefore, the encapsulation of ANE in β-CD will be an effective way to introduce ANE into gelatin matrix.

The study aimed to analyze the physicochemical and antimicrobial properties of gelatin-based edible films containing ANE as the active additive. ANE was firstly included into β-CD to enhance the aqueous solubility and physicochemical stability. Then the inclusion complex was incorporated into gelatin to prepare edible films with dialdehyde carboxymethyl cellulose (DCMC) as the crosslinking reagent. The physicochemical and antimicrobial properties of the gelatin-based edible films were systematically evaluated for food packaging material.

Materials and Methods

Materials

Bovine hide gelatin type B (Bloom 250), trans-anethole (ANE, purity >99%), and β-cyclodextrin (β-CD, purity >98%) were purchased from Aladdin Reagent Database Inc. (Shanghai, China). The β-CD was purified by recrystallization before use. DCMC was prepared according to our previous method (Mu et al. 2012). All other chemicals were of analytical grade and purchased from Kelong Chemical Reagent Company (Chengdu, China).

Preparation of Gelatin-Based Edible Films

The ANE/β-CD inclusion complex (IC) was prepared by co-precipitation method described in our previous work (Zhang et al. 2015). The IC and gelatin were used as raw materials to prepare edible films by casting method as follows. One gram of gelatin powder and 45 mL of distilled water were blended at 40 °C for 30 min to prepare gelatin solution. Then IC powder was added into gelatin solution and stirred at 40 °C for 3 h. The achieved mixture was conditioned at −20 °C for 24 h and subsequently thawed to obtain gelatin-IC solution. The glycerol and DCMC solution (1%, w/v) were added into the gelatin-IC solution as plasticizer and crosslinking reagent, respectively. The ratios of glycerol and DCMC to gelatin were controlled at 20 and 6 wt% based on dry gelatin weight. Thereafter, the achieved mixture was poured into the polytetrafluoroethylene dishes and dried at 40 °C and 30% relative humidity for 3 days. The obtained gelatin-based edible films were named G-IC0, G-IC5, G-IC10, G-IC15, G-IC20, and G-IC25 when the ratio of IC to gelatin was 0, 5/100, 10/100, 15/100, 20/100, and 25/100, respectively. Three repetitions of each type of film were prepared at the same time.

X-ray Diffraction

The X-ray diffraction (XRD) profiles were obtained using an 18 KW rotating anode X-ray diffractometer (X’Pert Pro, Philips, Almelo, Netherlands) with a fixed CuKα radiation of 0.154 nm. The diffraction angle was scanned from 5° to 30° 2θ at a rate of 2°/min.

SEM Observation

The cross-section morphology of gelatin-based edible films was directly observed by a scanning electron microscope (SSX-550, Shimadzu, Kyoto, Japan). The films were fractured in liquid nitrogen and fixed on the surface of stub using double-sided adhesive carbon tape so as to permit the observation of the cross-section of the films. The samples were coated with gold and examined under an acceleration voltage of 15 kV. Three repetitions of each type of film were used for the observations. Three random areas of each sample were observed.

Light Barrier Properties and Transparency

The light transmittance and transparency of the edible films were measured by an UV-VIS-NIR spectrophotometer (UV-3600, Shimadzu, Kyoto, Japan) according to ASTM method D1746-92. The results were used to evaluate the ultraviolet and visible light barrier properties of the films. The transparency was calculated as follows:

where T is the light transmittance (%) while x is the thickness (mm) of the film.

Water Contact Angle

The surface hydrophobicity of gelatin-based edible films was determined by measuring the water contact angle (WCA) of the film surface using a WCA analyzer (OCAH200, Dataphysics Co., Ltd., Germany). Ten microliters of distilled water was carefully dropped on the surface of films through a 2.0-mL micrometer syringe and the contact angles and images were immediately recorded. For each film, the test was repeated at least three times.

