Abstract

Stress relaxation has traditionally been employed as one of the principal means for measuring the viscoelastic behavior of foods. In this study, first the quinces slices were dried in an infrared—hot air dryer (375 W, 60 °C and 1 m/s flow rate). The effects of quince powder substitution (0, 5, 10, 15 and 20%) on stress relaxation and textural parameters of sponge cakes were evaluated by the Texture Analyzer. The results showed that mechanical stress relaxation data of quince sponge cakes were fitted well by both the Peleg-Normand and four-element Maxwell models. The initial force (F0) and percentage stress relaxation (%SR) parameter of quince sponge cakes increased with increasing substitution. Generally, increasing the substitution of flour by quince resulted in less elasticity and higher hardness of sponge cakes. The elasticity of the sponge cakes was the lowest at 20% substitution of quince powder. The consistency and hardness values of baked cakes increased with increasing quince powder levels, whereas the cohesiveness, resilience and chewiness of samples showed a reverse trend.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Rheology concerns the flow and deformation of a material. Stress relaxation has traditionally been employed as one of the principal means for measuring the Viscoelastic behavior of foods. Generally, experimental force decay curves have been presented in the form of discrete Maxwell model containing 2–4 elements [1,2,3]. Peleg and Normand suggested that stress relaxation data can be recalculated to a normalized stress (or force) and next fitted with time. The Peleg-Normand model has fewer constants than the Maxwell model, thus the former is a simple, quick and effective method to handle stress relaxation data. Singh et al. [4] reported that the k2 value in the Peleg-Normand model was suitable for differentiating various food products. Hatcher et al. [5] reported that uniaxial stress relaxation provided a complementary discriminating method for texture measurement of yellow alkali noodle. Sozer et al. [6] found the stress relaxation data of spaghetti enriched with fiber were fitted well by both the three-element Maxwell and Peleg-Normand models. Huang et al. [7] found that stress relaxation was significantly and negatively correlated with the overall eating quality of steamed bread. Study on the stress relaxation of steamed bread is very rare so far.

Stress relaxation behaviour of high acyl gellan gels was investigated by Chen et al. [1], and data were fitted successfully by a seven elements empirical model and a four term modified Maxwell model with three fixed relaxation times. Relaxation appeared to be associated with the shifting of cross-links in the gel matrix. Stress relaxation of date at different temperature and moisture content was studied by Zare et al. [3]. A texture analyzer was used to apply uniaxial compression tests. Individual date fruit was uniaxially compressed at speed of 1 mm s–1. They was found that Generalized Maxwell and Nussinovitch models appropriately describe viscoelastic characteristics of date fruits as compared to Peleg model.

Bakery products are consumed all over the world and the enrichment of these products with fibers and polyphenols may be achieved through the incorporation of rich fibers and polyphenols sources [8]. Masoodi et al. [9] studied cake making from apple pomace wheat flour blends at 5, 10 and 15%, so as to enrich the cake with fiber content. Chen et al. [10] used apple pomace in cookie and muffin formulations at 4% level so that the quality of the end product was acceptable. The benefits of fibers for the gut are amply recognized, fact that has determined its consideration as a nutrient. Besides this, fibers can be used for technological purposes because of its functional properties. Quince is one of these sources, which have a great potential [11]. Silva et al. [12] reported profiles of Fibers, phenolics, organic acids, and free aminoacids of Cydonia oblonga Miller.

Quince, (Cydonia oblonga Miller) from Rosaceae family, is a tree cultivated as a medicinal and nutritional plant in the Middle East, South Africa, and central Europe [13]. They are used to make jam, marmalade, jelly and quince pudding [14]. Drying is one of the important preservation methods employed for storage of quince [15, 16]. One of the ways to shorten the drying time is to supply heat by infrared radiation. Advantages of infrared radiation over convective heating include high heat transfer coefficients, short process times and low energy costs [17]. Comparison of infrared drying with convective drying of apple showed that time of the process can be shortened by up to 50% when heating is done with infrared energy [18]. The combination of infrared with hot air provides the synergistic effect, resulting in an efficient drying process. Energy and quality aspects were studied during combined far infrared and convective drying of barley [19].

