Abstract

For high process reproducibility and optimized coating quality in thermal spray applications on complex geometries, atmospheric plasma spraying and high-velocity oxygen fuel torches are guided by advanced robot systems. The trajectory of the torch, the spray angle, and the relative speed between torch and component are crucial factors which affect the coating microstructure, properties, and, especially, the residual stress distribution. Thus, the requirement of high-performance thermally sprayed coatings with narrow dimensional tolerances leads to challenges in the field of robot-assisted handling, and software tools for efficient trajectory generation and robot programming are demanded. By appropriate data exchange, the automatically generated torch trajectory and speed profile can be integrated in finite element method models to analyze their influence on the heat and mass transfer during deposition. Coating experiments assisted by online diagnostics were performed to validate the developed software tools.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The development of innovative software tools for the virtual production of coatings is one of the most promising fields in modern production engineering by thermal spraying. In this multidisciplinary field, the analysis of the influence of the jet trajectory on the coating properties as well as the numerical simulation of heat and mass transfer during deposition should be included. The automatic generation of improved robot trajectories for the production of coatings with narrow dimensional tolerances on complex surfaces is a further aim.

A crucial issue therefore is the development of flexible software tools for trajectory generation on complex geometries and time saving off-line robot programming. Due to the influence of the robot trajectory, speed profile, and coating angle on the residual stress distribution and coating quality, modules for process simulation should be integrated and coupled with the tools for trajectory generation. The simulation of the coating process involves computational fluid dynamics (CFD) for calculation of gas and particle properties as well as heat flux on the component during coating. Additionally, simulations by finite element method (FEM) can be used to model temperature distribution, residual stresses, and coating growth. By the interconnection of the tools for trajectory generation with numerical simulation of the coating process, the influence of the jet movement on the heat transfer during deposition can be evaluated.

Influence of Torch Handling on Coating Properties and Residual Stress Distribution

Parameters included in the robot program, like torch trajectory and speed profile, influence the heat transfer during deposition and the coating properties. The thermal energy of gases and particles as well as the torch trajectory and the relative speed between torch and substrate determine the state of local temperatures and thermal gradients during deposition. This is related to the residual stress distribution in coating and substrate. Regarding the spray angle, the production of thermally sprayed coatings on complex surfaces requires continuous orthogonal torch orientation to ensure homogeneous coating thickness and hardness.

The influence of the torch trajectory on the functionality and reliability of coated heater films was first analyzed by Li et al. (Ref 1). Different meander trajectories were developed for the production of heating conductor coatings on planar glass ceramic surfaces. After coating, the temperature distribution under operating conditions was measured by infrared camera. Reduced thermal load and balanced temperature distribution were obtained by using meander trajectories with improved reversal point and offset distances.

The spray angle is defined as the angle between the symmetry axis of the jet and the surface of the substrate. It is a factor affecting the splat formation, coating microstructure, adhesion, hardness, and porosity. The relevance of appropriate spray angle definition increases if complex surfaces have to be thermally coated. To remark the importance of the torch handling in thermal spraying, coating experiments with WC-Co as spray material were performed. The coatings were deposited by varying the spray angle and the relative speed between torch and substrate.

The coatings were produced by means of the K2 torch (GTV GmbH, Luckenbach, Germany). Kerosene as liquid fuel was used for high energetic combustion with pure oxygen, applied at elevated pressure (Ref 2). Maximum temperature of the particles in the high-velocity oxygen fuel (HVOF) spray process depends on the spray torch design as well as on the feed rate, morphology, size distribution of the used spray powder particles, and oxygen/fuel ratio (Ref 3). Due to the high kinetic energy of the impinging particles, this technique is able to produce extremely dense coatings with improved properties against abrasive wear. Tungsten carbide powder was used as feedstock material for the coating tests. An evaluation program was carried out to analyze the morphology of the powder material. The measured values for particle size distribution were d 10 = 21 μm and d 90 = 46 μm.

For standard applications, the spray angle is normally close to 90°, but it will vary if the substrate has a nonplanar surface (Ref 4). A variation in the spray angle results in a change in the average splat shape (splat elongation can be observed when the spray angle decreases). Previous works showed that increased porosity and reduced hardness and coating adhesion are expected if the coating was deposited with low spray angles (Ref 5).

