Abstract

Gallium oxide (Ga2O3)-based photodetectors are attracting more and more attention for their wide range of applications in optical imaging, spatial communication, etc. In this work, solar-blind deep-ultraviolet thin-film transistors (TFTs) based on polycrystalline β-Ga2O3 thin film were constructed by pulsed laser deposition. The photoelectric performance of β-Ga2O3 TFT is effectively improved by a Si-doping method. The turn-on voltage (Von) of Si-doped β-Ga2O3 TFT is negatively shifted by 20 V, exhibiting enhancement-mode (E-mode) operation. The optimized Si-doped Ga2O3 TFT photodetector shows a high on/off ratio of ~ 105, a turn-off current (Ioff) of ~ 10−11 A at drain voltage (VD) = + 20 V, responsivity (R) of 3.23 A/W, detectivity (D*) of 4.41 × 1013 Jones, and a photocurrent/dark current (Ilight/Idark) of ~ 104 at gate voltage (VG) = − 5 V, VD = + 20 V under 254 nm light. The obtained results suggest that the Si-doping method can effectively modulate the Von of β-Ga2O3 TFT and promote photoelectric performance.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Recently, β-phase gallium oxide (β-Ga2O3) has achieved great attention as a promising semiconductor material for high-power electronics. Ga2O3, with an ultra-large energy band gap of ~ 4.8 eV, is of great potential in deep-ultraviolet (DUV) detection.1 DUV signatures have a weak solar background interface because of strong absorption of stratospheric ozone, contributing to applications in flame detection, missile early alarm, and so on.2 Therefore, photodetectors based on β-Ga2O3 have been widely studied in recent years.3,4,5,6 Furthermore, the Baliga’s figure of β-Ga2O3 at 3214 is considerably higher than those of SiC at 317 and GaN at 846,7 which means that β-Ga2O3 electronics are more efficient than other wide band-gap materials.

β-Ga2O3 photodetectors have been developed rapidly based on various structures, such as Schottky barriers,5,6 p–n junctions,8,9,10 metal–semiconductor–metal (MSM),11,12 etc. Recently, Ga2O3 -based thin-film transistors (TFT) have received increasing attention and been successfully demonstrated.13,14,15,16,17,18 TFT-type devices achieve excellent photoelectric performance through three-terminal control, and easily integrate with other devices in circuits.19 Most transistors are based on bulk single-crystal β-Ga2O3. Jinho et al. demonstrated a dual-field single-crystal β-Ga2O3 nano-field effect transistor (FET) with an off-state hard breakdown voltage exceeding + 400 V.15 Yaxuan et al. obtained FET solar-blind photodetectors based on high-quality single-crystalline Ga2O3 flakes, achieving high photocurrent/dark current (Ilight/Idark) of 8 × 105, a responsivity (R) of 4.79 × 105 A/W, and an external quantum efficiency (EQE) of 2.34 × 106%.18 However, high-quality materials always demand strict experimental conditions. Differently, β-Ga2O3 thin films make up for the defects of bulk materials, along with low cost, easy growth, great repeatability and flexibility,3,10,11 most of which show polycrystalline or amorphous phrases prepared by pulsed laser deposition (PLD), metal–organic chemical vapor deposition (MOCVD), sputtering, and spin-coating. Yuan et al. pioneered an enhancement-mode solar-blind metal-oxide–semiconductor field-effect phototransistor based on molecular beam epitaxy (MBE) homoepitaxial β-Ga2O3 film, obtaining a high R of 3 × 103 A/W, an EQE of 1.5 × 106%, and short rise and decay times of 100 ms and 30 ms,17 respectively. Xi et al. presented amorphous Ga2O3:CdO thin film-based TFT devices prepared by spin-coating, and demonstrated a large negative shift in the turn-on voltage (Von) due to the increase in the electron concentration.14 Yuan et al. investigated a solar-blind phototransistor based on low-cost magnetron-sputtered amorphous GaOx thin film, which achieved ultra-high responsivity, detectivity (D*), and EQE.16

Here, we demonstrate polycrystalline β-Ga2O3 solar-blind DUV TFTs with gate-tunable photodetection. PLD was used to deposit the β-Ga2O3 thin film on a Si/SiO2 substrate to fabricate TFT-type devices. We discuss the characteristics of the deposited β-Ga2O3 thin film with and without Si-doping, including their crystallinity, morphology, and defects. Moreover, the electric and photo-response performances of TFTs based on pure β-Ga2O3 and Si-doped β-Ga2O3 are analyzed.

