Abstract

The moisture sorption isotherms of grain and kernel of barnyard millet (Echinochloa frumentacea) were determined at 20, 30, 40, and 50 °C. A gravimetric static method was used under 0.112–0.964 water activity (a w) range for the determination of sorption isotherms. The models were compared using the coefficient of determination (r 2), reduced chi-square (χ 2) values, and on the basis of residual plots. In grain, modified Chung–Pfost (r 2 > 0.99; χ 2 < 0.7) and modified Oswin (r 2 > 0.99; χ 2 < 0.55) models were found suitable for predicting the M e –a w relationship for adsorption and desorption, respectively. Modified Henderson model was found to give the best fit (r 2 > 0.99 and χ 2 < 0.55) for describing the adsorption and desorption of the kernel. The isosteric heat, calculated using Clausius–Clapeyron equation, was varied between 46.76 and 61.71 kJ g−1 mol−1 at moisture levels 7–21% (d.b.) for grain and 47.11–63.52 kJ g−1 mol−1 at moisture level between 4% and 20% (d.b.) for kernel. The monolayer moisture content values ranged from 4.3% to 6% d.b. in the case of adsorption of barnyard millet grain and 5.2–6.6% d.b. in the case of desorption at the temperature ranges of 50–20 °C. The monolayer moisture values of barnyard millet kernel ranged from 4.4% to 6.67% d.b. in adsorption and 4.6% to 7.3% d.b. in desorption in the temperature ranges of 50–20 °C.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Barnyard millet (Echinochloa frumentacea) is a commonly grown millet crop in the arid and semi-arid regions of the world. It is one of the most important millet grown in India and is popularly known as Madira, Jhungora, or Sanwa in different regions of the country. The grains of barnyard millet are low in phytic acid and rich in iron and calcium. Magnesium and Niacin (vitamin B3) in barnyard millet can help reduce the effects of migraines and level of cholesterol respectively. Phosphorus in millet helps in fat metabolism, body tissue repair, and converting food into energy. Almost all types of essential amino acids are present in barnyard millet. Barnyard millet is three times richer in minerals as compared to wheat and four times richer in fat, seven times richer in minerals, and two times richer in calcium as compared to rice (Gopalan et al. 1997). The harvesting of barnyard millet crop has been done when the grain moisture content is around 24–26% (d.b.). The harvested grains are dried to about 12% (d.b.) moisture content (Ajisegiri and Sopade 1990). The grain at around 12% moisture content are either dehulled or stored for dehulling application at later date. The property of food material, which influences dehydration, shelf life, and storability, is its water sorption characteristics (Labuza 1968, 1975), and sorption characteristic is highly influenced by environmental conditions such as temperature and relative humidity (Iglesias et al. 1986).

A number of isotherm equations have been developed to describe the relationship between equilibrium moisture content (M e), water activity (a w), and temperature of biological materials (Aviara et al. 2006; Bellagha et al. 2008; Chen 2003; Chen and Weng 2008; Denloye and Ade-John 1985; Menkov 2000a, b; Rekha et al. 2008; Tarigan et al. 2006). The extent of hysteresis is related to the nature and state of food components, reflecting their potential for structural and conformational rearrangements, which alter the accessibility of energetically favorable polar sites (Kapsalis 1981; Jaya and Das 2009). Water activity and monolayer moisture content are a very useful factor to forecast the stability conditions in foods, to select formulations and storage conditions in new products, and to improve drying process and equipment. Water activity of any food material determines the amount of water available to microorganisms and degradation reaction. Attempts made to find a general isotherm equation were not successful because water activity depends on food composition and the interaction of the different constituents with water in thermodynamical equilibrium conditions (Aroldo et al. 2006).

Accurate information on equilibrium moisture contents of barnyard millet grain at various relative humidity and temperatures are not available. There is also a need for comprehensive study of the M e of dehulled barnyard millet kernel to understand its drying and storage behavior. The paper deals with sorption isotherms of barnyard millet grain and its kernel determined under different temperatures and relative humidity levels, suitability of models describing the isotherms, monolayer moistures, and the net isosteric heat of sorption.

