Abstract

Vegetable oils are typically extracted with hexane; however, health and environmental concerns over its use have prompted the search for alternative solvents. Mustard oil was extracted with isopropyl alcohol (IPA) to produce an IPA-oil miscella suitable for industrial applications. Single-stage extraction resulted in 87.6 % oil yield at a 10:1 (v/w) IPA/flour ratio. Multiple-stage extraction resulted in higher extraction efficiency with lower IPA use. Four-stage cross-current extraction at an IPA/flour ratio of 2:1 (v/w) per stage resulted in 93.7 % oil yield. At 45 °C, a 91.5 % oil yield was achieved with three-stage extraction using a 2:1 (v/w) IPA/flour ratio. Any changes to the pH of the mixture resulted in reduced oil yield. Water also reduced the extraction efficiency. The azeotropic IPA solution containing 13 % water extracted ~40 % less oil than did dry IPA in both single and multiple-stage extractions. Some polar compounds were also extracted, including sugars; however, protein extraction was negligible. The protein left in the extracted meal was not degraded or lost during the extraction. The results suggest that IPA is an excellent solvent for mustard oil, but water content exceeding 5 % in the solvent adversely affects the oil extraction and reuse of the IPA.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Mustard is a member of the Brassica family of plants. It is related to canola but is more tolerant of drought, heat and frost than its famous cousin [1]. Yellow mustard is most commonly used as a condiment for food flavoring and preservation. In 2008, nearly 160,000 tonnes of mustard were produced in Canada, accounting for over 50 % of all mustard seed exports worldwide and making Canada the world’s largest exporter of mustard seed. Yellow mustard comprises 44 % of the Canadian mustard production. Yellow mustard seeds contain approximately 27 % high quality protein and 30 % oil [2]. The seed proteins in yellow mustard have a well-balanced amino acid profile, which makes them an attractive source of food [3]. The oil in yellow mustard seed is low in saturated fatty acids but high in erucic acid, and therefore this oil is illegal for human consumption in Europe and North America. The oil has industrial uses as a lubricant and release agent; however, its superior lubricating properties, due to erucic acid, make it an excellent feedstock for biodiesel production [4].

Hexane is the most commonly used solvent for recovering oil from seeds. Unfortunately, hexane is volatile, flammable and potentially explosive. Its vapour reacts to form photochemicals that have detrimental effects on human health [5]. Although the U.S. Environmental Protection Agency has identified n-hexane emissions as a major source of air pollution, and has considered tighter emission standards to reduce hexane losses, its use as an extraction solvent is still permitted [6]. Knowing the health and environmental effects and potential risks of this solvent, it is prudent to look for alternative solvents. A good option to consider is alcohols such as IPA [5, 7], which has high solubility with triglycerides. IPA is safer than hexane, due to its higher flash point, upper explosive limits and auto-ignition temperature. Oil solubility in IPA varies with temperature and water content [8, 9].

In direct solvent extraction of oilseeds, solvent holdup in the solid residue, which entraps the extracted liquid by capillary forces, is one of the factors affecting oil extraction [7, 10]. Cottonseed flakes and collets have been used to compare the extraction efficiency as well as the crude oil composition of the extracted oil using aqueous IPA and hexane [10–12]. Zhang et al. [10], reported that the residual oil content and solvent hold-up of the collets for 95 % IPA were 1.6 and 33.0 % compared with 4.5 and 53.2 % for the flakes, respectively. The residual oil content of the cottonseed collets extracted with hexane was 1.2 % while the solvents containing 97, 93, and 88 % IPA resulted in 1.5, 1.9, and 2.4 % residual oil content, respectively. IPA is less effective as a solvent than hexane because diffusion is slower; as a result more time and more stages are required for removal of oil from seeds [10, 13]. As hexane is less viscous (0.29 cP at 25 °C) than IPA (2.4 cP at 25 °C) it drains more easily and solvent holdup in the meal residue is lower than IPA [7, 10]. Higher solvent holdup requires more energy to recover the solvent from the meal residue.

Isopropyl alcohol (IPA) is a polar solvent; therefore, some non-acylglycerol material may also be extracted along with the oil, such as phosphorus compounds, water, carbohydrates and protein [14, 15]. Crude cottonseed oil extracted with 97 % IPA contained more sugars (2.3 %) than hexane-extracted cottonseed oil (1.3 %). However, due to the water solubility of sugars, the sugar level increased with an increase in the water content of IPA. On the other hand IPA extraction decreased the free fatty acid (FFA) content in refined cottonseed and soybean oils [12, 16]. The major disadvantage of IPA is its greater latent heat of vaporization in comparison with hexane. Due to the formation of an azeotrope with water at 87.7 wt% alcohol (b.p. of mixture 80.4 °C, at 1 atm), it is impossible to completely dehydrate IPA without using azeotropic distillation or techniques such as pervaporation.