Experimental

β-Ga2O3 Preparation and Device Fabrication

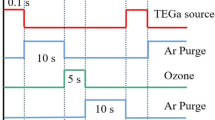

A p-type Si substrate was cleaned in acetone, alcohol, and deionized water. PLD was used to deposit the β-Ga2O3 thin film on the (100)-oriented Si with a 320-nm SiO2 layer. A highly purified (99.99%) Ga2O3 ceramic target and a Si-doped Ga2O3 ceramic target (Ga2O3: SiO2 = 99.5: 0.5 wt%) were used, respectively, both of which were 50.8 mm in diameter and 5 mm in thickness. The target–substrate distance was 69 mm. The substrate temperature during deposition was fixed at 700 °C. The deposition chamber was pumped down to a base pressure of 3 × 10−5 Pa. Subsequently, a working pressure of oxygen of 0.1 Pa was introduced. A 248-nm KrF excimer laser, with a repetition rate of 3 Hz and an energy density of 5 J cm−2 , was used to deposit β-Ga2O3 thin films for 30 min. Next, the Ga2O3 thin films were annealed at 800 °C by a rapid thermal annealing method for 30 min, reducing defects such as oxygen vacancies.20 To fabricate the TFT, Si wafers with a SiO2 layer were used as the gate electrode, gate dielectric, and substrates. The drain/source electrode regions were defined by depositing Au/Ti (50/20 nm) using e-beam evaporation through a shadow mask. The length and width of the channel were 1000 μm and 100 μm, respectively.

Material and Device Characterization

X-ray diffraction (XRD; PANalytical X-pert Powder) with CuKα radiation was used to measure the crystalline properties of the films. The surface morphologies and roughnesses of the films were characterized by scanning electron microscopy (SEM; SU-70; Hitachi) and atomic force microscopy (AFM; Multimode-8; Bruker Nano). The defect type and content were examined by x-ray photoelectron spectroscopy (XPS; Kratos AXIS Supra). The electrical performance was measured using semiconductor parameter analyzers (Keithley 4200). A 254-nm ultraviolet (UV) light-emitting diode was provided as the light source to measure the photo-response properties.

Results and Discussion

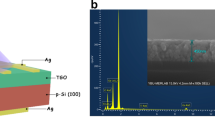

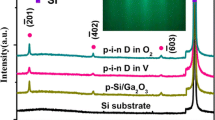

The XRD study was carried out on pure β-Ga2O3 film and Si-doped β-Ga2O3 film. Figure 1a shows the XRD diffraction patterns of the Ga2O3 films grown on the (100) Si substrate deposited at 700 °C. Both samples show polycrystalline β-Ga2O3 with a monoclinic structure. The peaks indexed to (− 201), (110), (− 402) and (− 601) are dominant in the pure β-Ga2O3 film, while such peaks decrease in the Si-doped β-Ga2O3 film, indicating that the Si-doping method might have reduced the crystallinity in the presence of lattice distortion. Different growth temperatures and the rapid thermal annealing method are also discussed in detail in the Supporting Information (see Figures S1, S2). A cross-section SEM image of β-Ga2O3 is shown in Fig. 1b. The thickness of the β-Ga2O3 film is ~ 86 nm (depositing time 30 min). Figure 1c and d present the 3D AFM images of the surface of the β-Ga2O3 films in a 5 × 5 μm2 area. The root-mean-square surface roughness of the Si-doped β-Ga2O3 films is 1.26 nm, which is smaller than that of pure β-Ga2O3 films (2.59 nm), suggesting that the Si-doped β-Ga2O3 film is relatively smooth. Pure Ga2O3 film exhibits a state of high resistance while the carrier density is 9.5 × 1010 cm−3. The Si-doped Ga2O3 film exhibits n-type conductance, and the resistivity and carrier density are 1986 Ω cm and 2.4 × 1016 cm−3, respectively, as previously reported.21 In brief, the crystal quality is slightly reduced after Si-doping, and both films are of good quality with flat surfaces and high uniformity.

