Abstract

The main purpose of this study was to develop a heterogeneous interesterification catalyst for the modification of edible oils to enhance their physicochemical and functional performances. To achieve this, 1,3-dicyclohexyl-2-octylguanidine was covalently immobilized on the SBA-15 (Santa Barbara Amorphous 15) material and then used as solid catalysts for the interesterification between soybean oil and methyl stearate. The characterization of the guanidine-functionalized SBA-15 material included Fourier transform infrared spectra, scanning electron microscopy, elemental analysis, and nitrogen adsorption–desorption techniques. It was shown that the solid base catalyst could efficiently catalyze the interesterification reaction. After the interesterification, the fatty acid profiles and triacylglycerol compositions of interesterified products were substantially varied. The influence of interesterification parameters, such as the substrate ratio, reaction time, reaction temperature and catalyst loading, on the interesterification reaction was investigated regarding the percentage of stearic acid in interesterified triacylglycerols. The stearic acid percentage of 27.9 % was achieved at 100 °C within 4 h when the methyl stearate/soybean oil molar ratio of 6:1 was employed. The catalyst could be recovered easily by filtration and reused without significant loss of activity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Several chemical processes are employed for the modification of native vegetable oils to improve their functional performances, such as plasticity, tractility and shortening property, to meet the specifications for certain food applications. Hydrogenation and interesterification are the commonly used methods available to tailor the physicochemical properties of food oils, but the hydrogenation method can generate larger amounts of trans fatty acids (FAs), depending on the hydrogenation degree [1]. It is reported that the trans FAs can contribute several health problems, such as the increase in the level of low density lipoprotein and the decrease in the level of high density lipoprotein in human blood, and accordingly the risk of coronary artery disease is increased [2]. Interesterification of vegetable oils has received much interest as an alternative approach to improve their physical and functional properties, which has no possibility for the formation of trans FAs. As a result, this interesterification process can extend the commercial use of edible oils, and the modified oil can be used in a wide variety of foods [3].

Generally, the interesterification reaction can be carried out enzymatically or chemically, rearranging the distribution of FAs located at the glycerol backbone of triacylglycerol (TAG) molecules without varying the FA compositions [4]. Enzymatic interesterification (EIE) can provide several benefits such as mild reaction conditions, low side reactions and ease of product recovery [5]. However, the widespread application of EIE reactions is still hampered owing to the high cost of the lipase employed. From the viewpoint of practical application, chemical interesterification (CIE) seems to be an efficient and feasible method in the edible oil industry.

Industrially, the CIE process is usually conducted by homogeneous base catalysts to produce distributed FA residues among TAG molecules, in which sodium alkoxide and sodium hydroxide are the most preferred choice of catalysts for the CIE processes [6, 7]. Even though these homogeneous catalysts are robust and low cost, the removal of them after the reaction is needed, and hence the undesired wastewater is inevitably generated in downstream processes [8]. To circumvent the aforementioned problems, the heterogenization of active catalysts is an appealing option from both environmental and commercial points of view. Recently, the research on heterogeneous catalysts has attracted tremendous attention of scientific researchers [9]. In heterogeneous catalysis, the catalyst is neither consumed nor dissolved during the reaction processes, and therefore it can be easily separated from the reaction mixture with no wastewater originating from the catalyst neutralization step. Over the last decade, several solid base catalysts, such as guanidines immobilized on polymers or encapsulated in zeolite cages, have been developed and used as recyclable catalysts for biodiesel production from vegetable oils [10, 11]. However, only limited numbers of studies have dealt with the heterogeneous base catalysts for the CIE reaction [12], despite their favorable catalytic performances in other organic reactions [13]. Therefore, the design and development of efficient solid catalysts for the CIE reactions have become an area of great importance particularly from the green chemistry points of view.

In recent years, ordered mesoporous materials have been of great concern especially in their broad application in heterogeneous catalysis, because they exhibit extraordinary properties such as high surface area, large pore volume, sustainability and recyclability [14]. Among the mesoporous materials, SBA-15 (Santa Barbara Amorphous 15) silica has emerged as a promising catalyst support in heterogeneous catalysis. The SBA-15 material can offer favorable attributes such as well-ordered structures, nanosized channels, and sufficient silanol groups for surface modification [15]. It is reported that the SBA-15 silica can be functionalized with organic base groups, by grafting or co-condensation, to fabricate efficient solid catalysts with improved properties as compared with conventional homogeneous catalysts [16]. In general, the condensation method can be commonly used for organic modification of SBA-15 material, which allows the functionalized SBA-15 material to have a uniform organic group distribution on the pore wall.