Materials and Methods

Sample Preparation and Experimentation

Barnyard millet grains (variety VL-172) and their kernels (dehulled by Vivek millet dehuller) were taken from Vivekananda Institute of Hill Agriculture, Almora, Uttarakhand, India. The initial moisture content of grains and kernels were 9.2% and 10.6% (d.b.), respectively. For the adsorption isotherm determination, the samples were dried in an air oven at 100 °C for 24 h. While for the desorption isotherms, the samples were placed in pure distilled water until no significant weight gain was observed. The procedure suggested by (Iglesias and Chirife 1982) was followed for deriving sorption isotherms at 20, 30, 40, and 50 °C. Approximately 2 g samples of barnyard millet grain and its kernel filled in sterilized glass petri dishes were placed in six separate desiccators containing saturated salt solutions (LiCl, MgCl2, Mg(NO3)2, NaCl, KCl, and K2SO4) for maintaining relative humidity levels from 11% to 96% (Palipane and Driscoll 1992). Measurement of desorption and adsorption isotherms were made at temperatures 20, 30, 40, and 50 °C for grain and kernel. A small glass bottle containing 5 ml toluene was placed in each desiccator to prevent fungal growth. The equilibrium moisture content (EMC) is the condition when two consecutive weight measurements showed a stationary difference (±0.001 g). The equilibrium condition of barnyard millet grains and its kernels were achieved in 26 to 28 days from start. After achieving the EMC, the experiment was stopped, and the sample were weighed and placed in drying oven at a fixed temperature of 100 °C for 72 h (Hall 1980) to achieve the dry mass of the sample.

Modeling of Sorption Isotherm

The adsorption and desorption equilibrium moisture content data (Table 1) of barnyard millet grain and kernel were fitted to the five moisture isotherm models given in Table 4 using Origin 7.5 software. These five sorption models have been adopted as standard equations by the American Society of Agricultural Engineers (ASAE 1999). The constants of the sorption models were estimated using advance nonlinear curve fitting function of software Origin 7.5.

Statistical Analysis

The suitability in predicting the sorption behavior equations were validated on the basis of coefficient of determination (r 2), reduced chi-square (χ 2) values, and residuals. The coefficient of determination and reduced chi-square were calculated by Eqs. 1 and 2, respectively.

The value of coefficient of determination should be higher (r 2 > 0.95) and reduced chi-square should be lower (χ 2 < 0.5) for achieving sufficient goodness of fit for predicted models. Residuals were obtained from the difference between experimental equilibrium moisture content values (M ex) and values obtained from models (M pr). The residuals were plotted against M pr. If the residual plot showed a clear pattern, then the model was not applied for the sorption data. The residual plots were uniformly distributed and random in nature; therefore, it was considered acceptable. Three replications were recorded for analysis.

Isosteric Heat

The moisture content at which the net isosteric heat of sorption becomes equal to the latent heat of vaporization of water is indicative of the presence of bound water in food (Wang and Brennan 1991). The isosteric heat of sorption (Q st), at the temperature of 20 and 50 °C, was calculated from the relationship given in Eq. 4 (Table 2).

The net isosteric heat of sorption (Eq. 3) was determined using the Clausius–Clapeyron equation (Rao et al. 2006).

The ΔH value at given temperature was taken from the steam table.

Monolayer Moisture Content

The monolayer moisture content value of a food provides a good first estimate of the water content, providing maximum stability of a dry product. It is a crucial parameter in the determination of the surface potential of moisture sorbed in food (Table 3). It was suggested (Rockland 1969) as a satisfactory specification for the lower limit of moisture in dehydrated food. The monolayer moisture values were obtained by fitting parameter “A” in Guggenheim–Anderson–de Boer (GAB) equation (Table 4).

The second-order regression equations of type Eq. 5 was developed for adsorption and desorption of grain and kernel between monolayer moisture content (m 0) and temperature (t) by using Origin 7.5 software.

The suitability of the equation in predicting the monolayer moisture content were validated on the basis of coefficient of determination (r 2) and reduced chi-square (χ 2).

Results and Discussion

Moisture Sorption Isotherm

To forecast the stability conditions of foods to select formulations and storage conditions in new products and to improve drying process and equipment, adsorption and desorption isotherm is prerequisite. Water activity and monolayer moisture content are very useful factor as it indicates the biological activity of the material and as we can store particular grain and kernel below monolayer moisture content at specific temperature (Fennema 1985). The study will be helpful for post-harvest and seed technologists.

