Abstract

Alkannin, a red-purple dye and bioactive compound found in the roots of Arnebia hispidissima has antibiotic and anti-inflammatory properties and is also used in cosmetic and textile industries at a large-scale. In the present communication, we demonstrate the establishment of callus and cell suspension culture of A. hispidissima with the aim of optimizing the production of alkannin. Highest alkannin content was recorded in cell suspension and callus culture established on M-9 medium. Production of alkannin was influenced by the different culture medium. Evaluation of alkannin content of roots of field-grown plants and in vitro grown cell, tissue and organ showed that alkannin production was higher in all in vitro grown culture systems (cell suspension, callus and roots) than the roots of field-grown plants. The present investigation may be applicable in designing systems for the large-scale cultivation of A. hispidissima cell suspensions for the production of alkannin.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Plants produce various secondary metabolites like alkaloids, flavonoids, terpenoids, anthocyanins etc. which are biologically active compounds and have great commercial values. However, production of these secondary metabolites through plants in natural conditions is limited by several environmental, ecological and climatic conditions (Praveen and Murthy 2011). Moreover, the production of secondary metabolites is tissue-specific and also depends upon the age of plants (Nasim et al. 2010). In recent years, plant cell, tissue and organ culture technology has been efficiently utilized in the production of secondary metabolites (Praveen et al. 2010; Rathore and Shekhawat 2009; Piekoszewska et al. 2010). In comparison with the field-grown plants, the production of several biologically active compounds through in vitro culture system has many advantages like cell/organ culture having a higher rate of metabolism than field-grown plants and thus cell/organ can proliferate at higher growth rate. In addition, cell, tissue and organ culture are not limited by environmental or ecological conditions and can be easily controlled and monitored (Praveen and Murthy 2011). Earlier, several studies also reported that cell, tissue and organs grown under in vitro conditions showed higher production of biologically active secondary metabolites than the field-grown plants (Wu et al. 2007; Nasim et al. 2010; Praveen and Murthy 2011). Among all culture methods, cell suspension culture represents the best system for producing secondary metabolites because of their fast growth rate (Chan et al. 2010; Praveen and Murthy 2011).

Arnebia hispidissima, which belongs to the family Boraginaceae, is an important medicinal plant of Indian Thar desert. It grows generally in sandy soil and has the ability to tolerate both chilling and drought stress. The alkannin (Fig. 1) and its optical isomer shikonin, a red dye, are root-specific secondary metabolites of A. hispidissima (Sharma et al. 2009). The alkannin has recently attracted the interest of researchers due to its anti-inflammatory, antimicrobial, antitumor activities and wound-healing properties. In addition, it has wide applications as a colorant in food, cosmetic and textiles industries (Pal and Chaudhury 2010).

Owing to the increasing human and livestock populations, the status of wild plants have been affected, particularly those used in herbal medicine. Plant tissue culture is a useful tool for the conservation and rapid propagation of medicinally important plants and the production of bioactive compounds (Singh et al. 2009; Praveen et al. 2010). For improved secondary metabolite production through tissue culture technologies, several other biotechnological advances like establishment of cell suspension culture, optimization of culture medium and culture conditions, selection of high-producing strain, metabolic engineering, etc. have been made (Praveen and Murthy 2010). Recently, Pal and Chaudhury (2010) reported the regeneration of A. hispidissima and production of shikonin using tissue culture technique. However, for the large-scale application of process, several other methodologies should be exploited for improved production of alkannin. Therefore, the present investigations were carried out with the aim to: (1) establish callus and cell suspension culture and optimize culture medium and culture conditions for the production of alkannin and (2) evaluate and compare production of alkannin in roots from plants originated in vitro and traditionally.

Materials and methods

Collection of plants, explants preparation and surface sterilization

The plants of A. hispidissima were procured from sandy region of Bikaner and Nagaur districts of Rajasthan (the Indian desert) during November–January and transplanted in the Nursery of Biotechnology Centre, Department of Botany, JNVU, Jodhpur. Nodal segments obtained from plants grown in Nursery were used as explants for the establishment of cultures. Explants were treated with 0.1% (w/v) Bavistin (a systemic fungicide; BASF India Ltd., India) for 10 min. Surface sterilization was carried out with 0.1% (w/v) HgCl2 (disinfectant, Hi-Media, India) for 5–6 min after a brief rinse in 90% alcohol for 40–50 s under aseptic condition in laminar air hood. It was finally rinsed 8–10 times with sterile distilled water.

