Abstract

Cooked and oven-dried cowpea in different four concentrations of 0%, 10%, 20%, and 30% was incorporated into nutrition bars (CNB0, CNB10, CNB20, and CNB30 respectively). The nutrition bar contained other ingredients including roasted crushed peanuts, almonds, cashew, oatmeal, raisins, date syrup, hazelnut butter, glucose syrup, sorbitol, and glycerol. The bars were packed and stored at room temperature for 180 days and experiments were conducted at interwall of 30 days. Nutritional value, moisture content, hardness, organoleptic properties, and microbial test of the bars were evaluated. Nutritional values showed that CNB30 is generally more nutritious than other treatments with less energy value. Decrease in moisture content directly affected the hardness of nutrition bar during 6 months storage. However, water–protein interaction modified the textural properties of the samples. Addition of cowpea as a protein source resulted in greater organoleptic properties so that CNB30 received the highest score in overall acceptability even after 180 days with score 6. Microbial count of sample CNB30 was within the standard acceptable range showing the product remained stable and safe for consumption until the end of 180 day. Consequently, the use of cowpea protein in nutrition bars had significant impact on physicochemical properties and overall acceptability of the bars.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cowpea (Vigna unguiculata) is an annual herbaceous legume, which belongs to the Fabaceae family and is mostly cultivated for human consumption and animal-feed in African countries [1]. Cowpeas might be used to provide wide variety of meals and snacks [2]. Cowpeas are rich in protein, fiber, and have a low glycemic index, making them very nutritious and potentially health-beneficial [3,4,5]. Besides containing a high proportion of carbohydrates (68% to 73%) [6], cowpea seeds are a potential novel source of proteins, since they contain 18.2–30.4% protein [7]. Most of the cowpea grain proteins consist of globulins with lower levels of albumins, glutelin, and prolamins [8, 9]. The amino acid composition of the cowpea is rich in lysine, leucine, arginine and other essential amino acids; thus, can largely fulfil the essential amino acid requirements of a human diet. However, cowpeas are low in the sulfur amino acids (methionine and cysteine) compared to cereals and animal products and thus, for a balanced diet, cowpeas need to be supplemented with cereals or vegetables, meat and/or dairy products [10]. The lipid content of cowpea whole grain ranges from 0.5 to 3.9% [8]. With respect to fatty acids, linoleic acid and palmitic acid predominate followed by oleic acid, stearic acid and linolenic acid [8, 11]. Cowpeas are a source of essential minerals, calcium, magnesium, potassium, iron, zinc and phosphorus [7].

Snack bars are ready-to-eat convenient products in the shape of a bar occupying larger space in the consumer market which not only satisfy the hunger, but prove as a quality source of nutrients and a convenient means of replacement of a meal. They are made up of proteins, carbohydrates, fats, vitamins, and minerals [12, 13] and provide different functions such as energy boosting [14]. Employing a variety of components to appeal to a wide range of consumer groups [15], nutrition bars are fascinating healthy snacks among a wide range of people namely the youth, athletes, vegans, people who are on diet etc. [16]. These healthy snacks may contain cereals, nuts, nut paste, seeds, and dried fruits replacing junk foods. In this study, cowpea seed is offered as an ingredient in such bars with the concept of boosting energy. Nutritional and physicochemical properties as well as consumer preference during shelf-life were analyzed to determine the impact of protein addition to the nutrition bars.

Materials and methods

Materials

To improve the acceptability of the product for vegetarians, the food ingredients were preferentially chosen from plant origin; nevertheless, the presence of all main food categories was kept in mind. Cowpea grains, Almonds, Cashew, Peanuts, Oatmeal, Raisins, Date syrup, and Glucose syrup were purchased from the local markets in Tehran, Iran.

Preparation of nutrition bars

Granulated, steamed, and oven-dried cowpea, roasted crushed peanuts (8.5 g), almonds (10.5 g), cashew (8.5 g), and oatmeal (39.5 g), raisins (5.0 g), date syrup (13.5 g), sorbitol (2.5 g), glucose syrup (3.0 g), and hazelnut butter (9.0 g) were combined in a mixing bowl, poured into rectangle molds, and chilled for 2 h. The bars were then cooked for 30 min at 180 °C. The size of the bars was 30 × 11 × 120 mm and weighed approximately 35 g. They were packed individually in cellophane and aluminum foil and stored in fridge until further study. Four variants of the cowpea nutrition bars (CNB) were formulated: CNB0, CNB10, CNB20, and CNB30 with 0%, 10%, 20%, and 30% incorporation of cowpea, respectively. Samples were stored for 180 days and experiments were conducted at interwall of 30 days.

