Abstract

Scanning electron microscopy studies with energy dispersive x-ray analyses of as-cast and annealed samples of Ni-Ru-Y were used to produce a solidification projection, a liquidus projection surface and an isothermal section at 1200 °C. The ~YNi2, ~YNi3 and ~YRu2 phases had wider solubilities than line compounds, and also extended the furthest into the system. The binary phase extensions into the ternary were: ~51 at.% Ru for ~YNi2; ~22 at.% Ru for ~YNi3; ~13 at.% Ru for ~YNi5; ~7 at.% Ru for ~YNi; ~12 at.% Ni for ~YRu2 and ~10 at.% for ~Y44Ru25. Ruthenium stabilised ~YNi2, so that it solidified at a higher temperature in the ternary than in the Ni-Y binary. A ternary phase was confirmed at Y51Ru15Ni34 (at.%), which forms in a peritectic reaction. The ~Y3Ru and ~Y3Ni phases were isomorphous and formed a continuous solid solution. Heat treatment at 1200 °C gave the phases: (Ru), ~YRu2, ~YNi2, ~YNi3, ~YNi4, ~YNi5 and (Y).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The Ni-Ru-Y system was studied for a potential new coating material. It is of interest because ruthenium increases the corrosion resistance of titanium alloys,[1] hardmetals[2] and stainless steels,[3] and yttrium has been used as a component for coating Ni-based alloys.[4]

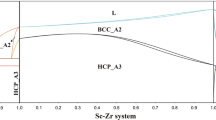

The Ni-Ru (Fig. 1) and Ni-Y (Fig. 2) binary phase diagrams are well established, but the reactions in Ru-Y are less certain, although the phases are known (Fig. 3).[5] The Ni-Y and Ru-Y phase diagrams are complex with many phases,[5] whereas Ni-Ru is a simple peritectic, with no intermetallic phases.

Ni-Ru phase diagram[5]

Ni-Y phase diagram[5]

Ru-Y phase diagram[5]

A structure type for Y(Ru x Ni1−x )2, where x = 0 − 0.78 (i.e. ~YNi2 up to Y33Ru52Ni15) was reported as Cu2Mg.[6] Chunxiao et al.[7] studied the transect from YNi2 to YRu2 in Ni-Ru-Y and found a two-phase region between the binary phase extensions, and that ~YNi2 extended much further into the ternary than ~YRu2. Both YNi2 and YRu2 are Laves phases; YNi2 has the Cu2Mg structure, and YRu2 has the Zn2Mg structure.[8]

Sokolovskaya et al.[9] produced an isothermal section at 600 °C for Ni-Ru-Y. For the terminal solid solutions, (Ni) was shown with solubility for only ruthenium, and (Ru) was shown with considerable solubility for nickel. In the redrawn version (Fig. 4),[10,11] (Ru) was drawn with less solubility for Ni, but both solubilities decrease with temperature,[5] and phases which had previously been drawn as line compounds,[9] were drawn with small solubility ranges. Not all of the accepted binary intermetallic phases[5] were indicated on the isothermal section, and the missing phases were: Y2Ni7, Y3Ni2, Y3Ru2, Y44Ru25 and Y5Ru2. The reason for this is probably that the phases did not penetrate the ternary sufficiently for the samples to contain them, and the original paper[9] did not provide sample compositions. There was no solubility shown in Y. All the binary phases present were shown to extend into the ternary as line compounds, along constant Y content.[9] At 600 °C, the extent of ~Y3Ni was at ~Y75:Ru6:Ni19 (at.%) and the extent of ~Y3Ru was at Y75:Ru17:Ni8 (at.%). The phase extents of ~YNi2 and ~YRu2 agreed well with Chugxiao et al.[7] and these phases extended towards each other, with a two-phase region between. It should be noted that, considering the tie-triangles (three-phase regions) and the two-phase regions, there are no true ternary phases on that transect, and the extents of the YNi2 and YRu2 phases are ~Y34:Ru49:Ni17 and ~Y34:Ru55:Ni11 (at.%) respectively. These phase extension limits are marked on the most recent compilation diagrams.[10,11] The phase widths were drawn to be ~1 at.% in the compilation (Fig. 4),[11,12] wider than in the original.[9] A true ternary phase, ~Y5Ru2Ni2,[9] was reported with a solubility range of ~5 at.%, which was involved in four three-phase fields,[9] but in the subsequent compilations,[10,11] the range was smaller. In this investigation, the ternary phase is denoted τ, or ~Y51Ru15Ni34 (at.%).

The aim of this work was to study as-cast alloys, and derive a liquidus surface. Additionally, samples were annealed at 1200 °C, and compared to the lower temperature results of the isothermal section at 600 °C.[9,10] The phase nomenclature is given in Pettifor order.[12] Although some preliminary work has already been published from the current study,[13-19] this is the final version, and some of the interpretations have been changed using evidence from more samples.

Experimental Procedure

The samples were made by arc-melting minimum 99.9% pure elemental components, Table 1, under an argon atmosphere, after pumping out and flushing repeatedly with argon, and titanium was used as an oxygen-getter. The samples were then sectioned, as near as possible into halves, mounted, and prepared metallographically. The first five samples were also sealed in silica ampoules, back-filled with argon, and annealed at 1200 °C (rather than the planned 1000 °C) for 1000 h. Although there was a concern that Y could reduce SiO2, there were no other methods available.

Analyses were undertaken using pure element standards, in a Philips XL 30 ESEM with an EDAX Phoenix EDX system, and at least five analyses were taken on different phases or over areas to obtain the averages presented. The phases were identified by comparing the compositions to the 600 °C isothermal section,[9] the binaries[5] and also using the phase morphologies in the microstructures. When not in use, the samples were stored in ethanol or methanol. Unfortunately, most of the samples oxidized and disintegrated before x-ray diffraction (XRD) could be undertaken to confirm the phases, but some were analysed on a Philips PW 3710 powder diffractometer giving patterns of poor quality.

Results

Some of the alloys had small particles of Y2O3, which were assumed to be present before, or in an early stage of melting, despite taking the precautions of melting under argon and storing in alcohol. Since the oxide particles were mainly in minor proportions, and have a very high melting point (2458 °C),[5] they were ignored in the interpretation of the microstructures, despite the fact that they were sometimes nucleation sites. Although these particles were analysed, being more brittle, they were usually at least partially removed on sample preparation and the resulting poor surface gave low wt% totals and high errors. Ignoring the oxides in the samples’ compositions, the solidification sequences were justified since attempts to interpret them as (Y), which then subsequently oxidized, gave impossible solidification reaction sequences for most of the samples, except for the very Y-rich samples. However, regions with Y2O3 were avoided as far as possible during analysis. Another problem was that all the high Y content samples were found to be contaminated with Ta. Subsequently, when the pure Y source material was studied, 1-1.5 μm diameter Ta-rich spheroids were found. Since in energy dispersive x-ray analysis (EDX), the Ni Kα peak overlaps the Ta Lα peak, and the Y Lα peak overlaps with the Ta Mα peak, this made deconvoluting the presence of Ta very difficult, although Ta regions were always very bright in the microstructure in backscattered electron imaging mode (BSE), with Ta (73) having a much higher atomic number than Ni (28), Y (39) or Ru (44).