XPS measurements were performed to identify defect types and defect concentrations. The charge–shift spectrum was calibrated using an adventitious C 1s peak at 284.8 eV. Figure 2a and d shows the XPS survey scan of pure β-Ga2O3 thin film and Si-doped β-Ga2O3 thin film, respectively. Both curves show characteristic peaks of Ga (2p, 3p, 3d), O (1s) and C (1s), and there is no significant difference between them. Thus, a small amount of Si-doping would not have a huge impact on the composition of thin films. Recent studies show that Si would diffuse into the oxide from the Si substrate when annealed at a higher temperature.22,23 Similar situations have occurred in Al2O3, GaN, and so on.24,25 The XPS narrow scans of the Ga 2p core level and O 1s level were also conducted. Figure 2b and e shows the Ga 2p peaks of pure Ga2O3 film and Si-doped Ga2O3 film, respectively. The Ga 2p peak can be separated into two peaks, one corresponding to Ga+ (Ga2O), the other to Ga3+ (Ga2O3)4. For pure Ga2O3, the relatively lower peak appears at 1117.8 eV (Ga+), and its higher peak appears at 1118.1 eV (Ga3+). The peak ratio of Ga+/Ga3+ is 19.18%. For the Si-doped Ga2O3, the peak ratio increases to 38.55%, implying that the Ga2O3 content reduces and crystal quality degrades. In other words, Si-doping results in poor crystallization, which might be caused by lattice distortion and changed electron orbits. Therefore, the XPS results exactly match with the XRD curves (see Fig. 1a). From Fig. 2c and f, the O 1s peaks of two samples are compared and the charge–shift can be divided into two components: the lower one is assigned to lattice oxygen ions (OI), and the other to the oxygen ions in the oxygen vacancies regions (OII).26,27,28 Thus, the peak ratio of OII/ OI is used to characterize the content of the oxygen vacancies, while there is little difference between the two samples, 26.01% and 25.50%, for pure Ga2O3 and Si-doped Ga2O3 , respectively. It is said that there is no obvious relevance between oxygen vacancies and Si-doping. It is worth noting that the binding energy (BE) of Si-doped samples positively shifts by 0.2–0.3 eV. Since the Si atoms are expected to be the electron donor, the carrier concentration increases correspondingly, resulting in Fermi-level movement. Absorption curves show a lower band gap of the Si-doped sample compared to the pure one (see Figure S3, Supporting Information). Therefore, the BE peaks shift to being higher because of Fermi-level movement (for the details of the XPS analysis data, see Table SI in Supporting Information).23

The bottom-gate TFTs were fabricated employing those β-Ga2O3 thin films as channels, and the device's schematic structure is shown in Fig. 3a. To explore the photoelectric characteristics of β-Ga2O3 TFT, optoelectronic performance measurements were conducted under 254-nm DUV light illumination with an intensity of 245.9 μW cm−2. Figure 3b presents the drain current (ID)-gate voltage (VG) transfer curves of pure β-Ga2O3 and Si-doped Ga2O3 TFTs in the dark and under illumination. Over the channel current, the gate shows an apparent field-effect control ability and a low turn-off current (Ioff) of ~ 10−11 A. The on/off ratio of pure β-Ga2O3 TFT is over 105 at the drain voltage (VD) = + 20 V, and there is a slight increase in the on/off ratio after Si-doping. Furthermore, Si-doped Ga2O3 TFT shows a Von of − 4.4 V, while the Von of pure β-Ga2O3 TFT is 14.3 V. That is to say, the Si-doped Ga2O3 TFT works in depletion mode and the pure β-Ga2O3 TFT works in enhancement mode. A negative shift of Von (about − 20 V) is observed in the Si-doped sample. β-Ga2O3 prepared by PLD has a high resistance due to the many oxygen vacancies and other defects,29 so it is inevitable that the Von of the device is large. It is said that pure Ga2O3 TFT is usually turned on with difficulty. For more carriers supplied by Si-doped TFT, it is easier to present an open state when it reaches a certain value. In addition, the estimated field-effect carrier mobility (μFE) of the pure and Si-doped samples are 0.14 cm2 V−1 s−1 and 0.15 cm2 V−1 s−1, respectively, verifying the effect of increasing carrier concentration on mobility. The μFE can be obtained from the following:30

where L and W denote the length and width of the channel, respectively, Cg is the gate dielectric capacitance per unit area, and VG is the gate bias. Similarly, the photocurrent of the Si-doped Ga2O3 TFT is larger than that of pure Ga2O3 TFT due to a higher carrier concentration. The measured results demonstrate that the Ilight/Idark is higher than 104, showing ultra-high sensitivity under DUV light. In order to quantitatively assess the photoelectric performance of both Ga2O3 TFTs, key figure-of-merit of the photodetectors have been calculated. The responsivity is defined as the photocurrent generated per unit power of the incident light on the effective area of a photodetector, which can be obtained at VD = + 20 V bias as follows:

where Ilight is the photocurrent, Idark is the dark current, Pλ is the light intensity, and S is the effective illumination area of the device. As shown in Fig. 3b, the R of the pure Ga2O3 TFT and the Si-doped Ga2O3 TFT are estimated to be 2.20 A/W (VG = + 5 V) and 3.23 A/W (VG = − 5 V), respectively, indicating the sensitivity of β-Ga2O3 photodetectors in the solar-blind region. The EQE factor can be determined by:

where h is the Plank’s constant, c is the velocity of light, and λ is the wavelength of light. The EQE of the pure Ga2O3 TFT and the Si-doped Ga2O3 TFT are estimated to be 1.1 × 103% and 1.6 × 103%, respectively, under corresponding conditions. Another important factor, D* , which is usually used to describe the smallest detectable signal, can be expressed by:

(a) Schematic structure of the β-Ga2O3 TFTs. (b) ID-VG transfer curves of pure β-Ga2O3 and Si-doped β-Ga2O3 TFTs in the dark and under 254-nm light illumination with an intensity of 245.9 μW cm−2. (c, d) ID-VG transfer curves of pure β-Ga2O3 and Si-doped β-Ga2O3 TFTs measured at different VD in linear and logarithmic scales, respectively. (e, f) ID-VD output characteristics with VG decreasing from 60 V to 10 V with a step voltage of − 10 V in the dark.

