Abstract

Solving practical mechanical problems is considered as a real challenge for evaluating the efficiency of newly developed algorithms. The present article introduces a comparative study on the application of ten recent meta-heuristic approaches to optimize the design of six mechanical engineering optimization problems. The algorithms are: the artificial bee colony (ABC), particle swarm optimization (PSO) algorithm, moth-flame optimization (MFO), ant lion optimizer (ALO), water cycle algorithm (WCA), evaporation rate WCA (ER-WCA), grey wolf optimizer (GWO), mine blast algorithm (MBA), whale optimization algorithm (WOA) and salp swarm algorithm (SSA). The performances of the algorithms are tested quantitatively and qualitatively using convergence speed, solution quality, and the robustness. The experimental results on the six mechanical problems demonstrate the efficiency and the ability of the algorithms used in this article.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The main objective of a mechanical engineer during the design procedure of a machine element is the search for the best compromise between both economic and technological imperatives. The mechanical design optimization problems involve multiple objectives and mixed variables, in addition to several nonlinear constraints on kinematic, geometric conditions and materials resistance. During the three last decades, several mathematical programming algorithms have been developed to solve problems in various engineering and industrial applications. However, most of these methods always require the knowledge of the gradients of the objective function and constraints [5]. In the majority of cases, the classical algorithms are not able to find the global optimal solutions because usually terminate when the gradient of the function is very close to zero, and this can happen both in case of local and global solutions [43, 46].

Unlike the deterministic methods, metaheuristic approaches do not require the gradient information of the optimization problem to achieve the global solution [43]. These algorithms can be broadly classified into three major categories: evolutionary algorithms (EAs), physical algorithms and swarm-based methods. The EAs mimic the process of natural evolutionary principles [7] in order to develop search and optimization techniques. In this class of methods, the most well-known EAs are genetic algorithm (GA) [24], genetic programming (GP) [33], differential evolution (DE) [55], evolution strategy (ES) [4], and biogeography-based optimizer (BBO) [54].

The second group includes the algorithms that inspired by a physical process, where Monte Carlo [16] and the simulated annealing (SA) [32] can be considered as the first two developed approaches in this category. Later on, other physics-based techniques are developed such as big-bang big-crunch (BBBC) [12], small-world optimization algorithm (SWOA) [11], central force optimization (CFO) [14], gravitational search algorithm (GSA) [45], charged system search (CSS) [29], artificial chemical reaction optimization algorithm (ACROA) [3], galaxy-based search algorithm (GBSA) [47], colliding bodies optimization (CBO) [28], black hole (BH) [21], ray optimization (RO) algorithm [27], and curved space optimization (CSO) [40].

The third class of metaheuristics includes swarm-based algorithms that mimic the collective behavior of social creatures [9]. Among the most famous methods in this category the particle swarm optimization (PSO) [30], ant colony optimization (ACO) [10], wolf pack search algorithm [58], cuckoo search (CS) [57], dolphin partner optimization (DPO) [53], bat-inspired algorithm (BA) [59] and hunting search (HUS) [41] can be found. Furthermore, other swarm intelligence techniques are developed recently, such as dragonfly algorithm (DA) [36] and whale optimization algorithm (WOA) [38]. In recent years several metaheuristics has been successfully used for solving different optimization problems in various areas and real industrial cases such as mechanical precision engineering [1, 2, 20], structural design optimization [22, 23], machining applications [63–66, 71], automotive industries [26, 31, 42, 60, 62, 67–70, 72–75], and so on.

Despite the wide application of the meta-heuristic approaches in numerous fields of engineering, their applications for mechanical design optimization problems remains relatively inadequate. For this purpose, the main contribution of this paper is to introduce the application of ten recent meta-heuristic algorithms for solving six challenging mechanical problems of mixed variables type. The problems are the coupling with a bolted rim, car side impact, rolling element bearing, step-cone pulley, belleville spring, and speed reducer problem. Among the used algorithms: the artificial bee colony (ABC) [25], PSO [30] algorithm, moth-flame optimization (MFO), ant lion optimizer (ALO), water cycle algorithm (WCA), evaporation rate WCA (ER-WCA), grey wolf optimizer (GWO), mine blast algorithm (MBA), whale optimization algorithm (WOA) [38] and salp swarm algorithm (SSA) [37]. The performances of each used algorithm are validated in terms of convergence speed, solution quality, and robustness. The rest of the paper is organized as follows:

Section 2 provides a summary of the optimization algorithms employed in this work to solve the challenging problems. The problems and experimental results are presented and discussed in Sect. 3. Finally, Sect. 4 provides the conclusions and future works.

2 Optimization Algorithms

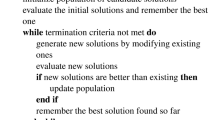

In this section, each algorithm employed in this study is presented briefly. Only the main phases are discussed, and the interested readers by the algorithms can find all the necessary details in the cited publications.

