Abstract

Extensive usage of synthetic plastics poses a negative impact on environment and concomitantly increasing fossil fuel demand. Hence, bioplastic like polyhydroxyalkanoates (PHAs) has gained attention due to their analogous properties with synthetic plastics. However, its cost competitiveness is a big confront. In this context design of a substrate facilitator, mixed bacterial culture (MBC) can address this burning issue and augment avenue to industrial PHAs production. Herein, PHAs production by MBC comprised of Bacillus species was investigated. Eight preserved PHAs producing Bacillus species were selected of which 04 strains showed accumulation of PHAs granule. Among them, Bacillus sp. C1 and Bacillus sp. O6 were compatible to each other as revealed from antagonistic activity. Independently, Bacillus sp. C1 (2013) and Bacillus sp. O6 produced 0.90 ± 0.01 g/L & 1.30 ± 0.02 g/L PHAs. However, 2.70 ± 0.01 g/L of PHAs was recovered from MBC through submerged fermentation. Infra-red spectra illustrated sharp peak at 1719.86 cm−1 denoting carbonyl-ester (C = O) functional group of polyhydroxybutyrate (PHB). It was degraded within 21 days as confirmed from open windrow composting. This research represents a new approach for PHAs production however before pilot scale operation, evaluation of inexpensive carbon sources as substrate is highly indispensable.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Petrochemical-based plastic waste is the major cause of white pollution. Recent trends in its production and management strategies predicted accumulation of 12,000 Mt of waste in the environment by 2050. Thus, creating a significant burden on recalcitrant plastic waste management (Geyer et al. 2017). Petrochemical energy depletion coupled with white pollution has drawn attention of scientist to produce bioplastics or biopolymer (Muneer et al. 2020). Polyhydroxyalkanoates (PHAs) are the bioplastics synthesized by microbes, which serves as energy storage granule during carbon starvation. The structural, thermal, mechanical and biocompatible properties validate it as a suitable substitute to petrochemical-based plastic, which can address issues concerned with white pollution (Maity et al. 2020).

PHAs synthesis is a stress regulated phenomenon triggered by microbes during macro and micro nutrient limited condition (Mohapatra et al. 2016a, b). Many bacteria including the genera Bacillus, Clostridium, Nocardia, Streptomyces, Staphylococcus, Corynebacterium, Rhodococcus and Klebsiella, Escherichia, Methylobacterium, Alcaligenes, Rhizobium, Ralstonia, Enterobacter, Aeromonas, Azotobacter, Pseudomonas, Citrobacter, Zobellella and Cupriavidus were reported as PHAs producers (Javaid et al. 2020; Maity et al. 2017; Carpa and Barbu-Tudoran 2011). Additionally, certain genetically engineered bacteria such as E. coli MG1655, P. putida KT2440, R. eutropha 5119, B. subtilis H16, C. necator DSM 428, P. citronellolis NRRLB-2504, S. degradans 2–40, C. necator IPT 026, X. campestris IBSBF1867, A. hydrophila ATCC7966, A. junii BP25 and S. elongatus PCC 7942 were also exploited for PHAs production in contrast to wild strain (Liu et al. 2020; Bhatia et al. 2018; Rebocho et al. 2020; Sawant et al. 2017; Rodrigues et al. (2019);;;;; Anburajan et al. (2019); Lowe et al. 2017). So far 150 distinct monomers of PHAs with molecular weight 2 × 102 to 3 × 103 KDa have been recovered from bacteria. Such variations of monomer depend on the type of bacteria, substrate and bioprocess technology used for production. Considering carbon configuration of the monomer, PHAs can be categorized in to three subtypes viz., short, medium and long chain length PHAs (Zhu et al. 2022). These biomaterials imitate properties of petrochemical-based plastic, biodegradable under natural conditions and non-cytotoxic in nature. Therefore, it can be used in the preparation of domestic plastic, photographic film, biomedical devices, drug delivery carriers, drugs, fine chemicals & nutritional supplements (Mohapatra et al. 2020). However, replacement of petrochemical-based plastic by PHAs has been limited due to cost competitiveness, which restricts its lucrative market penetration and adoption (Pati et al. 2020).