Moisture Content and Water Solubility

Moisture content (MC) and total soluble matter (TSM) were measured by the method proposed elsewhere (Gontard et al. 1992). Briefly, the films (2 × 2 cm2) were dried in an oven at 105 °C for 24 h. The weight loss was measured as water content. The MC value was identified as water content per 100 g of dry film. Afterward, the dry films were directly immersed into 30 mL of distilled water and softly stirred at 25 °C for 24 h. Then the samples were collected and dried in an air-circulating oven at 105 °C for 24 h again. The TSM value was identified as the ratio of weight loss to the initial weight of dry films. The measurements were repeated three times for each type of film and an average was taken as the result.

Water Vapor Permeability Measurement

Water vapor permeability (WVP) was measured according to the ASTM E96-92 method reported by Gontard et al. (1992). Distilled water was added into a glass permeating cup. Then the film was sealed on the top of the cup, which was placed in a desiccator containing silica at 20 °C. The vapor pressure in the cup and the desiccator were 2337 and 0 Pa, respectively. The weight change of the cup was monitored over time. Then the WVP value of the film can be calculated as follows:

where w is the weight loss (g); x is the film thickness (m); A is the area of exposed film (m2); t is time (s); and (P 2 − P 1) is the vapor pressure differential across the film (Pa). This entire procedure was repeated three times for each film type.

Tensile Strength and Elongation at Break Measurement

Tensile strength (TS) and elongation at break (EB) of the films were measured by an electronic universal testing machine (CMT6202, MTS systems Co., Ltd., China) at 25 °C and 50% RH according to ASTM D882-97. The mechanical crosshead speed was set at 100 mm/min while the initial grip separation was set at 25 mm. TS (MPa) was calculated by the following equation:

where F max is the maximum load (N) to pull the film apart and A is the cross-sectional area (m2) of the film. EB (%) was calculated by following equation:

where L is the film elongation at the moment of rupture (mm) and 25 is initial grip length (mm) of samples. In each film type, three samples were tested.

Release Characteristic of ANE

G-IC25 was flatly spread in glass dishes and put in desiccators at different temperatures, with saturated salt solution of MgCl2 to control the relative humidity. At 24-h intervals, the lids of desiccators were opened and humid air with the same relative humidity was blown into the desiccators to purge the gas. Then about 100 mg of sample was collected and the content of ANE in the sample was determined by spectrophotometric analysis according to previous method (Zhang et al. 2015). All the experiments were done in triplicate.

Antimicrobial Activity Test

The antimicrobial activity test was carried out using two methods. The zone of inhibition assay on solid medium was firstly used for determination of the antimicrobial effects of films. Escherichia coli and Pseudomonas aeruginosa were used as the models of Gram-negative bacteria while Staphylococcus aureus and Bacillus subtilis were used as the models of Gram-positive bacteria. Ten milliliters of molten Luria-Bertani medium was inoculated by 200 μL of bacterial cultures (colony count of 1 × 108 CFU/mL). Test film discs with 1 cm diameter were placed on the plates. Then the plates were incubated at 37 °C for 24 h in the appropriate incubation chambers. The plates were examined for “zone of inhibition” of the film discs. The diameter of the whole zone was measured with a caliper then subtracted from the film disc diameter and this difference in diameter was reported as the zone of inhibition.