Shoot multiplication, rooting of shoots and culture conditions

For the shoot multiplication, nodal explants were cultured on 0.8% agar (w/v; Hi-Media, India) solidified MS (Murashige and Skoog 1962) medium containing either BAP or Kn (0.0–5.0 mg dm−3) alone or combination of BAP or Kn (0.1–2.00 mg dm−3) with IAA (0.1–1.0 0 mg dm−3). To study the effect of repeated transfer on shoot multiplication, mother explants were transferred to the same medium for 2–4 passages. For the root induction, in vitro regenerated shoots (2–4 cm in length) were excised and subcultured to half-strength MS medium supplemented with different concentrations (0.0–2.0 mg dm−3) of auxins IAA, IBA or NAA and 200 mg dm−3 activated charcoal. The pH of the medium was adjusted to 5.8 ± 0.02 using 1 N NaOH or 0.1 N HCl prior to autoclaving at 121°C for 15 min. Cultures were maintained in a growth room at 25 ± 2°C with a 16 h photoperiod at a photosynthetic photon flux density (PPFD) of 50–70 μmol m−2 s−1 from cool white fluorescent tubes (Philips, India).

Callus induction and establishment of cell suspension culture

For the callus induction, leaves excised from in vitro proliferated multiple shoots (obtained from nodal segments) were transferred to MG-5, M-9 (Fujita et al. 1981) or MS medium containing different concentrations of 2,4-D (0.0–2.0 mg dm−3). Callus cultures were placed in growth room under the same culture conditions described above. The cell suspension cultures were initiated by culturing approximately 500 mg callus in 250-Erlenmeyer’s flasks each containing 50 ml MG-5 or M-9 or MS medium. The cell suspension cultures were maintained under continuous agitation at 110 rpm on a shaker (Infors AG, CH-4103, Switzerland) and incubated under same culture conditions as described for the induction of callus culture. The cells were subcultured 2–3 times after every 3–4 weeks. Cell growth was observed after 4 weeks of culture using an inverted-microscope (Leica Microsystems, Germany).

Extraction and analysis of alkannin content

The roots collected from the field-grown plants as well as root tissues and callus developed in vitro were oven-dried at 35–40°C for 24 h. After drying, tissues were grounded in a mortar, weighed and dye extracted in chloroform at the room temperature. In the case of cell suspension culture, the cells were centrifuged (5 min at 3,000 rpm) and dye extracted from pellet using procedure described above. For each treatment, samples were used in three replicate. The extracted dye solution was filtered through Whatman paper (Whatman International Ltd., UK). The organic phase was washed thrice with distilled water, dehydrated with MgSO4 and evaporated in vacuo. The residues were weighed and used for the dye analysis. Chloroform soluble alkannin dye was separated on pre-silica coated aluminum sheets (Silica Gel 60, F.254) by TLC. The quantity of alkannin was determined using UV/VIS spectrophotometer (Elico SL 164) according to the procedure of Tabata et al. (1974) and Mita et al. (1994).

Effect of medium compositions on the alkannin content

To evaluate the effect of medium compositions on the alkannin synthesis, callus were cultured on different media, i.e., MS, WPM (McCown and Lloyd 1981), B5, White’s medium (White 1943), MG-5 or M-9 medium.

The alkannin content of roots of field-grown plants and in vitro culture systems

Since alkannin dye is found only in the roots of A. hispidissima, the alkannin content of roots of the field-grown plants and three in vitro culture system, i.e., roots excised from in vitro regenerated plantlets and callus or cell suspension culture established on M-9 medium were analyzed for their comparative study.

Experimental design and statistical analysis

For the aforementioned experiments, 24 replicates were used for each treatment and each experiment was repeated thrice. One replicate means one explant. The results were expressed as mean ± SE of three independent experiments. The data were analyzed statistically using one-way analysis of variance (ANOVA), and the significant differences between means were assessed by Duncan’s multiple range test at P < 0.05.