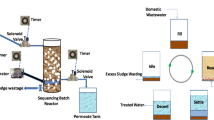

Reports suggest, higher PHAs production can be achieved by using pure culture under optimized conditions (Dash et al. 2020). Nevertheless, life cycle analysis of the overall process indicated a negative impact on its cost affordability. In contrast, recent reports emphasize on usage of high PHAs producing microbes, reasonable carbon sources like agro-industrial & domestic waste (Mohapatra et al. 2017), genetically engineered microbes and native mixed bacterial culture (MBC) for cost-effective PHAs production (Zhang et al. 2018). Moreover, PHAs production by MBC reduces the energy required to maintain axenic conditions which can resolve issues linked with low metabolic activities, conversion efficiency and wide variety of substrate utilization by pure culture (Zhu et al. 2022). As PHAs yield is directly proportional to microbial cell biomass, therefore usage of MBC is considered as a promising approach for cost-effective PHAs production. Though the concept of PHAs production by MBC has been described earlier (Cavaille et al. 2016; Coats et al. 2016; Zhu et al. 2022) still many facts associated with it are unclear. In light of above, an attempt has been made to investigate PHAs production by MBC via submerged fermentation and analyze improvement of yield in comparison to pure culture.

Materials and methods

Bacterial source

Previously, 16 PHAs producing Bacillus sp. & Zobellella sp. were isolated from rhizospheric soil region of different plants & fish processing industry effluent respectively and preserved in glycerol stock at -20 °C (Mohapatra et al. 2014; Maity et al. 2017). These bacterial isolates were revived in nutrient agar (NA), and then induced for synthesis of PHAs granule in mineral salt medium (MSM) (K2HPO4—2.5, NaCl -10.0, (NH4)2SO4—3.38, KH2PO4—2.5, CaCl2—0.052, yeast extract—2, MgSO4.7H2O—0.2, Na2HPO4—1.5 and glucose—20.0 in g/L). Further, PHAs granule accumulation by these preserved bacterial isolates were examined via Sudan black staining (Dash et al. 2020). Reagents and cultivation media utilized in the research were procured from Merck-Millipore, Sigma-Aldrich and Hi-Media Lab. Pvt. Ltd.

In-vitro antagonistic activity among PHAs producers

Antagonistic activity (in-vitro) among PHAs granule accumulating bacteria were studied using agar well diffusion technique. Desired bacteria were lawn cultured on NA plate and 10 μL of another bacterial suspension was placed in the agar well. Culture plates were incubated at 37 °C ± 2/24 h to observe zone of inhibition (Khokhar et al. 2012). MBC was prepared using compatible PHAs accumulating bacteria. Inoculum was developed individually and then mixed in 1:1 ratio to formulate MBC comprising of pre-determined cell biomass 1.5 × 108cells/mL (0.5 McFarland standard).

Optimization of growth parameters

In general, PHAs production by many bacteria is parallel to cell biomass yield (Mohapatra et al. 2015). Therefore, different parameters viz., culture media, pH, temperature, carbon source, nitrogen source and inoculum volume regulating optimal growth of bacteria were optimized by variation of one-factor at a time (OFAT) method (Maity et al. 2017). Inoculum having 1.5 × 108 cells/ mL (0.5 McFarland standards) was developed to evaluate role of growth parameters on PHAs accuring bacteria. Parameters including culture media [growth media (GM) & MSM], pH (5–9), temperature (23–42 °C), inoculum size (5–20% v/v), carbon source (maltose, sucrose, dextrose, glucose, fructose) and nitrogen source (ammonium chloride, sodium nitrate, yeast extract, peptone, ammonium sulphate) were optimized. Here, carbon to nitrogen ratio was maintained at 6:1. Regarding culture media optimization, GM & MSM (each 100 mL) was taken, 10 mL of day-old inoculum was added and incubated at 37 °C ± 2/24 h with 120 rpm. Culture medium depicting higher cell biomass yield was determined (OD600) through spectroscopic assay (λ35-Perkin-Elmer). Similarly, other parameters were studied using optimized culture media.