The D* of the pure and Si-doped samples are calculated to be as high as 4.23 × 1013 Jones and 4.41 × 1013 Jones, respectively, surpassing most ever-reported Ga2O3 photodetectors.9,14,31 The high D* can offset the impact of the noise from the relatively high dark current.

Figure 3c and d shows the ID–VG transfer curves of pure β-Ga2O3 and Si-doped β-Ga2O3 TFTs measured at different VD in linear and logarithmic scales, respectively. From the linear scale, it is clear that ID grows as VD increases and, when VD reaches a certain value, ID tends to be constant. Figure 3e and f presents the ID–VD curves of the two TFTs in the dark, respectively. As we can see, ID reduces as VG decreases from 60 V to 20 V, with a step voltage of − 10 V. The comparison shows that the Si-doped sample has a higher value of ID under different voltages.

To explore the relationship between the photo-response characteristics and light intensity, different light intensities varying from 38.4 μW cm−2 to 245.9 μW cm−2 have been tested. Figure 4a and b presents the ID-VG transfer curves of the pure β-Ga2O3 and the Si-doped β-Ga2O3 TFTs in the dark and under 254-nm light illumination, respectively, with the intensity varying from 38.4 μW cm−2 to 245.9 μW cm−2 at VD = + 20 V. It is obvious that the photocurrent increases with increasing light intensity, showing a higher Ilight/Idark ratio. No matter the value of the light intensity, the Si-doped sample shows better light sensitivity. The values of the key factors R, D*, and EQE measured under different light intensities are shown in Table SII in Supporting Information. The ID–VD output characteristics with VG decreasing from 60 V to 10 V, with a step voltage of − 10 V, under different light intensities, are shown in Figure S4 in Supporting Information. By comparison, the photocurrent of the pure Ga2O3 TFT tends to be flat as the VG increases in the initial stage, while that of the Si-doped sample grows rapidly. Because there are large amounts of defect states in the β-Ga2O3 thin films and the Ga2O3/SiO2 interface, most of them serve as carrier-capturing centers. The traps can be populated by photo-excited carriers as VG increases. Since there are more carriers in the Si-doped sample, the trap-populating process performs faster, and more carriers are involved in the current transmission.14,32

(a and b) ID-VG transfer curves of pure β-Ga2O3 and Si-doped Ga2O3 TFTs in the dark and under 254 nm light illumination, respectively, with the intensity varying from 38.4 μW cm−2 to 245.9 μW cm−2. (c and d) Time-dependent photo-responses of the pure β-Ga2O3 and the Si-doped Ga2O3 TFTs under 254 nm light with different light intensities, respectively. (e and f) Experimental and fitting curves of the rise and decay process photo-responses, respectively, under 254 nm light with the intensity of 245.9 μW cm−2. (g and h) R and EQE as functions, respectively, of light intensity.

The photo-responses of the pure β-Ga2O3 and Si-doped Ga2O3 TFTs with different light intensities under alternate on and off cycles are shown in Fig. 4c and d, respectively. It can be clearly observed that the photocurrent increases step by step when the light intensity increases gradually. Meanwhile, the Si-doped Ga2O3 TFT shows a higher and more stable photocurrent at different light intensities. Figure 4e and f presents the response times of the pure β-Ga2O3 and Si-doped Ga2O3 TFTs under 254 nm light illumination with the intensity of 245.9 μW cm−2, respectively. The rise time (tr) and fall time (td) are then defined as the times taken by the signal to vary between 10% and 90% of the saturation value. As shown in the photo-response fitting curves, the tr are 1.1 s and 0.5 s for the TFTs made from pure Ga2O3 and Si-doped Ga2O3, respectively. And the td are 0.4 s and 0.9 s for the TFTs made from Ga2O3 without and with Si-doping, respectively. The fast-response component can be attributed to the rapid change of carrier concentration as soon as the light is turned on/off.33 The tr for the pure Ga2O3 TFT is much higher than that for the Si-doped Ga2O3 TFT. The photo-response of a semiconductor is a complex process, including electron–hole generation, trapping, and recombination.34 The photo-generated carriers may firstly fill the traps and reach their maximum after the traps are saturated, while a lower density of traps is involved in this process for pure β-Ga2O3 with better crystalline quality, Si-doping induces more carriers participating in current transfer, which shortens the time to reach the maximum value. The fast decay process indicates weak persistent photoconductivity (PPC), for which the light-induced current persists after the excitation has been removed.34 The anion vacancies with a metastable state and the presence of surface states may contribute to the PPC behavior.34,35,36 According to the XRD curves (see Fig. 1a), the Si-doping method has reduced the crystallinity in the presence of lattice distortion. Dislocation defects can act as recombination centers of non-equilibrium carriers,37,38 resulting in a longer carrier lifetime in the β-Ga2O3 thin film. As shown in Fig. 4g and h, the R and EQE, respectively, of both samples decrease with increasing light intensity, which is similar to previous reports.16,39 The maximum values of R and EQE of the Si-doped Ga2O3 TFT reach 5.8 A/W and 2.8 × 103 , respectively, under 254-nm light illumination with the intensity of 38.4 μW cm−2. The thermal effect-induced carrier scattering and absorption saturation may induce this phenomenon.39,40