Due to the complex component in the reaction mixture, it is difficult to evaluate quantitatively the interesterification process. In the present study, to simplify the interpretation of the interesterification reaction, soybean oil and methyl stearate were employed as the reactants. Here, the methyl stearate could act as a general and useful model compound for the interesterification of complex TAGs [17], and soybean oil was chosen owing to the large amount of linoleic and linolenic acids. On the other hand, 1,3-dicyclohexyl-2-octylguanidine (DCOG) is a strong guanidine base that can serve as a homogeneous base catalyst [13]. Several methods have been reported for the preparation of heterogeneous base catalysts, in which the organic base can be covalently anchored onto solid supports, such as the mesoporous SBA-15 silica [18, 19]. However, few publications have so far appeared on the interesterification catalyzed by heterogeneous catalysts [12, 20]. In this work, we report the functionalization of SBA-15 silica with DCOG to obtain a heterogeneous catalyst used for the interesterification of soybean oil with methyl stearate. For this purpose, the DCOG was first linked to 3-glycidyloxypropyl-trimethoxysilane, and was then bound onto the mesoporous SBA-15 silica. The as-prepared organic–inorganic hybrid mesoporous materials (SBA-15–pr-DCOG) were characterized by means of Fourier transform infrared (FT-IR) spectra, scanning electron microscopy (SEM), elemental analysis and nitrogen adsorption–desorption techniques. Moreover, the blends of soybean oil and methyl stearate in different ratios were interesterified by using this solid base catalyst. The original blend and interesterified products were examined in terms of FA profiles, slip melting point (SMP), and TAG compositions. It was found that the solid catalyst had the potential for catalyzing the interesterification reaction. The reaction variables, such as the substrate ratio, reaction time, reaction temperature, catalyst amount and stability of the catalyst, were also investigated in the present study.

Experimental Procedures

Materials

Soybean oil was purchased from a commercial source and its compositions in FAs were: 11.1 % palmitic, 4.6 % stearic, 23.5 % oleic, 53.2 % linoleic, 7.1 % linolenic and traces of other fatty acids. Methyl stearate, which contained 7.8 % methyl palmitate, was obtained from Sinopharm Chemical Reagent (Shanghai, China). Pluronic copolymer P123 (EO20PO70EO20; average molecular weight 5800), 3-glycidyloxypropyl-trimethoxysilane (≥99.8 %), 1,3-dicyclohexyl-2-octylguanidine (DCOG; ≥98 %) and tetraethylorthosilicate (TEOS; ≥98 %) were purchased from Sigma-Aldrich and used as received. All the other materials used were of analytical or chromatographical grades.

Catalyst Preparation

Mesoporous SBA-15 silica was readily prepared according to the methodology described in the literature [15]. In a typical run, 10 g of copolymer P123 was first dissolved in a mixture of 75 mL of distilled water and 300 mL of 2 mol/L HCl, and then stirred at 40 °C until a clear solution was obtained. Thereafter, to this clear solution, 21 g of tetraethyl orthosilicate (TEOS) was added under stirring, and the resulting mixture was kept under stirring for 24 h at 40 °C. Subsequently, the solution was transferred to a Teflon-lined stainless steel autoclave and hydrothermally treated at 100 °C for 48 h. The solid precipitate was formed and recovered by filtration, then washed with water, and finally air-dried at room temperature. The SBA-15 powder was subjected to a calcination procedure at 550 °C for 6 h. The mesoporous SBA-15 silica was employed as a support material for the preparation of the solid catalyst.

The guanidine-functionalized SBA-15 materials were synthesized by two successive reactions. In the first reaction, the DCOG-organosilane was initially prepared by the reaction of 3-glycidyloxypropyl-trimethoxysilane with the DCOG. Typically, 4 mL of DCOG was introduced into a solution of 3-glycidyloxypropyl-trimethoxysilane (4 mL) in dry DMF (8 mL), after which the resulting mixture was further stirred for 48 h at room temperature under nitrogen atmosphere. In this case, the DCOG could react with the epoxide group of 3-glycidyloxypropyl-trimethoxysilane, affording DCOG-modified silane. In the second reaction, the surface silanol groups of the SBA-15 silica were attached by the DCOG-organosilane. For this purpose, 12 mL of the prepared DCOG-modified silane solution was added to a flask containing dry toluene (30 mL) and SBA-15 silica (2.5 g). After this, the mixture was stirred for 48 h at reflux temperature under nitrogen atmosphere. Thereafter, the guanidine-functionalized SBA-15 silica thus obtained was recovered by filtration under vacuum, washed with toluene, and extracted for 24 h with a 1/1 diethyl ether/methylene chloride mixture. Finally, the solid catalyst was vacuum-dried for 12 h before use for the interesterification reaction.

Catalyst Characterization

Fourier transform infrared (FT-IR) spectra were collected on a Shimadzu IR-Prestige-21 spectrometer using the standard KBr disk method. Scanning electron microscope (SEM) measurements were performed with a field-emission microscope (JEOL, JSM-6390LV) using an accelerating voltage of 15 kV. The amount of DCOG tethered on the SBA-15 silica was determined by elemental analysis performed on a Carlo-Erba 1106 elemental analyzer.

The textural properties of the solid catalysts were obtained from the N2 adsorption–desorption isotherms at −196 °C measured with a Quantachrome NOVA 1000e apparatus. The specific surface area was determined by using the Brunauer–Emmett–Teller (BET) method. The total pore volume and the pore size distribution were calculated by applying the Barrett–Joyner–Halenda (BJH) method [21].