In the present investigation, oil recovery from yellow mustard flour using IPA has been evaluated and the oil-IPA-water system was investigated for predicting the optimum extraction conditions for oil extraction and solvent recovery. The composition of miscella and meal samples resulting from the extractions was determined. Effect of primary extraction factors including extraction time, number of successive extraction stages, contact ratios, pH and temperature on oil recovery have been examined in order to find favorable conditions for oil extraction. A ternary phase diagram of IPA-oil-water system was developed and the effect of water content of the IPA on the extraction yield and components dissolved in the solvent was investigated by performing single and multiple-stage extraction with IPA containing water and compared with values predicted by this phase diagram.

Materials and Methods

Materials

De-hulled yellow mustard flour was used as the starting material of the IPA extraction process. The flour was obtained from GS Dunn-Dry Mustard Millers in Hamilton, ON, Canada and was kept at room temperature in high density polypropylene-lined, multiwall paper bags. The flour contained 32.4 ± 0.5 wt% oil (as-is basis), 34.5 ± 0.4 wt% protein (as-is basis), 26.7 ± 0.6 wt% carbohydrates (as-is basis), and 5.5 ± 0.6 wt% moisture. The isopropyl alcohol (ACS reagent grade) was obtained from Caledon Laboratories Ltd., Georgetown, ON, Canada. Analytical reagents were obtained from Sigma Aldrich, Toronto, ON, Canada.

Methods for Single and Multiple-stage Extraction

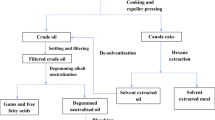

Figure 1 shows the experimental procedure for the single-stage oil extraction. IPA was added to a known amount of mustard flour varying between 20 and 75 g at selected IPA/flour ratios ranging from 1.5:1 to 15:1 (v:w) in 50-, 250-, or 500-mL polypropylene centrifuge bottles. A wrist action shaker was used to agitate the mixture for 30 min to ensure adequate extraction (Wrist Action Shaker-Model 75: Burrel, Pittsburgh, PA, USA). The mixture was then centrifuged for 20 min at 6,500 rpm (10,500×g) (Beckman Coulter J20XP High Speed Refrigerated-Centrifuge, Beckman Instruments, Fullerton, CA, USA). Following centrifugation, two phases were separated: a liquid miscella, which was made up of mostly IPA, oil triglycerides (TAGs), FFA, phospholipids and a small amount of water, protein and sugars, and a residual solid phase, which also contained some absorbed IPA and water. The weights of the solid and miscella phases were recorded. Aliquots of miscella and the meal residue were collected in an aluminum dish, and most of the solvent was removed by heating on a hot plate under a fume hood. This was followed by drying in a forced air oven for an hour at 105 °C (Blue M-Constant Temperature Cabinet Model No. 0V-490A-2-Electric Company, Blue Island, IL, USA). The oil left in the residual meal was determined by Soxhlet extraction with petroleum ether. The composition of oil in the IPA retained in the meal matrix was assumed to be the same as the miscella composition. The oil yield and extractability were calculated using Eqs. (1) and (2) respectively.

For multiple-stage oil extraction the single stage oil extraction process described previously was followed. However, following centrifugation, the solids were re-extracted with the same volume to weight ratio of IPA. The mixture was then shaken for a further 30 min and centrifuged. The procedure was repeated for subsequent stages. Oil yield was calculated by determining the oil content in the miscella. After the last stage, the solids were dried as described above to determine IPA holdup. The oil extractability was calculated as the sum of the oil yields in the collected miscella and the oil in the IPA holdup in the meal remaining after the last stage of extraction.

Methods for Evaluating Effect of Process Variables on IPA Extraction

The single stage extraction with 2:1 (v/w) IPA/flour ratio was carried out for 15, 30 and 60 min as well as 24 h at room temperature. The oil yield was subsequently calculated, and the effect of time on extraction efficiency and the optimum extraction time were determined.

In order to examine the effect of pH on extraction efficiency single stage extractions were repeated at different pH values at IPA/flour ratios of 2:1 and 4:1 (v/w). For the extraction at pH 3 the pH of IPA was adjusted by the addition of concentrated HCl. After addition to the flour the pH was readjusted by adding drops of diluted acid. pH 10 IPA was prepared by dissolving solid NaOH pellets in IPA. Final pH adjustment was made with dilute NaOH.

To examine the effect of temperature on the single stage extraction, mixtures of IPA and flour at 2:1 and 4:1 (v/w) solvent-to-flour ratios were refluxed for 30 min at 45 and 82 °C and the extracted oil was determined as described above. To examine the effect of temperature on multiple-stage extraction, the three stage extraction process described previously was followed at 45 °C.