PHAs production

PHAs production by pure and MBC was carried out through submerged fermentation using shake flask technique (Pati et al. 2020). In brief, 1 L of MSM (pH 7) was taken, inoculum (10%) was added and incubated at 37 °C/72 h. Bacterial cell biomass was harvested through centrifugation (10,000 rpm/15 min) and dried at 50 °C for 12 h. Cell biomass was suspended in aqueous sodium hypochlorite solution (3:1) and incubated at 37 °C/1 h. Suspension was then centrifuged and rinsed with acetone, methanol and diethyl-ether in 1:1:1 ratio. Subsequently, cell biomass was collected in chloroform, and dried to get PHAs. PHAs yield was estimated using the formula;

Fourier Transform Infrared Spectroscopic (FTIR) analysis

FTIR analysis was conducted to detect the functional groups of PHAs. Extracted film (2 mg) was placed on attenuated total reflectance (ATR) and IR (infra-red) spectra were noted within the spectral range 4000—400 cm−1, scan: 16 and window material: CsI using single beam spectrometer (Perkin-Elmer RX I) (Pati et al. 2020).

Biodegradability of PHAs

Biodegradability of PHAs was estimated by open windrow composting technique in natural conditions (Mohapatra et al. 2016a, b). PHAs film was composted under the soil in natural (pH—7.2 & temperature—35 °C ± 2) conditions. Biotransformation of surface of the film was observed under stereomicroscopic imaging. Further, the rate of biodegradation was estimated from weight loss dynamics of PHAs film at 7 days interval up to 21 days. Biodegradability in terms of percentage was calculated using the formula; Biodegradability (%) = [(W1-W2) / W1] X 100, where W1—initial and W2—final weight of the PHAs film.

Statistical analysis

Statistical interpretation of growth parameters optimization and PHAs production was analyzed by one-way ANOVA, where significant level is p < 0.05.