Interesterification Reaction

The reaction mixture, consisting of 20 g of soybean oil and 41 g of methyl stearate, was charged into a 250-mL round-bottom flask, and dried under reduced pressure at 80 °C for 2 h. The interesterification reaction was initiated by addition of 8 wt.% of the guanidine-functionalized SBA-15 silica as a catalyst, which was allowed to proceed under reduced pressure at 100 °C in an oil bath with magnetic stirring. After completion of the reaction, the interesterified product was separated by filtration, and then employed for subsequent analysis.

The interesterification experiments were carried out by varying the reaction parameters. The effects of reaction times ranging from 1 to 5 h, substrate molar ratios (methyl stearate/soybean oil) ranging from 2:1 to 10:1, catalyst dosages ranging from 2 to 10 wt.%, reaction temperatures ranging from 60 to 120 °C on the percentage of stearic acid in the interesterified TAGs, were investigated systematically to optimize the reaction conditions. The physicochemical properties of the initial blend and interesterified products obtained under optimal reaction conditions were determined in terms of FA profiles, TAG compositions and slip melting points. For the catalyst reusability investigation, the used catalyst was separated from the reaction mixture by filtration, washed with cyclohexane and methanol, dried at 90 °C under reduced pressure, and then employed for the next interesterification reaction.

All interesterification reactions were carried out in triplicate. The obtained results of stearic acid percentages in the TAGs were presented as the mean ± standard deviations, and were analyzed using one-way analysis of variance (ANOVA). The level of statistical significance was set at P < 0.05.

Product Recovery by Thin-Layer Chromatography (TLC)

After interesterification reaction, the TLC method using silica gel 60G plates was employed to first isolate the TAG fractions. The reaction mixtures were spotted on TLC plates and placed in a TLC tank. The plates were developed with a solvent mixture consisting of petroleum ether/ethyl ether/acetic acid (90:10:1, by volume). The separated fractions were sprayed with a 0.2 % solution of 2,7-dichlorofluorescein in methanol and then visualized under UV light. The R f values for the TAGs and methyl esters were determined to be 0.25 and 0.61, respectively. The free FAs, monoglycerides and diglycerides formed by hydrolysis reactions, were not found in the interesterified products by TLC techniques as water was removed absolutely from the reaction mixture under reduced pressure prior to the reaction. The main TAG bands, which were identified with triolein as a standard, were scraped off the TLC plates. The TAG fractions were extracted three times with diethyl ether and dried using anhydrous sodium sulfate for the subsequent analysis.

Fatty Acid Composition Analysis

The progress of the interesterification reaction was followed by the determination of stearic acid percentage in the TAGs. The FA profiles of the interesterified TAGs were determined by gas chromatography (GC) analyses [22]. Initially, the methylation of isolated TAGs was conducted through transesterification catalyzed by 2 mol/L methanolic potassium hydroxide solution. Briefly, 50 mg of the sample, 2 mL of hexane and 3 mL of potassium hydroxide solution in methanol were added to the tube, and the mixture was shaken for 10 min. Afterwards, the resultant mixture was centrifuged, and then the separated upper layer was decanted and dried with anhydrous sodium sulfate for GC analysis.

After complete conversion of FA residues into their corresponding fatty acid methyl esters (FAMEs), the aliquots (0.2 μL) of the methylated FA residues were injected into a GC instrument fitted with an auto injector and a flame-ionization detector (Model 6890 N; Agilent Technologies, Santa Clara, CA, USA). The separation of FAMEs was performed in a fused silica capillary column coated with 0.25 μm of BPX-70 using nitrogen as carrier gas. The FAME composition was identified by comparison with the retention time of FAME standards. The oven temperature was initially held at 160 °C for 5 min, followed by temperature programming to 200 °C at a rate of 5 °C/min, and then held isothermally for another 42 min at the final temperature. The injector and detector temperatures were set at 260 and 300 °C, respectively. The relative FAME content was measured by area normalization and expressed as mass percentage.

Sn-2 Positional Fatty Acid Composition Analysis

The interesterified TAGs were isolated by the TLC method following the procedure described above. The FA compositions at the sn-2 position of the interesterified TAGs were determined by partial hydrolysis using pancreatic lipase [22]. Briefly, 2 mL of Tris–HCl buffer (1 mol/L, pH 7.6), 0.5 mL of 0.05 % bile salts, 0.2 mL of 2.2 % calcium chloride solution, and 10 mg pancreatic lipase were subsequently added to the TAG sample. The mixture was incubated in a water bath at 40 °C for 5 min with vigorous shaking. To quench the hydrolysis reaction, 1 mL HCl (6 mol/L) and 4 mL of diethyl ether were added, vortexed vigorously for 2 min, and then centrifuged at 1000 rpm for 3 min. The diethyl ether layer containing the lipid component was dried with anhydrous sodium sulfate, and subsequently evaporated under nitrogen to obtain the concentrated sample. Thereafter, the hydrolytic products were spotted on a silica gel TLC plate and then developed with hexane/diethyl ether/acetic acid (50:50:1, by volume). The TLC plates were air-dried and visualized after being sprayed with 0.2 % 2,7-dichlorofluorescein in ethanol, and the 2-monoacylglycerol bands were identified with 2-oleoylglycerol as a standard. After that, the bands corresponding to 2-monoacylglycerol were scraped off carefully and extracted with hexane. The FA profiles of the 2-monoacylglycerols were analyzed by GC techniques after methylation, as described previously.

