Abstract

This work describes the development and assessment of a novel electrochemical sensor based on silver nanoparticles (Ag NPs) and carboxylated multi-walled carbon nanotubes (c-MWCNTs) modified Glassy Carbon Electrode (GCE) for the detection of carbosulfan (CBS), a carbamate pesticide, in food samples using cyclic voltammetry (CV), and differential pulse voltammetry (DPV) analyses. By utilizing the complementary properties of Ag NPs and c-MWCNTs, the sensor’s sensitivity, selectivity, and stability are improved. With a noticeably decreased detection limit across a wide range of CBS concentrations, the Ag NPs/c-MWCNTs/GCE combination showed excellent electrochemical performance. The peak current and CBS concentration showed a strong linear connection between 1 and 726 µM. With a detection limit as low as 0.009 µM, the constructed sensor has a sensitivity of 0.31317 µA/µM. The sensor’s potential for monitoring CBS in actual samples was indicated by its good stability, repeatability, and satisfactory anti-interference performance. The results of a real sample analysis of CBS in tomato samples indicated a relative standard deviation value ranging from 3.42 to 4.52% and a significant recovery within the range of 97.00–99.33%. The creation of this sensor will have a big impact on public health and environmental monitoring. In the end, it can protect public health by lowering the danger of pesticide exposure, increasing food safety, and enabling more selective and sensitive detection of carbosulfan residues in food.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Chemicals called pesticides are applied to crops to keep pests under control and boost production. There are various reasons why the use of pesticides in food production is important. First and foremost, pesticides are essential for shielding crops from pests and guaranteeing more agricultural output. This is particularly crucial to ensuring dependable food supplies for expanding populations [1]. Furthermore, pesticides lessen the financial losses brought on by pest infestations. Nonetheless, there are a few benefits and drawbacks to using pesticides [2]. One benefit is that pesticides can help produce high-quality crops more effectively [3]. . One benefit is that pesticides can help produce high-quality crops more effectively [4]. When pesticide residues remain in food, especially carbamates, they can have a negative impact on human health. Moreover, overuse of pesticides can result in water pollution, which is harmful to human water supplies and aquatic habitats [5]. Pesticides that contain carbamates, such carbosulfan, are very dangerous for the environment and human health. Prolonged exposure to these chemicals can cause respiratory issues, cancer, and detrimental effects on the nervous system in humans. In addition, they have the potential to contaminate water and soil resources, harming wildlife and upsetting ecosystems. As a result, it is crucial to find and keep an eye out for carbamate insecticides in food and the environment.

A class of compounds called carbamate insecticides is frequently used in agriculture to control pests [6]. For this investigation, we decided to concentrate on carbosulfan (CBS) among the many carbamate insecticides. Due to its broad spectrum of pesticide effectiveness, CBS is one of the most widely used carbamate insecticides in agriculture globally. On the other hand, persistent exposure to it is known to be extremely hazardous to humans and the environment, resulting in major health concerns such respiratory and neurological illnesses. There are currently no reliable techniques for identifying CBS residues in food, despite the fact that it is highly hazardous and common. Because of CBS’s unique chemical characteristics, many of the detection techniques now in use are either too sensitive or too selective. Consequently, the goal of our research was to close this gap by creating a more accurate and focused CBS detection sensor. Carbasulfan (CBS; C20H32N2O3S), a member of the carbamate chemical class, is one well-known example. With regard to CBS in particular, Fig. 1 [7] illustrates how its chemical structure is distinguished by a carbamate functional group. Because eating them may pose health hazards, it is crucial to identify the presence of carbamate insecticides in food. In order to protect food safety and reduce the negative effects of pesticide residues on human health and the environment, these materials need to be investigated for potential detection methods [8].

Numerous techniques have been advanced in the field of pesticide detection to study and detect CBS residues in food, including colorimetric assay [9], micellar electrokinetic chromatography [10], high-performance liquid chromatography with post-column fluorescence [11], liquid chromatography coupled to quadrupole tandem mass spectrometry [12], surface-enhanced Raman spectroscopy [13] and Spectrophotometry [14]. Numerous techniques have been devised for the identification of pesticides, each possessing pros and cons concerning effectiveness, expense, and usefulness. For example, colorimetric assays are easy to use and reasonably priced, but they are not sensitive or selective [9]. High resolution and efficiency are provided by micellar electrokinetic chromatography, although it takes a long time and expensive equipment [10]. High-performance liquid chromatography provides high sensitivity and selectivity but is also costly and requires skilled operators [11]. Surface-enhanced Raman spectroscopy is highly sensitive but can be affected by environmental factors and requires complex sample preparation [13]. Because of their sensitivity, selectivity, and ability to conduct analyses quickly, electrochemical methods have drawn the most interest among these strategies [15, 16]. Benefits of electrochemical technologies include cost-effectiveness, real-time monitoring, and the capacity to function in watery settings. Additionally, there has been a surge in research into the use of nanostructures in electrochemical sensors [17]. Due to the enhanced analyte-sensing interactions and wide surface area that nanostructures offer, improved sensitivity and selectivity are made possible. Nanostructures are essential for improving the performance of electrochemical sensors because they offer a platform for immobilizing particular recognition elements [18]. Improved detection limit, reaction time, and overall resilience are all impacted by the introduction of nanostructures in electrochemical sensors. All things considered, addition of nanostructures to electrochemical sensors is a promising way to improve the identification of pesticide residues, including CBS, in food, improving food safety and safeguarding the environment [15].