Analytical Methods for Characterization of the Miscella and the Meal Residue

The water content of the miscella was determined by Karl Fischer titration (volumetric Karl Fischer ASTM standard method E203) [17]. Oil and IPA-water were determined gravimetrically by drying the miscella. The total IPA in the miscella was calculated by subtracting the weight of the water in the miscella from the total weight of IPA-water in the miscella. The water content of the meal residue was determined by subtracting the water in the miscella from the total water in the system. The remaining oil in the dried meal residue was determined by the Soxhlet method (AOCS Method Am 5-04) [18]. The IPA hold up in the meal residue can be determined by subtracting the weight of IPA-water from the weight of the remaining water in the meal residue. Samples of the miscella and meal residue were dried and then analyzed for sugar and protein content. The sugar content of both the miscella and meal residue was determined spectrophotometrically based on the phenol–sulfuric acid reaction [10, 19]. The protein content in the miscella and meal residue was determined by the Kjeldahl method (AOCS Method Ba4d-90) [20]. All analyses were carried out in triplicate.

Determination of Equilibrium Line and Partition Coefficient Value for IPA-oil System

Oil extraction with IPA was modeled by determining the equilibrium line. The extraction experiments have provided a large set of data on oil distribution between miscella (liquid phase) and meal residue (solid phase). The equilibrium line and partition coefficient values for oil in each stage were plotted and calculated by determination of the (w:w) ratio of oil concentration in the miscella to IPA over the (w:w) ratio of the oil concentration in the meal to defatted meal. In cross-current extraction, fresh IPA was fed into each stage and the corresponding miscella was obtained. All miscella collected were combined together to obtain the overall extract while the overall meal residue was obtained from the last stage. Each cross-current extraction system was solved in stages, i.e., starting with the first stage, obtaining the miscella and meal residue concentrations and forward substituting these values.

Development of the IPA-Oil–Water Ternary Phase Diagram

Since the solubility properties of canola oil at room temperature are similar to those of mustard oil [1] the phase distribution was initially studied on the IPA/canola oil/water system. Commercially available canola oil (Mazola) was used to prepare a phase diagram. In order to construct ternary phase diagrams the usual method used is to measure the compositions of the phases that are in equilibrium; and then the compositional pairs are connected by tie lines to build the solubility curve and the phase diagram. Within the IPA/oil/water system at room temperature, both oil/IPA and oil/water are partially miscible, whereas IPA tends to dissolve in water in any proportion; as a result, two pairs of partially miscible liquids are formed. In this system IPA is considered to be the solvent, water is the solute as it is more soluble in IPA and the oil is considered to be the diluent. The initial step was to determine the solubility of oil in IPA and the solubility of IPA in oil. As the cloud point method is not considered to be practical to measure the limited solubility of oil in water, the solubility of water in oil and oil in water was considered negligible [21]. Using this method for determination of the water-rich side of the solubility curve, different water/IPA mixtures of known composition were prepared. The canola oil was added from a burette to a stirred mixture, for each water/IPA mix, until the mixtures became turbid. The weight of oil used at the turbidity point was recorded. This same procedure was carried out for the oil-rich side of the solubility curve in which water was added to stirred mixtures of oil/IPA of known composition until the turbidity point was achieved. In order to form a mutual solubility curve the compositions of the resulting mixtures which were obtained by this route were plotted. In the second step, different solutions of canola oil, water, and IPA for the determination of tie lines were prepared. The IPA and oil content within these solutions were equivalent to the amount of IPA and oil in the mustard miscella collected from the 2:1 (v/w) IPA/flour ratio. The water content was increased from 2 to 85 % (w:w) of the miscella in order to study the effect of water on IPA and oil solubility. The water-rich phase was separated from the oil-rich phase and the composition of each phase was measured as according to the Mehta and Fraser methodology [22]. The water content was determined using the Karl Fischer titration method (Karl Fischer ASTM standard method E203) [17]. After evaporating all water and IPA, the oil content of both phases was measured by calculating the weight loss. The IPA content was determined from the difference between total weight and the sum of water and oil.

Results and Discussion

Single-Stage Extraction of De-hulled Yellow Mustard Flour with IPA

Single-stage extractions were performed with different IPA/flour ratios varying from 1.5:1 to 15:1 (v/w) at room temperature in order to study the effect of IPA amount on oil yield and extractability. In order to determine whether the time allowed for reaching IPA/oil equilibrium during the extraction process was sufficient, extractions at 2:1 (v/w) IPA/flour ratio were repeated with contact times of 15, 30 and 60 min as well as 24 h at room temperature. The oil yield increased from 25.1 ± 2.1 to 39.6 ± 0.9 % (Fig. 2) as the extraction time was increased from 15 min to 24 h. As the 30 and 60 min extractions yielded similar results, and the 24 h extraction was impractical, an extraction time of 30 min was used in all subsequent experiments.