2.1 Artificial bee colony

The ABC algorithm has been introduced by Karaboga and Basturk [25] to optimize mathematical problems. The method mimics the intelligent foraging behavior of a honey bee swarms. ABC works based on three principal phases accordingly: food sources, employed foragers, and unemployed foragers.

2.2 Particle Swarm Optimization

The second algorithm employed in this study is the PSO algorithm. This approach has been originally created and formulated by Kennedy and Eberhart [30] based on the mathematical modeling of the social behaviors of fish or birds. The algorithm belongs to the swarm-based methods and begins with a random set of agents (solutions) called particles. Each particle is characterized by two vectors including velocity and position [31].

2.3 Moth-Flame Optimization

The MFO is a novel population-based meta-heuristic algorithm proposed by Mirjalili [34]. The MFO approach is based on the simulation of the special navigation technique of moths in the night. Similarly to other meta-heuristics, it starts the optimization procedure by creating a set of random candidate solutions.

The moth used a mechanism called as transverse orientation for navigation when traveling during night time. In the MFO algorithm, candidate solutions are assumed to be moths and variables of a problem are assumed to be positions of moths in the search space [71].

2.4 Ant Lion Optimizer

ALO is a new nature-inspired intelligent technique, which is recently developed by Mirjalili [35]. The ALO algorithm mimics the hunting technique of ant lions in nature. The ant lions hide at the bottom of conical pits in the sand and wait for their prey to fall in. Then they throw sand towards prey so that the prey is unable to escape and is consumed, after which the pit is rebuilt for catching other ants.

2.5 Grey Wolf Optimizer

The GWO is a population-based optimization algorithm, which is inspired by both the leadership skills as well as hunting behavior of grey wolves in nature [39]. According to the social hierarchy and the ability of each wolf in the group, the grey wolves can be categorized into four principal classes: Alpha (α), Beta (β), Delta (δ), and Omega (ω). The alpha (α) wolf is the leader of the group and responsible for making the important decisions such as hunting, sleeping place, time to wake, and so on [15]. The grey wolf hunting technique involves three steps: tracking, encircling and attacking the prey.

2.6 Water Cycle Algorithm

Another meta-heuristic algorithm used in this article is the water cycle algorithm. This algorithm has been introduced for the first time in 2012 by Eskandar et al. [13] in order to optimize the constrained engineering problems. The fundamental idea of WCA approach is based on the water cycle and how rivers and streams flow downhill towards the sea in the real world. Like other population-based meta-heuristic algorithms WCA starts with multiple random solutions called the population of streams. Other steps are implemented to choose the best individual or sea such as the flow of streams to rivers or sea, evaporation and raining processes, and evaporation rate.

2.7 Evaporation Rate Water Cycle Algorithm

The ER-WCA algorithm is introduced by Sadollah et al. [50] for solving constrained and unconstrained optimization problems. It is considered as an extended version of WCA, where new concept of evaporation rate for different rivers and streams has been added. According to the authors, the ER-WCA shows a better balance between exploration and exploitation steps compared to WCA variant.

2.8 Mine Blast Algorithm

The MBA algorithm has been recently developed by Sadollah et al. [48]. This technique is successfully used to solve constrained engineering optimization problems and discrete sizing optimization of truss structures [48, 49]. The main idea of MBA procedure is based on the observation of mine bomb explosions in real situations. In Sadollah et al. [51] an improved variant of MBA (IMBA) is introduced for the optimization of truss structures.

2.9 Salp Swarm Algorithm

The salp swarm algorithm has been introduced recently by Mirjalili et al. [37] for optimizing the engineering design problems. The SSA method simulates the intelligent navigation behavior of the salps for food sources in oceans. Like other swarm-based algorithms, SSA begins the optimization process by creating a set of random candidate solutions. In the first step, the created population is divided into two groups: leader and followers. The leader is the salp at the front of the chain, whereas the rest of salps are considered as followers [37].

2.10 Whale Optimization Algorithm

The whale optimization algorithm (WOA) is a new population-based meta-heuristic algorithm. Proposed recently by Mirjalili and Lewis [38], the WOA approach is based on the simulation of the social behavior of humpback whales. The latter is considered as the biggest mammals on the whole earth. According to Mirjalili and Lewis [38] an adult whale can grow up to 30 m long and 180 t weight. Despite their huge size, these mammals are characterized by their intelligence as well as their sophisticated way on collective work during the hunting. In addition to the initialization step, WOA includes encircling prey, the bubble net hunting method and the search for prey.

3 Experimental Results

The performances of each used algorithm are validated by solving six mechanical design problems, namely, coupling with a bolted rim, car side impact, rolling element bearing, step-cone pulley, belleville spring, and speed reducer design problem. It is worth mentioning that an exterior penalty function is adapted for MFO, ALO, SSA, WOA, GWO, PSO and ABC algorithms to deal with constraints design. The mathematical formulations for the engineering problems can be found in the "Appendix". The maximization problems, in case of rolling element, are transformed into a minimization one by multiplying the objective function with − 1. The equality constraints are converted into inequality ones; the tolerance value is 0.001 (in case of step-cone pulley problem).