TAG Composition Analysis

The TAG compositions were determined by using reversed-phase high-performance liquid chromatography (RP-HPLC). The interesterified TAGs were diluted in chloroform (10 mg/mL) and used for the TAG analysis. Of these solutions, 20 µL aliquots were injected into a Waters Model 600 (Milford, PA, USA) liquid chromatograph equipped with an evaporative light-scattering detector (ELSD). The chromatographic separation of the TAG species was achieved with a commercially packed Genesis C18 HPLC column (15 cm length × 4.6 mm). The mobile phase used was a binary solvent of dichloromethane and acetonitrile (HPLC grade) system. The initial eluent was a mixture of 30 % dichloromethane and 70 % acetonitrile, and a linear gradient of dichloromethane from 30 to 70 % over 45 min was applied at a flow rate of 1.2 mL/min. The column temperature was set at 40 °C. The TAG species were detected by an Alltech 500 ELSD. Individual peaks were identified tentatively by comparing the retention times with pure TAG standards and according to the literature [4]. Quantification of the peaks was made by internal normalization of chromatographic peak area, and the results were expressed in relative percentages, assuming that the detector response was the same for all compounds [23]. The equivalent carbon number (ECN) method was applied to predict the elution order of TAGs according to AOCS Official Method Ce 5b-89 [22]. After comparing the TAG profiles before and after interesterfication, the variation in the amount of ECN can be used to evaluate the degree of the interesterification.

Determination of Iodine Value and Slip Melting Point

The slip melting point (SMP) of the interesterified TAGs was measured by the open capillary tube method, according to the AOCS Official Method Cc 3-25 [22]. In brief, a capillary tube was filled with 1-cm high column of the samples. Each sample was tempered in a refrigerator overnight prior to the measurements. The sample tube was heated in a water bath and the water was stirred and heated slowly. The temperature was recorded when the solid fat in the tube began to rise. The iodine value (IV) was determined from the FA composition according to the procedure described in the AOCS Official Method Cd 1c-85. Three replicates of this measurement were performed.

Results and Discussion

Catalyst Characterization

In the present study, the surface functionalization of SBA-15 silica has been utilized for the preparation of the solid catalyst through the condensation reaction of silanol groups with organosilane. Organotrialkoxysilanes are often used to incorporate functional groups into the mesoporous SBA-15 materials. The silanol groups on the SBA-15 silica act as immobilizing sites for organic moieties because they can react readily with the alkoxy groups of organotrialkoxysilanes by silylation reaction.

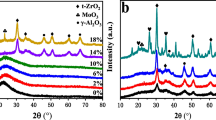

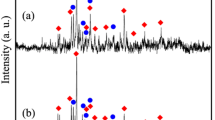

The comparative FT-IR spectra of parent SBA-15 and functionalized SBA-15 materials are presented in Fig. 1. For non-functionalized SBA-15 silica, a broad IR absorption band at 3460 cm−1 was clearly observed, which was mostly owing to the stretching vibration of isolated framework hydroxyl groups and adsorbed water in the samples, indicative of the presence of a high abundance of silanol groups on the pore wall surface. The peak around 1635 cm−1 was principally responsible for the bending mode of the adsorbed water [24]. Moreover, a shoulder band in the mid-infrared region at 950 cm−1 for the SBA-15 support could also be detected, corresponding to the stretching vibrations of Si–OH groups in the SBA-15 silica [15]. In addition, three IR absorption bands around 1100, 770, and 475 cm−1 were reasonably assigned to the mesoporous framework Si–O–Si stretching modes [15, 20]. It is worth noting that the IR spectra of the guanidine-functionalized SBA-15 exhibited obvious differences in comparison with the SBA-15 silica. For example, the IR bands of silanol groups located at 3460 and 950 cm−1 were found to reduce significantly in intensity after the functionalization of the SBA-15 silica with DCOG, and moreover two new distinct IR bands at 2950 and 2875 cm−1 owing to the CH2 vibrations clearly appeared for the functionalized SBA-15 catalyst. This phenomenon revealed that the silanol groups reacted with DCOG-organosilane to afford the solid base catalysts [15, 19]. Additionally, there were characteristic bands at 1547 and 675 cm−1 to be observed for the functionalized SBA-15 silica, which could be assignable to the C=N stretching and N–H bending vibration of anchored DCOG [13]. However, these IR absorption peaks corresponding to DCOG were small due to the low loading amount of DCOG. These results demonstrated that the DCOG is successfully attached on the SBA-15 silica.

SEM techniques can be used to investigate the morphology of the organically functionalized SBA-15 material. The typical SEM micrograph of the SBA-15 silica is also presented for comparison purpose. As shown in Fig. 2, the SBA-15 silica exhibited curved faceted and smooth rods based on elongated worm-like structures [15]. The primary particles appeared to be aggregated or fused into large clusters. The guanidine-functionalized SBA-15 catalyst showed a similar worm-like morphology to SBA-15 material where agglomerates were still present, which suggested that the incorporation of DCOG into the SBA-15 material does not destroy the mesoporous structure of the material.