There are three major factors that determine the efficiency of solvent extraction, namely oil solubility in the solvent, percolation and the degree of solvent penetration in the solid matrix and finally drainage after oil extraction [23]. The solubility of oil in IPA at room temperature is limited due to the migration of water from the seed into isopropyl alcohol [7]. For complete miscibility of soybean oil and cottonseed oil, IPA concentrations higher than 91 % are needed [13]. Therefore, the amount of extracted oil was expected to rise with increasing solvent-to-flour ratio. In Fig. 3, the gray bars represent the oil yield, which is the percentage of oil extracted into the IPA from the flour. The white bars indicate the oil extractability, which is the oil yield plus the percentage of oil dissolved in the solvent held-up in the matrix. For an IPA/flour ratio of 1.5:1 (v/w) the oil yield was 26.42 ± 0.33 % and this increased to 59.24 ± 2.71 % for a ratio of 3:1 (v/w). Water in the flour was initially extracted into the IPA, reducing the solubility of the oil. At IPA-to-flour ratios above 3:1 (v/w), the proportion of water in the mixture decreased, and the oil became completely miscible in IPA. Therefore, increasing the IPA/flour ratio from 2:1 to 3:1 (v/w) resulted in a sharp increase in oil extractability and yield. The extractability reached a maximum of approximately 99 % at an IPA/flour ratio of 8:1 (v/w) with an 84.4 ± 0.23 % oil yield. The oil yield increased slightly with higher IPA/flour ratios, reaching 87.6 % at the ratio of 10:1 (v/w). A small increase in oil yield to 90.3 ± 0.58 % was achieved with a significant increase in the IPA/flour ratio to 15:1 (v/w). In this case, apart from oil left in IPA hold up, the only oil remaining in the flour is that left in intact cells. This residual oil can only be extracted via osmosis, which tends to be a very slow process depending on the molecular sizes of the oil and the solvent [24]. The concentration of oil in the miscella steadily decreased from 15.17 ± 0.44 to 4.97 ± 1.68 % as the solvent-to-solid ratio increased from 1.5:1 to 15:1 (v/w).

Solvent holdup is defined as the amount of the miscella remaining in the meal residue following centrifugation. The solvent holdup increased as the solvent ratio was increased from 1.5:1 to 4:1 (v/w) but essentially leveled off at higher ratios (Fig. 4). When solvent percolates through the meal it removes oil and the contact area is increased which results in increased extraction yield. However, after draining, the solvent holdup in the meal residue increases by filling the enlarged pores in the solid matrix. High solvent holdup values indicate poor drainage due to high retention of miscella. We found that the residual oil content varied inversely with solvent holdup, consistent with data reported in the literature [13, 21] (Fig. 5).

Effect of Process Variables on Single Stage Extraction

The effect of pH, temperature and water content on IPA extraction has been examined in order to identify favorable operating conditions. The maximum solubility of the oil in dry IPA at native pH and room temperature was 24.4 ± 0.3 wt%. Under the same conditions the maximum solubility of the oil was 17.63 ± 0.41 and 21.57 ± 1.35 % at pH 3 and 10, respectively. The oil yield was also reduced at both acidic and alkaline conditions when extracting with 2:1 and 4:1 (v/w) solvent-to-flour ratios. Therefore, the native pH was chosen as a practical extraction condition in further tests.

Extraction at 82 °C, the boiling point of IPA, was measured at two solvent-to-flour ratios. As expected, the oil yield increased with increased temperature, since the oil solubility in IPA increases with increased temperature (Fig. 6). It has been shown previously that extraction at temperatures above 60 °C can damage protein quality and extractability [25], therefore, to avoid protein loss or degradation during extraction, the solvent-to-solid ratios from 1.5:1 to 8:1 (v/w) were measured at 45 °C in order to determine whether performing the extraction at elevated temperatures was justified. The results indicated that in a single-stage extraction significantly higher yields could be achieved at 45 than at 25 °C. In addition, the oil yield increased with increasing solvent-to-solid ratios up to a ratio of 3:1 (v/w) after which increasing solvent ratios had minimal effect on oil yield (Fig. 7). Overall, performing single-stage extraction with the aim of removing the oil almost completely from the flour required high solvent-to-flour ratios at both 25 and 45 °C. The effect of temperature at 45 °C on multiple-stage extraction with a lower IPA-to-flour ratio (2:1 v/w) is reported later in this paper. Although oil extraction at 45 °C was more effective than at 25 °C, the difference was small and did not warrant the extra cost or effort.

In order to determine the effect of water on single stage extraction with IPA, the contact ratio of 10:1 (v/w) IPA/flour was selected as the favorable solvent-to-flour extraction ratio at room temperature. This selection was primarily made due to the relatively high oil yield (87.6 %) that was achieved for this solvent-to-flour ratio. The miscella collected from this ratio contained 95.68 ± 0.3 % IPA, 4.03 ± 0.06 % oil and 0.3 ± 0.01 % water, which was co-extracted from the flour. The extraction was repeated with the same solvent-to-flour ratio (10:1 v/w), while the water content of the solvent varied from 2 to 13 % of the IPA.

