Abstract

Maltodextrin (MD) with a dextrose equivalency of 10 and 20 (10DE and 20DE) and Arabic gum (AG) were used as encapsulating materials for beetroot juice by spray drying. The produced encapsulates were evaluated in terms of encapsulation yield, moisture content, hygroscopicity, bulk density, color parameters (L*, a*, b* and TCD), radical scavenging activity (RSA), total phenolic content (TPC) and betalain content. The binary blend of encapsulating material significantly (P < 0.05) affected the studied responses. The highest bulk density (0.549 g/mL) was observed in encapsulates based on MD (20DE) as the encapsulating material. A highest encapsulating yield of 73.27 % and a redness (a*-value) of 39.03 was referred to the formulation of MD (DE10) and AG. Formulation with MD (20DE) and MD (DE20) + AG kept better retention of functional assets (RSA and TPC) in microencapsulates produced. The increase in the value of betalain content (208.06 mg/100 g dm) was well correlated with redness (a*-value). The studied responses ties of all encapsulate produced with formulation MD (DE10) + AG was found to be satisfactory with an exception for their lower bulk density.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Betalains are used as natural colorants for red shades in the food industry. These pigments from red beetroot (Beta vulgaris L. Rubra) contain two groups of water-soluble nitrogen-containing betalain pigments: red-violet betacyanins and yellow betaxanthins [1]. Betalains with antiviral, anti-inflammatory effects, cell proliferation inhibition in human tumor cells and rich presence of antioxidants can contribute to protection from age-related diseases [2]. Confirmed by the European Union as a food colorant, extracts of betalains are used for pigmenting milk products, yogurts, jellies, confectionery, beverages and supplements for sportsmen.

Being a natural pigment, stability of betalain can be sensitive to environmental or technological process conditions [3]. Moreover, as a colorant, commercial application of beetroot juice concentrate in dry food products, such as bread, cake, cookie mixes, breakfast cereals, and dried soups is also a cumbersome process. For this reason, the food industry is now concentrating attention on the microencapsulation of vegetable juices. Microencapsulation by spray drying improves the encapsulation yield as well as extends the shelf life of the resulting product by lowering the water activity in powder form.

In principle, microencapsulation avails the system for transforming liquids to solids by modifying colloidal and surface properties in feed suspension [4]. Commercially for microencapsulation process, the advantage of low production costs and less time consumption compared to other drying techniques (e.g., freeze drying, coacervation, molecular inclusion, extrusion and fluid bed drying), is achieved by spray drying technology. High costs and complications associated with spray drying trial under industrial conditions give a way to pilot scale spray dryers which help in exploring the effect of drying parameters on different properties of the produced encapsulates.

The Presence of low molecular weight components (sugars and organic acids) having low glass transition temperatures imparts difficulty in spray drying of juices without any encapsulating material [5].This presence of sugars results in the problem of stickiness in drying chamber which persists during the whole drying session. The stickiness sequentially lower encapsulation yield which is critically defined by the properties of the encapsulating and core materials [6].

The selection of method-based and material science-based approach to get encapsulating material is crucial to minimize stickiness problem. The material science-based approach is more common as the method-based approach is non-easy hand and non-viable economically [7]. The addition of encapsulating materials based on starch is a general practice in material science-based approach. Maltodextrins (MD), AG, modified starches and also less commonly inulins, are some examples used for spray drying of fruits and vegetable juices. The polymer MD is more common, economic with a neutral taste, color, high water solubility (>75 %) and low viscosity. The dextrose equivalency of MD determines their reducing capacity and is inversely related to their average molecular weight. However, the low emulsifying capacity and peripheral retention of volatiles of this encapsulating material lead to its unification with other wall materials [8]. Being a processed outcome of acacia fruit, AG is widely used in encapsulation because of its surface-active and drying matrix properties. However, its application has a concern because of high cost and limited supply which can be compensated with lower price and abundance availability of MD.

There is limited published work stating the importance of aforesaid mixtures of encapsulating materials on the spray-dried beetroot juice. Therefore, in present study binary blend of AG with MD with various DE were selected and the changes in physicochemical, functional and structural properties of encapsulated beetroot juice were determined.

