Abstract

Frozen potato puree samples were tempered using an ohmic heating technique. Three salt concentrations (0.50, 0.75, and 1.00 %) and three frequency levels (10, 20, and 30 kHz) were used as experimental variables, and the effects of salt concentration and frequency on ohmic tempering were investigated. Temperature, electrical current, and voltage were measured during the ohmic tempering. Electrical conductivities were evaluated based on the sample geometry and the ohmic heating principle. Increasing the salt concentration and/or frequency increased the electrical conductivity and heating rate, and hence contributed to decreasing the tempering time for the frozen potato puree samples. The tempering time was lowest with the highest salt concentration employed, and longest for the lowest salt concentration and frequency. Temperature differences within the sample during ohmic heating were found to be lowest when employing 0.50 % salt concentration and 10 kHz frequency.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Freezing preservation of food has been used for thousands of years. Under the frozen storage conditions (−10 to −18 °C), the free water is transformed to ice, making it unavailable to microorganisms and enzymes, thereby extending the storage life of frozen foods. For industrial preparations, frozen foods are “tempered” by raising their temperatures to just below their freezing point (−5 to −2 °C) so they can be readily cut, shaped, or further processed (James 1999). Thawing takes place when the temperature of the food rises above 0 °C. The two processes should not be confused because tempered food is still frozen while thawing completes the melting process (James and James 2002).

Thawing and tempering methods have triggered considerable interest in the frozen food industry because uncontrolled thawing/tempering can negate the high quality of a frozen food product often achieved with considerable effort by maintaining rapid freezing and frozen storage conditions (Clements 2006). The main problem associated with conventional thawing methods include long thawing times, increased microbial loads, reduced yield, and lowered product quality (Farag et al. 2011). To retain the advantages achieved by rapid freezing, controlled thawing at refrigerated temperatures is often employed, but it takes a long time. Volumetric heating methods involving ohmic and microwave offer better solutions to industrial thawing problems. Ohmic heating is a novel method and an emerging technology touted as the futuristic (space age) concept for food processing (Sastry et al. 2009). Ohmic heating is based on the passage of an alternating electrical current through a food product. The food becomes part of the electrical circuit, and like in electric heaters, relatively rapid and uniform heating occurs. Ohmic heating has good energy efficiency since almost all of the electrical power supplied is transformed into heat. The advantages of ohmic thawing are shorter thawing time, easy process control, relatively uniform heating, no water used in the process, no waste water generated, and high energy conversion efficiency (Roberts et al. 1998).

Ohmic heating is generally applied using alternating currents at low frequencies (50 or 60 Hz), but these are conducive to electrolytic effects. To overcome this problem, non-steel electrodes like titanium are often employed. Several studies have shown that with high frequency alternating currents, stainless steel electrodes can be effectively used without electrolysis problems (Lima et al. 1999). Several factors affect the ohmic heating of foods: electrical conductivities of fluid and particles, the product formulation, specific heat, particle size, shape and concentration, as well as particle orientation in the electric field. The most important food property is the electrical conductivity of the food product.

Naveh et al. (1983) carried out ohmic thawing in liquid, thus preventing the direct electrode contact with the frozen food and reported that the method offered rapid thawing conditions. Miao et al. (2007) also used an electrode solution to ohmic thaw frozen surimi cubes and observed a 90 % reduction in thawing time. Roberts et al. (1998) designed and tested an automated, computer-controlled prototype ohmic thawing unit with shrimp blocks. They reported that the ohmic thawing rate was comparable to water immersion thawing, although no water was used. Icier et al. (2010) found that the ohmic-thawed meat samples had lower textural and histological changes than conventionally thawed ones. Further, Bozkurt and Icier (2012) carried out an extensive study of ohmic thawing for frozen beef cuts evaluating the effects of sample size, thawing method, and voltage gradient on thawing time, drip loss, color, and temperature homogeneity. They found significant differences between thawing methods in terms of the temperature homogeneity, thawing time, and thawing loss (p < 0.05). They also found that as the voltage gradient increased, the thawing time decreased, but thawing loss remained unchanged. Li and Sun (2002), Norton and Sun (2008), and Varghese et al. (2012) provide a good review of new developments in methods of freezing and thawing for foods focusing on high pressure, microwave, ohmic, and acoustic thawing techniques. From industrial perspective, ohmic heating has been mostly studied for aseptic processing and pasteurization of particulate food, while ohmic thawing and tempering have received less attention. The purpose of this study is to investigate the effects of salt concentration and frequency on ohmic tempering of frozen potato puree and to determine if this method shortens the tempering process significantly as compared to natural convection tempering. Frozen potato puree was chosen as a sample since it represents a real food system, and it is easy to give a shape to it.