For the coating experiments, spray angles varying from 90° to 30° were considered. The influence of spray angle on coating thickness and hardness of the WC-Co coatings was experimentally studied (Table 1). As the spray angle decreases, the available energy for particle deformation and spreading decreases. This results in low adhesive strength and rebounding. Thus, the maximum values of coating thickness were obtained for samples coated with the spray jet orthogonal to the surface (spray angle 90°). As shown in Table 1, the measured hardness and coating thickness values decrease almost linearly with the spray angle. This is due to the increased porosity and the formation of interlamellar cracks which tilt toward the spray direction. The hardness HV0.5 was measured by an automated universal hardness indenter equipment Fischerscope™ HCU (Helmut Fischer GmbH, Sindelfingen-Maichingen, Germany).

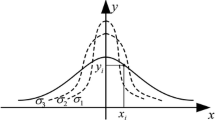

The state of residual stresses in the coating composite is a result of temporary stresses that emerge during the manufacturing process. During coating deposition and solidification, phase transitions in the coating as well as rapid cooling of the coating material splats due to heat conduction in the substrate lead to a contraction of the coating and a simultaneous expansion of the substrate. These mechanisms result in temporary stresses in the coating which are called quenching stresses. After the coating process, the temperatures of coating and substrate adjust. The mismatch between the thermal expansion coefficients of coating and substrate material leads to the development of thermal stresses (Ref 6). By varying the torch velocity, the thermal load during coating can be modified. To evaluate the dependency of the thermal load during deposition on the residual stress distribution, samples were coated with constant spray angle 90° and different torch velocities (400, 650, and 900 mm/s). A stoichiometric combustion with 800 L/min O2 and 24 L/h kerosene was defined. The powder feed rate for the coating experiments was 64 g/min. A powder feeder PF2 (GTV GmbH, Luckenbach, Germany) with N2 as carrier gas was used.

Figure 1 shows the relationship between torch velocity (correlated with thermal load) and residual stress distribution. For the characterization of the residual stress distribution in coating and substrate, the microhole drilling method was used. As shown in Fig. 1, by increasing the speed of the robot-guided torch, reduced local temperatures as well as lower thermal gradients are obtained. This is reflected in the measured residual stresses. By low torch speed, coating and substrate are subjected to high thermal load during deposition. Additionally, these samples cool down from a higher temperature level after coating. This can significantly affect the formation of compressive stresses in the steel substrate. Gray bars represent the location of the coating/substrate interface for each torch velocity. The stress distribution in the coating/substrate interface is a factor which affects the coating adhesion. Previous works showed the influence of tensile stresses on reduced coating adhesion (Ref 7, 8). As presented in Ref 9 samples with compressive stress distributions in the coating/substrate interface showed high bending strength and resistance to thermal shock. By adapting the speed of the torch, an optimal residual stress distribution with moderate compressive stresses which improve the mentioned coating properties can be achieved. Improved speed profiles can be defined and implemented in robot motion sequence to obtain desired or even designed stress distributions.

Development of Software Tools for Improved Trajectory Generation in Thermal Spraying

In thermal spraying applications, the torch is required to describe a defined trajectory with an appropriate speed profile, spray distance, and relative orientation between torch and substrate. Due to the influence of the torch trajectory on the coating properties, software tools for efficient and flexible robot programming are needed.

Previous approaches in the field of the computed-aided generation of trajectories for thermal spraying are based on the use of simplified geometrical descriptions of the component to be coated, so that complex surface geometries are not exactly defined in the final robot program (Ref 10). The software tools presented in Ref 11, 12 are designed for specific robot systems. Thus, the direct application of these tools on different robot or handling devices is not possible. Regarding the influence of the robot trajectory on the deposition process and coating properties, an experimental study of the influence of the spray angle, spray distance, and the relative torch/substrate speed on the coating thickness, porosity, and hardness of plasma sprayed coatings can be found in Ref 13. The study is based on the use of a database interfaced with robot simulation. The tools are limited to ABB robots (ABB Automation Technology Products AB, Gothenburg, Sweden) and numerical simulation models were not developed.