Materials and methods

Preparation of feed suspension for microencapsulation

The sample of beetroot juice was prepared under rotary vacuum (IKA HB10 Digital, Germany) evaporator using optimized conditions based on previous studies [9] which included a thermal treatment of this juice at 55 °C with a working vacuum pressure of 200 mbar. A lower total soluble solid (TSS) of 22° Brix was set for further encapsulation process because an easy clogging of the atomizer is seen if the feed has high viscosity [10].

Blending of encapsulating materials and selection of spray drying conditions

The non-feasibility of drying beetroot juice in a spray dryer without the addition of any encapsulating material was because of the presence of its low molecular weight sugars and hence the low glass transition temperature (measured Tg of juice 45 ± 2 °C). So, a total of six formulations (F1, F2, F3, F4, F5 and F6) were established (Table 1) with encapsulating materials employed for the current process included MD (10 & 20 DE) and AG. This selection was based on the high stability of encapsulating materials in feed suspensions and the high quality of encapsulates it can produce [11]. The addition rate was set to a maximum of 20 % (on total solid basis) as a higher concentration of encapsulating material will lead to risky health effects [12]. Before feeding to spray dryer, MD and AG were added to this semi-concentrate of beetroot juice (TSS below 30° Brix) on a total solid basis [13] and feed was thoroughly blended for complete dissolution of core and encapsulating materials. The physicochemical properties of beetroot juice and encapsulating materials are shown in Table 2.

The prepared suspensions from various formulations were provided to laboratory scale co-current spray dryer Scientech’s (Kolkata, India) main chamber (500 mm × 215 mm) through a peristaltic pump and a 0.5 mm inner diameter nozzle. As feed flow rate has a minor negative effect on moisture content and hygroscopicity of the produced encapsulates [14] so this operating condition for suspensions was controlled by the pump rotation speed to 500 mL/h. For purposeful and non-thermal degradative drying in case of fruit and vegetable juices, the inlet air temperature range is kept narrower (140–180 °C) in comparison to general drying range (140–240 °C) [15]. Hence, the current operational condition of inlet air temperature was kept constant at 170 °C on review literature basis. Encapsulates were collected in an insulated glass bottle connected at the end of cyclone after drying and packed in polyethylene pouches and stored in a desiccator containing silica gel at 25 °C till they were further analyzed.

Physicochemical properties

Encapsulation yield

The spray dried encapsulate yield was estimated by the relationship between the mass of the final product and the mass of the feed mixture and was calculated by the equation given below [16].

where Y is encapsulation yield (%), Mc is the moisture content (wb), F is the feed volume, TS is the total solid content, and W is the weight of the encapsulates obtained after spray drying, accordingly.

Moisture content

The analysis for moisture content was conducted according to the method of AOAC [17]. One gram of sample was dried in a vacuum oven at 70 °C until constant weight is obtained. The calculations were as follows:

Hygroscopicity

For hygroscopicity determination according to the method proposed by Cai and Corke [18], samples of each encapsulates (approximately 1 g) were placed at 25 °C in a desiccator with NaCl saturated solution (75.29 % RH). After 1 week, samples were weighed and hygroscopicity was expressed as the gram of adsorbed moisture per 100 g dry solids (g/100 g).

Bulk density

The bulk density (g/mL) of the samples was determined by placing 2 g of encapsulates in a 10 mL graduated cylinder and calculating the volume from the scale [19].

Color analysis

The L*, a*, b* color values of samples were determined by using CIE color lab Minolta chroma meter (CR-400; Minolta Corp, Japan). After standardization, the L* (lightness), a* (red component), b* (yellow component) values were measured in the juice sample and in complete microcapsules (Table 3) by placing the lens of the color reader on respective samples in respective containers. Total color difference (TCD) was calculated by the transformation of L*, a* and b* values in the following equation:

Functional properties

DPPH radical scavenging activity and TPC

A stable free radical 2, 2-diphenyl-1-picryl hydrazyl (DPPH·) was used for determining antioxidant activity of samples [20]. The sample mixture with methanolic DPPH· solution (1 mM) was shaken vigorously and then left to stand for 30 min in the dark. The absorbance was measured at 517 nm using UV–VIS spectrophotometer (Hach DR 6000, Germany). The absorbance of control was obtained with methanol. DPPH· radical scavenging activity (RSA) of the sample was calculated as follows:

where Acontrol is absorbance of control and Asample is absorbance of the sample [21].