The C, N and H contents for the guanidine-functionalized SBA-15 materials were determined to be 34.15, 2.54, and 5.84 %, respectively. There was no C, N and H on the support since the SBA-15 material was prepared through a calcination procedure at 550 °C for 6 h. The total organic group content tethered onto the SBA-15 silica can be determined according to the elemental analysis results, assuming all the nitrogen atoms in the catalysts are in DCOG form. Based on this assumption, the loading of DCOG on the functionalized SBA-15 silica was quantified to be 1.74 mmol/g.

In Fig. 3 are shown the nitrogen adsorption–desorption isotherms and the pore size distribution curves of SBA-15 silica and the solid catalyst. The two samples exhibited a hysteresis loop resembling the type IV isotherm with H1-type according to IUPAC classification, which is characteristic of highly ordered two-dimensional hexagonal meso-structured materials with a uniform mesoporous size distribution, consistent with other SBA-15-type materials [15, 19]. Moreover, as seen in Fig. 3, the adsorption branch of isotherm presented a sharp inflection at a relative pressure range of 0.65–0.75. This is a typical behavior of capillary condensation with uniform pore dimensions and high-ordering of the material [18]. After the organofunctionalization of SBA-15, the shape of the isotherm of the functionalized SBA-15 silica was similar to the original siliceous SBA-15, demonstrating that the uniform mesoporous structure is retained after DCOG incorporation. The capillary condensation step of the isotherm occurred at a lower relative pressure for the functionalized SBA-15 silica than for pure SBA-15 silica, as a result of the decrease in the mean pore diameter due to DCOG incorporation.

The textural properties of the samples such as the BET surface, pore volume, and mean pore sizes were determined. For pure SBA-15 silica, the measured BET surface was 807 m2/g, while the pore volume and mean pore size calculated from the N2 adsorption–desorption isotherm were 1.25 cm3/g and 6.65 nm, respectively, in accordance with the values reported in the literature [15, 18]. The guanidine-functionalized SBA-15 catalyst displayed a surface area of 261 m2/g and a pore volume of 0.38 cm3/g, and the pore size distribution was narrow with an average pore diameter of 4.12 nm. It can be noticed that the surface area, pore volume and average pore diameter of the functionalized SBA-15 silica were diminished after DCOG incorporation. Such a decrease in the pore diameter and BET surface area was mainly owing to the partial filling of anchored DCOG on the SBA-15 material. Accordingly, the guanidine-functionalized SBA-15 silica still retained the typical mesoporous structure of SBA-15 silica though there is a change in the textural properties after the organofunctionalization reaction.

Influence of Reaction Parameters on the Interesterification Reaction

In this present study, the DCOG base can be tethered onto the surface of mesoporous SBA-15 silica by silylation reaction of the alkoxy groups of silane compounds to form the guanidine-functionalized SBA-15 catalyst. For the solid base catalyst, DCOG contains three tertiary amine groups, which are considered as the active sites for the interesterification reaction, and the ordered mesoporous SBA-15 silica possesses large surface areas that are favorable for the catalysis. The catalytic performance of the prepared catalyst was investigated for the interesterification of soybean oil with methyl stearate, under heterogeneous reaction conditions. The degree of interesterification could be assessed on the basis of the stearic acid percentage in the interesterified products. As expected, no stearoyl incorporation was observed when the SBA-15 support was employed as a catalyst. However, when the DCOG was anchored onto the SBA-15 silica, the thus-prepared solid catalyst exhibited activities in the interesterification reaction. Table 1 shows the stearic acid percentage in the interesterified products as a function of reaction time. At a reaction time of 1 h, the catalytic interesterification proceeded with a low stearic acid percentage of 19.5 %. With the reaction progress to 4 h, the percentage of stearic acid in the TAGs interesterified with methyl stearate was gradually increased up to 27.9 % (P < 0.05). However, when the reaction duration was increased beyond 4 h, the further increase in the percentage of stearic acid was negligible (P > 0.05). Hence, the reaction time for attaining the best stearic acid percentage is 4 h.

Reaction temperature also exerts an important influence on the interesterification reaction. Generally, the reaction rate of interesterification increases as the temperature is increased. Table 1 also shows the influence of reaction temperature on the percentage of stearic acid in the interesterified TAGs. With increasing reaction temperature from 60 to 100 °C, the stearic acid percentage was increased significantly from 14.8 to 27.9 % by the catalytic interesterification (P < 0.05). The highest stearic acid percentage was achieved at a reaction temperature of 100 °C. The further increase in the reaction temperature did not led to the subsequent increase in the stearic acid percentage (P > 0.05). Considering the above results, the suitable temperature for the interesterification reaction is 100 °C.