Results and discussion

Influence of PGRs on shoot multiplication from nodal segments

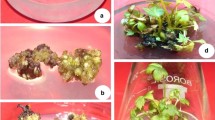

Irrespective of PGRs, the axillary shoots proliferated from the nodal segments within 1–2 weeks of culture. Multiple shoots were induced when nodal segments were inoculated on MS media supplemented with different concentrations of BAP or Kn. The nodal segments cultured on media containing BAP alone had better potential for the multiple shoot induction than kinetin alone (Data not shown). Superiority of BAP over other cytokinins for the shoot multiplication was reported in number of other medicinal plant species (Agarwal et al. 2005; Ray and Bhattacharya 2008; Singh et al. 2009). The probable reason for this may be attributed to the ability of plant tissues to metabolize BAP more readily than other synthetic growth regulators or to the ability of BAP to induce production of natural hormones such as zeatin within the tissue (Rai et al. 2010). However, the number of shoots per explants increased significantly (P < 0.05) when IAA was added in BAP or Kn containing medium. MS medium containing 0.5 mg dm−3 BAP and 0.1 mg dm−3 IAA was most effective for shoot multiplication (Table 1; Fig. 2). It was observed that repeated or successive transfer of explants on this medium increased the number of shoots to 17.2 from 4.2 after 2–3 transfers (Table 1). The increase in shoot number may be due to suppression of apical dominance during subculture that induced basal dormant meristametic cells to form new shoots (Tripathi and Kumari 2010).

Rooting in in vitro regenerated shoots

Successful rooting in regenerated shoots is the prerequisite to facilitate their establishment in soil. In the present study, the role of different auxins (IAA, IBA and NAA) in the root induction was tested. Among different concentrations of three auxins tested, IBA (1.0 mg dm−3) was found to be better for the rooting in shoots (Table 2; Fig. 3). Auxins especially IBA is used widely to induce adventitious roots in many woody and herbaceous plant species (Rathore and Shekhawat 2009; Rathore et al. 2010). The present study clearly indicates that half-strength MS medium was adequate for the root induction. Relatively low salt concentration in the medium is known to enhance rooting of shoots (Rai et al. 2010).

Effect of medium compositions on the alkannin content in callus and cell suspension culture

Among different medium compositions (MS, WPM, B5, White, MG-5 or M-9 medium) tried, highest alkannin content was recorded in callus culture established on M-9 medium (Fig. 4). Cell suspension cultures of A. hispidissima were established by culturing the friable calluses (induced on callus induction medium) in liquid MS, MG-5 or M-9 medium. Similar to callus culture, highest alkannin content from cell suspension culture was also observed on M-9 medium. M-9 medium contains low concentrations of nitrogen. Zhong and Wang (1998) also reported that lower concentrations of nitrogen resulted in the highest accumulation of ginsenoside in Panax quinquefolium suspension cultures. Reduced levels of NH4 + have also been found to promote the production of secondary metabolites in many plants (Fujita et al. 1981; Praveen and Murthy 2011).

The alkannin content of roots of field-grown plants and in vitro culture systems

The alkannin content in the roots of A. hispidissima plants growing under field conditions was significantly (P < 0.05) less than the alkannin content of all in vitro grown culture systems, i.e., cell suspension, callus and roots (Table 3). Under in vitro conditions, differentiation of cell or tissue is generally associated with an increased synthesis of secondary products because these cells are more metabolically competent (Collin 2001; Nasim et al. 2010). Similar to our observation, a higher accumulation of bioactive compounds was also reported in in vitro culture systems of many plants when compared with natural plants (Wu et al. 2007; Nasim et al. 2010; Praveen and Murthy 2011).

In conclusion, our study points out that the alkannin production varies depending upon the type of tissue, culture medium and culture conditions. The present investigation may be applicable in designing systems for the large-scale cultivation of A. hispidissima cell suspensions for the production of alkannin, and offers the possibility of production of other secondary metabolites like arnebinol, arnebinone, cycloarnebin-7, tiglic acid found in this plant (Sharma et al. 2009). As the regeneration system developed from nodal explants in the present study is direct, the system also has implications for the genetic manipulations and propagation of genetically modified plants.

Abbreviations

- BAP:

-

6-benzylaminopurine

- 2,4-D :

-

2,4-dichlorophenoxyacetic acid

- IAA:

-

Indole-3-acetic acid

- IBA:

-

Indole-3-butyric acid

- Kn:

-

Kinetin

- MS:

-

Murashige and Skoog (1962) medium

- NAA:

-

α-naphthalene acetic acid

- PGRs:

-

Plant growth regulators

- PPFD:

-

Photosynthetic photon flux density

- TLC:

-

Thin layer chromatography

- WPM:

-

Woody plant medium

References

Agarwal V, Kumar R, Sharma K (2005) In vitro clonal propagation of Holarrhena antidysenterica (L.) Wall. through nodal explants from mature trees. In Vitro Cell Dev Biol Plant 41:137–144

Chan LK, Lim PS, Choo ML, Boey PL (2010) Establishment of Cyperus aromaticus cell suspension cultures for the production of juvenile hormone III. In Vitro Cell Dev Biol Plant 46:8–12

Collin HA (2001) Secondary product formation in plant tissue cultures. Plant Growth Regul 34:119–134