Total Phenolic Content (TPC) was determined according to the method of Singleton and Rossi [22] using the Folin–Ciocalteau reagent with some modifications. A calibration curve was drawn with gallic acid as standard (AR grade). The results were expressed as gallic acid equivalents in milligrams per 100 g of dry matter (mg GAE/100 g of dm).

Betalain content

Betalain (Fig. 1) (betacyanins + betaxanthins) content of encapsulates was calculated according to Janiszewska [12].

where, A is the absorption at 538 and 480 nm for betacyanins and betaxanthins respectively. DF is the dilution factor and L is the path length (1 cm) of the cuvette of volume 3 mL. Molecular weights (MW) and molar extinction coefficients (ε) of betacyanin and betaxanthin are 550 and 308 g mol−1 and 60,000 and 48,000 L mol−1 cm−1 respectively.

Scanning electron microscopy (SEM)

A double-sided adhesive tape mounted on aluminum SEM stubs, was used for particle attachment and then coated with 5–20 mA gold using gold sputtering INCA X-act JEC auto fine coater (Oxford Instruments, Tokyo, Japan) under vacuum to a thickness of 10 nm. The coated samples were then analyzed using the SEM (JSM 6510 LV model) (JEOL Co., Ltd., Tokyo, Japan) operated at 15 and 20 kV with magnifications of ×500.

Statistical analysis

All experiments were conducted in triplicates and a one-way analysis of variance was performed. The least significant difference at p < 0.05 was calculated using Duncan’s multiple range tests in Statistica software 7.0.61.0 (Stat Soft. Inc. 2004, USA). The data was expressed as mean ± SD. The graphs of mean values and error bar were created using Microsoft Excel version 2010.

Results and discussion

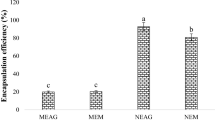

Encapsulation yield

The type of encapsulating material showed a significant (P < 0.05) influence on encapsulation yield of encapsulated beetroot juice. The yield calculated for various formulations was above to the satisfactory criterion (>50 %) for spray dried encapsulates [10]. It ranged between 59.06 and 73.27 % for the various encapsulating blends used. Lower yield in case of dried encapsulates obtained with AG in F3 could be caused by short chain branched structure of AG and hence its high hydrophilic nature which possibly assisted in particles adherence to spray drier wall and to other dried particles [23]. An increase in yield was observed for BJ encapsulates obtained with the formulation F5 of encapsulating materials. The encapsulates obtained using F2 formulation showed a competitive yield to the BJ encapsulates obtained with the blend of MD (DE10) and AG in formulation F5. A similar type of result was observed previously in the case of the spray-dried blueberry extract by Ferrari et al. [13].

Moisture content

The encapsulates of beetroot juice with varying formulation of encapsulating material obtained moisture content (Table 3) in a range of 1.26–2.88 (below 4 %) which was sufficiently necessary to make food powder microbiologically safe. These values for moisture content were close to the values reported by Tonon et al. [23] and Quek et al. [24] for spray dried acai and watermelon respectively. The highest percent of moisture content was found for encapsulates obtained by formulation F3 with AG as the encapsulating material. Such behavior was probably due to complex hetero-polysaccharide and highly ramified structure of AG, containing shorter chains and more hydrophilic groups. The encapsulates produced with 20 % MD (DE10) showed significant lower moisture content (1.26 %) (P < 0.05) in comparison to encapsulates obtained with 20 % MD with DE20 (Table 3). As stated by Cai and Corke [18], higher DE MDs caused an increase in encapsulates moisture content, because lower molecular weight MDs having fewer longer chains in its structure and more groups having an affinity for water. The combination of MD and AG in the case of design F4, F5 and F6 did not significantly affect this response. Same results were reported by Ferrari et al. [13] while working with spray dried chicken meat protein hydrolysate.