Proximate analysis

The fat content of samples was evaluated according to AOAC Method [17]. Sadasivam and Manickam’s Anthrone technique was used to evaluate the carbohydrate content of the samples [18]. The protein content and total fiber were determined according to the methods described in AACC [19]. The moisture content of the samples was evaluated using oven method [20]. The Atwater factor method was used to calculate the energy value of each sample [21]. The standard procedure outlined by Sadasivam and Manickam was used to determine sodium, potassium, and iron in each sample [18]. Calcium and zinc were measured using the titrimetric method and atomic absorption spectrophotometry, respectively [19]. Employing the phosphovanado-molybdate colorimetric technique, the phosphorus was calculated by generating color with ammonium molybdate solution [17].

Texture hardness

Hardness of cowpea nutrition bars was studied by the texture analyzer (Texture Analyzer, TA-XT2, UK) at room temperature. This was done to test the products’ hardness. The probe height was adjusted to 5.0 mm from the sample and the measurement mode settings compression was set to a constant speed of 1 mm/s. The samples were compressed to 50% of their original size. All of the measurements were carried out in triplicate on each sample.

Sensory evaluation

Sensory evaluation was carried out to know the level of acceptance by consumers. It is used to analyze and interpret the responses to products that are perceived by sense of smell, color, nature, texture, taste, and touch. A panel of twenty untrained judges evaluated and assessed the products on a 9-point hedonic rating scale in this research. It was done on a scale of likes and dislikes; starting with ‘dislike extremely’ (1) and ‘like extremely’ (9). Five denotes the neutral choice (neither like nor dislike). The panelists were asked to rate the nutrition bars on their appearance, color, flavor, taste, texture, and overall acceptability.

Microbial analysis

The total mesophilic count, as well as the yeast and mold count, was examined bimonthly. Total fecal coliforms and Bacillus cereus were also tested for safety for the first time, as stated in the AOAC [20].

Statistical analysis

Statistical analyses were conducted using SPSS software version 16. Tukey’s adjusted p-value was used to determine significance (p < 0.05) after applying ANOVA to check the significant differences on different parameters.

Result and discussion

Proximate analysis

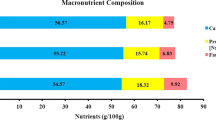

Since the nutritious profile of food products reflects the quality and proportion of components used, the relationship between the proportion of integrated cowpea and the nutritional value of the bar was evaluated (Table 1). The proximate analysis of the cowpea nutrition bars revealed that the nutrition bar with 30% cowpea (CNB30) had less fat and more protein and carbohydrate than others. It is important to highlight the fact that the findings of the analysis prove that the cowpea nutrition bars are high protein bars with a protein content of 15.39–17.20% [22,23,24]. Calorie values in cowpea nutrition bars showed that the gaining energy from carbohydrates and protein increased since in samples containing cowpea fat was reduced and protein as well as carbohydrates were increased. However, in protein bars, calorie from protein and fat is preferred [22, 25]. Crude fiber in all samples was between 8.43% and 9.08%. The mineral composition of the cowpea nutrition bars was significantly different among the samples (p < 0.05) (Table 1). The CNB30 is rich in zinc and phosphorous. CNB0 has a higher concentration of iron and calcium.

The moisture content in cowpea nutrition bars revealed that, like most of other snack bars, they are in the category of intermediate moisture foods (10–40% moisture) [26]. During 6 months of storage, all samples exhibited a decrease in moisture content from (15.65–15.84%) to (15.30–15.35%) and no significant difference was observed at ambient temperature (p < 0.05) (Table 2). This phenomenon has also been reported by Silva et al. for cassava flour-based food bars [27].