Materials and Methods

Preparation of the Sample

Commercial potato puree powder (Knorr, Turkey) was used for making the frozen food samples. The chemical composition of the commercial potato puree powder was 72 % carbohydrate, 8 % protein, 1 % fat, and 6 % moisture. It contained potato, emulsifier (mono- and diglyceride), stabilizer (disodium diphosphate), food preservative (sodium metabisulphite), spice extract, and antioxidant (ascorbyl palmitate). Hot water at 100 °C was used to prepare potato puree containing 15 % (w/w) potato puree powder. The potato puree was shaped as a cylindrical slab with a diameter of 4.5 cm and height of 3 cm, and then was frozen.

Ohmic Tempering

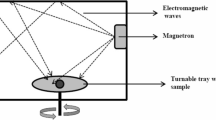

A variable frequency ohmic heating unit (Scientifix Ltd., Guelph, Ontario) with the frozen test sample sandwiched between two stainless steel plate electrodes was used for tempering tests in this study. The dimensional details of the test cell are shown Fig. 1. The unit was operational up to 170 V, and the adjustable frequency range was 1–30 kHz. The system included a local 110 V 60 Hz AC input power supply, with an AC/DC transformer and a variable frequency generator. Potato puree samples with three different salt concentrations (0.50, 0.75, and 1.00 %) were prepared, frozen, stored at −40 °C, and then tempered by ohmic heating. Three different frequencies (10, 20, and 30 kHz) of square-wave electrical power were used for ohmic tempering. The duty time ratio of the square wave was 0.7 for all processing tests, and the maximum current allowed was 9 A.

Conventional Tempering

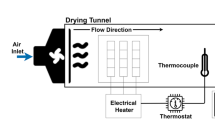

As control, frozen potato puree samples were tempered conventionally by natural convection at 4 °C until the sample surface reached to −2 °C.

Measurement of Temperature

K-type thermocouples (Omega, Stamford, CT, USA) were used to collect the temperature data during ohmic tempering. In order to avoid the influence of electrical field on temperature signal, all thermocouples were insulated using heat shrink plastic tubing. Three thermocouples were placed in the sample, located at the center, close to the surface, and midway between the two. Temperatures were recorded in every 10 s using a data logger (Agilent 34970A, CA, USA) during each heating process.

Evaluation of Electrical Conductivity

The voltage and the current were measured during ohmic heating experiments. Electrical resistance (R, ohm) of test samples were determined from the measured voltage (V, V) and current (I, A) data using the relationship: R = V / I. The electrical conductivity (σ, S / m) of the food product was then calculated using the following equation adapted from Palaniappan and Sastry (1991): σ = 100 L / RA, where L is the gap between the electrodes (cm), A is the cross-sectional surface area of the electrodes (cm2), and R is the resistance of the product (Ω). The ratio of L/A is known as the cell constant of the ohmic heating unit.

Results and Discussion

The small prototype variable frequency ohmic heating unit could be used for evaluating the ohmic tempering behavior of frozen potatoes as influenced by frequency, temperature, and salt concentration. Likewise, the influence of these parameters on the electrical conductivity could also be simultaneously evaluated since parameters required for the computation of electrical conductivity could also be obtained for each heating condition. The effect of ohmic heating frequency on electrical conductivity, tempering time, and temperature distribution could also be extracted as valuable data which are lacking for tempering situations. As discussed before, electrical conductivity is a very important parameter with a major influence on ohmic heating. It depends strongly on salt concentration, so different levels of salt were used to evaluate their influence on the resulting electrical conductivity and subsequently on tempering time and heating uniformity. The maximum level of salt used was 1 % since higher salt levels were unacceptable in food preparations since they impair the sensory quality.