Hygroscopicity

Hygroscopicity is the measurement of the capacity of the food to contain obstructed moisture and is of considerable importance for judging the behavior of spray dried food powders [25]. The current study showed a significant (P < 0.05) effect of encapsulating materials on the hygroscopicity of the BJ encapsulates. The hygroscopicity values varied from 14.09 to 19.33 g/100 g dry solid for the samples obtained with varying encapsulating materials. Encapsulates obtained with a whole AG concentration gave rise to a higher hygroscopicity. This phenomenon of increase might be due to high moisture adsorption by AG which is further attributed to the links between the hydrogen present in water molecules and the hydroxyl groups available in the amorphous regions of the substrate, as well as on the surface of crystalline regions [23]. On the contrary, F1 with MD (DE10) as an encapsulating material showed minimum hygroscopic values along with F5 [MD(DE10) + AG]which can be appreciatory gained by examining Table 3. The decrease lies in less hydroxylation of MD (DE10), showing less hydrophilic groups and thus adsorbing less water. Additionally, MD is a material having the property of low hygroscopicity has been well established [26]. The results were well coordinated with Rodriguez-Hernandez et al. [27] and Cai and Corke [18] while working on spray drying of cactus pear juice powder and betacyanin pigments, respectively.

Bulk density

Bulk density as a response is a useful asset for determining the weight and amount of material that will accommodate a container and hence making a highly dense dry product to be stored in a smaller container [28]. The bulk density values of the samples ranged from 0.516 to 0.578 g/mL. Encapsulates produced with encapsulating formulation F2 [MD (DE20)] showed the highest bulk density, followed by encapsulates produced with F5 a blend of MD (DE20) and AG. Formulation F1 [MD (DE10)] showed the lowest bulk density. An increase in MD dextrose equivalent leads to an increase in bulk density (Table 3). This can be attributed to the fact that the higher the MD DE, the lower its glass transition temperature and as consequence stickiness will be more in the mixture [7].

Color

For beetroot juice, all produced encapsulates had a high value of color parameter a* which is attributed to their betacyanin content. This parameter showed statistically significant (P < 0.05) difference regarding encapsulating materials. Redness values were significantly higher (39.03) for the samples produced using a combination [MD (DE10) + AG] in comparison to the values for other formulations. This behavior can be co-related to betalain content results because encapsulates produced with formulations combined with MD and AG (F4–F6) showed better betalain content (Fig. 2). The reason might be the formation of denser and more oxygen impermeable wall systems, providing better stability for betacyanin pigments. The results were well supported by the research of Jiménez-Aguilar et al. [29] and Ersus and Urdagel [30] where a positive correlation of pigments with color was seen. The lowest value (26.17) for redness parameter was seen for F1 relying upon the reason that a lower MD (DE10) used contained a major part of long chain saccharides which in turn produced an obstinate barrier during microencapsulation which might be permeable to external degradative factors [31]. Another informative model is TCD which is a colorimetric parameter extensively used to characterize the variation of color in foods during processing. As reported by Maskan, [32] high values of TCD parameter indicate more color changes during processing. TCD of encapsulates was found to vary between 26.94 and 39.10 (Table 3). The higher values of experimental TCD (TCD value >6) indicated more color change and encapsulates produced lied under the greatly noticeable category as per the classification proposed by Cserhalmi et al., [33] for TCD.

DPPH radical scavenging activity and TPC

Possession of strong antioxidant capacity by beetroot has been confirmed by Ravichandran et al., [11]. The increase in radical scavenging activities of treated samples shows that this activity depends not only on the presence of betalains but also on other polyphenols which could have been increased during the treatments. The RSA of encapsulated beetroot juice with different treatment of encapsulating materials was evaluated applying the DPPH method. As processed fruits and vegetables tend to have lower antioxidant activity compared to their raw and fresh counterparts due to degradation of phytochemical content during processing. But capsule formation of encapsulating material over core material during spray drying resulted in the increase in antioxidant activity. Upon considering the antioxidant activity with the blend of AG + MD (20DE), there was an increase (67.12 %) in RSA. The reason might be the good emulsifying properties of AG and good protection against oxidation for high reducing capacity in high DE (20) of MD [34]. In the case of encapsulates obtained with lower MD (DE20), the RSA decreased (Fig. 3a) as a major part of this encapsulating material contains long chain saccharides which in turn proves a poor barrier to oxygen. The results were in agreement with the results of Duan et al. [31] while working with antioxidants of litchi fruit pericarp.