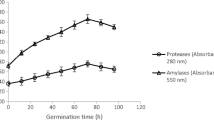

The adsorption and desorption isotherm of barnyard millet grain and kernel at temperature 20, 30, 40, and 50 °C are shown in Fig. 1a–d. There isotherms were found to be type II sigmoid. For any particular temperature and relative humidity (say temperature 30 °C and relative humidity 74.7%), the equilibrium moisture content, M e, of grain (15.6% d.b.) was observed to be higher than M e of barnyard millet kernel (14.2% d.b.) samples. It might be due to the presence of hulls having high fiber content and higher moisture absorption. Oil content in hulls was lower than the kernel. It is evident from Fig. 1 that the M e decreased with increase in temperature at constant water activity. It might be contributed to activation of water molecule to a high energy level due to enhancement of temperature. High energy level allows water molecules to break away from sorption sites, thus decreasing the M e. The result is in agreement with the study of Arslan and Togrul 2005, Kaya and Kahyaoglu 2005, and Tarigan et al. 2006. In the study of Tarigan et al. 2006, the decrease in moisture content with the increase in temperature in shelled and unshelled kernel of candle nut was reported.

Isotherm Equations

Five models, namely modified Halsey, modified Chun–Pfost, modified Oswin, modified Henderson, and GAB, were fitted for adsorption and desorption of barnyard millet grain and kernel. For grain, modified Chung–Pfost and modified Oswin models fitted well with respect to adsorption and desorption, respectively. While for kernel, modified Henderson model was fitted well for both adsorption and desorption. The results fitting the modified Chung–Pfost and modified Oswin model to the grain desorption are given in Table 5. The coefficient of determination (r 2) was higher than 0.99, and the value of reduced chi-square (χ 2) was varied from 0.02 to 0.7. Higher r 2 and lower χ 2 values indicated that the modified Chung–Pfost model was found fit for adsorption of barnyard millet grain, whereas modified Oswin model was found fit for grain desorption in entire range of relative humidity measured.

Following the value of r 2 (0.99 to 0.99981) and χ 2 (0.02657 to 0.51043) for adsorption and desorption of barnyard millet kernel, it was concluded that the isotherm followed modified Henderson model (Table 6). This means modified Henderson model adequately describes the experimental data of barnyard millet kernel adsorption and desorption in entire range of relative humidity. Figure 2a and b shows residual plots for adsorption of barnyard millet grain and kernel at 30 °C, whereas residual plots for desorption is presented in Fig. 3a and b. The residual values, which lies in horizontal band, concentrated on zero trend, indicating best fit of the models.

Moisture Sorption Hysteresis

The adsorption and desorption plots of barnyard millet grain and kernel at 30 °C, presented in Fig. 4a and b, show evidence of the moisture sorption hysteresis. The graph clearly showed that the equilibrium moisture content for desorption was higher than that of adsorption at particular water activity. Polar sites in the molecular structure of the material were almost entirely occupied by adsorbed water in the wet condition. Due to drying and shrinkage, the molecules and their water holding sites were drawn closely to satisfy each other. This reduces the water holding capacity of the material upon subsequent adsorption (Mohsenin 1986).

Isosteric Heat

The isosteric heat, calculated using Clausius–Clapeyron equation, varied between 46.76 and 61.71 kJ g−1 mol−1 at moisture levels 7–21% (db) for grain and 47.11–63.52 kJ g−1 mol−1at moisture level between 4 and 20% (d.b.) for kernel. The variation of isosteric heat of adsorption and desorption of barnyard millet grain and kernel with moisture content at temperatures 20 and 50 °C is shown in Fig. 5a and b. It is evident from figure that the isosteric heat of desorption was higher than that of heat of adsorption for both grain and kernel. It may be due to structural changes that occur in the product during dehydration, which made the removal of water easier (Yanniotis and Zarmboutis 1996; Tarigan et al. 2006). It is also evident from figure that the isosteric heat decreased sharply (from 60 to 47 kJ/mol in desorption of grain) with increase in moisture content (from 7% to 17%). Several researchers, viz., Saravacos et al. (1986) in sultana raisins, Yanniotis and Zarmboutis (1996) in pistachio nuts, Palou and Lopez-Malo (1997) in cookies and corn snacks, and Samapundo et al. (2007) in whole yellow dent corn reported similar trend. It might be due to the fact that initially, sorption occurs on the most active sites, giving rise to higher energy of interaction between the sorbet and sorption sites. As these active sites become occupied, sorption subsequently occurs on the less active sites, giving lower heat of sorption (Iglesias and Chirife 1982).