Secondly, the antimicrobial activity of the film surface was measured according to ISO 22196:2011 standard with a slight modification. E. coli was used as the model of Gram-negative bacteria while S. aureus was used as the model of Gram-positive bacteria. Test film specimen with 2 cm diameter was placed into a sterile Petri dish. The surface of the specimen was inoculated with 100 μL of S. aureus or E. coli suspension (colony count of 1 × 108 CFU/mL). Then the inoculum was covered with a polyethylene film (sterilized by washing with 70% ethanol before the test) and incubated at 37 °C for 24 h. After that, the inoculum was transferred into a tube and diluted to 100 mL with sterilized phosphate-buffered physiological saline (0.0425 g KH2PO4, 8.49 g NaCl, 1000 mL distilled water, pH 6.8~7.2). Then 100 μL aliquots were removed from the tube and homogeneously distributed on LB agar plate. The LB agar plate was kept in an incubator at 37 °C for 48 h and the bacterial colonies were observed and counted to evaluate antimicrobial performance. For the control, the inoculum was directly pipette into the sterile Petri dish without film specimen with the other conditions kept constant. To precisely count the colony units, we also prepared an additional 100-times-diluted and an additional 1000-times-diluted aliquot after the first 24 h incubation for the control (control ×100 and control ×1000). Three repetitions of each type of film were used for the measurements. Three specimens were randomly cut from each film and used for the testing.

Statistical Analyses

The normal distribution of experimental data was analyzed and then SPSS version 17.0 software was used for statistical analysis. Data were assessed with one-way analysis of variance (ANOVA) by using Duncan’s multiple range test. A value of p < 0.05 was considered to be significant.

Results and Discussion

Structural Characterization of the Gelatin-Based Edible Films

X-ray diffraction (XRD) is an effective method to study the microstructure of crystal and some amorphous materials. It is considered as a simple and useful method for the detection of inclusion complex (Zhang et al. 2015). Figure 1a shows the XRD patterns of β-CD and ANE/β-CD inclusion complex (IC). The results showed that some sharp peaks at 10.6°, 12.5°, 15.4°, 17.4°, 19.7°, 22.9°, and 27.1° (2θ) were observed in the diffractogram of β-CD, indicating its crystalline nature. In contrast, the diffractogram of ANE/β-CD inclusion complex exhibits the disappearance of the peaks which originally belong to β-CD. And some new sharp peaks were found, including three weak peaks at 5.8°, 6.7°, and 18.0° and a strong one at 11.6°. Indeed, the ANE/β-CD inclusion complex was successfully prepared and characterized by the same method in our previous work. The same results of XRD were obtained, which confirm the formation of inclusion complex of ANE and β-CD (Zhang et al. 2015).

The XRD patterns of the edible films with different contents of inclusion complex are shown in Fig. 1b. It is well known that the partially crystalline gelatin has a characteristic peak at 7~8° (2θ), which is due to the triple helical structure in collagen and in renatured gelatin (Guo et al. 2014). As shown in Fig. 1b, a relative weak peak 1 at 7.5° (2θ) was observed. In addition, Fig. 1b shows a broad peak 2 at about 20° (2θ), which is attributed to the amorphous fraction of the films. It is worth to note that a new weak diffraction peak 3 was observed in G-IC20 and G-IC25, which originally belongs to the inclusion complex (Fig. 1a). But then the characteristic peak 3 cannot be observed in G-IC5, G-IC10, and G-IC15. The results indicate that the ANE/β-CD inclusion complex is evenly dispersed in the gelatin-based edible films with appropriate addition. However, the compatibility of gelatin and inclusion complex decreases with the increase of the content of inclusion complex. Too much addition of inclusion complex will induce phase separation of the edible films.

To further understand the dispersion of ANE/β-CD inclusion complex in the edible films, the SEM micrographs of the cross-section of gelatin-based edible films are measured and shown in Fig. 2. It shows that the cross-sections of G-IC0 to G-IC15 present similarly smooth and homogenous structure. The results indicate that the ANE/β-CD inclusion complex is evenly dispersed in G-IC0 to G-IC15. However, the cross-sections of G-IC20 and G-IC25 exhibit more and more heterogeneous and rough morphology with increasing content of ANE/β-CD inclusion complex. Notably, the aggregates of ANE/β-CD inclusion complex were observed in G-IC20 and G-IC25 (red circles in Fig. 2e, f). Furthermore, more aggregates were observed in G-IC25 than that in G-IC20. The results confirm the results of XRD that too much addition of the inclusion complex in G-IC20 and G-IC25 will induce phase separation of the edible films.