The specific parameter settings of each algorithm are given in Table 1. In order to study the convergence behavior of the algorithms, the maximum number iterations and the population size are equal for each case study as shown in Table 2. To measure the robustness of the compared meta-heuristics in solving the six problems we run each algorithm 50 times. The statistical results including the best, mean, and worst solutions as well as the standard deviation. For more readability, the better solution obtained among the ten optimizers is in boldface.

3.1 Design of the Coupling with a Bolted Rim Problem

The problem was initially proposed by Giraud-Moreau and Lafon [17]. As shown in Fig. 1, a torque \(M\) is transmitted by adhesion using \(N\) bolts of diameter \(d\) placed at radius \(R_{B}\). The objective function includes three terms with weighting coefficients. \(d\) is discrete, \(N\) is an integer, \(R_{B}\) and \(M\) are continuous variables. The problem is subjected to eleven inequality constraints.

Tables 3 and 4 present the best optimal solution and the statistical simulation results obtained by the algorithms for the coupling with a bolted rim problem. From Table 3, it can be seen that all used approaches are able to find the global feasible solution. However, the MFO algorithm is the most robust in solving this problem with standard deviation values of 1.6943E−15, followed by ER-WCA, WCA, ALO, ABC, SSA, MBA, GWO, WOA, and PSO. The convergence behavior of the algorithms for the first case study is presented in the Fig. 2. From the figure, it can be observed that both ER-WCA and WOA approaches reach practically the best value in the 18th iteration, and this clearly indicates how fast these latter compared to other algorithms.

3.2 Design of the Car Side Impact Problem

This problem was originally proposed by Gu et al. [18]. The car, Fig. 3, is exposed to a side impact on the foundation of the European Enhanced Vehicle Safty Committee (EEVC) procedures. The objective is to minimize the total weight of the car using eleven mixed variables. The eight and the nine variables are discrete, and the rest of them are continuous. The problem is subjected to ten inequality constraints.

The car side impact design is considered as a real case of a mechanical optimization problem with mixed discrete and continuous design variables. The best optimal solutions obtained by the methods for the problem are listed in Table 5, and their statistical results are given in Table 6. From Table 5, the MFO algorithm achieves the best value among the algorithms. Regarding the robustness, it can be observed from Table 6 that the used algorithms almost have the same standard deviation. Among the used algorithms it can be observed that the WOA is not able to find the near optimal solution.

Figure 4 shows the comparison of the convergence speed of the algorithms to the best value for the car side impact. In this case, both MFO and WCA converge much faster than the other used methods.

3.3 Design of the Rolling Element Bearing Problem

As the third problem, the goal is to maximize the dynamic load carrying capacity of rolling element bearing [19]. There are ten mixed design variables among them the pitch diameter \(D_{m}\), ball diameter \(D_{b}\), number of balls \(Z\), inner and outer raceway curvature coefficients \(f_{i}\) and \(f_{o}\) (Fig. 5) in addition to five other variables that affect the geometry of the bearing (\(K_{Dmin}\), \(K_{Dmax}\), \(\varepsilon\), \(e\) and \(\zeta\)). All variables are continuous except the number of balls which is discrete. The problem is subjected to nine nonlinear constraints on kinematic conditions and manufacturing requirement.

As depicted in Table 7, the best optimal solution for the bearing design problem is − 85,546.80 and this value is obtained by almost compared algorithms except for the ABC, GWO, and WOA. Table 8 compares the statistical results delivered by each method. From Table 8, it is clear that the small value is obtained by MFO. Figure 6 shows the convergence curve of the ten selected algorithms for the rolling element bearing. As can be observed from the zoom part of the Fig. 6, the ER-WCA and MBA are the fastest to achieve the near optimal solution for this problem (after 27 iterations).

3.4 Design of the Step-Cone Pulley Problem

The four step-cone pulley problem, Fig. 7, must be designed for minimum weight [44]. The problem includes five variables, the diameters of each step \(d_{i }\) (i = 1,…, 4), and the width of the pulley \({\omega}\). Eleven constraints are considered, three equality constraints and eight inequality constraints. The step pulley transmitted at least 0.75 hp, with an input speed of 350 rpm and output speeds of 750, 450, 250 and 150 rpm.

The best optimal solutions and statistical results of the methods for the problem are demonstrated in Tables 9 and 10 respectively. According to the Table 9, expect to GWO approaches all other algorithms can obtain the global solution. From the statistical results, it can be observed that SSA and MFO are the most effective in solving this problem with lowest best values.