All samples containing different DE levels and the combinations among themselves and to AG had a significant effect on TPC of dried beetroot juice (BJ) (Fig. 3b). The highest total phenolic content was found for the blend of AG and MD (DE20) with 26.36 mg GAE/100 g while the lowest total phenolic content was obtained with BJ encapsulates with formulation F1 of total MD (10-DE). However, AG was found to be the better encapsulating material as compared to other wall materials when all are used alone as in formulation F3.

Betalain content

Beetroots comprise of large quantities of water soluble betalains, serve as coloring pigments and also possess high antioxidant potential. Natural pigments were well protected against heat due to stabilizing the effect of encapsulation [35]. Experimental data for the present study showed that encapsulation with the blend of AG + MD (DE20) retained betalains (208.06 mg/100 gm dm) to a high degree (Fig. 2). This higher retention was due to the higher proportion of short-chain saccharides present in MD (DE20) which increased the barrier properties to oxygen. Limitation or absence of oxygen, which is the most deteriorative agent, may decrease the negative effect of heat on natural pigments. Same results were well established in studies of Ravichandran et al. [11]. The lowest content of betalain was found for encapsulates with formulation F1 which might be due to the lower DE of MD and its permeable barrier to oxygen during microencapsulation.

Microstructure of spray dried encapsulated beetroot juice

All encapsulates produced showed hollow spherical shape which is typical in microencapsulation occurred by spray drying (Fig. 4). Cracking and any cleft was non-marked in any sample which consequently improvises low gas permeability and provides better retention of pigments. The BJ encapsulates obtained with formulation F1 [[maltodextrin (DE10)] possessed a higher fraction of spherical (Fig. 4a) particles because of elastics matrices and expanding and puffing tendency provided by MD during the drying process. These results are confirmed for spray dried extract of pomegranate, blackberry powder and black mulberry powder by Robert et al. [36], Ferrari et al. [13] and Fazaeli et al. [37] respectively. In contrast, encapsulates produced with MD 20DE (F2), were amorphous and aggregated with a strong attraction for each other (Fig. 4b). This can be explained by the molecular structure of encapsulating materials. The SEM pictures of BJ encapsulates with the binary blend of AG + MD (DE10) showed smooth surface and a much round shape because of the observed higher solid content (Fig. 4c).

Conclusion

MD with different dextrose equivalency along with AG showed effective results as microencapsulating material for beetroot juice (semi-concentrate) by spray drying. All encapsulates of BJ produced by spray drying with different encapsulating material exhibited low moisture content (1.26–2.88 %) of microbiologically safe range. The minimum hygroscopicity and maximum bulk density values were referred to encapsulate produced with the formulation F1 and F2. As far as the formulations with binary blends were concerned, the formulation F5 proved to be more efficient for retention of redness in encapsulates even better than 100 % MD DE10 and DE 20. The results obtained in the present work also indicate that formulation F6 was proved the best encapsulating material for spray drying of BJ with the highest retention of TPC and RSA (%). In conclusion, microencapsulation by spray drying could be suggested as a suitable method for color stabilizing of beetroot pigment extract by means of blends of MD and AG along with an achievable mean of production of food-grade functional colorants.

References

F.C. Stintzing, R. Carle, Trends Food Sci. Technol. 15(1), 19–38 (2004)

D. Strack, T. Vogt, W. Schliemann, Phytochemistry 62, 247–269 (2003)

B. Nemzer, Z. Pietrzkowski, A. Sporna, P. Stalica, W. Thresher, T. Michałowski, S. Wybraniec, Food Chem. 127, 42–53 (2011)

K. Shekhar, M. Madhu, B. Pradeep, D. Banji, Int. J. Pharm. Sci. Res. 5(2), 5862 (2010)

E. Pitalua, M. Jimenez, E.J. Vernon-Carter, C.I. Beristain, Food Bioprod. Process. 88, 253–258 (2010)

G.A. Reineccius, Dry. Technol. 22(6), 22–28 (2004)