The effect of quince powder on rheological properties of batter and physico-chemical and sensory properties of sponge cake was studied by Salehi and Kashaninejad [11]. Increasing the level of substitution of quince powder from 0 to 20% decreased the volume of cakes from 66.67 to 56.91 cm3 and the results of sensory evaluation indicated that the cake with 10% quince powder was rated the most acceptable.

The aim of this study was to investigate the stress relaxation and textural parameters of fiber-enriched sponge cake prepared with different quince powder substitutions.

Materials and methods

Infrared—hot air drying of quince

Fresh quince (Cydonia oblonga Miller) was obtained from the market and kept in cold storage at 4–5 °C. Slices of quince with 5 mm thickness were prepared with the aid of a steel cutter and were immediately placed into the dryer. The quince slices were dried in an infrared—hot air dryer (Infrared radiation lamp (NIR), Philips, Germany) with 375 W power and 60 °C with air at a velocity of 1 m/s. The dried samples were milled and passed through a 50 mesh sieve. Then the milled powder was weighed and stored in an air-tight bottle till the experiments.

Sponge cake preparation

The ingredients used in the formula of quince sponge cakes were cake flour (0.10 kg), fresh eggs (0.072 kg), sucrose (0.072 kg), sunflower oil (0.057 kg, Ladan Co. Iran), whey (0.004 kg, Pegah Co. Iran), baking powder (0.002 kg, Mahsa, Tehran, Co. Iran), vanilla (0.0005 kg, Shahsavand, Mashahd, Co. Iran), water (0.030 kg), nonfat dry milk powder (0.002 kg, Pegah Co. Iran) and Xanthan gum (0.00025 kg, Commercial, China) [11]. In this study the cake flour replaced by quince powder at five different levels of 0, 5, 10, 15 and 20%.

Sucrose and sunflower oil were poured into a bowl, and mixed for 4 min. Whole egg was added to the bowl, and then mixed for 2 min. The sifted cake flour, whey, baking powder, vanilla, xanthan gum, water, quince powder and nonfat dry milk powder was gradually poured into a bowl, and mixed for 4 min. Water was added to the bowl, and then mixed for 1 min [20]. For each cake, 30 g of cake batter was poured into a cake pan and baked at 195 °C for 20 min in a oven toaster (Noble, Model:KT-45XDRC). The cakes were allowed to cool for 30 min, and then were removed from the pans. The cooled cakes were packed in polypropylene bags at room temperature for 14 days [21].

Textural properties of cakes

The texture profile analysis (TPA) of sponge cake samples (2 × 2 × 2 cm) from the midsection of the cakes were performed using a texture analyzer (TA-XT Plus, Stable Micro Systems Ltd., Surrey, UK) with a 36 mm diameter cylindrical probe, 50% compressing and a test speed of 1.0 mm s− 1. The crust of cake samples was removed in cake texture determination. A double cycle was programmed and the texture profile was determined using Texture Expert 1.05 software (Stable Microsystems). Other parameters were defined as: pre-test speed 2.0 mm s− 1, post-test speed 2.0 mm s− 1 and trigger force 5 g. The texture parameters recorded were consistency, hardness, cohesiveness, adhesiveness, springiness, resilience, gumminess, and chewiness, and the texture parameter of cake was averaged from 4 replications.

Stress relaxation of quince sponge cake

Stress relaxation of quince sponge cake was measured according to the method proposed by Sozer et al. [6] with some modifications. The sponge cake was sliced horizontally to remove the top and then a 3 × 3 × 4 cm rectangular sample was taken through the center of the bread by cutting. The stress relaxation test was executed by using a Textural Analyzer (TA-XT Plus, Stable Micro Systems Ltd., Surrey, UK) equipped with a cylindrical probe of P/100 (100 mm diameter). The sample was deformed in penetration to a constant strain of 50% with test speed of 1 mm s–1. The data acquisition rate was 200 points per second. The residual force was continuously recorded as a function of time for 60 s. The stress relaxation data were analyzed by using a Peleg-Normand model as well as a Maxwell model. Equation 1 is a model proposed by Peleg and Normand.

where F0 is initial force, F(t) is the momentary force at time t, and k1 and k2 are constants. The k1 and k2 values are the intercept and slope of regressive straight line plotted by normalized force and time, respectively. In addition, percentage stress relaxation (% SR) was calculated from the following equation:

where F0 is initial force, and Ft=20 is the force at 20 s after the initial strain was achieved.