Results

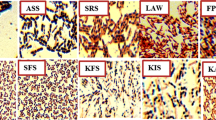

In our previous study, PHAs production efficacy of 16 different species of Bacillus sp. & Zobellella sp. were analyzed. Then, these PHAs producers were preserved in glycerol stock at -20 °C. Eight bacterial strains viz., Bacillus sp. C1 (2013) (KF626477), Bacillus sp. P1 (2013b) (KF626468), Bacillus sp. P2 (2013) (KF626472), Bacillus sp. P3 (2013) (KF626473), Bacillus sp. P4 (2013c) (KF626474), Bacillus sp. O6 (KF626479), Bacillus subtilis sp. G5 (KP172548) and Zobellella tiwanensis sp. DD5 (KX258951) were revived for the present study. Among them, 4 bacterial strains such as Bacillus sp. C1 (2013), Bacillus sp. P1 (2013b), Bacillus sp. P4 (2013c) and Bacillus sp. O6 showed accumulation of PHAs granules, which was confirmed from Sudan black staining under bright field microscopic imaging (Fig. 1). Based on the aim of the study these PHAs producers were evaluated for antagonistic activity prior to development of MBC. It was conducted among Bacillus sp. C1 (2013)—Bacillus sp. O6, Bacillus sp. C1 (2013)—Bacillus sp. P1 (2013b), Bacillus sp. C1 (2013)—Bacillus sp. P2 (2013), Bacillus sp. O6—Bacillus sp. P1 (2013b), Bacillus sp. O6—Bacillus sp. P2 (2013) and Bacillus sp. P1 (2013b)—Bacillus sp. P2 (2013). Results depicted that, Bacillus sp. C1 (2013) and Bacillus sp. O6 were compatible to each other (Fig. 2), while Bacillus sp. C1 (2013)—Bacillus sp. P1 (2013b), Bacillus sp. C1 (2013)—Bacillus sp. P2 (2013), Bacillus sp. O6—Bacillus sp. P1 (2013b), Bacillus sp. O6—Bacillus sp. P2 (2013) and Bacillus sp. P1 (2013b)—Bacillus sp. P2 (2013) showed a high degree of inhibition to each other. Therefore, native MBC was developed using Bacillus sp. C1 (2013) and Bacillus sp. O6 for PHAs production. In general, PHAs accumulation by many pure or MBC is parallel to cell biomass production. Thus, growth parameters affecting higher cell biomass production were optimized and results indicated that, MSM, pH 7.0, temperature 37 °C, carbon source (sucrose), nitrogen source (ammonium chloride) and inoculum volume 10% were optimum at significant level P < 0.05 (Fig. 3a-f, Supplementary material Table S1). Notably, carbon to nitrogen ratio was maintained at 6:1 during optimization of growth parameters and PHAs production. Subsequently, pure and MBC were evaluated for PHAs production under optimized conditions. Pure bacterial culture of Bacillus sp. C1 (2013) and Bacillus sp. O6 produced 0.90 ± 0.01 g/L & 1.30 ± 0.02 g/L of PHAs through submerged fermentation. However, 2.70 ± 0.01 g/L of PHAs was recovered from MBC in 72 h. Further, the rate of PHAs production was decreased.

The extracted PHAs was subjected to FTIR-ATR analysis for detection of functional group. In toto three distinct peaks were obtained from IR spectra (Fig. 4), where two distinct peaks at 1453.4 cm−1 and 1382 cm−1 depicted C-H bend and CH3 & C-H bend respectively. However, the high intense peak obtained at 1719.86 cm−1 confirmed carbonyl ester (C = O) functional group of PHB. Hence, the IR analysis provides an appropriate insight for chemical structure of the PHB. Surface morphology of the PHB film was rough and fairly regular as observed under stereomicroscopic imaging (Fig. 5). Biodegradability of PHB film was estimated from the weight loss dynamics at seven days interval. The initial weight of PHB film (0.106 gm) was reduced to 0.071 gm & 0.023 gm on 7th & 14th days respectively. Moreover, the PHB film was degraded completely within 21 days. Initially the rate of biodegradation (33.01%) was slower and then increased to 78.30—100% from 7th to 21st days. Thus, weight loss dynamics clearly validated biodegradability of MBC derived PHB film under natural condition.

Discussion

In the present context, sustainable biopolymer or bioplastic production is a matter of concern for academia and industry. PHAs being the potential biopolymer has gained attention for future endeavor. Extensive research has been undertaken on PHAs production using pure bacterial culture, however issues pertaining to its cost competitiveness is still unresolved. Synthetic biology recommended, usage of MBC is more appropriate to this aspect than pure bacterial culture. MBC are more robust to unfavorable environmental condition and can utilize wide array of substrate as carbon source to accumulate PHAs. In this finding out of 16, four bacterial isolates showed synthesis of PHAs granule even after three years of preservation. These bacterial isolates were energetically stable, therefore PHAs synthesis ability was not suppressed (Mohapatra et al. 2016a, b). Among them, Bacillus sp. C1 (2013) and Bacillus sp. O6 were compatible in nature. However, other bacterial isolates showed a high degree of inhibition to each other. This might be due to production of secondary metabolites such as antibiotics, toxins, pigments and immunomodulatory substances (Dagher et al. 2021). Moreover, Bacillus is preferred by several industries and academia over Gram-negative bacteria due to their predominance nature, faster growth rate, genetic stability, resistance to adverse environmental conditions and ability to metabolize low-cost carbon sources for production of endotoxin free PHAs (Mohapatra et al. 2017). Thus, native MBC was developed using Bacillus sp. C1 (2013) and Bacillus sp. O6.