Figure 5 illustrates the mechanism of the on/off states and photo-responses of semiconductors. An energy band diagram model is proposed to describe the observed transfer characteristics in Fig. 5a–c. Due to the presence of oxygen vacancies both in bulk Ga2O3 and the Ga2O3 film, a narrow region of depletion with the positively ionized oxygen vacancies appears on the surface of the Ga2O3.41,42 When using positive VG bias, the depletion region becomes narrower, which is attributed to conductivity (see Fig. 5b). The applied negative VG bias expands the depletion width and reduces the effective channel thickness (see Fig. 5c), showing the off state. For the Si-doped Ga2O3 TFT, the Si atoms can provide electrons acting as donor, neutralizing the oxygen vacancies at the interface and narrowing the width of the depletion region. The photo-response of a photodetector is a complex process including electron–hole generation, trapping, and recombination.43,44 Figure 5d–f presents the photo-conductance process in the Ga2O3 TFTs. Similarly, electrons flow from Ga2O3 to metal until both Fermi levels line up (see Fig. 5d). A small number of carriers are able to participate in electron transport when applying positive VD in the dark (see Fig. 5f). Upon light-on conditions, electron–hole pairs are generated (hv → e− + h+).41 The photogenerated electrons are trapped in positive charge density in the depletion region.44 After the recombination between the holes and the oxygen vacancies, the uncombined electrons become the major carriers which contribute to the photocurrent. Upon light-off conditions, oxygen molecules reabsorb onto the surface and current reduces to its original value.

Table I lists several key parameters of our Si-doped Ga2O3 solar-blind DUV TFT and other photodetectors based on polycrystalline or amorphous Ga2O3 materials with different device structures. The main parameters of our Si-doped Ga2O3 solar-blind DUV TFT, such as responsivity, detectivity, and Ilight/Idark and response times, are better than most other photodetectors based on polycrystalline or amorphous Ga2O3 materials. Meanwhile, the TFT structure shows its superiority, resulting in a large Ilight/Idark ratio and a lower dark current. Furthermore, various methods have been employed to fabricate Ga2O3 photodetectors with high performance, but there have been no reports on PLD-prepared TFT-type Ga2O3 photodetectors. Our work presents a simple and convenient fabrication process which gives polycrystalline β-Ga2O3 TFTs a high potential for the development of photodetectors in the future.

Conclusions

A solar-blind DUV TFT based on polycrystalline β-Ga2O3 thin film by PLD has been proposed. The Si-doping method greatly increases carrier transport, although it affects the crystal quality of the thin film. The Von of the Si-doped β-Ga2O3 TFT, which works in enhancement mode, was modulated about − 20 V compared to a pure one. The Si-doped Ga2O3 TFT displayed excellent transistor characteristics with a high ID on/off ratio of ~ 105, Ioff of ~ 10−11 A at VD = + 20 V. Both β-Ga2O3 TFTs showed high sensitivity to 254-nm UV light under different light intensities. An R of 3.23 A/W, an EQE of 1.5 × 103%, a D* of 4.41 × 1013 Jones and an Ilight/Idark of ~ 103 were achieved at VG = − 5, VD = 20 V for the Si-doped device under 254-nm light illumination with the intensity of 245.9 μW cm−2. Our work provides a new method of Si-doping to improve β-Ga2O3 TFTs, which advances the development of DUV TFTs based on Ga2O3.

References

L. Dong, J. Yu, R. Jia, J. Hu, Y. Zhang, and J. Sun, Self-Powered MSM Deep-Ultraviolet Beta-Ga2O3 Photodetector Realized by an Asymmetrical Pair of Schottky Contacts. Opt. Mater. Express 9, 1191 (2019).