Extraction with water containing IPA was more difficult to perform due to aggregation of the solids as the water content of the solvent increased. The oil yield and extractability resulting from these experiments were determined and compared with dry IPA extraction with the same ratio. When IPA has a water content of up to 4 %, a relatively slow drop in the oil yield was achieved (Fig. 8). From the water content of 5 %, the oil yield declined sharply by 40 % when the water content reached 13 %. The miscella and the meal residue collected from each extraction were analyzed. As the water content of the solvent increased from 0 to 13 %, the IPA content in each collected miscella decreased from ~96 to 85 % and the oil content decreased from ~4 to 2 %. On the other hand, the miscella water content also increased from ~0 to 13 %, indicating that most of the water from the solvent stayed in the miscella and did not transfer to the meal residue. As the water content of the solvent increased from 0 to 13 %, the average IPA content was ~51 % in each collected wet meal residue while the water content increased from ~2 to ~6 %. The oil remaining in the dry meal residue ranged from ~4 to 23 %. This is in line with the earlier results from the miscella analysis where oil extraction was hindered by the increasing water content of the solvent. The high affinity of IPA towards water is detrimental to the oil extraction process. Even at high IPA/flour ratios the presence of water >5 % limited oil extractability.

Multiple-Stage Extraction of De-hulled Yellow Mustard Flour with IPA

The effect of the number of successive extraction stages, contact ratio and temperature on oil yield and extractability in multiple-stage extraction with IPA was studied. The miscella produced by the single-stage extraction using 10:1 (v/w) IPA/flour ratio had an IPA content of 95.7 ± 0.3 %, oil content of 4.03 ± 0.06 % and a water content of 0.3 ± 0.01 %. The large, 272:1 IPA/oil mole ratio in the miscella renders it economically non-viable. Multiple-stage extractions with the aim of reducing the amount of solvent were tested at room temperature and at 45 °C. Since oil extraction yields as high as 70 % were observed at 1.5:1 to 5:1 (v/w) solvent-to-flour ratios, multiple stage extraction was performed at these ratios in order to determine the optimal conditions for oil recovery from de-hulled yellow mustard flour. Two and three stages of extraction were considered for all the ratios examined (Fig. 9). Multiple-stage extraction at 1.5:1 (v/w) IPA/flour ratio significantly improved the initial oil extraction yield from 24.8 to 46.2 and 64.8 % through the second and third extraction steps, respectively. The same ascending trend was also observed for the 2:1 (three-stage extraction) 3:1 and 5:1 (v/w) ratios (two-stage extractions). For all ratios, the highest oil yield was obtained in the first stage. In the first extraction stage, the oil from ruptured oil bodies is readily dissolved. In subsequent stages the oil extraction is controlled by diffusion of solvent into the cells, and diffusion of the miscella out of the matrix reducing the oil yield in the latter stages. Due to the high oil content, the first stage miscella had a strong yellow color. This miscella was easily separated from the defatted meal. The meal residue was very compact, which indicated low solvent hold-up. At lower ratios, the second stage miscella was lighter in color but following centrifugation the solids and the miscella tended to mix, and separation was more difficult due to the fact that the solids were easily disturbed. In latter stages, the extraction results in the breakdown of the meal into a fine powder, which easily disperses into IPA making the miscella cloudy. The total amount of IPA used during the three-stage oil extraction at 2:1 (v/w) IPA/flour ratio was less than the amount used for the single-stage extraction at 5:1 (v/w) IPA/flour ratio. While the oil yield for the single-stage extraction at the 5:1 (v/w) IPA/flour ratio was 73 %, the three-stage process recovered over 84 % oil using slightly less solvent. The highest oil yields, 93.4 and 91.5 ± 1.10 % were obtained at 45 °C using 5:1 (v/w) IPA/flour ratio with two-stage extraction and 2:1 (v/w) IPA/flour ratio with three-stage extraction, respectively. The oil extractability by multiple-stage extractions from the yellow mustard flour at different IPA/flour ratios at room temperature and 45 °C are presented in Table 1.

Four-Stage Extraction

Three stage extraction for 1.5:1, and 2:1 (v/w) IPA/flour ratios at room temperature resulted in 64.8 and 84.3 % oil yields, respectively. In order to better quantify and confirm the trends observed with three stages, four-stage extractions were performed for 1.5:1 and 2:1 (v/w) IPA/flour ratios. As expected, oil extraction yields increased with more stages and higher IPA/flour ratios (Fig. 10). At a 2:1 (v/w) IPA/flour ratio, the oil yield increased from 34.8 ± 0.5 to 63.7 to 83.4 to 93.7 % in the four stages. Additionally, in each stage of extraction, an average of 60 % of the total IPA was transferred to the miscella. The same ascending trend was also noted for the 1.5:1 (v/w) ratio. The best results were obtained using four extraction stages, each at 2:1 (v/w) IPA-to-flour ratio. Although the total amount of the IPA used during the four-stage oil extraction was less than the amount used for the single stage extraction at 8:1 (v/w) IPA/flour ratio (188 vs. 200 mL for 25 g of flour), the four-stage process yielded over 94 % oil compared with only 84 % in the direct extraction at 8:1 (v/w) ratio. The combined miscella created by mixing all of the miscella produced during the four-stage extraction of de-hulled yellow mustard flour at 2:1 (v/w) contained 8.7 ± 0.3 % oil, which is a more suitable feedstock for industrial applications than miscella collected from the single-stage extraction with 8:1 (v/w) IPA/flour ratio (4.95 ± 0.30 %) (Table 2). The overall oil yield from the four-stage oil extraction was 93.7 ± 1.1 %, and the oil extractability was 99.66 ± 0.14 %. The extracted oil trapped in the meal residue was 6.0 ± 1.11 %. In comparison with the three-stage extraction at 2:1 (v/w) IPA/flour ratio at 45 °C, the oil yield was similar to the four-stage extraction at room temperature for the same IPA/flour ratio. Therefore, both approaches could be considered equally effective. However, the oil quality may be degraded at higher temperatures as other components such as sugar become more soluble in IPA as the temperature rises. As the IPA/flour ratio was decreased to 1.5 (v/w), the trapped oil content increased to 13.4 ± 2.3 % despite almost identical (99.77 and 99.66 %) extractability. More efficient drainage methods are desirable for the 1.5:1 (v/w) ratio in order to remove more oil from the flour in the final stage.