Light Barrier Properties and Transparency

Oxidative reactions in food directly lead to the deterioration of quality attributes such as flavor, aroma, texture, and color (Elias et al. 2008). Therefore, different approaches to avoid the lipid oxidation have been taken in the process of food production and storage. It is well known that UV light in the range of 200–280 nm is one of the common oxidation initiators in food systems. Nowadays, there is an ever increasing interest in improving the barrier properties against UV light of protein films. Figure 3 shows the light transmission of the gelatin-based edible films incorporated with different contents of ANE/β-CD inclusion complex. The transparency of the films was calculated and presented in Table 1. It can be seen that the light transmission of the films in the UV range is quite low while the related transparency is high. It indicates that the films have great barrier properties against UV light, which agrees with previous reports (Mu et al. 2012). Indeed, protein films possess high ultraviolet barrier property owing to the high content of aromatic amino acids that can absorb UV light. In addition, the light transmission of the films in the visible light range is high while the related transparency is low. The results indicate that the films are very transparent. It is worth to note that the transparency of the films at 280 nm significantly increases with the increase of inclusion complex content. The results reveal that the addition of ANE/β-CD inclusion complex improves the UV light barrier properties of the films. It is known that ANE has a strong UV absorption capacity, which contributes to the improvement of the UV light barrier properties of the edible films (Zhang et al. 2015).

Water Contact Angle

Water contact angle (WCA) values are good indicators of the hydrophilic or hydrophobic character of film surface. Generally speaking, a high WCA means hydrophobicity, whereas a low angle indicates hydrophilicity. Figure 4 shows the shape of water droplets deposited on the surface of gelatin-based edible films during the measurements of WCA. The WCA values are collected and shown in Table 2. It shows that the WCA value of G-IC0 is relatively close to 110° in spite of the hydrophilic nature of gelatin, glycerol, and DCMC, which should be due to the strong forces that exist between the film-forming molecules (Mihaly Cozmuta et al. 2015). Furthermore, the crosslinking by DCMC can improve the hydrophobicity of the edible films by tightening the networks and reducing the hydrophilic groups. As shown in Table 2, the higher contact angles were noticed for those films incorporated with more inclusion complex. It indicates that ANE/β-CD inclusion complex contributes to the improvement of the surface hydrophobicity of the edible films. The result is mainly attributed to the hydrophobic compound of trans-anethole, which makes the edible film surface more hydrophobic.

Moisture Content and Water Solubility

The moisture content (MC) of gelatin-based edible films was measured and shown in Table 2. MC is a parameter related to the total void volume occupied by water molecules in the network microstructure of the film (Jiang et al. 2010). It is significant that the MC values of the films are decreasing with the addition of ANE/β-CD inclusion complex. The ANE/β-CD inclusion complex may be interacted with gelatin molecules by means of hydrogen bonding. Therefore, the hydroxyl positions capable of association with water have been blocked by inclusion complex, which results in less water molecules bonding to hydroxyl positions of gelatin molecules. Moreover, trans-anethole is one of components in essential oil of several plants with hydrophobic property. Hence, water molecules may be excluded from gelatin due to the hydrophobicity of trans-anethole evenly dispersing in gelatin by means of inclusion complex, which result in the decrease of MC value.

The total soluble matter (TSM) of gelatin-based edible films is shown in Table 2. As we know, gelatin is soluble in water completely. However, we found that the G-IC0 still maintained the integrity during the measurement and the TSM values of the edible films are all at low levels, which is attributed to the crosslinking effect of DCMC. Table 2 shows that the TSM values of the edible films become higher and higher with the increase of inclusion complex content. The soluble fraction in edible films should be principally attributed to the exudation of glycerol and the loss of low molar mass polypeptide chains without being crosslinked by DCMC. In addition, the hydrogen bonding is the main interaction among inclusion complex, glycerol and gelatin matrix in the films, which is low effective in preventing water solubility (Martucci and Ruseckaite 2010). Hence, the inclusion complex interacted with gelatin by hydrogen bonding is easily replaced by the water, resulting in exudation of inclusion complex and subsequently increase of TSM value.