S.J. Pearton, J. Yang, P.H. Cary, F. Ren, J. Kim, M.J. Tadjer, and M.A. Mastro, A Review of Ga2O3 Materials, Processing, and Devices. Appl. Phys. Rev. 5, 011301 (2018).

X. Chen, K. Liu, Z. Zhang, C. Wang, B. Li, H. Zhao, D. Zhao, and D. Shen, Self-Powered Solar-Blind Photodetector with Fast Response Based on Au/beta-Ga2O3 Nanowires Array Film Schottky Junction. ACS Appl. Mater. Interfaces 8, 4185 (2016).

L.-X. Qian, Z.-H. Wu, Y.-Y. Zhang, P.T. Lai, X.-Z. Liu, and Y.-R. Li, Ultrahigh-Responsivity, Rapid-Recovery, Solar-Blind Photodetector Based on Highly Nonstoichiometric Amorphous Gallium Oxide. ACS Photonics 4, 2203 (2017).

Y.-C. Chen, Y.-J. Lu, C.-N. Lin, Y.-Z. Tian, C.-J. Gao, L. Dong, and C.-X. Shan, Self-Powered Diamond/Beta-Ga2O3 Photodetectors for Solar-Blind Imaging. J. Mater. Chem. C 6, 5727 (2018).

H. Wang, H. Chen, L. Li, Y. Wang, L. Su, W. Bian, B. Li, and X. Fang, High Responsivity and High Rejection Ratio of Self-Powered Solar-Blind Ultraviolet Photodetector Based on PEDOT:PSS/beta-Ga2O3 Organic/Inorganic p–n Junction. J. Phys. Chem. Lett. 10, 6850 (2019).

H.A. Mantooth, M.D. Glover, and P. Shepherd, Wide Bandgap Technologies and Their Implications on Miniaturizing Power Electronic Systems. IEEE Trans. Emerg. Sel. Topics Power Electron. 2, 374 (2014).

M. Yu, H. Wang, W. Wei, B. Peng, L. Yuan, J. Hu, Y. Zhang, and R. Jia, Analysis of Electronic Structure and Properties of Ga2O3/CuAlO2 Heterojunction. Appl. Surf. Sci. 568, 150826 (2021).

M. Chen, B. Zhao, G. Hu, X. Fang, H. Wang, L. Wang, J. Luo, X. Han, X. Wang, C. Pan, and Z. Wang, Piezo-Phototronic Effect Modulated Deep UV Photodetector Based on ZnO-Ga2O3 Heterojuction Microwire. Adv. Funct. Mater. 28, 1706379 (2018).

B. Zhao, F. Wang, H. Chen, L. Zheng, L. Su, D. Zhao, and X. Fang, An Ultrahigh Responsivity (9.7 mA W-1) Self-Powered Solar-Blind Photodetector Based on Individual ZnO-Ga2O3 Heterostructures. Adv. Funct. Mater. 27, 1700264 (2017).

K. Arora, N. Goel, M. Kumar, and M. Kumar, Ultrahigh Performance of Self-Powered Beta-Ga2O3 Thin Film Solar-Blind Photodetector Grown on Cost-Effective Si Substrate Using High-Temperature Seed Layer. ACS Photonics 5, 2391 (2018).

S. Oh, C.-K. Kim, and J. Kim, High Responsivity Beta-Ga2O3 Metal-Semiconductor-Metal Solar-Blind Photodetectors with Ultraviolet Transparent Graphene Electrodes. ACS Photonics 5, 1123 (2018).

L. Dong, S. Zhou, K. Pu, C. Yang, B. Xin, B. Peng, and W. Liu, Electrical Contacts in Monolayer Ga2O3 Field-Effect Tansistors. Appl. Surf. Sci. 564, 150386 (2021).

X. Xiao, L. Liang, Y. Pei, J. Yu, H. Duan, T. Chang, and H. Cao, Solution-Processed Amorphous Ga2O3:CdO TFT-Type Deep-UV Photodetectors. Appl. Phys. Lett. 116, 192102 (2020).

J. Bae, H.W. Kim, I.H. Kang, and J. Kim, Dual-Field Plated β-Ga2O3 Nano-FETs with an Off-State Breakdown Voltage Exceeding 400 V. J. Mater. Chem. C 8, 2687 (2020).

Y. Qin, S. Long, Q. He, H. Dong, G. Jian, Y. Zhang, X. Hou, P. Tan, Z. Zhang, Y. Lu, C. Shan, J. Wang, W. Hu, H. Lv, Q. Liu, and M. Liu, Amorphous Gallium Oxide-Based Gate-Tunable High-Performance Thin Film Phototransistor for Solar-Blind Imaging. Adv. Electron. Mater. 5, 1900389 (2019).