For the trials performed using different ratios of substrates, the interesterification reactions were conducted with the solid catalyst at 100 °C for 4 h. From the data in Table 1, it can be seen that the percentage of stearic acid gradually ascended from 14.5 to 27.9 % (P < 0.05) as the methyl stearate/soybean oil molar ratio rose from 2:1 to 6:1. The best substrate molar ratio was found to be 6:1, attaining the stearic acid percentage of 27.9 %. However, for the substrate ratio of more than 6:1, the improvement in the stearic acid percentage was insignificant (P > 0.05). In view of the results, the appropriate molar ratio of methyl stearate to soybean oil is 6:1. According to random distribution theory, at a 6:1 ratio of methyl stearate/soybean oil, it looks like around 67 % of the fatty acids in the interesterified TAGs should be stearic acid if ignoring molecular weight differences and the small amount of stearic acid already present in the starting soybean oil. Based on this assumption, it does not appear that the full interesterification has been achieved, and only 41.8 % of full interesterification was obtained by using the catalyst, mostly owing to the low catalytic activity of the heterogeneous catalyst. In general, as porous inorganic materials are used as support of heterogeneous catalysts, a substantial decrease in activity of the supported catalysts is commonly observed, because of the problem of slow reactant diffusion to the catalytic sites on the catalyst surface.

The chemical interesterification of soybean oil and methyl stearate was investigated by using different catalyst loadings. In general, the increase in the catalyst loading will accelerate the interesterification rate and thus improve the percentage of stearoyl acid in the interesterified TAGs. As shown in Table 1, the stearic acid percentage was found to increase from 9.2 to 27.9 % (P < 0.05) by the interesterification by increasing the catalyst loading from 2 to 8 wt.%. However, when the catalyst loading was further increased beyond 8 wt.%, the stearic acid percentage decreased slightly (P < 0.05). This result may be caused by the higher viscosity of the reaction medium with the addition of higher amounts of the catalyst. Accordingly, the appropriate catalyst loading for the interesterification catalyzed by the solid catalyst is 8 wt.%. This catalyst loading seems high compared to lipase since the catalytic active component of DCOG is low in the guanidine-functionalized SBA-15 silica.

Fatty Acid Composition

The total FA compositions and the iodine values (IV) of the soybean oil and interesterified TAGs are presented in Table 2. As can be seen, the original soybean oil typically had a major FA composition of 53.2 % linoleic acid, 23.5 % oleic acid, 11.1 % palmitic acid, 7.1 % linolenic acid and 4.6 % stearic acid, with the IV of 131.7. After the interesterification with methyl stearate, a significant change in the FA composition was observed for the interesterified TAGs. For instance, for the 6:1 methyl stearate/soybean oil ratio, the percentage of stearic acid in the interesterified TAGs was increased significantly from 4.6 to 27.9 % (P < 0.05), while the linoleic acid was largely reduced from 53.2 to 21.1 % after the interesterification reaction (P < 0.05). As the methyl stearate used in this study contained 7.8 % methyl palmitate, an increase in the content of palmitic acid after the interesterification was also observed (P < 0.05). Obviously, the chemical interesterification yielded the increase of saturated FAs and the decrease of the unsaturated FAs, and thus the IV of the interesterified TAGs appeared to be decreased to 68.3.

The literature lacks information on the interesterification of soybean oil and methyl stearate using a heterogeneous catalyst. For the purpose of comparison, the interesterification was carried out by using NaOH as a catalyst under the same reaction conditions. The results displayed in Table 2 showed that the solid catalyst exhibited lower activities than NaOH due to lower amount of stearic acid in the interesterified TAGs for the solid catalyst to be found.

Table 3 contains a summary of the compositions of FAs located at the sn-2 position of the soybean oil and interesterified TAGs. As observed, the sn-2 position of soybean oil was mainly composed of 22.7 % oleic acid and 69.2 % linoleic acid, with a small amount of 6.4 % linolenic acid, 1.3 % palmitic acid, and 0.4 % stearic acid. The interesterification is generally employed to change the physiochemical characteristics of vegetable oils by altering the FA or its position on glycerol backbone. When compared to the original soybean oil, the major FA compositions at the sn-2 position were obviously varied after the interesterification. For the trial involving methyl stearate/soybean oil ratio of 6:1, the FA profiles at sn-2 position of the interesterified TAGs were greatly changed after the interesterification for oleic acid to 35.7 %, for linoleic acid to 32.1 %, for palmitic acid to 17.4 %, for stearic acid to 13.6 %, and for linolenic acid to 0.9 %. The change of FA moiety at sn-2 position mainly results from the catalytic interesterification with methyl stearate. When compared with the result obtained by using NaOH as a catalyst, the lower activity for the solid catalyst was also observed in terms of the sn-2 positional FA composition. By drawing on the results, the solid catalyst was shown to be active for the CIE reaction of soybean oil and methyl stearate.