The EDX analyses for the overall composition of the alloys and the composition of the individual phases of the as-cast samples are given in Table 2, with all compositions in at.%, while the area analyses of the eutectic structures are listed in Table 3. The analyses for the heat treated samples at 1200 °C for 1000 h are given in Table 4.

Unfortunately, the specimens oxidized and disintegrated very soon after scanning electron microscopy (SEM) analysis, and thus most of the samples were not suitable for XRD studies. Even keeping some of the samples in analar grade (AR) methanol and some of the samples in ultra low water (UL) ethanol did not protect the samples. An original sample of composition ~Ni15:Ru15:Y70 (at.%), i.e. high Y content, oxidized almost immediately and was never examined, and Sample 2, ~Ni54:Ru45:Y1 (at.%), although Y-poor, disintegrated soon after analysis. It was subsequently found that water readily reacts with Y and its compounds to form hydrogen and Y2O3,[20] and this is likely to have occurred during metallographic preparation.

As-Cast Samples

Nominal ≃Ni7:Ru72:Y21 (at.%), Sample 12

The nominal composition ~Ni7:Ru72:Y21 (at.%), Sample 12, solidified with (Ru) dendrites in a complex eutectic matrix (Fig. 5). The darkest phase showed a wide range of coring, and formed after the fine univariant binary (Ru) + ~YRu2 eutectic.

The solidification reactions were:

where the latter was a ternary peritectic reaction.

Nominal ≃Ni54:Ru45:Y1 (at.%), Sample 2

The nominal ~Ni54:Ru45:Y1 (at.%) sample solidified with very cored (Ru) dendrites, followed by very clear peritectially-formed (Ni) (Fig. 6). There were very small areas of a globular (Ni) + ~YNi5 eutectic. These were much too fine to analyse the components accurately (and even the overall composition of the eutectic were just on the limit for reasonable analyses).

The solidification sequence was:

Nominal Ni38:Ru42:Y20 (at.%), Sample 6

The Ni38:Ru42:Y20 (at.%) sample (Sample 6) had small primary (Ru) dendrites (Fig. 7). Next in the solidification sequence were two peritectic reactions forming large needles of ~YNi2 (sometimes pushing the dendrites aside), and ~YNi3. The ~YNi2 phase had a much wider solubility than in the redrawn isothermal sections.[9,10] At higher magnifications, another phase was observed, and all phases had distinct boundaries (Fig. 7), indicating distinct phases rather than coring. The small dark phase areas of ~YNi4 would have meant that the EDX analyses were affected by the surrounding phases, so their analyses are not reported. There were also lighter contrast regions within the ~YNi2 needles, assumed to be ~YNi2 with higher Ru content, which solidified before the ~YNi2 with lower Ru content, with the lightest being remnant (Ru) dendrites (i.e. an incomplete peritectic reaction). The ~YNi2 solidified at a higher temperature than in the Ni-Y binary, because of the higher Ru content, and the direction of slope of the liquidus is consistent with the phase contrasts and analyses (albeit not accurate).

Thus, the deduced solidification reactions are:

Nominal Ni69:Ru16:Y15 (at.%), Sample 5

Nominal Ni69:Ru16:Y15 (at.%) (Sample 5) was mostly dendrites of ~YNi5 with a fine lamellar eutectic structure comprising ~YNi5 and (Ru) (Fig. 8). The light phase was much too fine for accurate analysis, which was shown by the large errors (up to ±2.0 at.%), and should have had a much higher Ru content.

The solidification sequence was:

Nominal ≃Ni76:Ru13:Y11 (at.%), Sample 13

Nominal ~Ni76:Ru13:Y11 (at.%) (Sample 13) had ~YNi5 dendrites of slightly different BSE contrasts and compositions, and a fairly coarse lamellar eutectic structure (Fig. 9). There was also fine precipitation in the dendrites. The dendrite analyses were similar, with the differences deriving from different local dendrite compositions on solidification and varying amounts of precipitation within. These effects were caused by the ~YNi5 phase having a very sloping solvus, so the lighter dendrites had slightly more Ru and Y, which would account for the large errors. Both of the eutectic components were too fine to accurately analyse individually, but the overall analysis of the univariant binary eutectic was obtained (Table 2).

The solidification sequence was:

Nominal ≃Ni81:Ru10:Y9 (at.%), Sample 7

Nominal ~Ni81:Ru10:Y9 (at.%) (Sample 7) was similar to ~Ni76:Ru13:Y11 (at.%) (Sample 13), with the same solidification sequence, and precipitation within the dendrites. The true dendrite phase composition should be extrapolated away from (Ni) (which precipitated within), giving the phase to be ~YNi5 (also confirming the ~YNi5 phase in Sample 2).

Nominal ≃Ni61:Ru10:Y29 (at.%), Sample 8

In nominal ~Ni61:Ru10:Y29, the darkest phase was Y2O3 (Fig. 10) and in some regions there was high porosity associated with the last phase to solidify. The ~YNi2 needles formed first, followed by ~YNi3, and distinct interfaces between ~YNi2 and ~YNi3 were seen at higher magnification.

Ignoring the Y2O3, the solidification sequence was:

Nominal Ni70:Ru3:Y27 (at.%), Sample 16

Ignoring the light contrast contamination which filled some of the holes after polishing nominal ~Ni70:Ru3:Y27 (at.%) (Sample 16) and the prior Y2O3 phase, most of which had fallen out during sample polishing, leaving holes, there were four phases present (Fig. 11). The first phase to form, ~YNi4, could have been dendritic in morphology, although the subsequent peritectic reaction removed most of the outline, leaving an irregular needle-like appearance. The phase identification was achieved by comparison to the isothermal section of Sokolovskaya et al.,[9] and by assuming that the binary Ni-Y phases extended into the ternary at constant Y content. The solidification sequence agreed with the peritectic cascade of phases reported in the Ni-Y binary,[5] and ignoring Y2O3, was:

The ~Y2Ni7 and ~YNi2 phases were too small to analyse accurately, giving large errors, and the analyses were made more Ni-rich by the surrounding higher Ni-content phases.