The convergence history of the ten methods to the best solution for the step-cone pulley problem is given in Fig. 8. From the figure, it is clear that the MFO and MBA can converge rapidly to the near best solution from the initial iterations comparing with referred algorithms (Fig. 9).

3.5 Design of the Belleville Spring Problem

The problem was originally proposed by Coello [6], where the objective is to minimize the volume of the spring (the schematic view of the problem is shown in Fig. 9). There are four continuous variables including the external diameter \(D_{e}\), internal diameter \(D_{i}\), thickness t, and the height of the spring h. The problem is subjected to seven nonlinear constraints.

The best optimal value for the belleville spring problem is achieved by PSO, WCA, ER-WCA, MBA, and SSA, as shown in Table 11. From Table 12, it can be said that the MBA version is the most effective in solving this problem with the lowest standard deviation value. The WOA approach is not able to solve this problem may need more iterations to achieve the optimal solution. From the convergence graph given in the Fig. 10, the PSO is faster than the other employed algorithms for this problem and can achieve the near best solution after 126 iterations.

3.6 Design of the Speed Reducer Problem

The last problem considered in the present article is the optimization of the spur speed reducer [52], the schematic view of the problem and the variables are given in Fig. 11. The speed reducer must be designed for minimum volume using seven variables, namely, the face width b, teeth module m, number of teeth on pinion z, length of the first shaft between bearings l1, length of the second shaft between bearings l2, the diameter of first shaft d1 and diameter of second shaft d2. All the variables are continuous except the third one is an integer.

Table 13 lists the values of the variables and the objective function of the best optimal solution found by the algorithms for the problem. Also, Table 14 presents the statistical results of each algorithm. As shown in Table 13, ALO, GWO, SSA and WOA are not able to find the optimal global solution value. As for the robustness (Table 14), the MFO is the best one in solving the problem of the speed reducer with a small standard value.

The convergence curves of the algorithms for the spur speed reducer are shown in Fig. 12. From the zoom part of the figure, it can be seen that ABC and WCA are the much faster for this problem and can reach the optimal solution in 74 iterations.

3.7 Discussions

The present paper introduce the application of ten recent meta-heuristic for six real mechanical problems, including seven swarm techniques. Form the comparative results presented in the previous sub-sections; it is clear that the MFO technique exhibited an evident superiority compared with the other employed algorithms. More specifically, MFO is the very powerful in solving five studied problems. For the coupling with a bolted rim and speed reducer problems MFO is very competitive in both solution quality and robustness. Regarding the car side impact design, rolling element bearing and step-cone pulley problem, the MFO algorithm is the best one by given the lowest value of the objective function. In case of the belleville spring problem MFO is not able to find the global optimum solution.

The ER-WCA, WCA and MBA approaches can obtain the optimal solution for the six problems. Moreover, in terms of the convergence speed, these algorithms are relatively fastest than then the other used algorithms, that means required less computation time to reach the near-optimal global solution. However, the robustness of ER-WCA, WCA, and MBA remain weak and need to more improvement.

The WOA and ABC algorithm can be considered as the worst among the compared methods. These two algorithms can find only the optimal solution of two problems among the six studied problems (coupling with a bolted rim and speed reducer). The GWO method can solve three problems of the total of six. The SSA technique is able to find the optimal solution of five problems and fails in optimizing the speed reducer problem.

As we know, the meta-heuristic algorithms require an exact configuration of their internal control parameters for more efficient performance. Choosing the same NP value for all used algorithms may be an important factor in fails some methods.

In the present study an exterior penalty is adopted to MFO, ALO, SSA, WOA and GWO algorithms to deal with inequality and equality constraints. Really the use of such method is quite simple, however, deciding optimal values of penalty terms especially for the optimization problems with highly constraints turns out to be a difficult optimization problem itself. In the future works, theses algorithms will be reinforced by more advanced methods such as the superiority of feasible points mechanism of Deb [8], the adaptive epsilon mechanism of Takahama and Sakai [56] and others to treat the constrains design.

4 Conclusions

Solving the mechanical engineering design optimization problems is considered as a real challenge for the efficiency of each new developed meta-heuristic algorithm. More specifically, these problems involve multiple objectives and mixed variables (continuous, integer and discrete), in addition to various nonlinear constraints on kinematic conditions, manufacturing requirement and performance operating. In the present article, six mechanical optimization problems have been solved by using ten recent algorithms, namely the ABC, PSO, MFO, ALO, ER-WCA, GWO, WCA, MBA, SSA and WOA. The performances of these methods are compared regarding the solution quality, the convergence speed, and the robustness.

In terms of the solution quality and the robustness, MFO was better than the other used algorithms. Also, the meta-heuristics used in this study showed improved results for the coupling with a bolted rim, care impact side, rolling element bearing, and the step-cone pulley design problem comparing with the existing results in the literature. Finally, it can be concluded from this study that the used algorithms are important alternatives to solve other real-world optimization problems in such as automotive and other industries area.