Certain nanostructures, like multi-walled carbon nanotubes (MWCNTs) and silver nanoparticles (Ag NPs), can be used to create electrochemical sensors that can identify pesticide residues like CBS. The unique characteristics of these nanostructures greatly improve the functionality of electrochemical sensors. Ag NPs have a great electroactive surface area, excellent electrical conductivity, and chemical stability, all of which improve the performance of the electrochemical sensor [19]. Ag NPs’ characteristics enhance electron transfer kinetics, which raises sensitivity and lowers detection limits [20]. Furthermore, Ag NPs’ catalytic activity can improve the sensor’s selectivity for the target analyte, such as CBS [21]. MWCNTs, on the other hand, are renowned for their remarkable mechanical strength, electrical conductivity, and huge specific surface area [22]. The electrode performance of electrochemical sensors is directly improved by these characteristics. Because of their strong and conductive electrode surface, MWCNTs improve stability. Furthermore, because of their large surface area, they immobilize recognition components more effectively, improving sensitivity and selectivity against pesticide residues like CBS [23]. Moreover, MWCNT carboxylation can improve these sensor qualities even more. MWCNTs become more soluble and dispersible after carboxylation, which enhances their ability to interact with recognition elements [24]. This alteration also improves the sensor’s selectivity by enabling targeted binding interactions with the target analyte, which results in increased sensitivity and stability. As a result, it is a favorable option for detecting pesticide residue in food samples [25,26,27].

Ag NPs and c-MWCNTs are two examples of nanostructures that are essential to improving the functionality of our electrochemical sensor. Ag NPs, for example, enhance the performance of the electrochemical sensor due to their huge electroactive surface area, superior electrical conductivity, and chemical stability. Ag NPs’ unique properties improve electron transfer kinetics, lowering detection limits and increasing sensitivity. Furthermore, the selectivity of the sensor for the target analyte, such as CBS, can be enhanced by the catalytic activity of Ag NPs. Conversely, c-MWCNTs are well known for their enormous specific surface area, electrical conductivity, and exceptional mechanical strength. These features enhance electrochemical sensors’ electrode performance directly. Stability is enhanced by c-MWCNTs because of their robust and conductive electrode surface. They also more efficiently immobilize recognition components due to their wide surface area, which enhances sensitivity and selectivity against pesticide residues like CBS.

This study created an electrochemical sensor to detect CBS as carbamate pesticide residues in food samples. The sensor is based on a modified glassy carbon electrode with Ag NPs and MWCNTs. The addition of Ag NPs and carboxylated MWCNTs to the glassy carbon electrode, which greatly improves the sensor’s sensitivity, selectivity, and stability for the detection of CBS, is what makes this work novel. Highly sensitive and selective detection of carbamate residues in complex food matrices is made possible by the enhanced electrochemical response resulting from the synergistic actions of Ag NPs and carboxylated MWCNTs. In order to solve the difficulties in detecting carbamate pesticides in food, the electrode modification with these CBS is a novel strategy that shows promise for improving food safety and protecting the public’s health in the long run. This paper offers a thorough analysis of a new electrochemical sensor for the identification of CBS in ambient water. The sensor is built around a special framework made of cutting-edge nanomaterials. Using a variety of analytical techniques, the structure and morphology of the sensor were thoroughly investigated, exposing its special qualities and benefits. Using CV and DPV, the electrochemical behaviour of the sensor was investigated, and the optimal performance was attained by optimizing the parameters of both the electrochemical analysis and sensor manufacture. The sensor has a large linear range, a low detection limit, and outstanding sensitivity, stability, and selectivity. Additionally, it performed satisfactorily in an actual sample analysis.

Experimental section

Materials

Purchased from Sigma-Aldrich in the USA were multiwalled carbon nanotubes (MWCNTs, > 99% purity), concentrated sulfuric acid (H2SO4), nitric acid (HNO3), monosodium phosphate (NaH2PO4, ≥ 99.0%), and disodium phosphate (Na2HPO4, > 98% purity). We also acquired anhydrous trisodium citrate and silver nitrate (AgNO3, 99.8% purity) from Sigma-Aldrich, USA. Merck, a German company, provided 99.7% pure isopropanol. We purchased a glassy carbon electrode (GCE, 3 mm diameter) from bioanalytical systems, Inc. in the United States. Without any extra purification, all compounds were used exactly as they were supplied. The entire experiment was conducted with deionized water. The ingredients for 0.1 M phosphate buffered saline (PBS) were NaH2PO4 and Na2HPO4.