Nominal Ni19:Ru46:Y35 (at.%), Sample 3

There were some oxide particles in the nominal ~Ni19:Ru46:Y35 (at.%) alloy (Sample 3), and the main dendrites had an inner composition of Y33:Ru55:Ni12 (at.%), and an outer composition of ~Y24:Ru44:Ni32 (at.%). There were minor amounts of a two-phase interdendritic region of overall composition ~Y51:Ru15:Ni34 (Fig. 12), where the contrast of one phase was similar to the outer dendrite. In some places, the dendrites appeared cored, whereas in others, there was a distinct interface between the ~Y33:Ru55:Ni12 and ~Y24:Ru44:Ni32 (at.%). Both of these compositions, even with the relatively high errors (±3 at.% for the most Ni-rich component, and ±2 at.% for the most Ru-rich component) were on the ~YRu2 to ~YNi2 transect, and fairly close to the limits of the ~YRu2 and ~YNi2 phases.[7,9] The high errors in Ni and Ru contents are consistent with coring in the Ni and Ru directions, and the low errors in Y are consistent with the phases having constant Y content. In the absence of good x-ray data, the phases could only be deduced by morphology and composition. The ~YNi2 phase solidified as facetted dendrites with 48.3 at.% Ru (Sample 1) (Fig. 16) and 35.7 at.% Ru (Sample 4) (Fig. 17), facetted crystals with 49.8 at% Ru (Sample 11) (Fig. 13), needles as a secondary phase with 46.1 at.% Ru (Sample 6) (Fig. 7), and needles then dendrites with 14.4 at.% Ru (Sample 8) (Fig. 10). Thus, for higher Ru contents, ~YNi2 tended to solidify with a more facetted morphology, and with lower Ru contents, as dendrites. Here, the outer phase comprised 43.7 at.% Ru, which should have given a more facetted appearance, if it was ~YNi2. However, the phase was growing on a fair proportion of pre-existing ~YRu2, and so would have taken that shape initially. Thus, the two compositions and different contrasts were deduced to be inner dendrites of ~YRu2 (of ~55.4 at.% Ru). Since the analyses of the interdendritic region were actually of a sparse eutectic structure, which comprised mainly the darker component (lower atomic number contrast), the analysed composition of that component must lie near the univariant binary eutectic. However, since the overall analysis of this eutectic had large error bars (due to only small areas being available for analysis, and its univariant quality) and were near to the reported composition of ~Y5Ru2Ni2,[9] which here is called τ, (~Y51Ru15Ni34 (at.%)), the darker component was taken to be τ. Comparison with the isothermal section[9] shows that the overall composition of the univariant binary eutectic, ~Y51:Ru15:Ni34, was in the two-phase region of τ + ~YNi, but the sparse component had the same contrast as ~YNi2, and so is taken to be this phase.

Ignoring the Y2O3 phase, the sequence on solidification was:

Nominal ≃Ni10:Ru31:Y59 (at.%), Sample 11

The microstructure of Sample 11, nominal ~Ni10:Ru31:Y59 (at.%), was complex and there appeared to be two different primary phases, ignoring Y2O3. The yttrium oxide solidified first and acted as a nucleation site locally for either of the next phases, showing that the boundary between the ~YNi2 and ~Y44Ru25 liquidus surfaces was very close to the overall composition of the sample. In some places, ~YNi2 formed on the oxide as regular, almost square, facetted blocks (top left of Fig. 13), and next, facetted ~Y44Ru25 formed, with a final univariant binary eutectic reaction. The oxide was ignored for phase diagram considerations. The EDX analyses (Table 2) had unacceptably high errors for ~YNi2, although the light phase appeared large enough to analyse without collecting any x-rays from the surrounding phases. This would be consistent with a wider phase field in the Y direction and coring on solidification, i.e. the Ru direction. The overall composition of the univariant binary eutectic was close to the ternary ~Y5Ru5Ni2 phase,[9] and one eutectic phase was clearly ~Y44Ru25, as it was associated with the facetted blocks. The composition of the second eutectic phase was roughly estimated by extrapolating from the known (by EDX analysis) eutectic phase, ~Y44Ru25, through the overall composition of the eutectic, considering the proportions of the eutectic phases, to give τ, ~Y51Ru15Ni34. (This was very approximate, because it assumed the tie triangle of the univariant binary eutectic was a straight line.) The ~YNi2 phase also had another morphology, which was more irregular (centre of Fig. 13), but still facetted, and in this morph, it was associated with the univariant binary eutectic. This was deduced to be from mainly solid state precipitation (which occurred after solidification was complete), after forming as a coarse eutectic structure with ~Y44Ru25, and then the final, much finer, ~Y44Ru25 + τ eutectic structure. This indicates that the ~Y44Ru25 solvus is sloping with temperature, allowing the ~YNi2 to be precipitated subsequently in such a coarse morphology.

Ignoring the Y2O3 phase, which is not part of the true solidification sequence for this composition, the solidification sequence for the regions where very regular ~YNi2 formed (i.e. locally on that liquidus surface) is:

(1)

(2)

Alternatively, most of the sample solidified by:

The average overall composition for the regions of solidification reaction 1 was 5.5 ± 0.2 Ni, 31.8 ± 0.6 Ru, 62.7 ± 0.5 1 Y (at.%), with ~YNi2 solidifying first, whereas the average overall composition for the regions of solidification reaction 2 was 6.4 ± 0.5 Ni, 31.9 ± 0.6 Ru, 61.8 ± 1.1 Y (at.%), with ~Y44Ru25 solidifying first. Thus, the ~YNi2 and ~Y44Ru25 liquidus surface boundary runs between these different local overall compositions. The solidification reaction that occurred only locally showed that the peritectic reaction forming ~Y44Ru25 from ~YNi2 changed to a univariant binary eutectic at lower temperatures.

Nominal Ni6:Ru31:Y63 (at.%), Sample 17

Nominal Ni6:Ru31:Y63 (at.%) (Sample 17) was very similar to Sample 11, with the same phases and mostly the same morphologies, except that locally, ~YNi2 formed definite facetted dendrites and hollow hexagons (Fig. 14). This confirmed that the boundary between the ~YNi2 and ~Y44Ru25 liquidus surfaces must lie between these two compositions. The major primary phase was ~Y44Ru25 and the solidification reaction was the same as Reaction 2 for Sample 11.