Monolayer Moisture

The monolayer moisture content values for barnyard millet grain and kernels are shown in Table 3. The monolayer moisture content values (Table 4) ranged from 4.3% to 6% d.b. in the case of adsorption and 5.2–6.6% d.b. in the case of grain desorption of barnyard millet grain at the temperature ranges of 50–20 °C. The monolayer moisture values of barnyard millet kernel ranged from 4.4% to 6.67% d.b. in adsorption and 4.6% to 7.3% d.b. in desorption in the temperature ranges of 50–20 °C. As temperature increased from 20 to 50 °C, the monolayer value decreased in both adsorption and desorption processes. This may be due to higher water vapor pressure inside the barnyard millet grain at higher temperature. The effect of temperature on different dehydrated food products showed that monolayer moisture content decreases with increase in temperature (Rizvi 1986). The highest value of monolayer moisture content, i.e., 7.3% d.b., was found in desorption process at 20 °C, and the minimum value, i.e., 4.4% d.b., was found in the adsorption process at 50 °C. The monolayer values of the desorption process were higher than the adsorption process at all temperatures. Similar result was reported by Kaleemullah and Kailappan (2007) in red chillies. Second-order regression of monolayer moisture content, m o (% d.b.) due to temperature, t (°C) were fitted for both modified Chung–Pfost adsorption and modified Oswin desorption models (Eqs. 6 and 7).

The modified Henderson monolayer moisture values of barnyard millet kernel ranged between 7.2% and 11.0% d.b. in adsorption and 9.4% to 12.5% d.b. in desorption at the temperature ranges of 50–20 °C (Fig. 1c and d). As the temperature increased from 20 to 50 °C, the monolayer moisture content value decreased in both adsorption and desorption processes. It might be attributed to higher water vapor pressure in barnyard millet kernel due to enhancement in temperature. Maximum and minimum value of monolayer moisture content was 12.5% and 7.2% d.b. at 20 and 50 °C, respectively. The monolayer values of the desorption process were higher than that of the adsorption process at all temperatures. Second-order regression equations were fitted for modified Henderson monolayer moisture content, m o (% d.b.) due to temperature, t (°C) for both adsorption and desorption processes and are given as:

Conclusions

The moisture sorption isotherms of barnyard millet grain and kernel were determined at 20, 30, 40, and 50 °C exhibit type II sigmoidal behavior. The M e of desorption is higher as compared to adsorption across the entire range of the a w investigated. In grain, modified Chung–Pfost (r 2 > 0.99; χ 2 < 0.7) and modified Oswin (r 2 > 0.99; χ 2 < 0.55) models were found suitable for predicting the M e –a w relationship for adsorption and desorption, respectively. For kernel, modified Henderson model was found best fit (r 2 > 0.99 and χ 2 < 0.55) for describing the adsorption and desorption. The isosteric heat, calculated using Clausius–Clapeyron equation, was varied between 46.76 and 61.71 kJ g−1 mol−1 at moisture levels 7–21% (d.b.) for grain and 47.11–63.52 kJ g−1 mol−1 at moisture level between 4% and 20% (d.b.) for kernel. The highest value of monolayer moisture content, i.e., 7.3% d.b., was found in desorption process at 20 °C, and the minimum value, i.e., 4.4% d.b., was found in the adsorption process at 50 °C. This study will help in the determination of suitable drying process, level of drying, and storage design.

Abbreviations

- A, B, C:

-

constants used in sorption models

- P, q, r:

-

constants used in monolayer moisture content models

- a w :

-

water activity, decimal

- ΔH :

-

latent heat of vaporization of pure water, kJ mol−1 (43.53 kJ mol−1 at 35 °C)

- M :

-

moisture content, % (d.b.)

- M e :

-

equilibrium moisture content, % (d.b.)

- M ex :

-

experimental equilibrium moisture content, decimal

- M pr :

-

predicted equilibrium moisture content, decimal

- n :

-

number of constants

- N :

-

number of observation

- Q st :

-

isosteric heat sorption, kJ g−1 mol−1

- q st :

-

net isosteric heat of sorption, kJ g−1 mol−1

- R :

-

universal gas constant, kJ mol−1 K−1 (0.008314 kJ mol−1 K−1)

- r 2 :

-

coefficient of determination

- T :

-

temperature, K

- χ 2 :

-

reduced chi-square

- m o :

-

monolayer moisture content, % (d.b.)