Figure 2 shows the plots of electrical conductivity of frozen potato puree as a function of temperature at different levels of salt concentrations and frequency. It can be clearly observed that the electrical conductivity of frozen potato puree increased with an increase in sample temperature. This behavior has been observed in other studies (Halden et al. 1990; Palaniappan and Sastry 1991). In addition, the electrical conductivity increased with salt concentration. The increase in electrical conductivity with temperature was somewhat linear at the start but moved to an exponential pattern as the temperature approached the freezing point zone (Fig. 2a). The steep increase in the electrical conductivity near the freezing point zone can possibly be explained by the increased mobility of the electrical components in this temperature zone. Analysis of variance (ANOVA) results indicated both salt concentration and frequency to be significant (p < 0.05) factors affecting the electrical conductivity of frozen potato puree. Variation in salt concentration (0.5 to 1.0 %) at the mid-frequency level (Fig. 2a) and variation in frequency (10–30 kHz) at the middle level of salt concentration (Fig. 2b) showed similar trends with respect to changing temperatures; however, the temperature influence on electrical conductivity was more pronounced than the salt and frequency effects. Singh et al. (2008) also found that the increase in frequency increased the electrical conductivity of fruit juices, thus increasing the heating rates. Frequency of an electrical current is the number of oscillatory cycles it completes in a second. This causes the electrical current through the conducting material, and therefore increases with increasing frequency. However, when the frequency is increased above a certain higher limit, it causes a skin effect, making the electrical current to flow around a conductor. This usually happens when the frequency of the electrical current increases beyond 3 GHz, causing reduction in the electrical conducting properties of the material.

The temperature profiles obtained during different ohmic tempering conditions are shown in Fig. 3. In this figure, different markers indicate different thermocouple positions (surface, center, and midpoint in between) inside the frozen potato puree sample. There existed systematic differences in temperatures between the three locations during the entire tempering period. The initial differences were about 1 °C (caused by the delay in installing the test sample in to the ohmic heating set-up) which increased to 2–3 °C between the locations as the tempering time increased. Consistently, the location closest to the electrode was at the highest temperature, followed by the middle location and finally the center experiencing the lowest temperature.

At 10 kHz (both 1 and 0.5 % salt concentrations), the temperature differences were more moderate within the frozen potato puree sample as compared to tempering at 30 kHz. This was possibly due to the prevailing moderate tempering conditions (because of associated lower electrical conductivity), thus allowing the tempering to proceed more slowly, thereby yielding sufficient time for thermal conduction equilibration of the sample (Fig. 3a, b). ANOVA results suggested that there were no significant (p > 0.05) difference between the thermocouple positions for ohmic tempering for 10 kHz, meaning that the time-wise temperature differences were statistically uniform. Previous studies have also showed that homogeneous temperature distribution could be obtained at lower thawing rates, but the non-uniformity in temperature profiles resulted with increasing thawing rate (Miao et al. 2007).

On the other hand, at the higher frequency level of 30 kHz (with both 1.0 and 0.5 % salt concentrations), temperature differences between the three locations (surface, middle, and center) within in the frozen sample begun to clearly consolidate especially as they approached the tempering zone (−2 to −5 °C). The surface (closest to the electrode) had the highest temperature, and the center had the least (Fig. 3c, d). Statistics indicated the differences between the locations to be significant when grouped with respect to a given time (p < 0.05). At 10 kHz, the tempering time with 0.5 % salt concentration was 75 % longer than the tempering time with 1 % salt concentration, emphasizing the strong influence of salt concentration on tempering time. At 30 kHz also, salt concentration played a role with tempering times decreasing from about 340 to 210 s with an increase in salt concentration from 0.5 to 1.0 %. Overall, at 30 kHz frequency, ohmic heating resulted in a 10–15 % reduction in the tempering times as compare to the 10 kHz.

Figure 4a compares the time–temperature profiles with three different salt concentrations during ohmic tempering at 10 kHz. The tempering time increased with a decrease in salt concentration of the frozen potato puree because lower salt levels cause the electrical conductivity to decrease. In a conventional heating system, the thermal conductivity of the food controls its heating rate, whereas electrical conductivity is the controlling factor in ohmic heating (Halden et al. 1990; Sastry and Li 1996). Ohmic heating rate therefore can be enhanced by the addition of salt. However, salt concentration beyond 1.0 % is not acceptable because of its adverse effects on sensory properties and also for health concerns (e.g., hypertension). In the preliminary studies, 0.25 % salt concentration was also tried, but at that salt level, there was not much of flow of current which resulted in poor ohmic heating. The time–temperature profiles of ohmic tempering of potato puree at three different frequencies are shown in Fig. 4b, with salt concentration kept at 0.50 % level. The tempering rate increased with frequency resulting in a decrease in tempering time. This is again because of the increase in the electrical conductivity achieved by increasing frequency.