SEM-BSE image of as-cast nominal Ni6:Ru31:Y63 (at.%) (Sample 17), showing Y2O3 dendrites (very dark), hollow hexagonal sections and facetted ~YNi2 dendrites (light) and less-facetted coarse ~Y44Ru25 dendrites (medium contrast) with a small amount of fine ~Y44Ru25 + τ, ~Y51Ru15Ni34 (medium dark) eutectic structure

Nominal Ni16:Ru23:Y61 (at.%), Sample 18

Nominal Ni16:Ru23:Y61 (at.%) (Sample 18) had a high proportion of Y2O3, but the true primary phase (of the Ni-Ru-Y system) was ~YNi2, which formed as facetted dendrites (Fig. 15). The next phase was ~Y44Ru25, which formed long needles, and a univariant binary eutectic formed last. Although the morphology of the ~Y44Ru25 phase and ~Y44Ru25 + τ eutectic structure appeared different in Samples 11 and 17, this is because the overall compositions of the univariant binary eutectic and phase proportions were different.

The solidification reactions were (ignoring the oxides):

Nominal Ni24:Ru26:Y50 (at.%), Sample 1

The nominal Ni24:Ru26:Y50 (at.%) alloy (Sample 1) comprised primary ~YNi2 as facetted dendrites in a univariant binary eutectic (Fig. 16; Table 2). Both of the eutectic phases were too small to accurately analyse individually, without collecting x-rays from the neighbouring phases. Comparison to the other univariant binary eutectics in the same region (Samples 1, 3, 11, 17 and 18) showed that the morphologies of these eutectics were similar, except for that of Sample 3, which was more sparse, indicating that Samples 1, 11, 17 and 18 had the same univariant binary eutectic. This gave the eutectic here as ~Y44Ru25 + τ, ~Y51Ru15Ni34, whereas Sample 3 had a different univariant binary eutectic: ~YNi2 + τ, ~Y51Ru15Ni34.

Ignoring the oxides (which formed first, and are not part of the ternary system), the deduced solidification sequence was:

The latter was a ternary invariant transition reaction.

Nominal Ni41:Ru16:Y43 (at.%), Sample 4

The alloy of nominal composition Ni41:Ru16:Y43 (Sample 4) had facetted and apparently cored dendrites of ~YNi2 (Fig. 17). However, if cored, the insides of the dendrites should have been lighter in BSE contrast, because they should have been more Ru-rich than the outer region. Since the dendrite inners were actually darker, they were deduced to be a phase with less Ru than ~YNi2, and thus τ, ~Y51Ru15Ni34, since the alternative, ~YNi, formed subsequently. Surrounding the facetted dendrites was a sparse univariant binary eutectic with ~YNi as the major component, and the minor component was deduced by contrast to be ~YNi2.

Ignoring the oxide phases, the solidification sequence was:

Nominal Ni31:Ru11:Y58 (at.%), Sample 9

The microstructure of nominal Ni31:Ru11:Y58 (at.%) (Sample 9) (Fig. 18) shows small, dark oxide dendrites, some of which were larger than usual, which had mostly been removed by polishing (being more brittle). There were medium grey contrast ~YNi dendrites which sometimes formed on the oxide dendrites, followed by the light τ matrix. The errors for the EDX analyses, especially for the ~YNi and oxide phases, were unacceptably high, but their areas were small and the beam presumably spread more than expected.

The solidification sequence was:

Nominal Ni26:Ru8:Y66 (at.%), Sample 19

Apart from the usual small Y2O3 dendrites, nominal Ni26:Ru8:Y66 (at.%) (Sample 19) comprised a coarse globular eutectic structure, with the lighter component, τ, ~Y51Ru15Ni34 almost appearing dendritic (Fig. 19). However, the fine scale of the morphology showed that this was a univariant binary eutectic, with very small dendrites of τ, ~Y51Ru15Ni34 occasionally solidifying before the eutectic. Thus, the alloy composition was just on the τ-rich side of the τ, ~Y51Ru15Ni34 + ~Y3Ni2 univariant binary eutectic valley, and the sample mostly solidified to the globular eutectic.

The solidification sequence was:

Nominal Ni10:Ru12:Y78 (at.%), Sample 14

Unfortunately, the sample of nominal composition Ni10:Ru12:Y78 (at.%) (Sample 14) because it is Y-rich was noticeably contaminated by tantalum, which formed almost pure (Ta) dendrites on the small Y2O3 dendrites. The sample also formed a scale after manufacture and while in methanol. Although difficult to determine, because of the overlapping of the Ni and Y x-ray peaks with those of Ta, it was deduced that there was no Ta in the matrix (with the reasons given in the discussion).

It was difficult to differentiate whether the rest of the microstructure was two separate phases, or coring, but the first component to form (after Y2O3 and (Ta)) was the lighter component, originally assumed to be ~Y3Ru. The darker “interdendritic” regions were of the composition of ~Y3Ni at 600 °C,[8,9] and there was no discernable interface between them, indicating coring of an isomorphous phase, ~Y3(Ru,Ni), rather than the two separate binary phases.

Thus, the solidification in the ternary was:

Nominal Ni10:Ru11:Y79 (at.%), Sample 10

Sample 10, nominal Ni10:Ru11:Y79 (at.%), was the only sample to have two different contrast dendrites of Y2O3 and (Y), and these are thought to be (Y) in two different stages of oxidation (although these were a minor portion of the sample). There was also quite high Ta contamination, because of sample had a higher Y content. The major phase was dendritic ~Y3(Ru,Ni), with a comparable solubility for Ni with that reported at 600 °C.[9] The rest of the sample was an irregular ~Y3(Ru,Ni) + (Y) univariant binary eutectic viewed at different orientations, similar to that in Fig. 20, consistent with the eutectic in the Ru-Y binary.[5] The (Y) in the eutectic structure had a different morphology from the small Y2O3 dendrites, as though it was still being oxidised and falling out. There were also holes where the Y2O3 had been removed during sample preparation.

Ignoring the obvious Y2O3 and the Ta contamination associated with Y, the solidification sequence was:

Nominal Ni10:Ru6:Y84 (at.%), Sample 15

The sample of composition Ni10:Ru6:Y84 (at.%) was also contaminated with Ta, but once again, the Ta was only found as small pure Ta particles in the sample, and did not dissolve in any of the other phases. This sample also formed a scale after manufacture, and in methanol, and to a greater extent than Sample 14. There were holes where Y2O3 had been pulled out during sample polishing, and some small dark Y2O3 dendrites remained in the ~Y3(Ru,Ni) + Y2O3 (originally (Y)) eutectic (Fig. 20). The eutectic structure had two apparent morphologies, with either globular or more needle-like discrete phases, which was an orientation effect. The phases were too small to be analysed individually and accurately. Although there was more of ~Y3(Ru,Ni), its analysis was compromised by the (Y) particles in the eutectic structure, thus ~Y3(Ru,Ni) should have less Y than was found.