Water Vapor Permeability

The water vapor permeability (WVP) of gelatin-based edible films was studied and presented in Table 2. It shows that the WVP values of G-IC0, G-IC5, and G-IC10 are not significantly different while it increases to higher level for G-IC20 and G-IC25. The results indicate that the inclusion complex will not affect the WVP property of the edible films with appropriate addition. However, excessive amount of inclusion complex will increase the WVP value of the edible films. The WVP property of edible films is primarily related to the tortuous path through the polymer matrix for water molecules to pass (Rhim et al. 2006). As shown in SEM, the compatibility of gelatin and inclusion complex decreases with the content of inclusion complex increasing. Too much addition of the inclusion complex induces phase separation of the edible films, which can be easily observed in G-IC20 and G-IC25 (Fig. 2e, f). The G-IC20 and G-IC25 with phase separation structure maybe provide more direct paths surrounding the inclusion complex particles for water molecules to pass and thus to increase the WVP.

Tensile Strength and Elongation at Break

Generally, adequate mechanical strength and extensibility are required for packaging films to withstand external stress and maintain the integrity during applications. The tensile strength (TS) and elongation at break (EB) of gelatin-based edible films are shown in Table 2. The data show that the tensile strength of G-IC5, G-IC10, and G-IC15 are higher than that of G-IC0. G-IC15 exhibits a peak TS of 30.53 MPa and an EB of 102.1%, which are 1.2 and 1.4 times as that of G-IC0, respectively. The results show that the mechanical strength of the edible films has a significant improvement with the addition of inclusion complex. The increase in tensile strength and elongation at break may be attributed to the interactions (electrostatic forces, hydrogen bonding, and van der Waals forces) between both biopolymers and the entanglement of gelatin chains within the film matrix. The similar behavior was observed in previous works on gelatin-based edible films (Hosseini et al. 2012; Guo et al. 2014). However, the tensile strength of the edible films begins to decrease for G-IC20 and G-IC25. The gelatin-dialdehyde starch films had been prepared and characterized in previous study. The results indicated that higher amounts of dialdehyde starch could conduct to phase separation, which had detrimental effects on transparency and tensile properties of the films (Martucci and Ruseckaite 2009). In this study, excessive addition of inclusion complex induces phase separation of the edible films. Therefore, the phase separation structure of G-IC20 and G-IC25 results in the decrease of tensile strength.

Release Behavior of ANE from the Edible Films

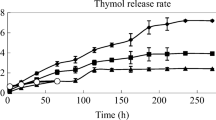

The influence of the gelatin-based edible films on the flavor/odor of the potentially packaged food is a problem that needs to be considered since ANE possesses strong odor. G-IC25 has the highest content of ANE compared to other films. Hence, the release behavior of ANE from G-IC25 was measured to evaluate the influence of the edible films on the flavor/odor of the potentially packaged food. It was reported that the release behavior of ANE from ANE/β-CD inclusion complex was considerably related to the temperature, which could be well controlled at low level at normal temperature (Zhang et al. 2015). Similar results were obtained in the present work. Figure 5 shows that the release of ANE from G-IC25 is faster at higher temperature. However, ANE is releasing at very low rate at 25 and 37 °C. The release ratios of ANE are only 5.5 and 8.3%, respectively, at 25 and 37 °C even in 15 days. Indeed, we could only smell light odor of ANE from the edible films in close range. Hence, the edible films will have little influence on the flavor/odor of the potentially packaged food.