Texture hardness

The hardness is the most key parameter of textural characteristics of nutrition bars which is directly related to consumer acceptance. The hardness of samples during storage is shown in Fig. 1. The instrumental results were consistent with the organoleptic evaluation of the bars (r = −0.978). As mentioned earlier, the samples harden as time passes by. The hardness of CNB0 and CNB30 increased from 28.90 and 32.27 N on the first day to 70.09 and 79.45 N, respectively at the end of 180 days of storage at ambient temperature. The differences in hardness levels between samples during storage were significant (p < 0.05). This demonstrates that a change in formulation has a significant effect on the product’s storage stability in terms of hardness. The water–protein interaction modifies the textural properties of the samples. Samuel et al. reported that moisture migrates to protein sources causing protein aggregation and sugar crystallization, which may enhance the hardness of the bars [24]. Previous researches have attempted to determine the influence that different protein sources have on the texture of nutrition bars [22, 26, 28]. This enhancement in hardness may also be attributed to the decrease in moisture content with an increase in storage time [27]. Hardening of protein buffer solutions (40% moisture) during storage at 34 ◦C and an increase in bound water from 64 to 68% of the total water has been reported. Moreover, there are some synergistic effects on preventing bar hardness between different proteins but the mechanism for this is unclear [29]. Similar trends were reported for increasing the hardness value of high protein bar and choco-quinoa bar, respectively during ambient storage [28,29,30].

Sensory evaluation

The changes in sensory properties of samples stored at ambient temperature are shown in Fig. 2. The organoleptic analysis of the samples to determine customer preference revealed that the cowpea nutrition bars were highly approved by the panelists for all sensory characteristics examined (Fig. 2). CNB0 and CNB30 flavor scores reduced from 8.45 and 7.81 on the first day to 5.10 and 7.03 at the end of 180 days of storage at room temperature. The changes in sample flavor scores were significant. This demonstrates that a modification in the formulation has a substantial influence on the product’s storage stability in terms of flavor attributes. In the beginning, samples with a lower proportion of cowpea flour received higher flavor and taste scores (up to 90 days of storage). However, this trend was reversed and in the last days of storage, samples with more cowpea content had higher flavor and taste scores. This could be related to the oil content of the nutrition bar. In this way, in the early days, a sample with higher oil content make consumers feel more palatable; but with increased storage time and the likelihood of lipid oxidation reactions, this trend changes and samples with lower fat content provide better flavor and taste. The protein in nutrition bars also tends to produce off-flavors and after-taste during prolonged storage [22].

The texture scores of CNB0 and CNB30 decreased from 8.41 and 8.03 on the first day to 5.50 and 4.99, respectively at the end of 180 days of storage. The changes in the body and texture scores were significant during storage. The body and texture scores of all samples decreased below 6.0 after 180 days of storage. Samuel and Peerkhan had also suggested that nutrition bars harden during storage resulting in lower consumer acceptance [24].

The color and appearance scores of the CNB0 and CNB30 increased from 7.90 to 8.42 at the first day. The CNB0 and CNB30 scores decreased to 5.02 and 6.03, respectively at the end of 150 days of storage. The changes in the scores of color and appearance among the samples were significant. This different trend of increased scores of the color and appearance in samples with higher cowpea content in all days of storage is probably due to the light color that increased with increasing the ratio of cowpeas.

The overall acceptability scores of all samples at the first day were similar to 8.25. The changes in the scores of overall acceptability among the samples were significant. The rate of decrease in overall acceptance scores of the samples declined with increasing cowpea content. Therefore, after 150 days of storage, the overall acceptance score of CNB0 and CNB30 reached 4.92 and 6, respectively. Based on sensory evaluation it was concluded that CNB20 and CNB30 samples were acceptable up to 180 days of storage. The results also showed that the scores of all studied traits for these sample up to day 90 were above 7. Researchers observed that all sensorial scores of omega-3 rich energy bars, energy bar utilizing potato extrudates, and Cereal Based Energy Bar were above 7 after 90 days at ambient storage [31,32,33]. Padmashree et al. also found that the initial score for sensory characteristics of a choco-quinoa Nutri-bar within metalized polyester packaging was over 8, but dropped to approximately 7 after 9 months of storage at 37 °C [30]. In contrast, Sobana reported that the overall acceptance score of the composite sport bar was decreased from 8.0 to 1.4 after 90 days at 37 °C [34].

Microbial quality

According to the previous results, the CNB30 bar was more acceptable. Therefore, it was initially tested for coliforms (total and fecal) and Bacillus Cereus, but neither were observed. CNB30 bar was screened for aerobic mesophilic count (CFU/g) and yeast and mold count (CFU/g) every 2 months for a period of 180 days, and the results are reported in Table 3. The aerobic mesophilic count was initially somewhat greater, but dropped steadily with storage time (p < 0.05). This decline might be due to a decrease in accessible oxygen in the packing material. Yeast and mold count increased considerably (p < 0.05) over the first 60 days of storage but subsequently decreased significantly (p < 0.05) with additional storage duration. The changes in microbial count might be attributed to differences in water activity during storage; nonetheless, the product remained stable and safe for consumption until the end of the 180-day period since the overall bacterial count was within the standard acceptable range (1000,000 CFU) [35]. A rise in total bacterial count as well as yeast and mold count (log cfu/g) from 3.4 to 4.6 and 3.45 to 3.62 was detected, respectively, following 90 days of storage in an energy bar containing flax seeds [31].