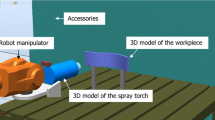

In this work, a new approach is presented. Software tools can be used for the generation of trajectories on complex free-form surfaces considering the real geometry of the component. By the definition of the trajectory by means of the ASCII data format, the generated paths can be used for the programming of different robot systems as well as for the analysis by means of numerical models of the influence of the torch trajectory and velocity on the temperature distribution during deposition. The required subroutines were developed at the IMTCCC by the computing environment and programming language MATLAB (The MathWorks™, Natick, MA). As a case study for the validation of the developed tools, the free-form geometry of a ship propeller was considered.

As an initial step, the real geometry of the surface to be coated has to be acquired. CAD models as well as 3D optical or tactile coordinate measurement systems can be used. If considering coordinate measurement systems, the surface is described as a point cloud. Figure 2 shows the point cloud obtained by laser scanning system ModelMaker Z (Descam 3D Technologies GmbH, Oberhaching, Germany).

By reverse engineering, the acquired surface is processed into a mathematical model, creating a mesh which contains the previously acquired points. For the trajectory generation of the robot-guided torch, the spatial points which define the movement of the plasma jet/flame on the surface during deposition have to be defined. In addition, the normal vector on each defined point is required for the further calculation of the orientation of the robot-guided torch, see Fig. 3.

Since the coordinates of the spatial points and normal vectors are referred to the coordinate system of the CAD model or measuring device, tools for coordinate transformation have to be programmed so that the geometrical data can be used in the real workcell.

For the calculation of the torch orientation during coating, the normal vectors of the substrate surface are required. The MATLAB subroutine SURFNORM returns the surface normal components. The obtained surface normals are based on a bicubic fit of the data (Ref 14). Figure 4 shows the surface with the normals emanating from it.

As shown in Fig. 5, meander trajectories were automatically calculated and stored by using the ASCII data format. Spatial points of the trajectory were obtained considering the required spray distance (250 mm) and meander offset (3 mm). Finally, program codes were generated for the implementation of the trajectory in the workcell. During the coating process, the torch was guided with a velocity of 400 mm/s and the WC-Co coating was deposited in three cycles of the meander trajectory. A stoichiometric combustion with 800 L/min O2 and 24 L/h kerosene was considered. The robot system for the coating experiments was programmed by using the language V+® (Adept Technologies Inc., Livermore, CA).

Numerical Simulation of Combustion and Heat Transfer During Coating Deposition

The analysis of heat and mass transfer is an essential tool for a better planning of process design and torch trajectories. The influence of the generated torch trajectory and speed profile on the heat transfer and temperature distribution can be analyzed by numerical simulation. As an initial step of a process design for numerical simulation of temperature distribution during coating, the heat transfer coefficient between impinging gases and substrate is required. Also the impacting particles and the heat dissipation by convection and radiation influence the total thermal load. The calculation of the contribution of gases and particles to the total thermal load was done by considering approaches presented in Ref 15, 16 and CFD simulations of the combustion and in-flight behavior of gases and particles.

The combustion process in the K2 torch was modeled by using FLUENT (Fluent Inc.). The fast chemistry assumption was considered in the modeling of the nonpremixed turbulent combustion. The essential feature for the calculation of the latter is the introduction of a chemistry-independent “conserved scalar” variable called the mixture fraction. All scalars such as temperature, concentration, and density are then uniquely related to the mixture fraction. For the modeling of the turbulence phenomena, the k-ε model was considered (Ref 17, 18). Figure 6 shows the results concerning temperature and velocity distributions for the combustion gases in combustion chamber, nozzle, and free jet.

The strongly expanding combustion gases accelerate the powder particles to reach high velocity values in the deposition phase. Tungsten carbide powder was considered as feedstock material for particle modeling. SprayWatch 2i (Oseir Ltd., Finland) was used for validation. The obtained gas and particle properties were used to estimate the total heat flux on the component.

The time-dependent temperature distribution during coating was modeled. In this work, the meshes are created by using the collected geometrical data (by CAD model or coordinate measurement device) of the surfaces to be coated. Thus, the real geometry of the component is considered in the heat transfer modeling. For the mesh definition and numerical simulations, ANSYS® (Ansys Inc., Canonsburg, PA) and ABAQUS® (Simulia, Providence, RI) were used.