PHAs accumulation by many pure or MBC is parallel to cell biomass production, which is regulated by various growth factors. Growth factors optimization data showed higher cell biomass yield in MSM at pH 7.0, temperature 37 °C in presence of sucrose & ammonium chloride as carbon & nitrogen source with 10% inoculum size. In line with this result, Bhatia et al. (2018) observed higher cell biomass production by MBC comprised of Bacillus subtilis, Bacillus amyloliquefaciens and Ralstonia eutropha at pH 7.0, temperature 30 °C and sucrose & ammonium chloride as carbon & nitrogen sources. Further, higher cell biomass production by mixed microbial culture at pH 7.0, temperature 37 °C were also reported earlier (Montiel-Jarillo et al. 2017; Colombo et al. 2016). In our previous study Bacillus sp. C1 (2013) and Bacillus sp. O6 also produced higher cell biomass in MSM at pH 7.0, temperature 37 °C with inoculum size 10% (Mohapatra et al. 2014). Moreover, many PHAs accumulating bacterial strains showed luxuriant growth and higher cell biomass production at 6:1 carbon to nitrogen ratio (Pati et al. 2020; Mohapatra et al. 2020). As these bacteria were isolated from rhizospheric region, thus prevailing physio-chemical parameters with 6:1 carbon to nitrogen ratio favored their growth and PHAs production (Koller et al. 2013).

Under optimized condition, Bacillus sp. C1 (2013), Bacillus sp. O6 and MBC produced 0.90 ± 0.01, 1.30 ± 0.02 and 2.70 ± 0.01 g/L of PHAs respectively. Comparatively 0.5 g/L of higher PHAs production was achieved by MBC than pure bacterial culture. Similarly, Bhatia et al. (2018) reported 2.30 g/L of PHAs production by MBC comprised of B. subtilis H16 and R. eutropha 5119 using sucrose as sole carbon source. The co-culture of S. degradans 2–40 and B. cereus also produced 0.27 g/L of PHAs from xylan (Sawant et al. 2017). Uma and Gandhimati (2020) obtained 1.66 g/L of PHAs from MBC of P. tuomuerensis and P. nitroreducens using oily bilge water as substrate. A bacterial consortium of genetically modified E. coli MG1655 and P. putida KT2440 enhanced PHAs production (1.32 g/L) from glucose-xylose mixtures (Zhu et al. 2022). Rebocho et al. (2020) recovered 1.85 g/L of PHB from MBC of C. necator DSM 428 and P. citronellolis NRRL B-2504 using apple pulp waste as substrate. Further, A. hydrophila ATCC7966 and A. junii consortia produced 2.64 g/L of PHAs from a mixture of acetic & butyric acid (Anburajan et al. 2019). Among all, MBC of C. necator IPT 026 and X. campestris IBSBF 1867 showed higher PHAs production (6.43 g/L) from palm oil (Rodrigues et al. 2019). Here, we report for the first time higher PHAs production from MBC comprised of Bacillus sp. C1 (2013) and Bacillus sp. O6 using sucrose as carbon source. Higher PHAs yield by MBC than pure bacterial culture is due to reduced dissolved oxygen and variation in bacterial population leading to nutrient limitation that created a selective pressure for PHAs synthesis. Additionally, MBC of Bacillus species has an added advantage over other bacterial genera due to lack of lipo-polysaccharides outer layer, which makes the downstream processing simpler there by enhancing PHAs yield (Coats et al. 2016; Chen et al. 2015).