Change history

19 June 2019

This erratum is published due to inconsistencies observed in referencing & citations on the final version.

References

Abderazek H, Ferhat D, Ivana A (2017) Adaptive mixed differential evolution algorithm for bi-objective tooth profile spur gear optimization. Int J Adv Manuf Technol 90(5–8):2063–2073

Abderazek H, Ferhat D, Atanasovska I, Boualem K (2015) A differential evolution algorithm for tooth profile optimization with respect to balancing specific sliding coefficients of involute cylindrical spur and helical gears. Adv Mech Eng 7(9):1–11

Alatas B (2011) ACROA: artificial chemical reaction optimization algorithm for global optimization. Expert Syst Appl 38(10):13170–13180

Beyer HG, Schwefel H-P (2002) Evolution strategies—a comprehensive introduction. Nat Comput 1(1):3–52

Cheng MY, Prayogo D (2014) Symbiotic organisms search: a new metaheuristic optimization algorithm. Comput Struct 139:98–112

Coello CAC (2000) Treating constraints as objectives for single-objective evolutionary optimization. Engineering Optimization 32(3):275–308

Darwin C (1859) On the origin of species by means of natural selection, or the preservation of favored races in the struggle for life. J Murray, London

Deb K (2000) An efficient constraint handling method for genetic algorithms. Comput Methods Appl Mech Eng 186(2–4):311–338

Dhiman G, Kumar V (2017) Spotted hyena optimizer: a novel bio-inspired based metaheuristic technique for engineering applications. Adv Eng Softw 114:48–70

Dorigo M, Birattari M, Stutzle T (2006) Ant colony optimization—artificial ants as a computational intelligence technique. IEEE Comput Intell Mag 1:28–39

Du H, Xiaodong, W, Jian Z (2006) Small-world optimization algorithm for function optimization. In: International conference on natural computation, Springer, Berlin

Erol OK, Eksin I (2006) A new optimization method: big bang–big crunch. Adv Eng Softw 37(2):106–111

Eskandar H, Sadollah A, Bahreininejad A, Hamdi M (2012) Water cycle algorithm–A novel metaheuristic optimization method for solving constrained engineering optimization problems. Comput Struct 110:151–166

Formato RA (2009) Central force optimization: a new deterministic gradient-like optimization metaheuristic. Opsearch 46(1):25–51

Gandomi AH, Kashani AR (2018) Construction cost minimization of shallow foundation using recent swarm intelligence techniques. IEEE T Ind Inform 14(3):1099–1106

Gentle JE (2003) Random number generation and Monte Carlo methods. Springer, Berlin

Giraud-Moreau L, Lafon P (2002) A comparison of evolutionary algorithms for mechanical design components. Engineering Optimization 34(3):307–322

Gu L, Yang RJ, Tho CH, Makowskit M, Faruquet O, Y-Li YL (2001) Optimisation and robustness for crashworthiness of side impact. Int J Veh Des 26(4):348–360

Gupta S, Tiwari R, Nair SB (2007) Multi-objective design optimisation of rolling bearings using genetic algorithms. Mech Mach Theory 42(10):1418–1443

Hamza F, Abderazek H, Lakhdar S, Ferhat D, Yildiz AR (2018) Optimum design of cam-roller follower mechanism using a new evolutionary algorithm. Int J Adv Manuf Technol 99(5–8):1267–1282

Hatamlou A (2013) Black hole: a new heuristic optimization approach for data clustering. Inf Sci 222:175–184

Ho-Huu V, Nguyen-Thoi T, Nguyen-Thoi MH, Le-Anh L (2015) An improved constrained differential evolution using discrete variables (D-ICDE) for layout optimization of truss structures. Expert Syst Appl 42(20):7057–7069

Ho-Huu V, Nguyen-Thoi T, Truong-Khac T, Le-Anh L, Vo-Duy T (2016) An improved differential evolution based on roulette wheel selection for shape and size optimization of truss structures with frequency constraints. Neural Comput Appl 29(1):167–185

Holland JH (1975) Adaptation in natural and artificial systems. University of Michigan Press, Ann Arbor

Karaboga D, Basturk B (2007) A powerful and efficient algorithm for numerical function optimization: artificial bee colony (ABC) algorithm. J Glob Optim 39(3):459–471

Karagöz S, Yildiz AR (2017) A comparison of recent metaheuristic algorithms for crashworthiness optimization of vehicle thin-walled tubes considering sheet metal forming effects. Int J Veh Des 73(1–3):179–188

Kaveh A, Khayatazad M (2012) A new meta-heuristic method: ray optimization. Comput Struct 112:283–294

Kaveh A, Mahdavi VR (2014) Colliding bodies optimization: a novel meta-heuristic method. Comput Struct 139:18–27