For the modeling of the heat flux along the generated meander trajectory, coordinates of spatial points of the generated trajectory and corresponding process times (P i , t i ) were transferred in ASCII format to the numerical simulation software. The spatial points are still referred to the coordinate system of the FEM software. A FORTRAN subroutine was programmed to associate each point of the trajectory with the nearest node of the FEM mesh, see Fig. 7. Thus, the generated jet trajectory is correlated with nodes of the finite element model. To model according to real conditions, the thermal load was modeled as heat flux. Taking into account the diameter of the plasma jet or flame, the elements where the heat flux has to be applied can be defined. The process time for heat flux application is related to the desired torch velocity. The heat transfer during deposition can be simulated for different meander trajectories, torch velocities, and total heat flux. For model validation, calculated temperatures on selected nodes can be compared with temperature measurements by infrared thermography.

Temperatures can be calculated also on the complete component surface to obtain time-dependent temperature distributions, gradients, and corresponding stresses. Thus, the influence of the component geometry on heat transfer can be considered for further process improvement. Figure 8 shows obtained temperature distributions for case studies where planar and free-form surfaces are coated.

By computer-aid trajectory generation tools which allow appropriate definition of meander offset, spray angle, spray distance, and relative speed between torch and surface, thermally sprayed coatings with homogeneous coating thickness and hardness can be obtained.

Coating process on the free-form component was performed, see Fig. 9. For the torch handling, a RX-170 robot arm with 6 degrees of freedom (Stäubli Tec-Systems GmbH, Germany) was used. Cross sections were obtained to evaluate coating thickness and hardness on different areas of the surface. As shown in Fig. 10, homogeneous values for both measured properties were achieved.

Summary and Conclusion

The production of net shape, high performance thermally sprayed coatings on complex geometries requires advanced automation systems. The torch trajectory, speed profile, and spray angle are becoming important process parameters as the demand of sprayed coatings on complex-shaped parts increases. Due to the influence of these parameters on the temperature distribution during deposition, residual stresses, and various coating properties, software tools for efficient and flexible robot programming are required.

A new approach for trajectory generation and off-line robot programming is proposed. To consider the real component geometry, CAD tools and optical or tactile coordinate measurement systems can be used to provide the required geometrical data. Specific software tools were developed for processing the substrate geometry, coordinate transformation, and calculation of normal vectors and trajectories for thermal spraying.

By the interconnection of the modules for trajectory generation with CFD and FEM models, the influence of the torch trajectory and speed profile on the heat transfer during deposition can be analyzed. The proposed interconnection of the modules for the programming of the handling devices with the numerical simulation of heat transfer is a first step in the development of completely virtual workcells for thermal spraying. By following the presented methodology, codes for different substrate geometries and robot programming languages can be off-line generated. Coating experiments on free-form case study were performed to demonstrate robot programming and to validate the developed simulation tools. Homogeneous coating thickness and hardness distributions were obtained.

References

C. Li, A. Killinger, and R. Gadow, Product Development with Thermally Sprayed Functional Coatings on Glass and Glass-Ceramics Substrates, H.T. Lin, Ed., Int. J. Appl. Ceram. Technol., 2005, 2(6), p 493-503

M. Buchmann, R. Gadow, D. Scherer, and M. Speicher, Ceramic Lightmetal Composites, Product Development and Industrial Application, Ceram. Eng. Sci. Proc. 23(4), p 103–113 (2002)

H. Kreye, F., Gärtner, A. Kirsten, and R. Schwetzke, High Velocity Oxy-Fuel Flame Spraying. State of the Art, Prospects and Alternatives, 5th HVOF Colloquium High Velocity Oxy-Fuel Flame Spraying (Erding, Germany) GTS Gemeinschaft Thermisches Spritzen e.V., Ed., Unterschleißheim, Germany, 2000, p 5-18

J. Ilavsky, A. Allen, G. Long, and S. Krueger, Influence of Spray Angle on the Pore and Crack Microstructure of Plasma-Sprayed Deposits, J. Am. Ceram. Soc., 80(3), p 733–742 (1997)

C.C. Berndt and S.H. Leigh, Evaluation of Off-Angle Thermal Spray, Surf. Coat. Technol., 89, p 213–224 (1997)

R. Gadow, M. Wenzelburger, Methods and application of residual stress analysis in thermally sprayed coatings and composites, Surf. Coat. Technol., 2006, 201(5), p. 1995–2001