Antimicrobial Activity

Antimicrobial packaging is a form of active packaging that can extend the shelf life of products and provide microbial safety for consumers. The antimicrobial activity of the gelatin-based edible films was firstly determined using the zone of inhibition assay on solid medium. The zone of inhibition is shown in Table 3. Apparently, the control gelatin film (G-IC0) does not show any antimicrobial activity against the test microorganisms, but the edible films incorporated with inclusion complex present clear antimicrobial activity. Table 3 shows that the zone of inhibition significantly increases from 3.1 and 4.6 mm (G-IC5) to 9.4 and 12.2 mm (G-IC25) against S. aureus and B. subtilis, respectively. The result indicates that the incorporation of trans-anethole provides good antimicrobial activity against Gram-positive bacteria for gelatin-based edible films. However, Table 3 shows that there are no significant inhibitory zones against P. aeruginosa and E. coli for G-IC5 and G-IC10. G-IC15, G-IC20, and G-IC25 exhibit low antimicrobial activities against P. aeruginosa and E. coli. The result indicates the poor antimicrobial activity of the edible films against Gram-negative bacteria. ANE is a broad-spectrum antimicrobial substance. Indeed, ANE was volatilizing to space during the long incubation periods and that is the reason of the poor antimicrobial activity. Hence, it is necessary to check the antimicrobial properties using a more appropriate approach.

Then the antimicrobial activity was determined on the film surface according to ISO 22196:2011 standard again. The typical photographs of E. coli and S. aureus colonies grown on LB agar plates after incubation with gelatin-based edible films are shown in Fig. 6c, d. The corresponding E. coli survival rate (Fig. 6a) and S. aureus survival rate (Fig. 6b) compared to G-IC0 were calculated to evaluate the antimicrobial performance of the edible films. Apparently, the edible films exhibit good antimicrobial activity against both Gram-positive and Gram-negative bacteria. Figure 6a, b shows that the survival rates of E. coli and S. aureus significantly decrease from 55 (G-IC5) to 9% (G-IC25) and from 4.6 (G-IC5) to 0.02% (G-IC25), respectively, which means the improvement of antimicrobial activity with the increase of ANE/β-CD inclusion complex content. Note that the edible films show more excellent antimicrobial activity against Gram-positive bacterium (S. aureus) than Gram-negative bacterium (E. coli) too, which may be due to the characteristic difference of the outer membrane between those two kinds of bacteria (Smith-Palmer et al. 1998). Singh et al. (2006) had observed the similar results that S. aureus was more sensitive to trans-anethole-rich extract than E. coli.

Antimicrobial assessments of gelatin-based edible films against E. coli (a) and S. aureus (b). Photographs of E. coli colonies (c) and S. aureus colonies (d) grown on LB agar plates after incubation with gelatin-based edible films. Means with the same letter are not significantly different (p > 0.05)

Conclusions

The trans-anethole/β-cyclodextrin inclusion complex was prepared and incorporated into gelatin to prepare edible films. The physicochemical and antimicrobial properties of the edible films were systematically evaluated for food packaging. The results showed that the addition of inclusion complex improved the UV light barrier property, surface hydrophobicity, and tensile strength and reduced the moisture content of the edible films. However, excessive addition of inclusion complex induced phase separation of the edible films, resulting in decrease of the water vapor barrier ability and mechanical strength. It was interesting that the edible films showed good antimicrobial activity, which increased with the inclusion complex content increasing. The study demonstrated that encapsulation with β-cyclodextrin was an effective way to introduce trans-anethole into gelatin films for antimicrobial activity. The developed antimicrobial gelatin-based edible films showed great potential as bioactive packaging materials.

References

Barba, C., Eguinoa, A., & Maté, J. I. (2015). Preparation and characterization of b-cyclodextrin inclusion complexes as a tool of a controlled antimicrobial release in whey protein edible films. LWT-Food Science and Technology, 64, 1362–1369.

De, M., De, A. K., Sen, P., & Banerjee, A. B. (2002). Antimicrobial properties of star anise (Illicium verum Hook f). Phytotherapy Research, 16(1), 94–95.