Y. Qin, H. Dong, S. Long, Q. He, G. Jian, Y. Zhang, X. Zhou, Y. Yu, X. Hou, P. Tan, Z. Zhang, Q. Liu, H. Lv, and M. Liu, Enhancement-Mode Beta-Ga2O3 Metal-Oxide-Semiconductor Field-Effect Solar-Blind Phototransistor with Ultrahigh Detectivity and Photo-to-Dark Current Ratio. IEEE Electron Device Lett. 40, 742 (2019).

Y. Liu, L. Du, G. Liang, W. Mu, Z. Jia, M. Xu, Q. Xin, X. Tao, and A. Song, Ga2O3 Field-Effect-Transistor-Based Solar-Blind Photodetector with Fast Response and High Photo-to-Dark Current Ratio. IEEE Electron Device Lett. 39, 1696 (2018).

J. Yu, K. Javaid, L. Liang, W. Wu, Y. Liang, A. Song, H. Zhang, W. Shi, T.C. Chang, and H. Cao, High-Performance Visible-Blind Ultraviolet Photodetector Based on IGZO TFT Coupled with p–n Heterojunction. ACS Appl. Mater. Interfaces 10, 8102 (2018).

H. Altuntas, I. Donmez, C. Ozgit-Akgun, and N. Biyikli, Electrical Characteristics of β-Ga2O3 Thin Films Grown by PEALD. J. Alloys Compd. 593, 190 (2014).

C.X. Xu, H. Liu, X.H. Pan, and Z.Z. Ye, Growth and Characterization of Si-Doped β-Ga2O3 Films by Pulsed Laser Deposition. Optic. Mater. 108, 110145 (2020).

K. Henkel, K. Karavaev, M. Torche, C. Schwiertz, Y. Burkov, and D. Schmeißer, Al-Oxynitride Interfacial Layer Investigations for PrXOYon SiC and Si. J. Phys. Conf. Ser. 94, 012004 (2008).

M.K. Yadav, A. Mondal, S. Das, S.K. Sharma, and A. Bag, Impact of Annealing Temperature on Band-Alignment of PLD Grown Ga2O3/Si (100) Heterointerface. J. Alloys Compd. 819, 153052 (2020).

M. Fleischer, W. Hanrieder, and H. Meixner, Stability of Semiconducting Gallium Oxide Thin-Films. Thin Solid Films 190, 93 (1990).

Y. Liu, S.P. Singh, L.M. Kyaw, M.K. Bera, Y.J. Ngoo, H.R. Tan, S. Tripathy, G.Q. Lo, and E.F. Chor, Mechanisms of Ohmic Contact Formation and Carrier Transport of Low Temperature Annealed Hf/Al/Ta on In0.18Al0.82N/GaN-on-Si. ECS J. Solid State Sci. Technol. 4, P30 (2014).

D. Guo, H. Liu, P. Li, Z. Wu, S. Wang, C. Cui, C. Li, and W. Tang, Zero-Power-Consumption Solar-Blind Photodetector Based on Beta-Ga2O3/NSTO Heterojunction. ACS Appl. Mater. Interfaces 9, 1619 (2017).

N. Xu, L.F. Liu, X. Sun, X.Y. Liu, D.D. Han, Y. Wang, R.Q. Han, J.F. Kang, and B. Yu, Characteristics and Mechanism of Conduction/Set Process in TiN/ZnO/Pt Resistance Switching Random-Access Memories. Appl. Phys. Lett. 92, 232112 (2008).

Y. An, S. Wang, L. Duan, J. Liu, and Z. Wu, Local Mn structure and room temperature ferromagnetism in Mn-doped In2O3 films. Appl. Phys. Lett. 102, 212411 (2013).

Y. Berencen, Y. Xie, M. Wang, S. Prucnal, L. Rebohle, and S. Zhou, Structural and Optical Properties of Pulsed-Laser Deposited Crystalline Beta-Ga2O3 Thin Films on Silicon. Semicond. Sci. Technol. 34, 035001 (2019).

J. Kim, M.J. Tadjer, M.A. Mastro, and J. Kim, Controlling the Threshold Voltage of Beta-Ga2O3 Field-Effect Transistors Via Remote Fluorine Plasma Treatment. J. Mater. Chem. C 7, 8855 (2019).

W. Feng, X. Wang, J. Zhang, L. Wang, W. Zheng, P. Hu, W. Cao, and B. Yang, Synthesis of Two-Dimensional Beta-Ga2O3 Nanosheets for High-Performance Solar Blind Photodetectors. J. Mater. Chem. C 2, 3254 (2014).