- t :

-

temperature, °C

References

Ajisegiri, E. S., & Sopade, P. A. (1990). Moisture sorption isotherm of Nigerian millet at varying temperature. Journal of Food Engineering, 12, 283–292. doi:10.1016/0260-8774(90) 90003-Q.

Aroldo, A., Fernando, D. S., Zilda, D. S. A., Salles, A., Abraham, D. G. Z., & Rosalinda, A. P. (2006). Desorption isotherms for murci (Byrsonima sericea) and inga (Inga edulis) pulps. Journal of Food Engineering, 76, 611–615. doi:10.1016/j.jfoodeng.2005.06.011.

Arslan, N., & Togrul, H. (2005). Moisture sorption isotherms for crushed chillies. Biosystems Engineering, 90, 47–61. doi:10.1016/j.biosystemseng.2004.10.008.

ASAE. (1999) ASAE Standards, Standards Engineering Practices Data 1999. ASAE, St. Joseph, MI 49085.

Aviara, N. A., Ajibola, O. O., Aregbesola, O. A., & Adedeji, M. A. (2006). Moisture sorption isotherms of sorghum malt at 40 and 50 °C. Journal of Stored Products Research, 42, 290–301. doi:10.1016/j.jspr.2005.05.001.

Bellagha, S., Sahli, A., & Frhat, A. (2008). Desorption isotherms and isosteric heat of three tunisin dale cultivars. Food and Bioprocess Technology, 1, 270–275. doi:10.1007/s11947-007-0006-1.

Chen, C. (2003). Moisture sorption isotherms of pea seeds. Journal of Food Engineering, 58, 45–51. doi:10.1016/S0260-8774(02) 00332-1.

Chen, C., & Morey, R. V. (1989). Comparison of four EMC/ERH equations. Trans ASAE., 32, 983–990.

Chen C. & Weng Y.-K. (2008). Moisture sorption isotherm of oolong tea. Food and Bioprocess Technology. doi:10.1007/s 11947-008-0075-9.

Denloye, A. O., & Ade–John, A. O. (1985). Moisture sorption isotherms of some Nigerian food grains. Journal of Stored Products Research, 2(21), 53–58. doi:10.1016/0022-474X(85)90020-7.

Fennema, O. R. (1985). Food Chemistry. New York: Marcel Dekker.

Gopalan, C., Ramasastri, B. V., & Balasubramanian, S. C. (1997). Nutritive value of Indian Foods. Hyderabad: National Institute of Nutrition, Indian Council of Medical Research.

Hall, C. (1980). Drying and storage of agricultural crops, pp. 69–71. Westport: Avi.

Iglesias, H. A., & Chirife, J. (1982). Handbook of Food Isotherms: water sorption parameters for food and food components. New York: Academic.

Iglesias, H. A., Chirife, J., & Fontan, F. C. (1986). Temperature dependence of water sorption isotherms of food materials. Journal of Food Science, 51, 51–553. doi:10.1111/j.1365-2621.1986.tb13876.x.

Iglesias, H. A., & Chirife, J. (1976). Prediction of the effect of temperature on water sorption isotherms of food materials. Journal of Food Technology, 11, 109–116. doi:10.1111/j.1365-2621.1976.tb00707.x.

Jaya, S., & Das, H. (2008). Glass transition and sticky point temperatures and stability/mobility diagram of fruit powders. Food and Bioprocess Technology, 2, 89–95. doi:10.1007/s11947-007-0047-5.

Kaleemullah, S., & Kailappan, R. (2007). Monolayer moisture, free energy change and fraction of bound water of red chillies. Journal of stored product research, 43(2), 104–110. doi:10.1016/j-jspr.2005.12.001.

Kapsalis, J. G. (1981). Moisture Sorption Hysteresis. In L. B. Rockland & G. F. Stewart (Eds.), Water activity: influences on food quality, pp. 143–177. New York: Academic.

Kaya, S., & Kahyaoglu, T. (2005). Thermodynamic properties and sorption equilibrium of Pestil (grape leather). Journal of Food Engineering, 71, 200–207. doi:10.1016/j.jfoodeng.2004.10.034.

Labuza, T. P. (1968). Sorption phenomenon in foods. Food Technologist, 22(3), 15–24.