Equation 3 is a Maxwell model with four elements:

where F(t) is the actual force as a function of time in a stress relaxation test, λ1, λ2, and λ3 are the relaxation times, and F1, F2, and F3 are the decay forces. F4 is the additional spring. The experimental data were modeled by using non-linear regression in Curve Expert 1.34 software.

Relative force [F(t)/F0] was calculated from the following equation:

Statistical analysis

Each measurement was conducted in quadruplicate. The experimental data were subjected to an analysis of variance (ANOVA) for a completely random design using a statistical analysis system (SAS 9.1 Institute, Inc, Cary, NC, USA). Duncan’s multiple range tests were used to determine the difference among means at the level of 0.05.

Results and discussion

Texture profile analysis (TPA) of quince sponge cakes

In texture profile analysis (TPA), the hardness of samples measured showed that the cake became harder with increasing levels of quince powder (Tables 1, 2). The hardness of cakes was directly related to the density of the tested materials (indirectly to its volume). The weight of samples was not significantly different among any of the cakes in this study. Thus, the increase in hardness was mainly related to the volume of these cakes. The area under the curve up to the target deformation was taken as a measurement of consistency. TPA results showed a increase in the cake consistency with an increased level of quince powder. The consistency values increased from 4578.83 to 8760.07 g s with increasing quince powder levels from 0 to 20%.

Cohesiveness quantifies the internal resistance of food structure. Briefly, cohesiveness is the ability of a material to stick to itself. TPA results showed significantly different in the cake cohesiveness and it was decreased with increasing level of quince powder from 0 to 15%.

Springiness measures elasticity by determining the extent of recovery between the first and second compression. Resilience is the ratio of recoverable energy as the first compression is relieved. TPA results showed a decrease in the cake springiness with increasing level of quince powder from 0 to 15%.

Gumminess is determined by hardness multiplied by cohesiveness. Chewiness is determined by gumminess multiplied by springiness, and represents the amount of energy needed to disintegrate a food for swallowing. TPA results showed a decrease in the cake gumminess and chewiness with increased level of quince powder from 0 to 10% but they were increased with increasing quince powder level from 15 to 20%.

Stress relaxation of quince sponge cakes

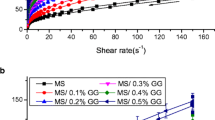

Fundamental viscoelastic properties of foods have frequently been measured by stress relaxation. The stress relaxation data of quince sponge cakes in this study were analyzed by Peleg-Normand model and Maxwell model, and % SR. Figures 1 and 2 shows the relaxation curves of sponge cakes at different substitutions of quince powder at days 1 and 14, respectively. As for most viscoelastic materials, after application of a constant strain, a decrease in force values necessary for maintaining the deformation was observed.

Relative residual force values of the quince sponge cakes during the stress relaxation test were shown in Figs. 3 and 4 and they were decreased with increasing substitution of cake flour with quince powder. This indicated that the quince sponge cakes had more solid-like behavior at lower substitution.

Initial force (F0) values using stress relaxation data of sponge cakes with various substitutions of quince powder were reported in Table 3. Increasing substitution of cake flour with quince powder in the range of 0–20% increased the initial force values from 15.84 to 31.78 N and from 17.76 to 40.46 N for days 1 and 14, respectively.

The increase in hardness and F0 of sponge cakes enriched with quince powder maybe related to the decrease of free water in the cake. Sangnark and Noomhorm [22] found that bread with 5% fiber from rice straw had higher firmness and lower springiness than control bread. Kaack et al. [23] found that the hardness of bread increased with the quantity (0–12%) of potato fiber with high insoluble dietary fiber content. The addition of 15% sugar-beet fiber [24] and 10% hydrated hazelnut testa, decreased the quality of bread crumb [25]. However, white pan bread with bran addition up to 20% possessed a lower compression force than control bread [26].