A. Candel, R. Gadow, and D. López, Advanced robot assisted manufacturing and control system for the internal HVOF series coating process of cylinder bores in light weight engine manufacturing, SAE 2004 Trans. J. Mater. Manuf., 113(5), p 232–237 (2005)

H. Steffens, B. Wielage, and J. Drozak, Adhesion of thermally sprayed coatings; Adhesion in composite materials, DGM Informationsgesellschaft, Germany, 1989, p 115-128 (in German)

J. Wilson, J. Kim, J. Shadley, E. Rybicky, W. Emery, D. Somerville, J. Nuse, R. McGrann, and D. Greving, Fatigue Life of HVOF Tungsten Carbide Coated Aluminum and Hard Anodized Aluminum in Cyclic Bending and the Influence of Coating Residual Stresses, United Thermal Spray Conference (Düsseldorf, Germany), 1999, p 468-473

S. Ahmaniemi, P. Vuoristo, T. Mäntylä, J. Latokartano, and I. Salonen, Optimization of the Robot Controlled Plasma Spraying of Thermal Barrier Coating for Gas Turbine Transition Duct, Thermal Spray 2002, E. Lugscheider and C.C. Berndt, Ed., March 4-6, 2002 (Essen, Germany), DVS Deutscher Verband für Schweißen, Düsseldorf, Germany, 2002, p 208-212

S. Deng, H. Li, H. Liao, C. Coddet, C. Zeng, P. Charles, and P. Uriot, New Functions of Thermal Spray Toolkit. A Software Developed for Off-Line and Rapid Robot Programming, Thermal Spray 2006, B.R. Marple, M.M. Hyland, Y.C. Lau, C.J. Li, R.S. Lima, and J. Voyer, Ed., May 15-18, 2006 (Seattle, WA), ASM International, Materials Park, OH, 2006

R. Zieris and A. Schmidt, Off-Line Programming for Spraying and Laser Cladding of Three-Dimensional Surfaces, Thermal Spray 2004: Advances in Technology and Application, May 10-12, 2004 (Osaka, Japan), ASM International, Materials Park, OH, 2004

F. Trifa, G. Montavon, and C. Coddet, Integrating a Deposition Model for Off-line Spray Tools Programming, Thermal Spray 2005, E. Lugscheider, Ed., ASM International, Materials Park, OH, p 280-285, 2005

The Mathworks™, Matlab 2007 Function List; Version R2007a, 2007

Y. Bao, T. Zhang, and D.T. Gawne, Computational Model for the Prediction of the Temperature in the Coating during Thermal Spraying, Thermal Spray 2004: Advances in Technology and Application, May 10-12, 2004 (Osaka, Japan), ASM International, Materials Park, OH (2004)

E.S. Davids, S.R. Duncan, and P.S. Grant, Modelling and Validation of Substrate Heat Transfer Coefficient Distribution in Vacuum Plasma Spraying, Thermal Spray 2006, B.R. Marple, M.M. Hyland, Y.C. Lau, C.J. Li, R.S. Lima, and J. Voyer, Ed., May 15-18, 2006 (Seattle, WA), ASM International, Materials Park, OH, 2006

E. Dongmo, R. Gadow, and M. Wenzelburger (2008) Analysis and Optimization of the HVOF Process by Combined Experimental and Numerical Approaches. Surf. Coat. Technol., 202:4470-4478

A. Candel, R. Gadow, and M. Wenzelburger, Process Automatization for the Coating of Light Metal Engine Crankcases and Cylinder Liners—Modeling of Heat and Mass Transfer During Thermal Spraying on Complex Geometries, 8th CIRP International Workshop on Modeling of Machining Operations, R. Neugebauer, Ed., Verlag Wissenschaftliche Skripten, Zwickau, Germany, 2005, p 147-156

Acknowledgments

The authors would like to thank Dr. José Andrés Moreno and Mr. Alejandro Frutos (Universidad Politécnica de Cartagena, Spain) for their important contribution to the development of tools for the simulation by FEM of the temperature distribution on free form surfaces.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Candel, A., Gadow, R. Trajectory Generation and Coupled Numerical Simulation for Thermal Spraying Applications on Complex Geometries. J Therm Spray Tech 18, 981–987 (2009). https://doi.org/10.1007/s11666-009-9338-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-009-9338-x