Triacylglycerol Composition

The TAG compositions of the soybean oil and interesterified TAGs are given in Table 4. According to the HPLC analyses, the main TAG species present in the original soybean oil used in our study were LLL (24.2 %), PLL (18.4 %), OLL (17.6 %), OOL (13.2 %), PLO (7. 6 %), LLLn (6.1 %), OPO (4.4 %), OLLn (3.1 %), and StLL (2.1 %). A similar composition of TAGs in soybean oil has been previously described in the literature [4]. Examination of the tabular entries indicated that the chemical interesterification led to a significant change in the TAG composition of the interesterified TAGs, as expected. For example, for the reaction mixture initially containing the methyl stearate/soybean oil ratio of 6:1, the interesterified product showed that the proportions of the TAGs, such as StLL, PPL, StPL, OStL, OPSt, and PPP, were increased significantly to 14.0, 4.9, 8.1, 9.1, 2.0, and 3.1 % after the CIE reaction, whereas the proportions of the other TAGs in the same sample such as LLL, OLL, PLL, OOL and OLLn were shown to reduce to 9.7, 8.9, 10.6, 9.1, and 0.1 %. A similar change trend for the TAG composition was also observed for the CIE reaction catalyzed by NaOH.

In order to better evaluate the interesterification process, the TAG species could be divided into different groups according to their ECN. The ECN for different TAGs can be calculated as \({\text{ECN}} = {\text{cn}} - 2\left( {\text{db}} \right)\), where cn is the number of carbons in the constituent FA and db is the number of double bonds. As indicated in Table 4, soybean oil displayed a predominance of lower molecular weight TAGs with C42, C44 and C46. After the CIE reaction, it can be observed that the C48 and C50 groups were increased as a result of the insertion of stearic acid. In addition, the CIE reaction also yielded a decrease in the C40, C42 and C44 groups formed mainly by unsaturated FAs. Owing to the significant variation in TAG compositions during the interesterification reaction, the interesterified TAGs tended to have higher SMPs of 33.6 °C for the 3:1 methyl stearate/soybean oil ratio and 34.5 °C for the 6:1 methyl stearate/soybean oil ratio. These results implied that the TAG compositions were ultimately varied during the interesterification processes and the solid base catalyst could catalyze the interesterification reaction.

Reusability of the Solid Catalyst

From the point of view of industrial application, the recycling capability of the catalyst is of importance for the evaluation of a heterogeneous catalyst. In this work, the operational stability assays were conducted to test the reusability of the catalyst. The recovered catalyst was utilized for the next cycle, and this process was repeated under reaction conditions similar to those described previously. As the solid catalyst was used for 1, 2, 3, 4, and 5 cycles, the percentage of stearic acid in the interesterified TAGs was 27.9, 27.4, 27.1, 25.3 and 24.2 %, respectively. It can be observed that the recovered catalyst could be reused for up to five times without significant loss of its catalytic efficiency. The reason for the slightly reduced catalytic performance may be due to the condensation of reactant or product species in the mesoporous of the solid catalyst, which could have resulted in poor catalytic accessibility.

Conclusion

An efficient heterogeneous catalyst, SBA-15-pr-DCOG, was prepared and then employed for interesterification between soybean oil and methyl stearate. The catalyst characterization results showed that the organic base (DCOG) was successfully anchored on the mesoporous SBA-15 silica. After the organofunctionalization of SBA-15 silica with the DCOG, the highly ordered mesoporous structure remained nearly unaltered, which was favorable for the catalysis. The solid catalyst was found to be active for the interesterification reaction of soybean oil with methyl stearate. The FA profiles and TAG compositions of the interesterified TAGs were obviously changed after the interesterification with methyl stearate. The solid catalyst offers several advantages, including high catalytic activity, easiness of separation and recyclability of the catalyst.

Abbreviations

- AOCS:

-

American Oil Chemists’ Society

- BET:

-

Brunauer–Emmett–Teller

- BJH:

-

Barrett–Joyner–Halenda

- CIE:

-

Chemical interesterification

- DCOD:

-

1,3-dicyclohexyl-2-octylguanidine

- DMF:

-

N,N-dimethylformamide

- ECN:

-

Equivalent carbon number

- EIE:

-

Enzymatic interesterification

- ELSD:

-

Evaporative light-scattering detector

- FA:

-

Fatty acid

- FAME:

-

Fatty acid methyl ester

- FT-IR:

-

Fourier transform infrared

- GC:

-

Gas chromatography

- HPLC:

-

High-performance liquid chromatography

- IV:

-

Iodine value

- L:

-

Linoleic acid

- Ln:

-

Linolenic acid

- MeSt:

-

Methyl stearate

- O:

-

Oleic acid

- P:

-

Palmitic acid

- SBA-15:

-

Santa Barbara Amorphous 15

- SEM:

-

Scanning electron microscopy

- SFA:

-

Sum of saturated fatty acid

- SMP:

-

Slip melting point

- SO:

-

Soybean oil

- St:

-

Stearic acid

- SUFA:

-

Sum of unsaturated fatty acid

- TAG:

-

Triacylglycerol

- TEOS:

-

Tetraethylorthosilicate

- TLC:

-

Thin-layer chromatography

References

Xu X (2000) Production of specific-structured triacylglycerols by lipase-catalyzed reactions: a review. Eur J Lipid Sci Tech 102:287–303

Dhaka V, Gulia N, Ahlawat KS, Khatkar BS (2011) Trans fats-sources, health risks and alternative approach: a review. J Food Sci Tech (Mysore) 48:534–541