Given the high Y content of the sample, it is likely that (Y) formed first, then oxidized. The solidification reactions were deduced to be:

Heat Treated Samples

Unfortunately, rather than being annealed at 1000 °C as planned, the samples were actually annealed at 1200 °C for 1000 h. This meant that some of the samples experienced partial melting, and there was oxidation in the form of minor rounded oxides in the matrix, while Y loss was often severe. However, the results did give more information on the system.

Nominal Ni38:Ru42:Y20 (at.%), Sample 6H

After heat treatment, nominal Ni38:Ru42:Y20 (at.%), Sample 6H comprised four different regions of different microstructures, although some were the same phases as in the as-cast sample, which are reported in Table 4 as 6H-1 to 6H-4 from the outside inwards. These four different regions, with two intermediate layers, comprised (Ru) in matrices of ~YNi3 of two different compositions, ~YNi4 and ~YNi5, from the inside to the outside (Fig. 21). The last layer had cracks within ~YNi5, which usually ran between (Ru) regions. There were very small differences in the (Ru) contents in the different regions. Small regions of Y2O3 were found throughout the sample, and were rounded and in a much smaller proportions than the Y2O3 seen in the as-cast samples.

Nominal Ni69:Ru16:Y15 (at.%), Sample 5H

The same phases, (Ru) and ~YNi5, as in the as-cast sample were found after heat treatment, but they had rounded and coarsened considerably. The sample had lost Ni.

Nominal Ni19:Ru46:Y35 (at.%), Sample 3H

The as-cast microstructure of nominal Ni19:Ru46:Y35 (at.%), Sample 3, had changed from the ~YRu2 (inside)/~YNi2 (outside) dendrites with minor amounts of the univariant binary ~YNi2 + τ eutectic, to regions of Si on the outside (which were ignored since this was contamination from the ampoules), (Ru) in ~YNi2; Y2O3 in ~YNi2; and higher proportions of (Ru) variously in adjacent regions of ~YRu2 and ~YNi2 (all with minor amounts of rounded oxides).[18] In Table 4, these are denoted as 3H-1 to 3H-4 working inwards in the sample. In 3H-4, a coarsened eutectic-like structure of (Ru) + ~YRu2 formed, consistent with the Ru-Y binary,[5] at lower temperatures in the ternary.

Nominal Ni24:Ru26:Y50 (at.%), Sample 1H

The ~YNi2 dendrites and τ + ~Y44Ru25 univariant binary eutectic microstructure of as-cast Ni24:Ru26:Y50 (at.%) (Sample 1 and Fig. 16), had changed totally on heat treatment to blocks of ~YNi2 in a matrix of ~YNi3 with large rounded regions of Y2O3, and smaller mixed regions of ~YNi3 and Y2O3 (Fig. 22). The latter mixed regions (of composition: 23.4 ± 7.0 Ni, 19.4 ± 1.6 Ru, 57.2 ± 7.6 Y (at.%)) at least had melted, as indicated by the associated coarse porosity, and these regions were taken as the liquid composition. The sample had lost some Y and Ni, and comprised many large pores.

Nominal Ni41:Ru16:Y43 (at.%), Sample 4H

As-cast Ni41:Ru16:Y43 (at.%) (Sample 4H) comprised τ in ~YNi2 dendrites in a sparse univariant binary eutectic of ~YNi2 + ~YNi, whereas after heat treatment, there was severe reaction with the ampoule’s silicon and much oxidation. Portions in the centre of the sample, which were surrounded by coarse connected porosity had very similar microstructures to Ni24:Ru26:Y50 (at.%) (Sample 1H, Fig. 22), with ~YNi2, ~YNi3 and rounded Y2O3 (although with no mixed regions). The sample had lost both Y and Ni.

Discussion

There were always problems with the (Y) phase being oxidised, despite keeping the samples in alcohol, and methanol was found to be better than ethanol. However, the higher Y content samples were even more problematic. The darkest phases were deduced as oxides because neither ruthenium nor nickel has been reported to have any discernible solubility in Y.[5] Thus, most of the samples had Y2O3 and the true presence of (Y) was deduced by the microstructure, the overall composition of the alloy and the solidification sequence. Mostly, the oxide results were ignored in the interpretation of the ternary, although when interpreted as oxidized (Y), they were plotted ignoring the oxygen content (Fig. 23).

Another problem was the contamination of Ta, which was from contamination of the source Y material and was observed more in higher Y content samples. Yttrium was supplied by Goodfellow Metals Cambridge Limited, who stated that the supplied Y lumps could contain up to 300 ppm Ta, as well as other lesser impurities (Table 1) which were not found, being below the EDX detection limit. This problem was exacerbated, because in the energy dispersive x-ray spectra, significant peaks of Ta were overlapped by Ni and Y peaks, and the Ta peaks could only be discerned in the very high Y content alloys. It was deduced that there was no Ta in the matrix (since Y and Ta are nearly exclusively immiscible[5]) and thus the matrix compositions could be used in the phase diagram determination (although Ta is soluble in both (Ni) and (Ru), this higher Y content region is far away from their solid solutions). This is further substantiated by considering the formation energies: the most negative formation energies were for the intermetallic compounds in the Ni-Y system,[21-23], (YNi3: −0.402 eV atom−1;[24] YNi2: −0.424 eV atom−1;[25] Y2Ni7: −0.380 eV atom−1;[26] YNi: −0.445 eV atom−1[27]), and although the compounds in the Ni-Ta systems had negative formation energies,[21-23] they were less negative than those of the Ni-Y compounds (TaNi3: −0.366 eV atom−1;[28] Ta2Ni: −0.232 eV atom−1;[29] TaNi2: −0.340 eV atom−1[30]). This was also the case for the reported Ru-Ta intermetallic compounds[21-23] (Ta3Ru: −0.215 eV atom−1; TaRu: −0.317 eV atom−1;[31] TaRu3: −0.196 eV atom−1) and the reported ternary compounds[21-23], (YTaRu2: −0.335 eV atom−1; Y2NiRu: −0.361 eV atom−1).