IPA is slightly polar, and when IPA is used as an extraction solvent for oil, compounds such as phospholipids, carbohydrates as well as other polar compounds, such as protein, have been reported in the miscella [26]. The miscella and the meal residue collected from each stage of cross-current four-stage extraction were analyzed for their components. The miscella composition of IPA, oil, water, sugar and protein in each stage of a four-stage oil extraction using a 2:1 (v/w) IPA/flour ratio are presented in Table 2. As expected, oil was the most soluble component and protein the least soluble among the compounds analyzed. As most of the protein stayed intact in the meal residue, high quality food grade protein isolate can be recovered from it. Preliminary tests indicate that oil extraction with IPA does not affect protein extraction from the meal (B-K Chen, internal report). In four-stage extraction with 2:1 (v/w) IPA/flour ratio, 39.0 ± 1.2 % of the flour mass was extracted to the miscella of which 31.3 ± 1.1 % was oil and the rest was non-fat components, such as sugar (4.7 ± 0.2 %), protein (0.8 ± 0.1 %) and water (2.2 ± 0.1 %).

The T test, was used to compare the oil content in the miscella of stages 1 and 2, stages 2 and 3 and stages 3 and 4. The oil content in the miscella phases was not significantly different (P > 0.05) between the first and second stages using a 2:1 (v/w) IPA/flour ratio. On the other hand, the oil content in the miscella phases was significantly different (P < 0.05) between stages two and three and stages three and for using the same 2:1 (v/w) IPA/flour ratio. One explanation is that in the first stage of extraction other impurities, such as water and sugar, were competing with oil for extraction by IPA; therefore, the oil did not saturate the available IPA. Additionally, from the first to the fourth stages of extraction, the concentration of oil in the meal for extraction with IPA shows a downward trend from 32.2 to 20.5 to 15.9 to 10.2 %. This indicates that IPA saturation was rapidly achieved in the first and second stages of extraction but in the third and fourth stages the amount of available oil was less than in the first two stages. Therefore, it can be concluded that the oil extraction became more difficult as the stages of extraction moved forward.

The compositions of meal residues are presented in Table 3. As the oil and water content decreased after each stage of extraction in the meal residue, the percentage of sugar and protein in the meal increased. Protein concentration of the dried meal increased from 40.31 ± 0.89 % in the first stage to 49.82 ± 0.24 % in the fourth stage, and the sugar concentration increased from 29.46 ± 0.63 to 36.28 ± 2.07 %. The IPA hold up increased slightly in each stage.

Oil and IPA Equilibrium

These extraction experiments provided a large set of data on oil distribution between miscella (liquid phase) and meal residue (solid phase). If the oil composition of one of the phases in equilibrium is known, the oil equilibrium line allows one to obtain the oil composition of the other phase. The equilibrium line for oil distribution has been determined from this data at room temperature. In Fig. 11 the X axis represents the weight ratio of oil concentration in the meal residue to defatted meal, and the Y axis represents the weight ratio of oil concentration in the miscella to IPA. The results obtained from four-stage extraction at 2:1 (v/w) IPA/flour ratio is well fit by the equilibrium model.

The effect of temperature on the equilibrium is shown in Fig. 11. The equilibrium line determined at 45 °C showed that the concentration of oil in the miscella collected is higher than at the same contact ratio of IPA:flour at room temperature; therefore the extraction occurred more rapidly at the higher temperature. Partition coefficients determined for single stage extraction between the ratios of 2:1–8:1 at room temperature varied between 0.5 and 0.7 but for 45 °C the partition coefficient values were higher: 1–2. This is consistent with the equilibrium model. The higher concentration of oil in the miscella, especially in low IPA:flour contact ratios, made the extraction procedure and the measurement of the oil content more precise at the higher temperature.