Instrumentation

A D8 Advance X-ray diffractometer (Bruker, Germany) was used for X-ray diffraction (XRD) analyses. X-ray photoelectron spectroscopy (XPS) measurements were done using an ESCALAB 250Xi (Thermo Fisher Scientific, USA). With a JSM-7800 F (JEOL, Japan), images for scanning electron microscopy (SEM) were taken. Photomicroscopy (TEM) images were captured using a JEM-2100 F (JEOL, Japan).

Using a three-electrode setup, cyclic voltammetry (CV), and differential pulse voltammetry (DPV) were performed as electrochemical analyses on a CHI660E Electrochemical Workstation (CH Instruments, USA). A working electrode (bare or modified GCE), a reference electrode (Ag/AgCl, 3 M KCl), and a counter electrode (platinum wire) were usually included in this arrangement. The CV measurements were performed at 20mV/s scan rate. A 20-mV pulse amplitude, a 50 ms pulse width, and a 2-mV step increment were utilized for the DPV experiments. 0.1 M PBS was the electrolyte utilized in the electrochemical analyses. With the use of a pH meter (pHS-3 C, Shanghai REX Instrument Factory, China), the pH of the PBS solution was measured and brought to 7.4. A battery of exacting tests was used to validate the sensor’s performance. In order to determine the link between the sensor’s response and the CBS concentration, calibration procedures were first performed using known concentrations of CBS. Using DPV to analyze the sensor’s response, it was discovered that, within a specific range, the peak current increased linearly with the CBS concentration, suggesting satisfactory calibration. Second, the selectivity of the sensor was assessed by seeing how it responded to CBS in the presence of possible interfering agents. The sensor’s exceptional selectivity was demonstrated by a noticeably stronger response to CBS than the interferents. Finally, utilizing common reference materials, the sensor’s performance was further verified. The sensor’s accuracy was confirmed when it was discovered that the CBS concentrations it measured agreed well with the verified values of the standard reference materials.

Preparation of Ag NPs/c-MWCNT/GCE

0.5 g of MWCNTs were evenly dispersed in 20 mL of a 3:1 volume ratio mixed solution of H2SO4 and HNO3 [28]. The concoction was stirred for an hour at 70 degrees Celsius. The mixture was then diluted with deionized water. After centrifugation, the carboxylated MWCNTs (c-MWCNTs) were extracted from the mixture and repeatedly washed with water. The finished product was dried at 30 °C in a vacuum oven.

Citrate was used to create Ag NPs as a reducing and stabilizing agent [29]. After heating 50 mL of a 1 mM AgNO3 solution, 50 mL of a 1 mM anhydrous trisodium citrate solution was added dropwise while stirring continuously at boiling temperature. This resulted in a pale-yellow mixture that exhibited the synthesis of citrate-capped Ag NPs. Subsequently, the light-yellow liquid was stirred for 20 min at 80 °C, resulting in a light orange suspension that suggested the production of silver nanoparticles.

A suspension of c-MWCNTs containing 0.5 weight% isopropanol was made by ultrasonography for a duration of one hour. To guarantee thorough coverage, 50 µL of the c-MWCNTs suspension was drop-casted onto a spotless GCE surface. The electrode was then left to dry for three hours at room temperature. Then, to obtain Ag NPs/c-MWCNT/GCE, 10 µL of an Ag NPs suspension was drop-cast on the prepared c-MWCNT/GCE and allowed to cure at room temperature for 10 h.

Real sample preparation

We purchased our tomatoes from a nearby market. To get rid of any surface impurities, distilled water was used to correctly wash each tomato. After that, about 300 g of the fresh tomatoes were roughly cut into little bits. Using a blender, the diced tomatoes were made uniformly smooth. After the material had been homogenized, 50 mL of 0.1 M PBS was added to a beaker. At room temperature, the mixture was swirled for thirty minutes. The mixture was stirred and then filtered using Whatman No. 1 filter paper. Before being subjected to an electrochemical study, the filtrate was collected, centrifuged for five minutes, and then kept at 4 °C.

Results and discussion

Structure and morphology

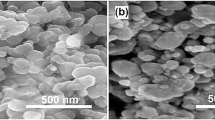

Ag NPs/c-MWCNT/GCE SEM picture is shown in Fig. 2. The typical diameter of a c-MWCNT is about 85 nm, and these c-MWNTs are long bundles with a smooth surface. Ag nanoparticles of various sizes are spherical and well-adorned on the surfaces of the c-MWNTs, as shown in the Ag NPs/c-MWCNT/GCE SEM picture. The surface area of the c-MWNTs is increased by the nanoparticle decorating, which can boost the material’s electrochemical performance.