Yttrium oxidized whereas the Ta did not, because yttrium has an exceptionally high affinity for oxygen, with a free energy of formation of the oxide of 1817 kJ mol−1, probably the highest of any element, and it also dissolves oxygen gas in relatively high concentrations.[32,33] The formation energies of the different structures of Y2O3 (−3.846 eV atom−1,[21-23,34] −3.809 eV atom−1,[21-23,35] −3.784 eV atom−1[21-23,35] and −3.714 eV atom−1[21-23,36]) are all more negative than those of the most stable (i.e. most negative) tantalum oxide (Ta2O5 at −3.186 eV atom−1[21-23,37]). Additionally, the amount of oxygen was limited in the closed environment of the arc-melter. When the Ti melted first as the oxygen getter, yttrium would have reacted next with the remaining oxygen (being in the larger proportion than tantalum), and subsequently would have left very little oxygen for Ta oxidation.

The phases were identified by comparing results with the isothermal section at 600 °C,[9] the component binary phase diagrams,[5] and comparing morphologies of the different phases. Limited XRD was undertaken, because by the time the samples had been fully analysed, they had oxidized to such an extent that XRD would have revealed a high proportion of the Y2O3 oxide phase. Additionally, at the time of this work, there were insufficient data in the ICDD[38] and Karlsruhe[39] databases for the binary phases, and the patterns of at least some of the phases would have had to be modelled, then compared to the limited data. Even when XRD was undertaken, the spectra were of such a poor quality that they were not helpful.

Some of the deductions are already described in the results of the individual alloys, and these were aided by plotting the compositions on a solidification projection (Fig. 23). For samples with Y2O3 which was not considered part of the ternary, the lines between the phases are shown with dotted lines. The solidification temperatures of Samples 1 and 3 must have been fairly different, because the lines between the component phases cross. Although in an isothermal section (i.e. of a specific temperature), the tie-lines are forbidden to cross, since these are as-cast samples, if the solidification ranges are at different temperatures, then the lines between the phases can cross (they are probably not true tie-lines), as long as they lie at a fairly low angle to each other. The lines between the different phases of Samples 1 and 3 are consistent with Sample 3 solidifying at a higher temperature than Sample 1.

The wide solubility range of ~YNi2 for Ru[7,9] was confirmed, and thus the phase was cored in the as-cast condition. The ~Y3Ni2 phase was only found in Sample 10, which would be expected, since it only has a very small liquid surface, and so is unlikely to penetrate very far into the ternary. The same was true for ~Y2Ni7. The ~Y3Ru2 and ~Y2Ni17 phases were not found at all. This was partly because of limited penetration into the ternary in both solubility, and liquidus surface. However, not finding ~Y3Ru2 could have been due to not having a sample composition near that phase. Not finding ~Y2Ni7 is consistent with Sokolovskaya et al.[9-11] Most of the phases had very narrow ranges, except for: ~YNi2, ~YNi3 (at least near the Ni-Y system), ~YNi and ~Y3(Ru,Ni). The binary phases penetrated into the ternary with constant Y content, agreeing with Sokolovskaya et al.[9-11] and being consistent with their reasoning.[9]

Assuming that the Ta contamination did not affect the other phases in which it did not dissolve, Sample 14 (Ni10:Ru12:Y78 (at.%)) indicated that the ~Y3Ru and ~Y3Ni phases were continuous, at least on solidification, which is possible, since they both have the same oP16 structure. However, no samples were made in that region, so this investigation cannot be conclusive on this. A miscibility gap for ~Y3(Ru,Ni) occurs at lower temperatures, since Sokolovskaya et al.[9-11] found two phases at 600 °C. Sample 14 (Ni10:Ru12:Y78 (at.%)) disagrees with Samples 10 and 15, and had more contamination. However, Samples 10 and 15 had the univariant binary ~Y3(Ru,Ni) + (Y) eutectic. Although the analyses of this eutectic from the different samples were different, due to the small areas analysed and the one degree of freedom of this binary, the true analysis is near the overall composition of Sample 15, since this sample was mostly eutectic. This was taken into account when the liquidus surface (Fig. 24) was drawn.

When compared with the isothermal section at 600 °C of Sokolovskaya et al.[9] the phase widths of line compounds on the YNi2 to YRu2 transect of this study were in agreement[9] although wider than the subsequent compiled sections.[10,11] It would be expected that the phase widths at 600 °C would be narrower than on solidification, since solubility tends to decrease with decreasing temperature. The extensions of the binary phase into the ternary were: ~51 at.% Ru for ~YNi2; ~22 at.% Ru for ~YNi3; ~13 at.% Ru for ~YNi5; ~7 at.% Ru for ~YNi; and ~12 at.% Ni for ~YRu2 and ~Y44Ru25. The ternary ~Y5Ru2Ni2 phase of Sokolovskaya et al.[9-11] was seen in Samples 1, 3, 4, 9, 11, 18 and 19, but at a slightly different composition: ~Y51Ru15Ni34 (at.%), and has been designated τ here (for ternary phase).

The solidification reactions were deduced from the microstructures. The liquidus surface (Fig. 24) was drawn to be consistent with the phases analysed and identified, as well as with the solidification sequences and the accepted binary phase diagrams.[5] The overall compositions of the alloys had to lie on their primary phase liquidus surfaces, but the overall compositions of the univariant binary eutectics were not always accurate, and so did not lie at the junctions of their relevant liquidus surfaces, and those known to be inaccurate (due to their small areas) were only used as guidelines (Samples 1, 2, 3, 10 and 12). Although the univariant nature of these binary eutectic reactions would allow for changing overall compositions, this should not have moved the analysed compositions from the surface junctions, and so it is likely that the small eutectic regions were causing the inaccuracies. In order for Sample 8 to solidify as interpreted, with ~YNi2 forming before ~YNi3, the addition of Ru raises the liquidus temperature for primary ~YNi2 relative to that of primary YNi3. This is consistent with ~YNi2 being stabilized by Ru, and so solidifying at higher temperatures than in the Ni-Y system. The directions of the reactions were drawn so that the reactions observed could be produced. For example, the microstructure of Sample 11 necessitated the L + ~YNi2 → ~Y3Ru2 + τ, ~Y51Ru15Ni34 invariant reaction, and so the arrows were drawn accordingly. The coarsening of the ~YNi2 + ~Y44Ru25 eutectic structure by the large growth of ~YNi2 in the solid state means that the ~Y44Ru25 solvus retreats significantly at decreasing temperatures, which agrees with Sokolovskaya et al.[9-11] not reporting it at 600 °C below ~5 at.% Ni.