Conclusions

Cooked and oven-dried cowpea in different four concentrations of 0%, 10%, 20%, and 30% was used to formulate the nutrition bars (CNB0, CNB10, CNB20, and CNB30 respectively) and measure change in nutrition value, moisture content, texture, organoleptic properties and microbial count. Bar CNB30 was generally more nutritious than other treatments with less energy value. Moisture content decreased in bars during storage which affected their hardness. Nevertheless, reaction between water and protein reduced hardness of the samples. Cowpea protein led to higher organoleptic scores and CNB30 got the highest score in overall acceptability. Microbial count of sample CNB30 was within the standard acceptable range showing the product remained stable and safe for consumption until the end of 180 day. Increased cowpea protein use in nutrition bar applications stands to benefit the confectionery industry through increased demand for complete protein bars. However, other researches need to be conducted on other protein sources and concentration to fortify nutrition bars with proteins.

Data availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

S. Muranaka, M. Shono, T. Myoda, J. Takeuchi, J. Franco, Y. Nakazawa, O. Boukar, H. Takagi, Genetic diversity of physical, nutritional and functional properties of cowpea grain and relationships among the traits. Plant Genet. Resour. 14(1), 67–76 (2016)

M. Asif, L.W. Rooney, R. Ali, M.N. Riaz, Application and opportunities of pulses in food system: a review. Crit. Rev. Food. Sci. Nutr. 53(11), 1168–1179 (2013)

P. Siddhuraju, K. Becker, The antioxidant and free radical scavenging activities of processed cowpea (Vigna unguiculata (L) Walp) seed extracts. Food Chem. 101(1), 10–19 (2007)

Y.N. Sreerama, V.B. Sashikala, V.M. Pratape, Phenolic compounds in cowpea and horse gram flours in comparison to chickpea flour: Evaluation of their antioxidant and enzyme inhibitory properties associated with hyperglycemia and hypertension. Food Chem. 133(1), 156–162 (2012)

S. Xiong, X. Yao, A. Li, Antioxidant properties of peptide from cowpea seed. Int. J. food Prop. 16(6), 1245–1256 (2013)

F.M.M. Maia, J.T.A. Oliveira, M.R.T. Matos, R.A. Moreira, I.M. Vasconcelos, Proximate composition, amino acid content and haemagglutinating and trypsin-inhibiting activities of some Brazilian Vigna unguiculata (L) Walp cultivars. J. Sci. Food Agric. 80(4), 453–458 (2000)

G. ElMasry, N. Mandour, Y. Ejeez, D. Demilly, S. Al-Rejaie, J. Verdier, E. Belin, D. Rousseau, Multichannel imaging for monitoring chemical composition and germination capacity of cowpea (Vigna unguiculata) seeds during development and maturation. Crop J. Article in Press (2021). https://doi.org/10.1016/j.cj.2021.04.010

P. Gonçalves, A. Goufo, R. Barros, H. Domínguez-Perles, E.A. Trindade, L. Rosa, M. Ferreira, Rodrigues, Cowpea (Vigna unguiculata L Walp), a renewed multipurpose crop for a more sustainable agri-food system: nutritional advantages and constraints. J. Sci. Food Agric. 96(9), 2941–2951 (2016)

I.M. Vasconcelos, F.M.M. Maia, D.F. Farias, C.C. Campello, A.F.U. Carvalho, R. de Azevedo Moreira, J.T.A. de Oliveira, Protein fractions, amino acid composition and antinutritional constituents of high-yielding cowpea cultivars. J. Food Compos. Anal. 23(1), 54–60 (2010)

FAO, Cowpea: post-harvest operations, food and agriculture organization of the United Nations, Rome, (2004). http://www.fao.org/3/a-au994e.pdf

D. Thangadurai, Chemical composition and nutritional potential of Vigna unguiculata ssp cylindrica (Fabaceae). J. Food Biochem. 29(1), 88–98 (2005)

M. Izzo, K. Niness, Formulating nutrition bars with inulin and oligofructose. C. F. W. 46(3), 102–106 (2001)

Lotz, R.: Color associations as advertising strategies: an analysis of consumer attitudes toward the healthfulness of energy bar packaging. University Honors Thesis, Portland State University (2016)