Kaveh A, Talatahari S (2010) A novel heuristic optimization method: charged system search. Acta Mech 213(3–4):267–289

Kennedy J, Eberhart RC (1995) Particle swarm optimization. In: Proceedings of IEEE international conference on neural networks, pp 1942–1948

Kiani M, Yildiz AR (2016) A comparative study of non-traditional methods for vehicle crashworthiness and NVH optimization. Arch Comput Methods Eng 23(4):723–734

Kirkpatrick S, Gelatt CD, Vecchi MP (1983) Optimization by simulated annealing. Science 220(4598):671–680

Koza JR (1992) Genetic programming II, automatic discovery of reusable subprograms. MIT Press, Cambridge

Mirjalili S (2015) Moth-flame optimization algorithm: a novel nature-inspired heuristic paradigm. Knowl Based Syst 89:228–249

Mirjalili S (2015) The ant lion optimizer. Adv Eng Softw 83:80–98

Mirjalili S (2016) Dragonfly algorithm: a new meta-heuristic optimization technique for solving single-objective, discrete, and multi-objective problems. Neural Comput Appl 27(4):1053–1073

Mirjalili S, Gandomi AH, Mirjalili SZ, Saremi S, Faris H, Mirjalili SM (2017) Salp Swarm Algorithm: A bio-inspired optimizer for engineering design problems. Adv Eng Softw 114:163–191

Mirjalili S, Lewis A (2016) The whale optimization algorithm. Adv Eng Softw 95:51–67

Mirjalili S, Mirjalili SM, Lewis A (2014) Grey wolf optimizer. Adv Eng Softw 69:46–61

Moghaddam FF, Moghaddam RF, Cheriet M (2012) Curved space optimization: a random search based on general relativity theory. arXiv, preprint arXiv:1208

Oftadeh R, Mahjoob M, Shariatpanahi MA (2010) Novel meta-heuristic optimisation algorithm inspired by group hunting of animals: hunting search. Comput Math Appl 60(7):2087–2098

Pholdee N, Bureerat S, Yildiz AR (2017) Hybrid real-code population-based incremental learning and differential evolution for many-objective optimisation of an automotive floor-frame. Int J Veh Des 73(1–3):20–53

Qing A (2009) Differential evolution: fundamentals and applications in electrical engineering. Wiley, New York

Rao RV, Savsani VJ, Vakharia DP (2011) Teaching-learning-based optimization: a novel method for constrained mechanical design optimization problems. Comput Aided Des 43:303–315

Rashedi E, Nezamabadi-Pour H, Saryazdi S (2009) GSA: a gravitational search algorithm. Inf Sci 179(13):2232–2248

Saravanan R (2006) Manufacturing optimization through intelligent techniques. CRC Press, Boca Raton

Shah-Hosseini H (2011) Principal components analysis by the galaxy-based search algorithm: a novel metaheuristic for continuous optimisation. Int J Comput Sci Eng 6(1–2):132–140

Sadollah A, Bahreininejad A, Eskandar H, Hamdi M (2012) Mine blast algorithm for optimization of truss structures with discrete variables. Comput Struct 102:49–63

Sadollah A, Bahreininejad A, Eskandar H, Hamdi M (2013) Mine blast algorithm: A new population based algorithm for solving constrained engineering optimization problems. Appl Soft Comput 13(5):2592–2612

Sadollah A, Eskandar H, Bahreininejad A, Kim JH (2015) Water cycle algorithm with evaporation rate for solving constrained and unconstrained optimization problems. Appl Soft Comput 30:58–71

Sadollah A, Eskandar H, Bahreininejad A, Kim JH (2015) Water cycle, mine blast and improved mine blast algorithms for discrete sizing optimization of truss structures. Comput Struct 149:1–16

Sandgren E (1990) Nonlinear integer and discrete programming in mechanical design optimization. ASME J Mech Des 112:223–229

Shiqin Y, Jianjun J, Guangxing Y (2009) A dolphin partner optimization. In: Global congress on intelligent systems. IEEE, pp 124–128

Simon D (2008) Biogeography-based optimization. IEEE Trans Evolut Comput 12(6):702–713

Storn R, Price K (1995) Differential evolution—a simple and efficient adaptive scheme for global optimization over continuous spaces. Technical Report TR-95-012, ICSI

Takahama T, Sakai S (2010) Efficient constrained optimization by the epsilon constrained adaptive differential evolution. In: Proceedings of 2010 IEEE congress on evolutionary computation (CEC2010)

Yang X-S, Deb S. (2009) Cuckoo search via levy flights. In: Proceedings of the world congress on nature and biologically inspired computing (NaBIC-2009), Coimbatore, India, pp 210–214

Yang C, Tu X, Chen J (2007) Algorithm of marriage in honey bees optimization based on the wolf pack search. In: IEEE 2007 international conference on intelligent pervasive computing (IPC), pp 462–467