Gibon V (2011) Enzymatic interesterification of oils. Lipid Technol 23:274–277

Ribeiro APB, Grimaldi R, Gioielli LA, Gonçalves LA (2009) Zero trans fats from soybean oil and fully hydrogenated soybean oil: physico-chemical properties and food applications. Food Res Int 42:401–410

Jeyarani T, Reddy SY (2010) Effect of enzymatic interesterification on physicochemical properties of mahua oil and kokum fat blend. Food Chem 123:249–253

Gibon V, Kellens M (2014) Latest developments in chemical and enzymatic interesterification for commodity oils and specially. In: Kodali DR (ed) Trans fats replacement solutions. AOCS, Champaign

Costales-Rodríguez R, Gibon V, Verhé R, De Greyt W (2009) Chemical and enzymatic interesterification of a blend of palm stearin: soybean oil for low trans-margarine formulation. J Am Oil Chem Soc 86:681–697

Soares FASDM, da Silva RC, Hazzan M, Capacla IR, Viccola ER, Maruyama JM, Gioielli LA (2012) Chemical interesterification of blends of palm stearin, coconut oil, and canola oil: physicochemical properties. J Agric Food Chem 60:1461–1469

Semwal S, Arora AK, Badoni RP, Tuli DK (2011) Biodiesel production using heterogeneous catalysts. Bioresour Technol 102:2151–2161

Chouhan AP, Sarma AK (2011) Modern heterogeneous catalysts for biodiesel production: a comprehensive review. Renew Sust Energy Rev 15:4378–4399

Xie W, Zhao L (2013) Production of biodiesel by transesterification of soybean oil using calcium supported tin oxides as heterogeneous catalysts. Energy Convers Manag 76:55–62

Xie W, Chen J (2014) Heterogeneous interesterification of triacylglycerols catalyzed by using potassium-doped alumina as a solid catalyst. J Agric Food Chem 62:10414–10421

Schuchardt U, Vargas RM, Gelbard G (1996) Transesterification of soybean oil catalyzed by alkylguanidines heterogenized on different substituted polystyrenes. J Mol Catal A 109:37–44

Lebeau B, Galarneau A, Linden M (2013) Introduction for 20 years of research on ordered mesoporous materials. Chem Soc Rev 42:3661–3662

Yue M, Sun L, Cao Y, Wang Z, Wang Y, Yu Q, Zhu JH (2008) Promoting the CO2 adsorption in the amine-containing SBA-15 by hydroxyl group. Microporous Mesoporous Mater 114:74–81

Bhange P, Bhange DS, Pradhan S, Ramaswamy V (2011) Direct synthesis of well-ordered mesoporous Al-SBA-15 and its correlation with the catalytic activity. Appl Catal A 400:176–184

Konishi H, Neff WE, Mounts TL (1993) Chemical interesterification with regioselectivity for edible oils. J Am Oil Chem Soc 70:411–415

Kalita P, Kumar R (2011) Immobilization of 1, 5, 7-triazabicyclo [4.4. 0] dec-5-ene over mesoporous materials: an efficient catalyst for Michael-addition reactions under solvent-free condition. Appl Catal A Gen 397:250–258

Xie W, Zhao L (2014) Heterogeneous CaO–MoO3–SBA-15 catalysts for biodiesel production from soybean oil. Energy Convers Manag 79:34–42

Xie W, Qi C (2014) Preparation of low calorie structured lipids catalyzed by 1, 5, 7-triazabicyclo [4.4.0] dec-5-ene (TBD)-functionalized mesoporous SBA-15 silica in a heterogeneous manner. J Agric Food Chem 62:3348–3355

Wang H, Zhai L, Li Y, Shi T (2008) Preparation of irregular mesoporous hydroxyapatite. Mater Res Bull 43:1607–1614

American Oil Chemists’ Society, Firestone D (2009) Official methods and recommended practices of The American Oil Chemists’ Society, vol 5. AOCS, Champaign

Fernandes Â, Barreira JCM, Antonio AL, Martins A, Ferreira ICFR, Oliveira MBPP (2014) Triacylglycerols profiling as a chemical tool to identify mushrooms submitted to gamma or electron beam irradiation. Food Chem 159:399–406

Çıtak A, Erdem B, Erdem S, Öksüzoğlu RM (2012) Synthesis, characterization and catalytic behavior of functionalized mesoporous SBA-15 with various organo-silanes. J Colloid Interface Sci 369:160–163

Acknowledgments

This work was financially supported by research grants from the National Natural Science Foundation of China (Project No. 21276066, 21476062), the Plan for Scientific Innovation Talent of Henan Province (144200510006), the Program for Innovative Research Team in Universities of Henan Province in China (2012IRTSTHN009) and the Fundamental Research Funds for the Henan Provincial Colleges and Universities.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Xie, W., Yang, X. & Zang, X. Interesterification of Soybean Oil and Methyl Stearate Catalyzed by Guanidine-Functionalized SBA-15 Silica. J Am Oil Chem Soc 92, 915–925 (2015). https://doi.org/10.1007/s11746-015-2651-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-015-2651-2