IR spectra of MBC derived PHAs exhibited sharp peak at 1719.86 cm−1 representing carbonyl-ester group (C = O) of PHB. Moreover, PHB is the most common homo-polymer of PHAs. Correspondingly, Bhatia et al. (2018), Rebocho et al. (2020), Rodrigues et al. (2019) and Pati et al. (2020) observed similar absorption band at 1720 cm−1, 1723 cm−1, 1728 cm−1 and 1720.01 cm−1 indicating chemical structure of PHB. Weight loss dynamics revealed, 78.30% of PHB film degradation on 14th day and complete degradation was observed within 21 days. Similar to our result, Pati et al. (2020) reported biodegradation of PHB film within 14 days under natural condition. In contrast, Volova et al. (2016) and Mohapatra et al. (2016a, b) also observed biodegradation of PHB film within 35 and 30 days respectively. In this research, we observed faster degradation of PHB film, which might be due to the rough surface that enhances attachment of microbes, leading to biodegradation of PHB to CO2 & H2O in oxic and CO2 & CH4 in anoxic condition (Varsha and Savitha 2011; Boyandin et al. 2012).

Conclusion

The major drawback of commercial PHB production is due to lack of economical bioprocessing technology. Thus, development of native MBC could pave the way towards cost competitiveness as it can utilize wide range of inexpensive substrates to achieve higher PHB yield than monoculture. Herein, relatively 0.5 g/L of higher PHB production was obtained from indigenous MBC than monoculture. Further, PHB production should be conducted through consolidated bioprocessing to scale up this approach.

Abbreviations

- PHAs:

-

Polyhydroxyalkanoates

- MBC:

-

Mixed bacterial culture

- (C = O):

-

Carbonyl-ester

- PHB:

-

Polyhydroxybutyrate

- Mt:

-

Metric tons

- NA:

-

Nutrient agar

- GM:

-

Growth media

- MSM:

-

Mineral salt medium

- OFAT:

-

One factor at a time

- DCW:

-

Dry cell weight

- ATR:

-

Attenuated total reflectance

- FTIR:

-

Fourier transform infrared spectroscopy

- IR:

-

Infra-red

- ANOVA:

-

Analysis of variance

References

Anburajan P, Kumar N, Sabapathy A et al (2019) Polyhydroxy butyrate production by Acinetobacter junii bp25, Aeromonas hydrophila ATCC 7966, and their co-culture using a feast and famine strategy. Bioresour Technol. https://doi.org/10.1016/j.biortech.2019.122062

Bhatia SK, Yoon JJ, Kim HJ et al (2018) Engineering of artificial microbial consortia of Ralstonia eutropha and Bacillus subtilis for Poly (3-Hydroxybutyrate-Co-3-Hydroxyvalerate) copolymer production from sugarcane sugar without precursor feeding. Bioresour Technol. https://doi.org/10.1016/j.biortech.2018.02.056

Boyandin AN, Prudnikova SV, Filipenko ML et al (2012) Biodegradation of polyhydroxyalkanoates by soil microbial communities of different structures and detection of PHAs degrading microorganisms. Appl Biochem Microbiol. https://doi.org/10.1134/S0003683812010024

Carpa R, Barbu-Tudoran L (2011) Investigation of the poly-β-hyroxybutyrate (PHB) producing in mountain bacterial strains by transmission electron microscopy. Rom Biotechnol Lett 16:5989–5995

Cavaille L, Albuquerque M, Grousseau E et al (2016) Understanding of polyhydroxybutyrate production under carbon and phosphorus-limited growth conditions in non-axenic continuous culture. Bioresour Technol. https://doi.org/10.1016/j.biortech.2015.11.003

Chen Z, Guo Z, Wen Q et al (2015) A new method for polyhydroxyalkanoates (PHAs) accumulating bacteria selection under physical selective pressure. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2014.10.027

Coats ER, Watson BS, Brinkman CK (2016) Polyhydroxyalkanoates synthesis by mixed microbial consortia cultured on fermented dairy manure: effect of aeration on process rates/yields and the associated microbial ecology. Water Res. https://doi.org/10.1016/j.watres.2016.09.039