Table 4 lists the fitting parameters of the Peleg-Normand model for sponge cakes with various substitutions of quince powder. The results showed that the stress relaxation data of sponge cakes were fitted well by the Peleg-Normand model (R > 0.999).

The Peleg-Normand model is easy to perform and to analyze the data. In Figs. 5 and 6, the normalized force values determined during stress relaxation were well fitted (R > 0.999) to the Peleg-Normand model (Eq. 1). Thus we could have the k1 and k2 parameters by regression. Generally, both k1 and k2 values (Day 1) of the sponge cakes decreased with increasing substitutions of quince powder. Hence 10–20% quince powder fiber-enriched sponge cakes were more rigid and less elastic than cakes with low quince powder (0–5%). The reciprocal of the k1 value in the Peleg-Normand model represents the initial decay rate. A high k1 value was associated with a low decay rate, indicating a pronounced elastic behavior. The k2 value is the representative of the degree of solidity and it varies between 1, for a material that is truly a liquid, to infinity, for an ideal elastic solid where the stress does not relax at all [27]. Singh et al. [4] indicated k2 was a better representative of elastic nature for food materials. Therefore the quince sponge cakes in this study are more elastic measured at low substitution. Nussinovitch et al. [28] indicated that the percent recoverable work (or elasticity) of bread decreased exponentially by increasing strain from 20 to 80%. Li et al. [29] indicated that the relaxation properties of dough depended on its gluten protein and that relaxation spectra of glutens were similar to those for the corresponding doughs. Zhang et al. [30] found moderate correlation coefficient (r = 0.55–0.61) between stress relaxation of steamed bread and glutenin fraction of wheat cultivar.

Percentage stress relaxation (% SR) is a convenient and informative parameter to understand viscoelastic properties of food products, and is obtained directly from the stress relaxation versus time plot at an arbitrary time [27]. For the ideal elastic solid, % SR is equal to 0, while for the ideal liquid, % SR is 100. Results showed that % SR of quince sponge cakes tested ranged from 45.19 to 48.66 (Table 5), and thus the sponge cake was classified as a viscoelastic solid. Safari-Ardi and Phan-Thien [31] observed the sufficient resolution of the stress relaxation responses of wheat doughs at a strain level of 20%.

Since stress relaxation data of sponge cakes has not been analyzed by Maxwell model, we tried to use different Maxwell model equations for fitting the experimental data. The number of Maxwell elements required to represent the viscoelasticity of the cake sample was determined by the R value. For one-element, two-element, three-element and four-element Maxwell models, the R values were approximately 0.68, 0.88, 0.91 and 0.999, respectively.

Hence the four-element Maxwell model fitted to the data better than the other Maxwell models. Table 6 lists the fitting parameters of the four-element Maxwell model of sponge cake with various substitutions of quince powder. The results showed that all stress relaxation data of cakes were fitted very well by the Maxwell model with four elements (R = 0.999).

A three-element Maxwell model was found adequate for demonstrating the stress relaxation data of spaghetti and fiber-enriched steamed bread [6, 27], and a generalized Maxwell model satisfactorily fitted the stress relaxation data of various bulky and sponge foods [2, 32].

The elastic component of the Maxwell element can be represented by the decay force (F1, F2, F3 and F4), which indirectly measures the rigidity of the material being tested. Relaxation time (λ1, λ2 or λ3) was defined as the time taken for a macromolecule to be stretched out when deformed [33]. Although all decay forces (F1, F2, F3 and F4) of the sponge cakes obviously increased with increasing substitutions of quince powder, λ1, λ2 and λ3 values were not significantly different at various substitution levels tested. This result showed that relaxation times in the Maxwell model were not sensitive to substitution of quince powder variable.

Higher decay force and shorter relaxation time of sponge cake with high quince powder content indicated that the cake had a more rigid and less elastic behavior, corresponding to the results from the Peleg-Normand model in Table 4.

Moreover, % SR of sponge cakes obviously increased with increasing substitution of quince powder (Table 5). This is the first study of using different mathematical models to describe the viscoelastic properties of sponge cakes to our knowledge. Dough from strong wheat cultivar exhibited slower rates of stress relaxation and higher storage modulus as compared to moderate, weak, and very weak cultivars [34]. The relaxation time of bran-enriched spaghetti was affected by cooking time [6]. Hatcher et al. [5] reported that significant correlations were found among textural characteristics (maximum cutting stress, resistance to compression, and recovery) and stress relaxation parameters (% SR, k1 and k2) of cooked yellow alkali noodles.