Elias, R. J., Kellerby, S. S., & Decker, E. A. (2008). Antioxidant activity of proteins and peptides. Critical Reviews in Food Science and Nutrition, 48(5), 430–441.

Gharib, R., Greige-Gerges, H., Jraij, A., Auezova, L., & Charcosset, C. (2016). Preparation of drug-in-cyclodextrin-in-liposomes at a large scaleusing a membrane contactor: application to trans-anethole. Carbohydrate Polymers, 154, 276–286.

Gómez-Estaca, J., Montero, P., Fernández-Martín, F., Alemán, A., & Gómez-Guillén, M. C. (2009). Physical and chemical properties of tuna-skin and bovine-hide gelatin films with added aqueous oregano and rosemary extracts. Food Hydrocolloids, 23(5), 1334–1341.

Gontard, N., Guilbert, S., & Cuq, J. L. (1992). Edible wheat glutenfilms: influence of the main process variables onfilm properties using response surface methodology. Journal of Food Science, 57, 190–195.

Guo, J. M., Li, X. Y., Mu, C. D., Zhang, H. G., Qin, P., & Li, D. F. (2013). Freezing–thawing effects on the properties of dialdehyde carboxymethyl cellulose crosslinked gelatin-MMT composite films. Food Hydrocolloids, 33(2), 273–279.

Guo, J. M., Ge, L. M., Li, X. Y., Mu, C. D., & Li, D. F. (2014). Periodate oxidation of xanthan gum and its crosslinking effects on gelatin-based edible films. Food Hydrocolloids, 39, 243–250.

Hafsa, J., Smach, M., Khedher, M. R. B., Charfeddine, B., Limem, K., Majdoub, H., et al. (2016). Physical, antioxidant and antimicrobial properties of chitosan films containing Eucalyptus globulus essential oil. LWT-Food Science and Technology, 68, 356–364.

Hosseini, S. F., Rezaei, M., Zandi, M., & Ghavi, F. F. (2012). Preparation and functional properties offish gelatinechitosan blend edible films. Food Chemistry, 136, 1490–1495.

Jiang, Y. F., Li, Y. X., Chai, Z., & Leng, X. J. (2010). Study of the physical properties of whey protein isolate and gelatin composte films. Journal of Agricultural and Food Chemistry, 58, 5100–5108.

Karim, A. A., & Bhat, R. (2009). Fish gelatin: properties, challenges, and prospects as an alternative to mammalain gelatins. Food Hydrocolloids, 23, 563–576.

Kavoosi, G., Rahmatollahi, A., Dadfar, S. M. M., & Purfard, A. M. (2014). Effects of essential oil on the water binding capacity, physicomechanical properties, antioxidant and antibacterial activity of gelatin films. LWT-Food Science and Technology, 57, 556–561.

Kfoury, M., Auezova, L., Greige-Gerges, H., Larsen, K. L., & Fourmentin, S. (2016). Release studies of trans-anethole from beta-cyclodextrin solid inclusion complexes by Multiple Headspace Extraction. Carbohydrate Polymers, 151, 1245–1250.

Kosalec, I., Pepeljnjak, S., & Kuštrak, D. (2005). Antifungal activity offluid extract and essential oil from anise fruits. Acta Pharmacologica Sinica, 55, 377–385.

Martucci, J. F., & Ruseckaite, R. A. (2009). Tensile properties, barrier properties and biodegradation in soil of compression-molded gelatine starch dialdehyde films. Journal of Applied Polymer Science, 112, 2166–2178.

Martucci, J. F., & Ruseckaite, R. A. (2010). Biodegradable three-layerfilm derived from bovine gelatin. Journal of Food Engineering, 99(3), 377–383.

Mihaly Cozmuta, A., Turila, A., Apjok, R., Ciocian, A., Mihaly Cozmuta, L., Peter, A., et al. (2015). Preparation and characterization of improved gelatin films incorporating hemp and sage oils. Food Hydrocolloids, 49, 144–155.