Colombo B, Sciarria TP, Reis M, Scaglia B, Adani F (2016) Polyhydroxyalkanoates (PHAs) production from fermented cheese whey by using a mixed microbial culture. Bioresour Technol 218:692–9. https://doi.org/10.1016/j.biortech.2016.07.024

Dagher F, Nickzad A, Zheng J, Hoffmann M, Déziel E (2021) Characterization of the biocontrol activity of three bacterial isolates against the phytopathogen Erwinia amylovora. Microbiologyopen 10(3):e1202. https://doi.org/10.1002/mbo3.1202

Dash A, Mohanty S, Samantaray DP (2020) Effect of carbon/nitrogen ratio on polyhydroxyalkanoates production by Bacillus species under submerged fermentation. J Environ Biol 41(1):118–124. https://doi.org/10.22438/jeb/41/1/MRN-1138

Geyer R, Jambeck JR, Law KL (2017) Production, use, and fate of all plastics ever made. Sci Adv. https://doi.org/10.1126/sciadv.1700782

Javaid H, Nawaz A, Riaz N, Mukhtar H, Ul-Haq I, Shah KA, Khan H, Naqvi SM, Shakoor S, Rasool A, Ullah K, Manzoor R, Kaleem I, Murtaza G (2020) Biosynthesis of polyhydroxyalkanoates (PHAs) by the valorization of biomass and synthetic waste. Molecules 25(23):5539. https://doi.org/10.3390/molecules25235539

Khokhar I, Haider MS, Mukhtar I et al (2012) Biological control of Aspergillus niger, the cause of black-rot disease of Allium cepa L. (onion) by Penicillium species. J Agrobiol. https://doi.org/10.2478/v10146-012-0003-5

Koller M, Niebelschutz H, Braunegg G (2013) Strategies for recovery and purification of PHAs biopolyesters from surrounding biomass. Eng Life Sci. https://doi.org/10.1002/elsc.201300021

Liu Y, Yang S, Jia X (2020) Construction of a “nutrition supply-detoxification” coculture consortium for medium-chain-length polyhydroxyalkanoate production with a glucose-xylose mixture. J Ind Microbiol Biotechnol. https://doi.org/10.1007/s10295-020-02267-7

Lowe H, Hobmeier K, Moos M et al (2017) Photoautotrophic production of polyhydroxyalkanoates in a synthetic mixed culture of Synechococcus elongatus cscb and Pseudomonas putida cscab. Biotechnol Biofuels. https://doi.org/10.1186/s13068-017-0875-0

Maity S, Das S, Mohapatra S et al (2020) Growth associated polyhydroxybutyrate production by the novel Zobellellae tiwanensis strain DD5 from banana peels under submerged fermentation. Int J Bio. Macromol. https://doi.org/10.1016/j.ijbiomac

Maity S, Das S, Samantaray DP (2017) Polyhydroxyalkanoates production by Zobellella species isolated from fish industrial effluents and its primary characterization. J Environ Biol. https://doi.org/10.22438/jeb/38/6/MRN-533

Mohapatra S, Mohanta PR, Sarkar B et al (2015). Production of polyhydroxyalkanoates (PHAs) by Bacillus strain isolated from waste water and its biochemical characterization. Proc Natl Acad Sci USA. https://doi.org/10.1007/s40011-015-0626-6

Mohapatra S, Pattnaik S, Maity S et al (2020) Comparative analysis of PHAs production by Bacillus megaterium OUAT 016 under submerged and solid-state fermentation. Saudi J Biol Sci. https://doi.org/10.1016/j.sjbs.2020.02.001

Mohapatra S, Rath SN, Pradhan SK et al (2016a) Secondary structural models (16S rRNA) of polyhydroxyalkanoates producing Bacillus species isolated from different rhizospheric soil, phylogenetics and chemical analysis. Int J Bioautomation 20:329–338