Conclusions

The results showed that the stress relaxation test of quince sponge cake can be performed at 50% strains. Mechanical stress relaxation data of quince sponge cakes were fitted well by both four-element Maxwell and Peleg-Normand models. Increasing substitution of cake flour with quince powder in the range of 0–20% decreased the k1 and k2 in the Peleg-Normand model and the λ2 in the Maxwell model of sponge cake. On the contrary, increasing substitution of cake flour with quince powder increased the initial force (F0), percentage stress relaxation (%SR), consistency and hardness of sponge cake. The fiber-enriched sponge cake (20% quince powder) with proper elasticity and texture can be prepared.

References

Q. Chen, M. Li, Y. Yuan, X. Han, Stress relaxation behaviour of high acyl gellan gels. Int. J. Food Sci. Tech. 48, 2571–2579 (2013)

S. Bhattacharya, Stress relaxation behaviour of moth bean flour dough: Product characteristics and suitability of model. J Food Eng. 97, 539–546 (2010)

D. Zare, M. Alirezaei, S. Nassiri, Stress relaxation of date at different temperature and moisture content of product: A new approach, In: 2012 Dallas, Texas, July 29-August 1, 2012, American Society of Agricultural and Biological Engineers, 2012, p. 1

H. Singh, A. Rockall, C. Martin, O. Chung, G. Lookhart, The analysis of stress relaxation data of some viscoelastic foods using a texture analyzer. J. Texture Stud. 37, 383–392 (2006)

D. Hatcher, G. Bellido, J. Dexter, M. Anderson, B. Fu, Investigation of uniaxial stress relaxation parameters to characterize the texture of yellow alkaline noodles made from durum and common wheats. J. Texture Stud. 39, 695–708 (2008)

N. Sozer, A. Kaya, A.C. Dalgic, The effect of resistant starch addition on viscoelastic properties of cooked spaghetti. J. Texture Stud. 39, 1–16 (2008)

S. Huang, K. Quail, R. Moss, J. Best, Objective methods for the quality assessment of northern-style Chinese steamed bread. J. Cereal Sci. 21, 49–55 (1995)

F. Salehi, Rheological and physical properties and quality of the new formulation of apple cake with wild sage seed gum (Salvia macrosiphon). J. Food Meas. Charact. 11, 2006–2012 (2017)

F.A. Masoodi, B. Sharma, G.S. Chauhan, Use of apple pomace as a source of dietary fiber in cakes. Plant Foods Hum. Nutr. 57, 121–128 (2002)

H. Chen, G. Rubenthaler, H. Leung, J. Baranowski, Chemical, physical, and baking properties of apple fiber compared with wheat and oat bran. Cereal Chem. 65, 244–247 (1988)

F. Salehi, M. Kashaninejad, The effect of quince powder on rheological properties of batter and physico-chemical and sensory properties of sponge cake. J. Food Biosci. Technol. 7, 1–8 (2017)

B.M. Silva, P.B. Andrade, R.C. Martins, R.M. Seabra, M.A. Ferreira, Principal component analysis as tool of characterization of quince (Cydonia oblonga Miller) jam. Food Chem. 94, 504–512 (2006)

A.A. Hemmati, H. Kalantari, A. Jalali, S. Rezai, H.H. Zadeh, Healing effect of quince seed mucilage on T-2 toxin-induced dermal toxicity in rabbit. Exp. Toxicol. Pathol. 64, 181–186 (2012)

M.F. de Escalada Pla, M. Uribe, E.N. Fissore, L.N. Gerschenson, A.M. Rojas, Influence of the isolation procedure on the characteristics of fiber-rich products obtained from quince wastes. J. Food Eng. 96, 239–248 (2010)

A. Kaya, O. Aydin, C. Demirtas, M. Akgün, An experimental study on the drying kinetics of quince. Desalination 212, 328–343 (2007)