To further verify that there were silver particles in the product, XRD was used. The XRD results for the Ag NPs/c-MWCNT and c-MWCNT are shown in Fig. 3a. Ag (111), Ag (200), Ag (220), and Ag (311), the four primary crystallographic planes associated with the face-centered cubic structure Ag (JCPDS no-65–2871), were exhibited by the Ag [30]. The XRD peak of crystalline graphite-like structures’ C (100) plane was visible in the MWCNT [31, 32].

A pristine MWCNTs sample devoid of carboxyl groups was used to generate a mesoporous Ag NPs/MWCNTs under the similar circumstances as the Ag NPs/c-MWCNTs in order to clarify the purpose of the carboxyl groups on MWCNTs (c-MWCNTs). The XPS survey spectra of Ag NPs/c-MWCNTs, Ag NPs/MWCNTs, and c-MWCNTs are shown in Fig. 3b. A C1s peak at around 284 eV, an O1s peak at roughly 530 eV, and an Ag3d peak at roughly 372 eV can be seen in the XPS spectra of Ag NPs/c-MWCNTs from Fig. 3b, suggesting that the Ag NPs/c-MWCNTs contain C, O, and Ag, respectively. While C and O come from c-MWCNTs, Ag comes from metallic nanoparticles. The C 1s XPS study of MWCNTs and c-MWCNTs is shown in Fig. 3c. Four peaks at 283.8, 284.9, 285.8, and 288.0 eV can be fitted to the C1s spectrum of c-MWCNTs, and they are attributed to the hydroxyl carbon (C–O), sp2 carbon, sp3 carbon, and O = C–O functional groups, respectively [33, 34]. The development of carboxylate functional groups in the c-MWCNTs is showed by the absence of a C = O group in the MWCNTs and the presence of this group in the c-MWCNTs [35]. The c-MWCNTs’ solubility and dispersion in a range of liquids can be improved by this carboxylation. Ag 3d5/2 peak at 368.1 eV and the Ag 3d3/2 peak at 374.1 eV are visible in the Ag3d XPS spectra of Ag NPs/c-MWCNTs (Fig. 3d), and they are ascribed to metallic Ag [36]. These results are entirely consistent with the data obtained by XRD and SEM.

Electrochemical studies

The c-MWCNTs’ solubility and dispersion in a range of liquids can be improved by this carboxylation. Ag 3d5/2 peak at 368.1 eV and the Ag 3d3/2 peak at 374.1 eV are visible in the Ag3d XPS spectra of Ag NPs/c-MWCNTs (Fig. 3d), and they are attributed to metallic Ag0 [37]. The cyclic voltammograms of electrodes in 0.1 M PBS, which contains a 25 µM CBS solution, are displayed in Fig. 4b. At a potential of 0.30 V, a low-intensity redox peak for GCE can be seen, which is connected to the oxidation of CBS. At 0.29 V, the c-MWCNTs/GCE shows a more pronounced peak. Ag NPs/MWCNTs/GCE and Ag NPs/c-MWCNTs/GCE had different, higher current oxidation peaks for CBS at 0.27 V and 0.28 V, respectively, and a typical oxidation peak for Ag0/Ag+ on their CVs. This implies that Ag NP binding to MWCNT walls enhances the oxidation peak current and makes a quick electron transport channel [38]. Ag NPs’ effective electron transfer and MWCNTs’ simple functionalization in Ag NPs/c-MWCNTs /GCE combine to produce a large amount of electrocatalytic activity for the simultaneous measurement of CBS [39]. In contrast to Ag NPs/MWCNTs/GCE, the Ag NPs/c-MWCNTs/GCE exhibits a higher peak current for the analyte’s oxidation. The carboxylation of the MWCNTs is responsible for this increase in peak current, which also enhances the electrode’s determination response.

Similar to aminocarb, carbosulfan can hydrolyze quickly if an unstable carbamate cation radical changes. A methylamine and a dimethylaminophenol cation radical may be produced as a result of this method [40, 41]. Given that carbosulfan and aminocarb have similar structures and levels of reactivity, the rate of this reaction may be faster for carbosulfan than for zectran [40, 42]. Dimethylbenzoquinoneimine might then be shaped by a second spontaneous oxidation of the result, phenol [40, 43]. Improved electrochemical performance could result from this two-step oxidation process by increasing the peak current for the oxidation of the analyte on the Ag NPs/c-MWCNTs/GCE surface. According to the proposed mechanism, one of the most important factors in enhancing the electrode’s determination response is the carboxylation of MWCNTs in relation to the electrodes’ CV responses. The MWCNTs’ carboxyl groups improve their solubility and dispersion in a range of solvents, which makes it easier for Ag NPs to adhere to them and increases the efficiency of electron transmission [44, 45]. Thus, improving the electrochemical performance of Ag NPs/c-MWCNTs/GCE needs carboxylation of MWCNTs.