Effect of Water on Four-Stage Extraction

The ternary phase diagram was developed to represent the behavior of the IPA-oil-water system. Solutions of canola oil, water, and IPA were prepared for the determination of tie lines. The effect of water on oil solubility in IPA was indicated by the solubility curves as well as the corresponding tie lines (Fig. 12). In Fig. 12 the area indicated by the letter L contains IPA, oil and water in a single phase. The maximum solubility of the oil in IPA in the absence of water is represented by the intersection of the left solubility curve and the horizontal axis (i.e., 24.4 % oil).

Ternary phase diagram of IPA-oil-water at room temperature (25 °C): Open squares show overall composition for tie lines. Solid lines with filled circles are solubility curves. Triangles pointing up represent composition of the miscella phases produced during four stage extraction with dry IPA. Triangles pointing down represent composition of the miscella phases produced during four stage oil extraction with 87 % IPA

All of the prepared mixtures with the exception of 0 and 2 % water were in the two-phase region of the IPA-oil-water system. These solutions separated into two phases. On the diagram, the water-rich phase and the oil-rich phase are connected by a tie line. The oil-rich phase shown on the right corner of the ternary diagram has high concentration of oil and a small amount of water. The water-rich phase shown on the left side of the ternary diagram has high levels of IPA and water. Increasing water levels in the mixture moved the tie lines upwards, while making them longer also pushed the oil-rich phase to the higher oil concentration region (Fig. 12). This indicates that having high levels of water reduces the solubility of oil in IPA; hence, the oil will be separated almost completely from the IPA-water mixture thereby affecting the oil extraction and yield.

As discussed previously, water had a significant effect on the single-stage extraction of de-hulled yellow mustard flour with IPA. To determine the effect of water on multiple-stage extraction with IPA and miscella components in each stage of extraction, the extraction was repeated with the IPA-water azeotrope. Extraction with IPA containing water was more difficult to perform due to aggregation of the meal residue. The composition of the miscella obtained from 2:1 (v/w) dry IPA/flour ratio extraction (Table 2, shown in upward pointing triangles in Fig. 12) are all in the single-phase area in which oil is completely dissolved in IPA. On the other hand, the miscella obtained from 87 % IPA/flour (v/w) ratio extraction (shown in downward pointing triangles of Fig. 12) was located in the two-phase region, and as the extraction stages move forward, the compositions reached the solubility curve. The oil concentrations in these miscella were lower than with dry IPA extraction, i.e., 7.9 ± 0.12, 2.4 ± 1.12, 1.8 ± 0.18 and 1.6 ± 0.29 % in the four successive stages. Around 10–14 % water and 80–85 % IPA were present in the miscella for all four stages. A comparison of oil yields from dry (Fig. 13) and water containing IPA (Fig. 14) extraction indicated that the oil yield with water containing IPA was 44.9 %, whereas extraction with dry IPA recovered 86.6 % oil. This means that the 13 % water present in the IPA-water mixture resulted in a reduction in oil yield by ~41 %. The crude oil yield obtained after drying off the miscella was 58.1 %, which was 37 % less than with pure IPA. Sugar extraction doubled to almost 30 % for the IPA-water mixture. The protein extraction did not change significantly at the native pH. This is in line with previous findings that suggest protein solubility tends to be markedly lower in polar solvents such as alcohols and that proteins are essentially insoluble in non-polar solvents such as cyclohexane [27–29]. Clearly, water content is critical in obtaining efficient oil extraction with minimal co-extraction of non-lipid components.

Conclusions

IPA was found to be an effective solvent for recovery of oil from mustard flour without any significant loss or degradation of the protein. For single-stage extraction at room temperature and native pH, the best IPA/flour ratio was 10:1 (v/w) with an oil yield of ~88 %. Multiple-stage oil extraction can minimize the solvent use and increase the oil yield. Four-stage oil extraction at IPA/flour ratio of 2:1 (v/w) resulted in ~94 % oil yield. Increasing the temperature to 45 °C increased the extraction rate. The miscella compositions obtained from the four stage oil extraction with 2:1 (v/w) IPA/flour ratio indicated that the main components extracted into the IPA were oil, water and sugar. The resulting miscella could be suitable for industrial applications, such as transesterification. The presence of water in IPA lowers the oil yield. With the azeotrope containing 13 % water, oil recoveries were reduced by more than 40 % in both single- and multiple-stage extractions. The results suggest that when the water content of the extraction solvent exceeds 5 %, removal of water becomes a necessary step for recovery and reuse of IPA and the extracted minor components also must be removed, and preferably utilized.