B. Koç, İ Eren, F. Kaymak, Ertekin, Modelling bulk density, porosity and shrinkage of quince during drying: the effect of drying method. J. Food Eng. 85, 340–349 (2008)

F. Salehi, M. Kashaninejad, A. Jafarianlari, Drying kinetics and characteristics of combined infrared-vacuum drying of button mushroom slices. Heat Mass Transfer. 53, 1751–1759 (2017)

D. Nowak, P.P. Lewicki, Infrared drying of apple slices. Innov. Food Sci. Emerg. Technol. 5, 353–360 (2004)

T. Afzal, T. Abe, Y. Hikida, Energy and quality aspects during combined FIR-convection drying of barley. J. Food Eng. 42, 177–182 (1999)

F. Salehi, M. Kashaninejad, F. Asadi, A. Najafi, Improvement of quality attributes of sponge cake using infrared dried button mushroom. J. Food Sci. Technol. 53, 1418–1423 (2016)

F. Salehi, M. Kashaninejad, E. Akbari, S.M. Sobhani, F. Asadi, Potential of sponge cake making using infrared–hot air dried carrot. J. Texture Stud. 47, 34–39 (2016)

A. Sangnark, A. Noomhorm, Chemical, physical and baking properties of dietary fiber prepared from rice straw. Food Res. Int. 37, 66–74 (2004)

K. Kaack, L. Pedersen, H.N. Laerke, A. Meyer, New potato fibre for improvement of texture and colour of wheat bread. Eur. Food Res. Technol. 224, 199–207 (2006)

N. Filipovic, M. Djuric, J. Gyura, The effect of the type and quantity of sugar-beet fibers on bread characteristics. J. Food Eng. 78, 1047–1053 (2007)

M. Anil, Using of hazelnut testa as a source of dietary fiber in breadmaking. J. Food Eng. 80, 61–67 (2007)

J.M. Al-Saqer, J.S. Sidhu, S.N. Al-Hooti, Instrumental texture and baking quality of high-fiber toast bread as affected by added wheat mill fractions. J. Food Process. Preserv. 24, 1–16 (2000)

M.-Y. Wu, Y.-H. Chang, S.-Y. Shiau, C.-C. Chen, Rheology of fiber-enriched steamed bread: stress relaxation and texture profile analysis. J. Food Drug Anal. 20, 133–142 (2012)

A. Nussinovitch, M. Steffens, P. Chinachoti, M. Peleg, Effect of strain level and storage time on the recoverable work of compressed bread crumb. J. Texture Stud. 23, 13–24 (1992)

W. Li, B. Dobraszczyk, J. Schofield, Stress relaxation behavior of wheat dough, gluten, and gluten protein fractions. Cereal Chem. 80, 333–338 (2003)

P. Zhang, Z. He, D. Chen, Y. Zhang, O.R. Larroque, X. Xia, Contribution of common wheat protein fractions to dough properties and quality of northern-style Chinese steamed bread. J. Cereal Sci. 46, 1–10 (2007)

M. Safari-Ardi, N. Phan-Thien, Stress relaxation and oscillatory tests to distinguish between doughs prepared from wheat flours of different varietal origin. Cereal Chem. 75, 80–84 (1998)

M. Del Nobile, S. Chillo, A. Mentana, A. Baiano, Use of the generalized Maxwell model for describing the stress relaxation behavior of solid-like foods. J. Food Eng. 78, 978–983 (2007)

B. Cuq, F. Gonçalves, J.F. Mas, L. Vareille, J. Abecassis, Effects of moisture content and temperature of spaghetti on their mechanical properties. J. Food Eng. 59, 51–60 (2003)

V. Rao, S. Mulvaney, J. Dexter, N. Edwards, D. Peressini, Stress–relaxation properties of mixograph semolina–water doughs from durum wheat cultivars of variable strength in relation to mixing characteristics, bread-and pasta-making performance. J. Cereal Sci. 34, 215–232 (2001)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Salehi, F., Kashaninejad, M. Texture profile analysis and stress relaxation characteristics of quince sponge cake. Food Measure 12, 1203–1210 (2018). https://doi.org/10.1007/s11694-018-9734-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-018-9734-3