Influence of pH and optimization of synthesis parameters

Under various pH settings, the electrochemical behavior of Ag NPs, c-MWCNTs, and GCE towards CBS was investigated. The peak current values from the CV curves at Ag NPs/c-MWCNTs/GCE for the oxidation of 25 µM CBS over a pH range of 3.0 to 8.5 (0.1 M PBS) are shown in Fig. 5a. Peak currents for CBS indicate that the pH increased from 3.0 to 7.2 and then decreased from 7.2 to 8.5. For the following investigations including the electrochemical detection of CBS, a pH value of 7.2 was selected because of the physiological context and enhanced electrochemical performance.

The impacts of different parameters in the electrode manufacturing process, such as the quantities of c-MWCNTs and Ag NPs, were examined in order to optimize the detection sensitivity of the Ag NPs/c-MWCNTs/GCE for CBS. By creating the Ag NPs/c-MWCNTs/GCE using varying volumes of c-MWCNTs suspension (5-100µL), the impact of the c-MWCNTs quantity was investigated. The peak current response of the CV of Ag NPs/c-MWCNTs/GCE is shown in Fig. 5b, which illustrates the effect of the c-MWCNTs suspension volume. The peak current was measured for CBS oxidation at a potential of 0.27 V in a 0.1 M PBS solution containing 25 µM CBS. As the volume of the c-MWCNTs suspension increases, the electrocatalytic current increases as well, improving the conductivity of the electrode. Nevertheless, the electrocatalytic current drops below a volume of 50 µL. Additionally, Fig. 5c displays how the peak current response of the Ag NPs/c-MWCNTs/GCE CV is affected by the suspension volume of Ag NPs. The findings show that the largest peak current for the prepared Ag NPs/c-MWCNTs/GCE is obtained when 10 µL of an Ag NPs suspension is drop-cast onto the prepared c-MWCNT/GCE. Consequently, the ideal conditions for preparing Ag NPs/c-MWCNTs/GCE were determined to be 50 µL of the c-MWCNTs suspension and 10 µL of an Ag NPs suspension. These results emphasize how crucial it is to refine the synthesis conditions in order to improve the Ag NPs/c-MWCNTs/GCE electrochemical performance towards CBS. The findings also highlight how important pH is in determining how the electrode behaves electrochemically.

Electrochemical Analysis of CBS using the ag NPs/c-MWCNTs/GCE electrode

In 0.1 M PBS, the electrochemical behavior of Ag NPs, c-MWCNTs, and GCE in response to different CBS concentrations was investigated. The DPV response at Ag NPs/c-MWCNTs/GCE at CBS concentrations ranging from 0 to 726 µM is revealed in Fig. 6a. when can be seen, when the concentration of CBS rises, so does the oxidation peak current. In Fig. 6b, the peak currents that correlate with various CBS concentrations are extracted and shown. It’s important to remember that many experiments (n = 4) were utilized to calibrate the artificial sensor for CBS detection. Peak current and CBS concentration show a strong linear connection from 1 to 726 µM; the fitting equation is y = 0.31317x + 0.98651 (R2 = 0.99983). The constructed sensor has a sensitivity of 0.31317 µA/µM and a detection limit (LOD) of 0.009 µM (S/N = 3). Table 1 provides a summary of these findings and compares them with earlier research utilizing different active nanomaterials. According to the data, the created Ag NPs/c-MWCNTs/GCE exhibits better electrochemical performance throughout a wide range of CBS concentrations, with a noticeably reduced detection limit. The porous structure of the Ag NPs/c-MWCNTs, which offers more active sites, and the anchoring Ag NPs, which are essential catalysts in the redox process, are responsible for this improved performance. This shows that the Ag NPs/c-MWCNTs/GCE’s low detection limit and great sensitivity for CBS are mostly due to their design and manufacture. With a notably smaller detection limit and a larger linear range than other sensors described in the literature, the Ag NPs/c-MWCNTs/GCE sensor created in this study performs better electrochemically, as Table 1 illustrates. This illustrates how well our sensor design works and how important Ag NPs and c-MWCNTs are to improving the sensor’s functionality.