Labuza, T. P. (1975). Sorption phenomena in foods: theoretical and practical aspects. In D. ChoKyun Rha (Ed.), Theory, determination and control of physicai properties of food materials, pp. 197–219. Holland: Reidel.

Menkov, N. D. (2000a). Moisture sorption isotherms of lentil seeds at several temperatures. Journal of Food Engineering, 44, 205–211. doi:10.1016/S0260-8774(00) 00028-5.

Menkov, N. D. (2000b). Moisture sorption isotherms of Vetch seeds at four temperatures. Journal of Agricultural Engineering Research, 76, 373–380. doi:10.1006/jaer.2000.0551.

Mohsenin, N. (1986). Physical properties of plant and animal materials. New York: Gordon & Hreach.

Palipane, K. B., & Driscoll, R. H. (1992). Moisture sorption characteristics of in shell macademia nuts. Journal of Food Engineering, 25, 63–76.

Palou, E., Lopez–Malo, A., & Argaiz, A. (1997). Effect of temperature on the moisture sorption isotherm of some cookies and corn snacks. Journal of Food Engineering, 31, 85–93. doi:10.1016/S0260-8774(96) 00019-2.

Pfost H. B., Mourer S. G., Chung D. S., Milliken G. A. (1976) Summarising and reporting equilibrium moisture data for grains. ASAE paper No. 76–3520, St. Joseph, Michigan.

Rao, K. J., Dhas, H. A., Emerald, F. M. E., Ghosh, B. C., Balasubramanyam, B. V., & Kulkarni, S. (2006). Moisture sorption characteristics of chhana podo at 5°C and 35°C. Journal of Food Engineering, 76, 453–459. doi:10.1016/j.jfoodeng.2005.04.048.

Rekha M. N., Yadav A. R., Dharmesh S., Chauhan A. S. & Ramteke R. S. (2008). Evaluation of antioxidants properties of dry soup mix extracts containing dill (Anethum sowa L.) leaf. Food and Bioprocess Technology. doi:10.1007/s11947-008-0123-5, in press.

Rizvi, S. S. H. (1986). Thermodynamic properties of foods in dehydration. In M. A. Rao & S. S. H. Rizvi (Eds.), Engineering properties of foods, pp. 133–214. New York: Marcel Dekker.

Rockland, L. B. (1969). Water activity and storage stability. Food Technologist, 23, 1241–1248. 1251.

Samapundo, S., Devlieghere, F., Meulenaer, B. D., Atukwase, A., Lamboni, Y., & Dedevere, J. M. (2007). Sorption isotherm and isosteric heats of sorption of whole yellow dent corn. Journal of Food Engineering, 79, 168–175. doi:10.1016/j.jfoodeng.2006.01.040.

Saravacos, G. D., Tsiourvas, D. A., & Tsami, E. (1986). Effect of temperature on the water adsorption isotherm of sultana raisins. Journal of Food Science, 51, 381–394. doi:10.1111/j.1365-2621.1986.tb11135.x.

Tarigan, E., Prateepchaikul, G., Yamsaengsung, R., Sirichote, A., & Tekasakul, P. (2006). Sorption isotherms of shelled and unshelled kernels of candle nut. Journal of Food Engineering, 75, 447–452. doi:10.1016/j.jfoodeng.2005.04.030.

Thompson, H. L. (1972). Temporary storage of high moisture shelled corn using continuous aeration. Trans ASAE., 15, 333–337.

Van den Berg, C. (1984). Description of water activity of food for engineering purposes by means of the GAB model of sorption. In B. M. McKenna (Ed.), Engineering and Foods, pp. 119–131. New York: Elsevier Science.

Wang, N., & Brennan, J. G. (1991). Moisture sorption isotherm characteristics of potatoes at four temperatures. Journal of Food Engineering, 14, 269–287. doi:10.1016/0260-8774(91) 90018-N.

Yanniotis, S., & Zarmboutis, I. (1996). Water sorption isotherm of Pistachio Nuts. Lebensmittel–Wissenchaft Technol., 29, 372–375. doi:10.1006/fstl.1996.0057.

Acknowledgment

The first author is grateful to the Indian Council of Agricultural Research (ICAR), New Delhi for the financial assistance provided to carry out the research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, K.P., Mishra, H.N. & Saha, S. Sorption Isotherms of Barnyard Millet Grain and Kernel. Food Bioprocess Technol 4, 788–796 (2011). https://doi.org/10.1007/s11947-009-0195-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-009-0195-x