None of the samples had the Y5Ru2 phase, and even though it forms congruently, it only has a small liquidus surface in the binary,[5] so lacking any other indication, it has been given a relatively small liquidus surface in the ternary. This and ~Y2Ni17 were the only liquidus surfaces for which there was no indication from the current samples, and so they are shown by dotted lines in Fig. 24. The solidification reactions were either directly observed in the samples, or derived from the liquidus surface, and are shown in Table 5. In order to experience the reactions observed in the microstructures, the univariant equilibria L → τ + ~YNi2 and L → τ + YNi must each have a maximum, which is consistent with the congruent solidification of YNi in the binary.[5]

On heat treatment, despite precautions, the samples lost Y (Ni38:Ru42:Y20 (at.%) to Sample 6H), or Ni (Ni69:Ru16:Y15 (at.%) to Sample 5H), or both (Ni24:Ru26:Y50 (at.%) to Sample 1; Ni19:Ru46:Y35 (at.%) to Sample 3H). The Ni38:Ru42:Y20 (at.%) alloy (Sample 6H) showed that the Y was lost on heat treatment, since the layers became less Y-rich towards the outside. There was also evidence that the ~YNi4 layer formed by diffusion at the ~YNi3/~YNi5 interface, since there were still small regions where this interface still existed (Fig. 20).

When the isothermal section at 1200 °C was plotted (Fig. 25), there was mainly (Ru), ~YRu2, ~YNi2, ~YNi3, ~YNi4, ~YNi5 and (Y) (Y2O3). The other phases were missing because of their lower melting points (e.g. ~YNi2, ~YNi, ~Y3Ni2 and ~Y3Ni), small penetration into the ternary (e.g. ~Y2Ni17 and ~Y2Ni7), lack of an annealed sample near the phase compositions (e.g. (Ni), or both the last two reasons (e.g. ~Y3Ru2, ~Y44Ru25, ~Y5Ru2 and ~Y3Ru). The mixed phase regions of Sample 1H were taken as the liquid composition at 1200 °C. The ~YNi3 phase had a larger extension than at 600 °C,[9] which is consistent with solubility decreasing with temperature. The increased stability of ~YNi2 agrees with the liquidus surface. The τ phase (~Y51Ru15Ni34) was not found at 1200 °C, indicating that it solidifies below 1200 °C.

Conclusions

Despite problems with oxidation of Y and its contamination by Ta, consistent interpretations were made using EDX results and phase morphologies. A solidification projection and a liquidus surface projection were drawn and were in agreement with the binary systems and the 600 °C isothermal section of Sokolovskaya et al. The ~YRu2, ~YNi2 and ~YNi3 phases have wider solubilities than at 600 °C, which is expected. The binary phase extensions into the ternary were: ~51 at.% Ru for ~YNi2; ~22 at.% Ru for ~YNi3; ~13 at.% Ru for ~YNi5; ~7 at.% Ru for ~YNi; and ~12 at.% Ni for ~YRu2 and ~10 at.% Ni for ~Y44Ru25. On solidification, the ~Y3(Ru,Ni) phase was seen, which indicates a miscibility gap above 600 °C, to give ~Y3Ru and ~Y3Ni as separate phases, as observed by Sokolovskaya et al. Only the ~Y3Ru2 and ~Y2Ni17 phases were not found, due to limited penetration into the ternary, and ~Y3Ni2 and ~Y2Ni7 were also seen to have very limited extents. One ternary phase was found at ~Y51Ru15Ni34 (at.%), which is a slightly different composition than reported before. Heat treatment at 1200 °C gave the phases: (Ru), ~YRu2, ~YNi2, ~YNi3, ~YNi4, ~YNi5 and (Y). The higher formation temperature of ~YNi2 in the ternary was seen in both the liquidus projection and the isothermal section at 1200 °C and is due to the stabilization by Ru.

References

J.H. Potgieter, A. van Bennekom, and P. Ellis, Investigation of the Active Dissolution Behaviour of a 22% Chromium Duplex Stainless Steel with Small Ruthenium Additions in Sulphuric Acid, ISIJ Int., 1995, 35(2), p 197-202

T.L. Shing, S. Luyckx, and I.T. Northrop, The Effect of Ruthenium Additions on the Hardness, Toughness and Grain Size of WC-Co, Int. J. Refract. Met. Hard Mater., 2001, 19(1), p 41-44

E. van der Lingen and R.F. Sandenbergh, Cathodic Modification Behaviour of Ruthenium Additions to Titanium in Hydrochloric Acid, Corr. Sci., 2001, 43(3), p 577-590

S. Grainger, Ed., Engineering Coatings—Design and Application, Abington Publishing, Cambridge, 1989

T.B. Massalski, H. Okamoto, P.R. Subramanaian, and L. Kacprzak, Binary Alloy Phase Diagrams, 2nd ed., ASTM International, Materials Park, 1990, vol. 3, Ni-Ru p 2850-2851; Ni-Y p 2884-2885; Ru-Y p 3269, 3271; O-Y p 2936-2937; Ru-Ta p 3255-3258; Ni-Ta p 2865, 2867-2868

E.F. Tolkunowa, V.V. Burnashova, M.B. Raevskaya, and E.M. Sokolovskaya, Laves Phases Interaction in Y-Ru-Fe Co, Ni Alloy Systems, Metallofizika, 1974, 52, p 109-111

H. Chunxiao, M. Guangchen, W. Wenna, W. Yongli, and Z. Huaizhi, Phase Diagrams of Precious Metal Alloys, The Metallurgical Industry Press, Beijing, 1983, p 275

W.B. Pearson, A Handbook of Lattice Spacings and Structures of Metals and Alloys, Pergamon Press, New York, vol. 1, (1958)

E.M. Sokolovskaya, M.V. Raevskaya, and E.F. Kazakova, The Influence of Ruthenium on the Stability of Intermetallic Compounds of the Rare-earth Metals, Moscow Univ. Chem. Bull. 1985, 40, p 71-76 (Engl. Transl.), from Vestnik Moskovskogo Universiteta, Khimiya, 1985, 26(3), p 295-301

P. Villars, A. Prince, and H. Okomoto, Handbook of Ternary Alloy Phase Diagrams, Vol 10, ASM International, Materials Park, 1995, p 12993-12995

P. Villars, H. Okomoto, and K. Cenzual, Eds., ASM Alloy Phase Diagrams Center, http://www.asminternational.org/AsmEnterprise/APD, ASM International, Materials Park, 2007, 10, p 12993, 12995-12996

D.G. Pettifor, The Structures of Binary Compounds. I. Phenomenological Structure Maps, J. Phys. C, 1986, 19, p 285-313

S.H. Coetzee, L.A. Cornish, and M.J. Witcomb, Solidification of Selected As-Cast Ni-Ru-Y Samples, Microsc. Microanal., 2005, 11(Suppl 2), p 1844-1845