Fujita Y, Hara Y, Suga C, Morimoto T (1981) Production of shikonin derivatives by cell suspension culture of Lithospermum erythrorhizon. II. A new medium for the production of shikonin derivatives. Plant Cell Rep 1:61–63

McCown BH, Lloyd G (1981) Woody Plant Medium (WPM)–a mineral nutrient formulation for microculture for woody plant species. Hort Sci 16:453

Mita G, Gerardi C, Miceli A, Bollini R, Deleo P (1994) Pigment production from in vitro cultures of Alkanna tinctoria Tausch. Plant Cell Rep 13:406–410

Murashige T, Skoog F (1962) A revised medium for rapid growth and bioassay with tobacco tissue culture. Physiol Plant 15:473–497

Nasim SA, Dhir B, Kapoor R, Fatima S, Mahmooduzzafar, Mujib A (2010) Alliin production in various tissues and organs of Allium sativum grown under normal and sulphur-supplemented in vitro conditions. Plant Cell Tissue Organ Cult 101:59–63

Pal M, Chaudhury A (2010) High frequency direct plant regeneration, micropropagation and shikonin induction in Arnebia hispidissima. J Crop Sci Biotech 13:13–19

Piekoszewska A, Ekiert H, Zubek S (2010) Arbutin production in Ruta graveolens L. and Hypericum perforatum L. in vitro cultures. Acta Physiol Plant 32:223–229

Praveen N, Murthy HN (2011) Effects of macroelements and nitrogen source on biomass accumulation and withanolide-A production from cell suspension cultures of Withania somnifera (L.) Dunal. Plant Cell Tissue Organ Cult 104:119–124

Praveen N, Naik PM, Manohar SH, Nayeem A, Murthy HN (2010) In vitro regeneration of brahmi shoots using semisolid and liquid cultures and quantitative analysis of bacoside A. Acta Physiol Plant 31:723–728

Rai MK, Asthana P, Jaiswal VS, Jaiswal U (2010) Biotechnological advances in guava (Psidium guajava L.): recent developments and prospects for further research. Trees Struct Funct 24:1–12

Rathore MS, Shekhawat NS (2009) Micropropagation of Pueraria tuberosa (Roxb. Ex Willd.) and determination of puerarin content in different tissues. Plant Cell Tissue Organ Cult 99:327–334

Rathore MS, Rathore MS, Shekhawat NS (2010) Ex vivo implications of phytohormones on various in vitro responses in Leptadenia reticulata (Retz.) Wight. & Arn.—an endangered plant. Environ Exp Bot (in press)

Ray A, Bhattacharya S (2008) An improved micropropagation of Eclipta alba by in vitro priming with chlorocholine chloride. Plant Cell Tissue Organ Cult 92:315–319

Sharma RA, Singh B, Singh D, Chandrawat P (2009) Ethnomedicinal, pharmacological properties and chemistry of some medicinal plants of Boraginaceae in India. J Med Plant Res 3:1153–1175

Singh SK, Rai MK, Asthana P, Sahoo L (2009) An improved micropropagation of Spilanthes acmella L. through transverse thin cell layer culture. Acta Physiol Plant 31:693–698

Tabata M, Mizukami H, Hiraoka N, Konoshima M (1974) Pigment formation in callus cultures of Lithospermum erythrorhizon. Phytochemistry 13:927–932

Tripathi M, Kumari N (2010) Micropropagation of a tropical fruit tree Spondias mangifera Willd. through direct organogenesis. Acta Physiol Plant 32:1011–1015

White PR (1943) Handbook of plant tissue culture. Cattell and Co, Lancaster

Wu CH, Murthy HN, Hahn EJ, Paek KY (2007) Large-scale cultivation of adventitious roots of Echinacea purpurea in airlift bioreactors for the production of chichoric acid, chlorogenic acid and caftaric acid. Biotechnol Lett 29:1179–1182

Zhong JJ, Wang SJ (1998) Effects of nitrogen source on the production of ginseng saponin and polysaccharide by cell cultures of Panax quinquefolium. Proc Biochem 33:671–675

Acknowledgments

We are grateful to the Department of Biotechnology (DBT), Department of Science and Technology (DST), University Grants Commission (UGC) for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by B. Borkowska.

Rights and permissions

About this article

Cite this article

Shekhawat, M.S., Shekhawat, N.S. Micropropagation of Arnebia hispidissima (Lehm). DC. and production of alkannin from callus and cell suspension culture. Acta Physiol Plant 33, 1445–1450 (2011). https://doi.org/10.1007/s11738-010-0680-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11738-010-0680-x