Yang XS (2010) A new metaheuristic bat-inspired algorithm. In: Nature inspired cooperative strategies for optimization (NICSO 2010). Springer, Berlin, pp 65–74

Yildiz AR (2009) A new design optimization framework based on immune algorithm and Taguchi's method. Comput Ind 60(8):613–620

Yildiz AR (2009) A novel hybrid immune algorithm for global optimization in design and manufacturing. Robotics Comput-Integr Manufactur 25(2):261–270

Yildiz AR (2012) A new hybrid particle swarm optimization approach for structural design optimization in the automotive industry. Proc Inst Mech Eng Part D J Automob Eng 226(10):1340–1351

Yildiz AR (2013) A new hybrid differential evolution algorithm for the selection of optimal machining parameters in milling operations. Appl Soft Comput 13(3):1561–1566

Yildiz AR (2013) Comparison of evolutionary-based optimization algorithms for structural design optimization. Eng Appl Artif Intell 26(1):327–333

Yildiz AR (2013) Cuckoo search algorithm for the selection of optimal machining parameters in milling operations. Int J Adv Manuf Technol 64(1–4):55–61

Yildiz AR (2013) Hybrid Taguchi-differential evolution algorithm for optimization of multi-pass turning operations. Appl Soft Comput 13(3):1433–1439

Yildiz AR (2013) A new hybrid bee colony optimization approach for robust optimal design and manufacturing. Appl Soft Comput 13(5):2906–2912

Yildiz BS (2017) A comparative investigation of eight recent population-based optimisation algorithms for mechanical and structural design problems. Int J Veh Des 73(1–3):208–218

Yildiz BS (2017) Natural frequency optimization of vehicle components using the interior search algorithm. Mater Test 59(5):456–458

Yildiz AR, Saitou K (2011) Topology synthesis of multi component structural assemblies in continuum domains. J Mech Des 133(1):011008

Yildiz BS, Yildiz AR (2017) Moth-flame optimization algorithm to determine optimal machining parameters in manufacturing processes. Mater Test 59(5):425–429

Yildiz BS, Yildiz AR (2018) Comparison of grey wolf, whale, water cycle, ant lion and sine-cosine algorithms for the optimization of a vehicle engine connecting rod. Mater Test 60(3):311–315

Yildiz BS, Lekesiz H, Yildiz AR (2016) Structural design of vehicle components using gravitational search and charged system search algorithms. Mater Test 58(1):79–81

Yildiz AR, Kurtulus E, Demirci E, Yildiz BS, Karagoz S (2016) Optimization of thin-wall structures using hybrid gravitational search and Nelder-Mead algorithm. Mater Test 58(1):75–78

Yildiz AR, Kıilicarpa UA, Demirci E, Dogan M (2019) Topography and topology optimization of diesel engine components for lightweight design in the automotive industry. Mater Test 61(1):27–34

Acknowledgements

The first author gratefully acknowledge the support provided by Bursa Uludag University Scientific Research Projects Centre (BAP) under Grant Nos. BUAP(MH)-2019/2.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

-

1.

Coupling with a bolted rim

The problem can be mathematically formulated as follows:

Objective function: \(f\left( x \right) = \beta_{1} \left( {\frac{N}{{N_{m} }}} \right) + \beta_{2} \left( {\frac{{R_{B} + \phi_{4} (d) + c}}{{R_{m} }}} \right) + \beta_{3} \left( {\frac{M}{{M_{T} }}} \right)\)

Subject to:

where \(K(d) = \frac{{0.9f_{m} R_{e} \pi \left( {\phi_{1} (d)} \right)^{2} }}{{4\sqrt {1 + 3(0.16\phi_{3} (d)f_{1} /\phi_{1} (d))^{2} } }}, \, M_{T} = 40\,{\text{Nm}}, \, M_{\hbox{max} } = 1000\,{\text{Nm}}, \, f_{m} = 0.15, \, f_{1} = 0.15\)

See Table 15.

-

2.

Car side impact design

The problem can be mathematically formulated as follows:Objective function: \(f\left( x \right) = 1.98 + 4.90x_{1} + 6.67x_{2} + 6.98x_{3} + 4.01x_{4} + 1.78x_{5} + 2.73x_{7}\)

Subject to:

\(g_{7} (x) = 46.36 - 9.9x_{2} - 12.9x_{1} x{}_{8} + 0.1107x_{3} x_{10} \le 32\)

where \(0.5 \le x_{1} - x_{7} \le 1.5,x_{8} ,x_{9} \in (0.192,0.345)\) and \(- 30 \le x_{10} ,x_{11} \le 30.\)

-

3.