S.H. Coetzee, L.A. Cornish, M.J. Witcomb, and P.K. Jain, Comparison of As-cast Results of Ni-Ru-Y with a 600 °C Isothermal Section, Proc. 44th Ann. Conf. Microsc. Soc. South. Afr., T.A.S. Aveling, K. Marcus, B.T Sewell, J. Theron, and J. Wesley-Smith, Eds., Dec 5-7 (Pietermaritzburg), MSSA, 2005, p 10

S.H. Coetzee, L.A. Cornish, and M.J. Witcomb, Derivation of the Liquidus Surface of the Ni-Ru-Y System using SEM and EDX, Microsc. Microanal., 2007, 13(Suppl 2), p 1052-1053

S.H. Coetzee, L.A. Cornish, and M.J. Witcomb, A Study of the Ni-Ru-Y System at 1200 °C Using SEM and EDX, Microsc. Microanal., 2008, 14(Suppl 2), p 578-579

L.A. Cornish, M.J. Witcomb, S.H. Coetzee, W. Tshawe, and S. Prins, Anomalies and Pitfalls in Phase Analyses Using BSE, Proc. 46th Ann. Conf. Microsc. Soc. South. Afr., T.A.S. Aveling, R. Knutsen, B.T Sewell, J. Theron, and J. Wesley-Smith, Eds., July 23-35 (Gaborone), MSSA, 2008, p 9

S.H. Coetzee, The Constitution of the Ni-Ru-Y Ternary System, M.Phil. Dissertation, University of Botswana, 2008

S.H. Coetzee, L.A. Cornish, M.J. Witcomb, and P.K. Jain, Progress on the Liquidus Surface Diagram for the Ni-Ru-Y System, Proc. 47th Ann. Conf. Microsc. Soc. South. Afr., T.A.S. Aveling, R. Knutsen, B.T. Sewell, Eds., Dec 8-11 (Durban) MSSA, 2009, p 78

J. Emsley, Nature’s Building Blocks: An A-Z Guide to the Elements, Oxford University Press, 2011, p 495

S. Curtarolo, W. Setyawan, S. Wang, J. Xue, K. Yang, R.H. Taylor, L.J. Nelson, G.L.W. Hart, S. Sanvito, M. Buongiorno-Nardelli, N. Mingo, and O. Levy, AFLOWLIB.ORG: A Distributed Materials Properties Repository from High-Throughput AB Initio Calculations, Comput. Mater. Sci., 2012, 58, p 227-235

S. Curtarolo, W. Setyawan, G.L.W. Hart, M. Jahnatek, R.V. Chepulskii, R.H. Taylor, S. Wang, J. Xue, K. Yang, O. Levy, M. Mehl, H.T. Stokes, D.O. Demchenko, and D. Morgan, AFLOW: An Automatic Framework for High-Throughput Materials Discovery, Comput. Mater. Sci., 2012, 58, p 218-226

J.E. Saal, S. Kirklin, M. Aykol, B. Meredig, and C. Wolverton, Materials Design and Discovery with High-Throughput Density Functional Theory: The Open Quantum Materials Database (OQMD), JOM, 2013, 65, p 1501-1509

B.J. Beaudry and A.H. Daane, Yttrium-nickel System, Trans. Am. Inst. Min. Metall. Pet. Eng., 1960, 218, p 854-859

J.F. Smith and D.A. Hansen, The structures of YNi3, YCo3, ThFe3 and GdFe3, Acta Crystallogr., 1965, 19, p 1019-1024

A. Raman and A.V. Virkar, Crystal structures of AB3 and A2B7 rare earth—nickel phases, J. Less-Common Met., 1969, 18(1), p 59-66

K.O. Klepp and E. Parthé, Yttrium-Nickel YNi with the FeB Structure Type, Acta Crystallogr. Sect. B, 1980, 36, p 3093-3094

H. Nowotny and H. Oesterreicher, Die Kristallstrukturen von β-TaNi3, Ta(Cu, Al)2, Nb(Cu, Al)2 und Ta6(Cu, Al)7, Mh. Chem., 1964, 95(3), p 982-989

P.I. Kripyakevich, and E.N. Pylaeva, Crystal Structure of the Compound Ta2Ni, Zhurnal Strukturnoi Khimii (J. Struct. Chem.), 1962, 3(1), p 30-32

P.I. Kripyakevich and E.N. Pylaeva, Crystalline Structure of Some Compounds in the Nb-Ni and Ta-Ni Systems, Kristallografiya, 1967, 12, p 350-352

T. Tsukamoto, K. Koyama, A. Oota, and S. Noguchi, Study of Structural Transformation in Near-Equiatomic M-Ru (M=V, Nb, Ta) Alloys Based on the Electron Theory, Nippon Kinzoku Gakkai-si, 1989, 53(3), p 253-257

Lanthanide Lanthology, Part II, Molycorp Inc. Mountain Pass, California, 1994, p 54

T.H. Okabe, T.N. Deura, T. Oishi, K. Ono, and D.R. Sadoway, Electrochemical Deoxidation of Yttrium-Oxygen Solid Solutions, J. Alloys Compd., 1996, 237(1-2), p 150-154

M. Faucher and J. Pannetier, Refinement of the Y2O3 Structure at 77 K, Acta Crystallogr. Sect. B, 1980, 36(12), p 3209-3211

B. Wu, M. Zinkevich, F. Aldinger, D. Wen, and L. Chen, Ab Initio Study on Structure and Phase Transition of A- and B-Type Rare-Earth Sesquioxides Ln2O3 (Ln= La-Lu, Y and Sc) Based on Density Function Theory, J. Solid State Chem., 2007, 180(11), p 3280-3287

R.M. Wentzcovitch and K. Umemoto, Effect of the d Electrons on Phase Transitions in Transition-Metal Sesquioxides, Phys. Chem. Miner., 2011, 38(5), p 387-395

P.E. Werner, I.P. Zibrov, M. Sundberg, and V.F. Filonenko, Structures and Phase Transitions of B-Ta2O5 and Z-Ta2O5: Two High-Pressure Forms of Ta2O5, Acta Crystallogr. Sect. B, 2000, 56, p 659-665

International Centre for Diffraction Data (ICDD), Powder Diffraction File (PDF-2), 12 Campus Boulevard, Newton Square, 2005

Acknowledgments

The assistance of the Department of Science and Technology and the National Research Foundation (South Africa), Carnegie-IAS, Mintek and the University of Botswana ORD are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Coetzee, S.H., Cornish, L.A., Witcomb, M.J. et al. Liquidus Projection Surface and Isothermal Section at 1200 °C of Ni-Ru-Y. J. Phase Equilib. Diffus. 36, 149–168 (2015). https://doi.org/10.1007/s11669-015-0368-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-015-0368-4