M. Fang, W. Zhao, F. Li, D. Zhu, S. Han, W. Xu, W. Liu, P. Cao, M. Fang, and Y. Lu, Fast Response Solar-Blind Photodetector with a Quasi-Zener Tunneling Effect Based on Amorphous In-Doped Ga2O3 Thin Films. Sensors 20, 129 (2020).

H. Shen, Y. Yin, K. Tian, K. Baskaran, L. Duan, X. Zhao, and A. Tiwari, Growth and Characterization of Beta-Ga2O3 Thin Films by Sol-Gel Method for Fast-Response Solar-Blind Ultraviolet Photodetectors. J. Alloys Compd. 766, 601 (2018).

X.Z. Liu, P. Guo, T. Sheng, L.X. Qian, W.L. Zhang, and Y.R. Li, Beta-Ga2O3 Thin Films on Sapphire Pre-Seeded by Homo-Self-Templated Buffer Layer for Solar-Blind UV Photodetector. Opt. Mater. 51, 203 (2016).

P. Sen, M. Balasubrahmaniyam, D. Kar, and S. Kasiviswanathan, Size-Dependent Persistent Photocurrent and Its Origin in DC Sputtered Indium Oxide Films Under UV and Sub-Band Gap Illuminations. J. Appl. Phys. 121, 185303 (2017).

P. Sen, D. Kar, R. Laha, M. Balasubrahmaniyam, and S. Kasiviswanathan, Hot Electron Mediated Enhancement in the Decay Rates of Persistent Photocurrent in Gold Nanoparticles Embedded Indium Oxide Films. Appl. Phys. Lett. 114, 211103 (2019).

Z. Alaie, S.M. Nejad, and M.H. Yousefi, Recent Advances in Ultraviolet Photodetectors. Mater. Sci. Semicond. Process. 29, 16 (2015).

L.X. Qian, Y. Wang, Z.H. Wu, T. Sheng, and X.Z. Liu, Beta-Ga2O3 Solar-Blind Deep-Ultraviolet Photodetector Based on Annealed Sapphire Substrate. Vacuum 140, 106 (2017).

W. Kong, G. Wu, K. Wang, T. Zhang, Y. Zou, D. Wang, and L. Luo, Graphene-Beta-Ga2O3 Heterojunction for Highly Sensitive Deep UV Photodetector Application. Adv. Mater. 28, 10725 (2016).

W.J. Yu, Y. Liu, H. Zhou, A. Yin, Z. Li, Y. Huang, and X. Duan, Highly Efficient Gate-Tunable Photocurrent Generation in Vertical Heterostructures of Layered Materials. Nat. Nanotechnol. 8, 952 (2013).

L. Li, E. Auer, M. Liao, X. Fang, T. Zhai, U.K. Gautam, A. Lugstein, Y. Koide, Y. Bando, and D. Golberg, Deep-Ultraviolet Solar-Blind Photoconductivity of Individual Gallium Oxide Nanobelts. Nanoscale 3, 1120 (2011).

J. Ma, and G. Yoo, Surface depletion effect on negative bias stress instability of beta-Ga2O3 (100) nanomembrane FETs. Jpn. J. Appl. Phys. 58, SBBD01 (2019).

D. Guo, J. Wang, C. Cui, P. Li, X. Zhong, F. Wang, S. Yuan, K. Zhang, and Y. Zhou, ZnO@TiO2 Core–Shell Nanorod Arrays with Enhanced Photoelectrochemical Performance. Sol. Energy 95, 237 (2013).

D.Y. Guo, Z.P. Wu, Y.H. An, X.C. Guo, X.L. Chu, C.L. Sun, L.H. Li, P.G. Li, and W.H. Tang, Oxygen Vacancy Tuned Ohmic–Schottky Conversion for Enhanced Performance in Beta-Ga2O3 Solar-Blind Ultraviolet Photodetectors. Appl. Phys. Lett. 105, 023507 (2014).

D. Zhang, W. Zheng, R.C. Lin, T.T. Li, Z.J. Zhang, and F. Huang, High Quality Beta-Ga2O3 Film Grown with N2O for High Sensitivity Solar-Blind-Ultraviolet Photodetector with Fast Response Speed. J. Alloys Compd. 735, 150 (2018).

Acknowledgments

This work was supported by National Natural Science Foundation of China (Grant No. 51972283, Grant No. 91833301) and the Key Research and Development Program of Zhejiang Province (2021C01030).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Shen, L., Pan, X., Zhang, T. et al. Improved β-Ga2O3 Solar-Blind Deep-Ultraviolet Thin-Film Transistor Based on Si-Doping. J. Electron. Mater. 51, 3579–3588 (2022). https://doi.org/10.1007/s11664-022-09599-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-022-09599-3