B. Adhikari, T. Howes, B.J. Wood, B.R. Bhandari, J. Food Eng. 94, 135–143 (2009)

S. Krishnan, A.C. Kshirsagar, R.S. Singhal, Carbohydr. Polym. 62, 309–315 (2005)

B. Bazaria, P. Kumar, J. Food Process. Preserv. (Available online) (2016)

Z. Fang, B. Bhandari, Food Res. Int. 48, 478–483 (2012)

K. Ravichandran, N.M.M.T. Saw, A.A.A. Mohdaly, A.M.M. Gabr, A. Kastell, H. Riedel, Z. Cai, D. Knorr, I. Smetanska, Food Res. Int. 50(2), 670–675 (2013)

E. Janiszewska, Powder Technol. 264, 190–196 (2014)

C.C. Ferrari, S.P.M. Germer, I.D. Alvim, F.Z. Vissotto, J.M. Aguirre, Int. J. Food Sci. Technol. 47, 1237–1245 (2012)

K. Thirugnanasambandham, V. Sivakumar, J. Saudi Soc. Agric. Sci. 15(2), 195–201 (2016)

J. Claude, J. Ubbink, Food Chem. 96, 402–410 (2006)

F.M. León-Martínez, L.L. Méndez-Lagunas, J. Rodríguez-Ramírez, Carbohydr. Polym. 81, 864–870 (2010)

AOAC International, AOAC International, Gaithersberg, MD (1990)

Y.Z. Cai, H. Corke, Production and properties of spray-dried Amaranthus betacyanin pigments. J. Food Sci. 65, 1248–1252 (2000)

O. Ozdikicierler, S.N. Dirim, F. Pazir, Powder Technol. 253, 474–480 (2014)

W. Luo, M. Zhao, B. Yang, G. Shen, G. Rao, Food Chem. 114, 499–504 (2009)

İ. Gülçin, Innov. Food Sci. Emerg. Technol. 11, 210–218 (2010)

V.L. Singleton, J.A. Rossi, Am. J. Enol. Vitic. 20, 144–158 (1965)

R.V. Tonon, A.F. Baroni, C. Brabet, O. Gibert, D. Pallet, M.D.J. Hubinger, J. Food Eng. 94, 215–221 (2009)

S.Y. Quek, N.K. Chok, P. Swedland, Chem. Eng. Process. 46, 386–392 (2007)

S. Jaya, H. Dass, J. Food Eng. 63, 125–134 (2004)

R.V. Tonon, C. Brabet, D.M. Hubinger, J. Food Eng. 88, 411–418 (2008)

G.R. Rodriguez-Hernandez, R. Gonzalez-Garcia, A. Grajales-Lagunes, M.A. Ruiz-Cabrera, M. Abud-Archila, Dry. Technol. 23, 955–973 (2005)

A.M. Goula, K.G. Adamopoulos, Innov. Food Sci. Emerg. Technol. 11, 342–351 (2010)

D.M. Jiménez-Aguilar, A.E. Ortega-Regules, J.D. Lozada-Ramírez, M.C.I. Pérez-Pérez, E.J. Vernon-Carter, J. Welti-Chanes, J. Food Comp. Anal. 24, 889–894 (2011)

S. Ersus, U. Yurdagel, J. Food Eng. 80, 805–812 (2007)

X. Duan, Y. Jiang, X. Su, Z. Zhang, J. Shi, Food Chem. 101, 1365–1371 (2007)

M. Maskan, J. Food Eng. 72, 218–224 (2006)

Z.S. Cserhalmi, Á. Sass-Kiss, M. Tóth-Markus, N. Lechner, Innov. Food Sci. Emerg. Technol. 7, 49–54 (2006)

Z.H. Qi, A. Xu, Cereal Food World 44, 460–465 (1999)

T. Jiratanan, R.H. Liu, J. Agric. Food Chem. 52, 2659–2670 (2004)

P. Robert, T. Gorena, N. Romero, E. Sepulveda, J. Chavez, C. Saenz, Int. J. Food Sci. Technol. 45, 1386–1394 (2010)

M. Fazaeli, S. Yousefi, Z. Emam-Djomeh, Food Res. Int. 50, 568–573 (2013)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bazaria, B., Kumar, P. Effect of dextrose equivalency of maltodextrin together with Arabic gum on properties of encapsulated beetroot juice. Food Measure 11, 156–163 (2017). https://doi.org/10.1007/s11694-016-9382-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-016-9382-4