Rajabi, F.: High protein bars based on whey proteins. Master’s Thesis, Norwegian University of Life Sciences (2017)

G. Palazzolo, Cereal bars: they’re not just for breakfast anymore. C.F.W. 48(2), 70 (2003)

A.A. Ayad, L.L. Williams, D.A. Gad El-Rab, R. Ayivi, H.L. Colleran, S. Aljaloud, S.A. Ibrahim, A review of the chemical composition, nutritional and health benefits of dates for their potential use in energy nutrition bars for athletes. Cogent Food Agric. 6(1), 1809309 (2020)

AOAC, Official methods of analysis, 18th edn. (Association of Analytical Communities, Gaithersburg, MD, 2005)

S. Sadasivam, A. Manickam, Biochemical methods, 2nd edn. (New Age Int. Publishers, New Delhi, 2005)

AACC, Approved methods of analysis, 11th edn. (Cereals and Grains Association, St. Paul, MN, 2010)

AOAC, Official methods of analysis, 16th edn. (Association of Official Analytical Chemist, Virginia, 1995)

C.E. Chima, M.A. Igyor, Micronutrients and anti-nutritional contents of selected tropical vegetables grown in South East, Nigeria. Niger. Food J. 25(1), 111–116 (2007)

N. Lu, P. Zhou, in Whey proteins. ed. by H.C. Deeth, N. Bansal (Academic Press, NY, 2019), pp.495–517

S.M. Loveday, J.P. Hindmarsh, L.K. Creamer, H. Singh, Physicochemical changes in a model protein bar during storage. Food Res. Int. 42(7), 798–806 (2009)

K.S. Samuel, N. Peerkhan, Pearl millet protein bar: nutritional, organoleptic, textural characterization, and in-vitro protein and starch digestibility. J. Food Sci. Technol. 57(9), 3467–3473 (2020)

D. Zhu, T.P. Labuza, Effect of cysteine on lowering protein aggregation and subsequent hardening of whey protein isolate (WPI) protein bars in WPI/buffer model systems. J. Agric. Food Chem. 58(13), 7970–7979 (2010)

J.C. Banach, S. Clark, B.P. Lamsal, Instrumental and sensory texture attributes of high-protein nutrition bars formulated with extruded milk protein concentrate. J. Food Sci. 81(5), S1254–S1262 (2016)

E.C.D. Silva, V.D. Santos Sobrinho, M.P. Cereda, Stability of cassava flour-based food bars. Food Sci. Technol. 33, 192–198 (2013)

Z. Jiang, K. Wang, X. Zhao, J. Li, R. Yu, R. Fu, Y. He, P. Zhao, K.-C. Oh, J. Hou, High-protein nutrition bars: hardening mechanisms and anti-hardening methods during storage. Food Control 127, 108127 (2021)

D.J. Mcmahon, S.L. Adams, W.R. Mcmanus, Hardening of high-protein nutrition bars and sugar/polyol–protein phase separation. J. Food Sci. 74, 312–321 (2009)

N. Padmashree, S. Negi, T. Haridas, K.R.A. Govindaraj, A.D. Kumar, G.K. Semwal, Sharma, development and quality evaluation of Choco quinoa Nutri bar during storage. Food Nutr. Sci. 9(7), 899 (2018)

D. Mridula, K.K. Singh, P. Barnwal, Development of omega-3 rich energy bar with flaxseed. J. Food Sci. Technol. 50(5), 950–957 (2013)

N.A. Giri, D. Mridula, Development of energy bar utilizing potato extrudates. Asian J. Dairy Food Res. 35(3), 241–246 (2016)

K.J. Jetavat, A.M. Patel, S. Balakrishnan, Sensory, physico-chemical, textural and microbial changes in milk protein concentrate and cereal based energy bar during storage. Int. J. Curr. Microbiol. App. Sci. 9(07), 697–707 (2020)

R.M. Sobana, Quality evaluation of millet based composite sports bar. Int. J. Food Sci. Nutr. 2(4), 65–68 (2017)

N. Garg, K.L. Garg, K.G. Mukerji, Laboratory manual of food microbiology (International Pvt Ltd, New Delhi, I.K, 2010), p.11

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Maleki, G., Shadordizadeh, T., Mozafari, M.R. et al. Physicochemical and nutritional characteristics of nutrition bar fortified with cowpea protein. Food Measure 17, 2010–2015 (2023). https://doi.org/10.1007/s11694-022-01768-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01768-6