Interference, stability and reproducibility

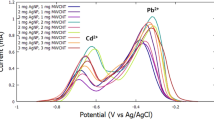

Certain chemicals have the ability to interfere with the precise measurement of CBS in food samples. Thus, an analysis of the interference research utilizing the Ag NPs/c-MWCNTs electrode for CBS detection was carried out. The resulting DPV peak at 0.27 V for the sequential addition of drugs with or without the CBS solution is shown in Fig. 7a. A 10-fold excess of putative interfering species (chlorpyrifos (CPF), malathion (MAL), permethrin (PMT), atrazine (ATZ), glyphosate (GLO), Cd2+, Pb2+, and Hg2+) was examined for the DPV response of 5 µM CBS in the PBS solution. No peak overlap was found. Furthermore, the DPV response shows only slight variations when the previously indicated interfering species are added one after the other in the electrochemical sensing of CBS. Furthermore, there was no appreciable change in DPV current for the substance’s solution at the changed electrode. This leads to the conclusion that, in the presence of a 10-fold excess of the required interferences, CBS can be accurately analyzed using Ag NPs/c-MWCNTs/GCE. The distinct electrocatalytic characteristics of the Ag NPs/c-MWCNTs electrode, which enable the precise identification and measurement of CBS even in the presence of substantial concentrations of interfering substances, are responsible for the observed selectivity in the detection of CBS among the possible interfering species. The DPV response’s absence of peak overlap and the interference testing’s steady, small changes highlight the electrode’s capacity to identify CBS with selectivity. For the accurate and trustworthy measurement of CBS in complex sample matrices, like food samples, where contamination from other compounds is a regular difficulty, this strong selectivity is essential. It has been determined that Ag NPs, c-MWCNTs, and GCE have outstanding stability towards CBS. With a relative standard deviation (RSD) of 2.38%, the DPV responses at Ag NPs/c-MWCNTs/GCE towards 5 µM CBS for 20 measurements indicate no discernible change in the current responses of CBS. The CBS electrochemical analysis at Ag NPs/c-MWCNTs/GCE was carried out at 5-day intervals, and the 30-day test showed outstanding stability in the current responses, with a current decay of 4.62%. The synergistic effect of Ag NPs and c-MWCNTs is responsible for the remarkable stability of Ag NPs/c-MWCNTs/GCE towards CBS. The c-MWCNTs increase the electrode’s conductivity and electron transfer rate, while the Ag NPs offer a significant surface area for the adsorption of CBS.

Seven different people created Ag NPs, c-MWCNTs, and GCEs using the identical conditions and procedures to test the reproducibility of these materials towards CBS. The analysis’s findings indicate that Ag NPs, c-MWCNTs, and GCE have good repeatability, with no discernible variation in the oxidation peak signals and a small fluctuation of roughly 4.05% in RSD on peak current. The produced Ag NPs/c-MWCNTs/GCE demonstrates good stability, anti-interference, and reproducibility, suggesting that it may find use in real-world sample CBS monitoring. The consistency of the Ag NPs/c-MWCNTs/GCE surface and the homogeneity of the fabrication process are responsible for the good repeatability of Ag NPs/c-MWCNTs/GCE towards CBS.

(a) The obtained peak current at 0.27 V from DPV response at Ag NPs/c-MWCNTs/GCE in 0.1 M PBS (pH 7.2) containing 5 µM CBS without and with 10-fold excess of potential interfering species, (b) Stability of DPV response at Ag NPs/c-MWCNTs/GCE in 0.1 M PBS holding 5µM CBS for 20 cycles. (c) Long-term stability measurements at Ag NPs/c-MWCNTs/GCE repeatedly tested within 30 days. (d) Reproducibility measurements for seven Ag NPs/c-MWCNTs/GCEs fabricated in the same condition and method

Evaluation of real sample analysis

Utilizing the conventional addition approach, the electrochemical detection of CBS in prepared tomato samples was carried out in order to verify the operational performance and viability of the Ag NPs/c-MWCNTs/GCE for real sample analysis. Table 2 provides a full overview of the related outcomes. Interestingly, the measured concentrations of CBS based on Ag NPs/c-MWCNTs/GCE closely match the concentrations of CBS, showing a significant recovery between 97.00% and 99.33% with an RSD value between 3.42% and 4.52%. This result proposes that the Ag NPs/c-MWCNTs/GCE combination developed in this work has great potential for highly reliable CBS detection in biological samples. The high recovery and low RSD, along with the observed strong agreement between the measured and CBS concentrations, highlight the Ag NPs/c-MWCNTs/GCE’s accuracy and resilience for real sample analysis. The low RSD values show the consistency and repeatability of the analytical measurements, while the high recovery % indicates the developed electrode’s capacity to efficiently extract and quantify CBS from complex biological matrices, such as tomato samples. All of these results support the Ag NPs/c-MWCNTs/GCE’s applicability and dependability for real-world applications, especially when it comes to the analysis of CBS in actual food and biological specimens.