Rolling element bearing

The problem can be mathematically formulated as follows:

Objective function:

Subject to:

where

where \(T = D - d - 2D_{b} , \, D = 160, \, d = 90, \, \beta_{\omega } = 30,0.5\left( {D + d} \right) \le D_{m} \le 0.6\left( {D + d} \right),0.15\left( {D - d} \right) \le D_{b} \le 0.45\left( {D - d} \right),\)\(4 \le Z \le 50,0.515 \le f_{i} \le 0.6,0.515 \le f_{o} \le 0.6,0.6 \le K_{D\hbox{max} } \le 0.7,0.3 \le \varepsilon \le 0.4,0.02 \le e \le 0.1,0.6 \le f_{i} \le 0.85.\)

-

4.

Step-cone pulley

The problem can be mathematically formulated as follows:

Objective function:

Subject to:

where:

-

\(C_{i}\) indicates the length of the belt to obtain speed \(N_{i}\) and is given by

$$C_{i} = \frac{{\pi d_{i} }}{2}\left( {1 + \frac{{N_{i} }}{N}} \right) + \frac{{\left( {\frac{{N_{i} }}{N} - 1} \right)^{2} }}{4a} + 2a,\quad \, i = 1, \ldots ,4$$ -

\(R_{i}\) is the tension ratio and is given by

$$R_{i} = \exp \left[ {\mu \left\{ {\pi - 2\sin^{ - 1} \left\{ {\left( {\frac{{N_{i} }}{N} - 1} \right)\frac{{d_{i} }}{2a}} \right\}} \right\}} \right], \, i = 1, \ldots ,4$$ -

\(P_{i}\) is the power transmitted at each step

$$R_{i} = st\omega \left[ {1 - \exp \left[ { - \mu \left\{ {\pi - 2\sin^{ - 1} \left\{ {\left( {\frac{{N_{i} }}{N} - 1} \right)\frac{{d_{i} }}{2a}} \right\}} \right\}} \right]} \right]\frac{{\pi d_{i} N_{i} }}{60}, \, i = 1, \ldots ,4$$$$\rho_{1} = 7200\,{\text{kg/m}}^{3} , \, a = 3\,{\text{m}}, \, \mu = 0.35, \, s = 1.75\,{\text{MPa}}, \, t = 8\,{\text{mm}},40 \le d_{i} \le 100,\,16 \le \omega \le 100.$$

-

5.

Belleville spring

The problem can be mathematically formulated as follows:

Objective function:\(f(x) = 0.07075\pi \left( {D_{e}^{2} - D_{i}^{2} } \right)t\)

Subject to:

where \(\alpha = \left( {\frac{6}{\pi \ln \left( K \right)}} \right)\left( {\frac{K - 1}{K}} \right)^{2} ,\beta = \left( {\frac{6}{\pi \ln \left( K \right)}} \right)\left( {\frac{K - 1}{K} - 1} \right),\gamma = \left( {\frac{6}{\pi \ln \left( K \right)}} \right)\left( {\frac{K - 1}{2}} \right)\)\(P = \frac{{\log_{10} \log_{10} \left( {8.122{\text{e}}6\mu + 0.8} \right) - C_{1} }}{n},h = \left( {\frac{2\pi N}{60}} \right)^{2} \left( {\frac{2\pi \mu }{{E_{f} }}} \right)\left( {\frac{{R^{4} }}{4} - \frac{{R_{o}^{4} }}{4}} \right),P_{\hbox{max} } = 1000\,{\text{lb}},\;\delta_{\hbox{max} } = 0.2\,{\text{in}} .,\;S = 200\,{\text{KPsi}},\)\(E = 30e6\,psi,\;\mu = 0.3,\;H = 2\,{\text{in}} .,\;D_{\hbox{max} } = 12.01\,{\text{in}} .,\;K = \frac{{D_{e} }}{{D_{i} }},\;\delta \left( l \right) = f\left( a \right)a,\;a = \frac{h}{t}.\)

See Table 16.

-

6.

Speed Reducer

The problem can be mathematically formulated as follows:Objective function: \(f\left( x \right) = 0.7854bm^{2} \left( {3.3333z^{2} + 14.9334z - 43.0934} \right) - 1.508b\left( {d_{1}^{2} + d_{2}^{2} } \right) + 7.4777\left( {d_{1}^{3} + d_{2}^{3} } \right) + 0.7854\left( {l_{1} d_{1}^{2} + l_{2} d_{2}^{2} } \right)\)

Subject to:

where \(2.6 \le b \le 3.6,0.7 \le m \le 0.8,17 \le z \le 28,7.3 \le l_{1} \le 8.3,7.3 \le l_{2} \le 8.3,2.9 \le d_{1} \le 3.9\) and \(5 \le d_{2} \le 5.5.\)

Rights and permissions

About this article

Cite this article

Yildiz, A.R., Abderazek, H. & Mirjalili, S. A Comparative Study of Recent Non-traditional Methods for Mechanical Design Optimization. Arch Computat Methods Eng 27, 1031–1048 (2020). https://doi.org/10.1007/s11831-019-09343-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11831-019-09343-x