Ohmic heating tempering times obtained at different levels of salt concentration and frequency are shown in Table 1. As can be seen from the table, an increase in salt concentration and frequency decreased the tempering times. The shortest tempering time was associated with the highest concentration of salt and highest frequency used within the experimental range, and the longest tempering time corresponded to the lowest values of these variables. Conventional tempering took almost 50 min for the same size frozen potato puree samples. Relative to this, the ohmic tempering at the different combinations of salt and frequency levels employed reduced the tempering time to between 3.5 and 7.2 min. Thus, it was possible to reduce conventional tempering time by 86–93 % when using ohmic heating.

Conclusions

The ohmic tempering method was successful in shortening the tempering time of frozen potato puree significantly when compared to conventional tempering. Increasing the salt concentration or frequency decreased the tempering time for frozen potato puree sample. The temperature differences within the sample were observed to be smaller with 0.50 % salt concentration and 10 kHz. Ohmic heating can be successfully used for tempering frozen foods, reducing the conventional tempering times by a margin of 90 %, but the parameters affecting the electrical conductivity should be carefully controlled.

References

Bozkurt, H., & İcier, F. (2012). Ohmic thawing of frozen beef cuts. Journal of Food Process Engineering, 35(1), 16–36.

Clements, R.A. (2006). Development of an ohmic thawing apparatus for accurate measurement of electrical resistance. Ph.D. Thesis. University of Florida, Gainesville, FL, USA.

Farag, K. W., Lyng, J. G., Morgan, D. J., & Cronin, D. A. (2011). A comparison of conventional and radio frequency thawing of beef meats: effect of product temperature distribution. Food & Bioprocess Technology, 4, 1128–1136.

Halden, K., De Alwis, A. A. P., & Fryer, P. J. (1990). Changes in electrical conductivity of foods during ohmic heating. International Journal of Food Science and Technology, 25, 9–25.

Icier, F., Izzetoglu, G. T., Bozkurt, H., & Ober, A. (2010). Effects of ohmic thawing on histological and textural properties of beef cuts. Journal of Food Engineering, 99, 360–365.

James, S. J. (1999). Food refrigeration and thermal processing at Langford, UK: 32 years of research. Trans Institution of Chemical Engineers, 77(C), 261–280.

James, S. J., & James, C. (2002). Meat refrigeration. Cambridge, UK: Woodhead Publishing Ltd.

Li, B., & Sun, D. W. (2002). Novel methods for rapid freezing and thawing of foods—a review. Journal of Food Engineering, 54, 175–182.

Lima, M., Heskitt, B. F., & Sastry, S. K. (1999). The effect of frequency and wave form on the electrical conductivity-temperature profiles of turnip tissue. Journal of Food Process Engineering, 22, 41–54.

Miao, Y., Chen, J. Y., & Noguchi, A. (2007). Studies on the ohmic thawing of frozen surimi. Food Science and Technology Research, 13(4), 296–300.

Naveh, D., Kopelman, I. J., & Mizrahi, S. (1983). Electroconductive thawing by liquid contact. Journal of Food Technology, 18, 171–176.

Norton, T., & Sun, D.-W. (2008). Recent advances in the use of high pressure as an effective processing technique in the food industry. Food and Bioprocess Technology, 1(1), 2–34.

Palaniappan, S., & Sastry, S. K. (1991). Electrical conductivity of selected juices: influences of temperature, solids content, applied voltage, and particle size. Journal of Food Process Engineering, 14, 247–260.

Roberts, J. S., Balaban, M. O., Zimmerman, R., & Luzuriaga, D. (1998). Design and testing of a prototype ohmic thawing unit. Computers and Electronics in Agriculture, 19, 211–222.

Sastry, S. K., & Li, Q. (1996). Modeling the ohmic heating of foods. Food Technology, 50(5), 246–248.

Sastry, S. K., Jun, S., Somavat, R., Samaranayake, C., Yousef, A., & Pandit, R. B. (2009). Heating and sterilization technology for long-duration space missions. Annals of the New York Academy of Science, 1161, 562–569.

Singh, S. P., Tarsikka, P. S., & Singh, H. (2008). Study on viscosity and electrical conductivity of fruit juices. Journal of Food Science and Technology-Mysore, 45(4), 371–372.

Varghese, K. S., Pandey, M. C., Radhakrishna, K., & Bawa, A. S. (2012). Technology, applications and modelling of ohmic heating: a review. Journal of Food Science and Technology. doi:10.1007/s13197-012-0710-3.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Seyhun, N., Ramaswamy, H.S., Zhu, S. et al. Ohmic Tempering of Frozen Potato Puree. Food Bioprocess Technol 6, 3200–3205 (2013). https://doi.org/10.1007/s11947-012-1002-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-012-1002-7