Conclusion

In order to detect the carbamate insecticide CBS in food samples, this study successfully created a unique electrochemical sensor based on Ag NPs and c-MWCNTs modified GCE. The sensor’s sensitivity, selectivity, and stability were all greatly improved by the design, which took advantage of the synergistic effects of Ag NPs and c-MWCNTs. The proposed sensor had an extensive linear range of 1–726 µM and a low detection limit of 0.009 µM, demonstrating excellent performance in terms of sensitivity, selectivity, and stability. An actual sample analysis of CBS in tomato samples was used to confirm the sensor’s performance, and the results showed a low relative standard deviation and high recovery %. However, there were also talks about possible drawbacks, like the difficulty of fabricating sensors and the requirement for additional testing on different kinds of food or environmental samples. Notwithstanding these possible drawbacks, our research offers a significant starting point for the creation of efficient pesticide detection sensors. Because the study’s findings make it possible to identify pesticide residues in food more precisely and selectively, they have important ramifications for enhancing food safety and safeguarding the general public’s health. The sensor performed better electrochemically, showing a much lower detection limit over a wide range of CBS concentrations. This demonstrates the sensor’s quality rather than merely how many detections it is capable of making. The sensor’s outstanding stability, repeatability, and anti-interference properties highlight its potential for real-world use in monitoring CBS in actual samples. The operational effectiveness and viability of the sensor were evaluated by real sample analysis of CBS in tomato samples. The sensor’s capacity to consistently and reliably extract and quantify CBS from complicated biological matrices is demonstrated by the high recovery percentage and low RSD values. Conclusively, Ag NPs/c-MWCNTs/GCE exhibit potential in identifying CBS in actual food and biological specimens, hence augmenting food safety and safeguarding public health. The study’s conclusions support the sensor’s applicability and dependability for real-world uses, highlighting the significance of creative solutions to the problems posed by the detection of carbamate pesticides in food. The intricate and labor-intensive nature of the sensor fabrication process is one of our study’s drawbacks, and it may prevent large-scale production. Subsequent investigations may concentrate on streamlining the production procedure or investigating more effective synthesis techniques for Ag NPs and MWCNT carboxylation. Another drawback is that more testing is required to see whether our sensor is capable of identifying CBS in environmental samples or other forms of food. More diverse sample types, such as various fruits, vegetables, and water samples from different sources, could be used in future research to test the sensor. Finally, a full investigation into the sensor’s long-term stability under a range of environmental factors, including temperature and humidity, is still pending. To make sure the sensor is reliable and resilient, further development may entail extensive testing in various environmental settings. Real-world uses for this sensor might include food safety, agriculture, and environmental monitoring, all of which depend on the quick and accurate identification of carbamate pesticides. We intend to test the sensor with several kinds of samples in the future, like tap water and industrial effluent. This will verify the sensor’s resilience in various application circumstances and offer insightful information about its potential limitations and practical usability.

References

F.P. Carvalho, Environ. Sci. Policy. 9, 685 (2006)

S.E. Sexton, Z. Lei, D. Zilberman, Int. Rev. Environ. Resource Econ. 1, 271 (2007)

J. Popp, K. Pető, J. Nagy, Sustainable Agric. Reviews: Volume. 13, 19 (2014)

L. Rani, K. Thapa, N. Kanojia, N. Sharma, S. Singh, A.S. Grewal, A.L. Srivastav, J. Kaushal, J. Clean. Prod. 283, 124657 (2021)

M.F.F. Bernardes, M. Pazin, L.C. Pereira, D.J. Dorta, Toxicol. studies-cells Drugs Environ. 195 (2015)

R.C. Gupta, J.K. Malik, D. Milatovic, Organophosphate and Carbamate Pesticides, in Reproductive and Developmental Toxicology (Elsevier, 2011), pp. 471–486

R.L. Ksheerasagar, B.B. Kaliwal, Ind. Health. 46, 210 (2008)

R. Zhou, B. Bai, G. Cai, X. Chen, Comput. Geotech. 167, (2024)

D. Zhu, N. Li, M. Zhang, Y. Wang, F. Li, T. Hou, Biosens. Bioelectron. 243, 115786 (2024)

C.-H. Hsu, C.-C. Hu, T.-C. Chiu, J. Sep. Sci. 35, 1359 (2012)

M. Brooks, A. Barros, Analyst. 120, 2479 (1995)

C. Soler, B. Hamilton, A. Furey, K.J. James, J. Mañes, Y. Picó, Anal. Chim. Acta. 571, 1 (2006)

Q. Ou, B. Tang, L. Jiang, M. Han, W. Yang, J. Tang, G. Liu, Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 290, 122315 (2023)

K. Suresh Kumar, K. Suvardhan, D. Rekha, K. Kiran, G. Chalapathi Rao, B. Jayaraj, K. Janardhanam, P. Chiranjeevi, Environ. Monit. Assess. 129, 271 (2007)

K. Kunpatee, K. Kaewdorn, J. Duangtong, S. Chaiyo, O. Chailapakul, K. Kalcher, M. Kerr, A. Samphao, Microchem. J. 177, 107318 (2022)

G. Lu, L. Duan, S. Meng, P. Cai, S. Ding, X. Wang, Dyes Pigm. 220, (2023)

N. Nesakumar, S. Sethuraman, U.M. Krishnan, J.Bosco, B. Rayappan, Biosensors and Bioelectronics 77, 1070 (2016)

N. Nesakumar, M.B. Gumpu, S. Nagarajan, S. Ramanujam, J.B.B. Rayappan, Measurement. 109, 130 (2017)

M. Waqas, A. Zulfiqar, H.B. Ahmad, N. Akhtar, M. Hussain, Z. Shafiq, Y. Abbas, K. Mehmood, M. Ajmal, M. Yang, Electrochim. Acta. 271, 641 (2018)