References

Appelqvist L-A (1971) Composition of seeds of cruciferous oil crops. J Am Oil Chem Soc 48:851–859

Agriculture and Agri-Food Canada (2011) The case for Canadian mustard. http://www.marquecanadabrand.agr.gc.ca/fact-fiche/4512-eng.htm. Accessed August 2014

Bell JM, Rakow G, Downey RK (2000) Comparisons of amino acid and protein levels in oil-extracted seeds of Brassica and Sinapis species, with observations on environmental effects. Can J Anim Sci 80:169–174

Canadian Grain Commission (2013) Quality of western Canadian mustard. http://grainscanada.gc.ca/mustard-moutarde/harvest-recolte/2013/hqm13-qrm13-en.pdf. Accessed August 2014

Lusas EW, Watkins LR, Rhee KC (1990) Separation of fats and oils by solvent extraction: non-traditional methods. World conference proceedings, edible fats and oils processing: basic principles and modern practices, Urbana, IL. J Am Oil Chem Soc Press, USA, pp 56–78

Environmental Protection Agency (2001) 40 CFR part 63, national emission standards for hazardous air pollutants: solvent extraction for vegetable oil production; final rule. Fed Reg 66:19005–19026

Johnson LA, Lusas EW (1983) Comparison of alternative solvents for oils extraction. J Am Oil Chem Soc 60:229–242

Wan P, Wakelyn PJ (1997) Technology and solvents for extracting oilseeds and non-petroleum oils. Am Oil Chem Soc Press, Champaign, III, pp 101–120

Lusas EW (1983) Comparative processing practices of the world’s major oilseed crops. Econ Bot 37(4):444–458

Zhang F, Rhee KC, Koseoglu SS (2002) Isopropyl alcohol extraction of cottonseed collets: efficiency and performance. J Food Lipids 9(2):147–160

Zhang F (1995) Extraction of expander-pretreated cottonseed with aqueous isopropyl alcohol, Ph.D. Dissertation, Texas A&M University, College Station, Texas

Zhang Rhee KC, Koseoglu SS (2002) Isopropyl alcohol extraction of cottonseed collets: crude oil composition. J Food Lipids 9(2):161–173

Lusas EW, Gregory SR (1996) New solvents and extractors. In: Koseoglu SS, Rhee KC, Wilson RF (eds) Proceedings of the world conference on oilseed and edible oils processing. AOCS Press, New York, pp 204–219

Harris WD, Bishop FF, Lyman CM, Helpert R (1947) Isopropanol as a solvent for extraction of cottonseed oil. I. Preliminary investigations. J Am Oil Chem Soc 24:370–375

Harris WD, Hayward JW, Lamb RH (1949) Isopropanol as a solvent for extraction of cottonseed oil. II. Separation of purified oil from miscella. J Am Oil Chem Soc 26:719–723

Ghandi AP, Joshi KC, Jha Krishna, Parihar VS, Srivastav DC, Raghunadh P, Kawalkar J, Jain SK, Tripathi RN (2003) Studies on alternative solvents for the extraction of oil-I soybean. Int J Food Sci Technol 38:369–375

ASTM (2008) Standard E203: standard test method for water using volumetric Karl Fischer titration. Developed by Subcommittee: E15.01, Book of Standards Volume 15.05

AOCS Official Methods (2009) Rapid determination of oil/fat utilizing high temperature solvent extraction, Method Am 5-04

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28(3):350–356

AOCS Official Method (2011) Nitrogen-ammonia-protein modified kjeldahl method titanium dioxide + copper sulfate catalyst, method Ba4d-90

Tabtabaei S, Pulido VMA, Diosady LL (2013) Destabilization of yellow mustard emulsion using organic solvent. J Am Oil Chem Soc 90:707–716

Mehta GD, Fraser MD (1985) A novel extraction process for separating ethanol and water. Ind Eng Chem Process Des Dev 24:556–560

Lajara JR (1989) Solvent extraction of oil from oilseeds: the real basics. In: Erickson DR (ed) Proceedings of the world conference on edible fats and oils processing: basic principles and modern practices. J Am Oil Chem Soc Press, Champaign, pp 49–55

Beckeles AC, Smith AK (1944) Alcohol extraction improves soya flour flavor and color. Food Ind 16:616–664

Xu L, Lui F, Luo H, Diosady LL (2003) Production of protein isolates from yellow mustard meals by membrane processes. Food Res Int 36(8):849–856

Rao RK, Arnold LK (1957) Alcoholic extraction of vegetable oils. V. Pilot plant extraction of cotton seed by aqueous ethanol. J Am Oil Chem Soc 35(6):277–281

Pace CN, Treviño S, Prabhakaran E, Scholtz JM (2004) Protein structure, stability and solubility in water and other solvents. Philos Trans R Soc Lond B Biol Sci 359(1448):1225–1234

Smith AK, Johnsen VL, Derges RE (1951) Denaturation of soybean protein with alcohols and with acetone. Cereal Chem 28:325

Wolf WJ, Sly DA, Babcock GE (1964) Denaturation of soybean globulins by aqueous isopropanol. Cereal Chem 41:328

Acknowledgments

This project was funded by the Natural Sciences and Engineering Research Council of Canada through its strategic grants program.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Sinichi, S., Diosady, L.L. Isopropyl Alcohol Extraction of De-hulled Yellow Mustard Flour. J Am Oil Chem Soc 91, 2143–2153 (2014). https://doi.org/10.1007/s11746-014-2556-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-014-2556-5