Mu, C. D., Guo, J. M., Li, X. Y., Lin, W., & Li, D. F. (2012). Preparation and properties of dialdehyde carboxymethyl cellulose crosslinked gelatin edible films. Food Hydrocolloids, 27(1), 22–29.

Otero, V., Becerril, R., Santos, J. A., Rodríguez-Calleja, J. M., Nerín, C., & García-López, M. L. (2014). Evaluation of two antimicrobial packaging films against Escherichia coli O157:H7 strains in vitro and during storage of a Spanish ripened sheep cheese (Zamorano). Food Control, 42, 296–302.

Padmashree, A., Roopa, N., Semwal, A. D., Sharma, G. K., Agathian, G., & Bawa, A. S. (2007). Star-anise (Illicium verum) and black caraway (Carum nigrum) as natural antioxidants. Food Chemistry, 104, 59–66.

Pires, C., Ramos, C., Teixeira, B., Batista, I., Nunes, M. L., & Marques, A. (2013). Hake proteins edible films incorporated with essential oils: physical, mechanical, antioxidant and antibacterial properties. Food Hydrocolloids, 30(1), 224–231.

Pranoto, Y., Salokhe, V. M., & Rakshit, S. K. (2005). Physical and antibacte rial properties of alginate-based edible film incorporated with garlic oil. Food Research International, 38(3), 267–272.

Przygodzka, M., Zielińska, D., Ciesarová, Z., Kukurová, K., & Zielńiski, H. (2013). Comparison of methods for evaluation of the antioxidant capacity and phenolic compounds in common spices. LWT-Food Science and Technology, 58, 321–326.

Rhim, J. W., Hong, S. I., Park, H. M., & Ng, P. K. W. (2006). Preparation and characterization of chitosan-based nanocomposite films with antimicrobial activity. Journal of Agricultural and Food Chemistry, 54, 5814–5822.

Sánchez-González, L., Cháfer, M., Hernández, M., Chiralt, A., & González-Martínez, C. (2011). Antimicrobial activity of polysaccharide films containing essential oils. Food Control, 22, 1302–1310.

Shankar, S., & Rhim, J. W. (2016). Tocopherol-mediated synthesis of silver nanoparticles and preparation of antimicrobial PBAT/silver nanoparticles composite films. LWT-Food Science and Technology, 72, 149–156.

Singh, G., Maurya, S., de Lampasona, M., & Catalan, C. (2006). Chemical constituents, antimicrobial investigations and antioxidative potential of volatile oil and acetone extract of star anise fruits. Journal of the Science of Food and Agriculture, 86, 111–121.

Smith-Palmer, A., Stewart, J., & Fyfe, L. (1998). Antimicrobial properties of plant essential oils and essences against five important food-borne pathogens. Letters in Applied Microbiology, 26, 118–122.

Sun, L. J., Sun, J. J., Chen, L., Niu, P. F., Yang, X. B., & Guo, Y. R. (2017). Preparation and characterization of chitosan film incorporated with thinned young apple polyphenols as an active packaging material. Carbohydrate Polymers, 163, 81–91.

Zhang, W. W., Li, X. Y., Yu, T. C., Yuan, L., Rao, G., Li, D. F., et al. (2015). Preparation, physicochemical characterization and release behavior of the inclusion complex of trans-anethole and β-cyclodextrin. Food Research International, 74, 55–62.

Acknowledgements

This study was financially supported by the National Natural Science Foundation (NNSF) of China (21276166) and Project of Youth Science and Technology Innovation Research Team of Sichuan Province (2017TD0010).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ye, Y., Zhu, M., Miao, K. et al. Development of Antimicrobial Gelatin-Based Edible Films by Incorporation of Trans-Anethole/β-Cyclodextrin Inclusion Complex. Food Bioprocess Technol 10, 1844–1853 (2017). https://doi.org/10.1007/s11947-017-1954-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-017-1954-8