L. Cui, J. Wu, J. Li, Y. Ge, H. Ju, Biosens. Bioelectron. 55, 272 (2014)

V. Montes-García, M.A. Squillaci, M. Diez-Castellnou, Q.K. Ong, F. Stellacci, P. Samori, Chem. Soc. Rev. 50, 1269 (2021)

B. Singh, D. Singh, R. Mathur, T. Dhami, Nanoscale Res. Lett. 3, 444 (2008)

I.-H. Cho, D.H. Kim, S. Park, Biomaterials Res. 24, 1 (2020)

M.N. Norizan, M.H. Moklis, S.Z.N. Demon, N.A. Halim, A. Samsuri, I.S. Mohamad, V.F. Knight, N. Abdullah, RSC Adv. 10, 43704 (2020)

L. Zhang, W. Guo, C. Lv, X. Liu, M. Yang, M. Guo, Q. Fu, Adv. Sens. Energy Mater. 1, 100081 (2023)

G. Lu, S. Yu, L. Duan, S. Meng, S. Ding, T. Dong, Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 305, (2024)

J. Chen, B. Bai, Q. Du, Mater. Today Commun. 39, (2024)

Y. Liu, B. Cao, X. Zhang, R. Luo, C. Luo, H. Lin, H. Peng, J. Mater. Sci.: Mater. Electron. 32, 13941 (2021)

N.G. Bastús, F. Merkoçi, J. Piella, V. Puntes, Chem. Mater. 26, 2836 (2014)

J. Wan, E. Liu, J. Fan, X. Hu, L. Sun, C. Tang, Y. Yin, H. Li, Y. Hu, Ceram. Int. 41, 6933 (2015)

A.K. Singh, B.P. Panda, S. Mohanty, S.K. Nayak, M.K. Gupta, J. Mater. Sci.: Mater. Electron. 28, 8908 (2017)

Z. Wang, R. Ma, B. Chen, X. Yu, X. Wang, X. Zuo, B. Liang, J. Yang, Biosens. Bioelectron. 244, (2024)

W.K. Maboya, N.J. Coville, S.D. Mhlanga, S. Afr. J. Chem. 69, 15 (2016)

M. Li, S. Lv, R. Yang, X. Chu, X. Wang, Z. Wang, L. Peng, J. Yang, Anal. Chim. Acta 1283, (2023)

W. Zhang, S. Cao, Z. Wu, M. Zhang, Y. Cao, J. Guo, F. Zhong, H. Duan, D. Jia, Sensors. 20, 149 (2019)

Y. Peng, H. Zhou, Y. Wu, Z. Ma, R. Zhang, H. Tu, L. Jiang, J. Colloid Interface Sci. 609, 188 (2022)

W.Z. Teo, M. Pumera, RSC Adv. 4, 5006 (2014)

P. Veerakumar, C. Rajkumar, S.-M. Chen, B. Thirumalraj, K.-C. Lin, J. Electroanal. Chem. 826, 207 (2018)

S. Mohan, O.S. Oluwafemi, S.P. Songca, D. Rouxel, P. Miska, F.B. Lewu, N. Kalarikkal, S. Thomas, Pure Appl. Chem. 88, 71 (2016)

G. Batley, B. Afgan, J. Electroanal. Chem. Interfacial. Electrochem. 125, 437 (1981)

B. Bai, T. Xu, Q. Nie, P. Li, Int. J. Heat Mass Transf. 153, (2020)

I. Vazquez-Garrido, J. Flores-Aguilar, J. Miranda, E. Santos, C. Jardinez, I. Ibarra, Int. J. Environ. Anal. Chem. (2022)

M.C. Carreno, M. Ribagorda, J. Org. Chem. 65, 1231 (2000)

S. Mallakpour, S. Soltanian, RSC Adv. 6, 109916 (2016)

J. Xiong, D. Wen, H. Zhou, R. Chen, H. Wang, C. Wang, Z. Wu, Y. Qiu, L. Wu, Food Control 137, (2022)

M.M. Ghoneim, H.S. El-Desoky, F.M. El-badawy, High Sensitive Analysis Method for Determination of Carbosulfan Pesticide in Bulk Form, in Soil and in Orange Matrix. in The International Conference on Chemical and Environmental Engineering. 2016. Military Technical College

B. Kuswandi, M.R. Taufikurrohman, A.S. Nugraha, J. Electrochem. Soc. 168, 077502 (2021)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, Z., Cao, L. Electrochemical sensor based on silver nanoparticles/ carboxylated multi-walled carbon nanotubes modified glassy carbon electrode for detection of carbamate pesticide in food. Food Measure 18, 6225–6236 (2024). https://doi.org/10.1007/s11694-024-02642-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-024-02642-3