Mohapatra S, Samantaray DP, Samantaray SM (2014) Phylogenetic heterogeneity of the rhizospheric soil bacterial isolates producing PHAs revealed by comparative analysis of 16s-rRNA. Int J Curr Microbiol App Sci 3:680–690

Mohapatra S, Samantaray DP, Samantaray SM et al. (2016b) Structural and thermal characterization of PHAs produced by Lysinibacillus sp. through submerged fermentation process. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2016.09.077

Mohapatra S, Sarkar B, Samantaray DP et al (2017) Bioconversion of fish solid waste into PHB using Bacillus subtilis based submerged fermentation process. Environ Technol. https://doi.org/10.1080/09593330.2017.1291759

Montiel-Jarillo G, Carrera J, Suarez-Ojeda ME (2017) Enrichment of a mixed microbial culture for polyhydroxyalkanoates production: effect of pH and N and P concentrations. Sci Total Environ 583:300–307. https://doi.org/10.1016/j.scitotenv.2017.01.06017.01.069

Muneer F, Rasul I, Azeem F et al (2020) Microbial polyhydroxyalkanoates (PHAs): efficient replacement of synthetic polymers. J Polym Environ. https://doi.org/10.1007/s10924-020-01772-1

Pati S, Maity S, Dash A et al (2020) Biocompatible PHB production from Bacillus species under submerged and solid-state fermentation and extraction through different downstream processing. Curr Microbiol. https://doi.org/10.1007/s00284-020-01922-7

Rebocho AT, Pereira JR, Neves LA et al (2020) Preparation and characterization of films based on a natural P(3HB)/mcl-PHA blend obtained through the co-culture of Cupriavidus necator and Pseudomonas citronellolis in apple pulp waste. Bioengineering. https://doi.org/10.3390/bioengineering7020034

Rodrigues PR, Assis DJ, Druzian JI (2019) Simultaneous production of polyhydroxyalkanoate and xanthan gum: from axenic to mixed cultivation. Bioresour Technol. https://doi.org/10.1016/j.biortech.2019.03.095

Sawant SS, Salunke BK, Kim BS (2017) Enhanced agarose and xylan degradation for production of polyhydroxyalkanoates by co-culture of marine bacterium, Saccharophagus degradans and its contaminant, Bacillus cereus. Appl Sci. https://doi.org/10.3390/app7030225

Uma V, Gandhimati R (2020) Effectiveness of ozone pre-treatment on bioconversion of oily bilge water into biopolymer. J Water Process Eng. https://doi.org/10.1016/j.jwpe.2020.101275

Varsha YM, Savitha R (2011) Overview on polyhydroxyalkanoates: a promising biopol. J Microb Biochem Technol. https://doi.org/10.4172/1948-5948.1000059

Volova TG, Prudnikova SV, Vinogradova ON, Syrvacheva DA, Shishatskaya EI (2016) Microbial degradation of polyhydroxyalkanoates with different chemical compositions and their biodegradability. Microb Ecol 73(2):353–367. https://doi.org/10.1007/s00248-016-0852-3

Zhang Y, Wusiman A, Liu X, Wan C, Lee DJ, Tay JH (2018) Polyhydroxyalkanoates (PHAs) production from phenol in an acclimated consortium: batch study and impacts of operational conditions. J Biotechnol 267:36–44. https://doi.org/10.1016/j.jbiotec.2018.01.001

Zhu Y, Ai M, Jia X (2022) Optimization of a two-species microbial consortium for improved mcl-PHA production from glucose–xylose mixtures. Front Bioeng Biotechnol. https://doi.org/10.3389/fbioe.2021.794331

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest to declare.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Devadarshini, D., Mohapatra, S., Pati, S. et al. Evaluation of PHAs production by mixed bacterial culture under submerged fermentation. Biologia 78, 895–902 (2023). https://doi.org/10.1007/s11756-022-01302-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11756-022-01302-5