Abstract

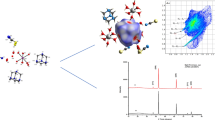

The thermodynamic data of various species in Ni-H2O, Co-H2O, Mn-H2O, and Ni-Co-Mn-H2O systems were obtained by thermodynamic calculation. The potential-pH diagrams for Ni-H2O, Co-H2O, and Mn-H2O systems at different ion activities at 323 K (50 °C), as well as Ni-Co-Mn-H2O complex systems at activity 1.00 at 298 K, 323 K, and 373 K (25 °C, 50 °C, and 100 °C) were constructed, respectively. The costable regions of Ni(OH)2, Co(OH)2, and Mn(OH)2 are verified to be thermodynamically stable in aqueous solution, which indicates the thermodynamic possibility of Ni-Co-Mn hydroxide coprecipitation. The potential-pH diagrams show that the temperature and ion activity have significant effects on the coprecipitation process. As the temperature increases or the ion activity decreases, the coprecipitation region of the Ni-Co-Mn hydroxide narrows. Moreover, the metal oxides, rather than the metal hydroxide, are more easily formed when the temperature increases. Experimental confirmation was performed to further verify the constructed potential-pH diagrams. The Ni-Co-Mn hydroxide with typical hexagonal CdI2 structure and quasi-spherical morphology was successfully obtained, and the SEM results show the uniform distribution of the elements Ni, Co, and Mn. The experimental results confirm the reliability of the prediction of thermodynamics analysis.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

A series of lithium cathode materials,[1] such as LiCoO2, LiNiO2, LiMn2O4, and LiFePO4, have been widely studied to date. LiCoO2[2] is believed to be the state-of-the-art cathode material due to its relative low irreversible capacity loss and good cycling performance. However, the shortage of cobalt resources and the serious pollution post a major threat to its further development. LiNiO2[3] gains its popularity because of a relatively low cost and a higher reversible capacity. However, stoichiometric LiNiO2 is difficult to synthesize due to the formation of lithium deficient compounds during the preparation process. In addition, it shows a poor cycle life when charged to a high voltage. LiMn2O4[4] has been extensively studied due to its low price, good thermal stability, and environmental benignity. However, the application of LiMn2O4 is greatly limited by its electrical capacitance decreasing at high temperatures, which result in decreased electrochemical stability and cycling performance. LiFePO4[5] has been reported with a long working life, high safety performance, and environmental benignity. However, it also shows a low conductivity at room temperature, which has an adverse effect on large power charge-discharge. LiNi1−x−y Co y Mn x O2 (x + y < 1, x > 0, and y > 0) has caused widespread concerns of scholars for its low-cost, stable cycling performance and safety. It has been considered as one of the most promising alternative positive materials for lithium ion batteries.

Several synthesis methods[6] have been developed to obtain LiNi1−x−y Co y Mn x O2 cathode material, such as a solid-state reaction approach,[7,8] a coprecipitation process,[9,10] a sol–gel route,[11] and a spray-pyrolysis method.[12,13] As is known, the physicochemical properties and electrochemical performances of the positive materials are greatly dependent on the morphology, particle size distribution, density, etc. of their precursor. Therefore, a good Ni-Co-Mn hydroxide precursor is a key link in the preparation of the LiNi1−x−y Co y Mn x O2 cathode material with an excellent performance. A Ni-Co-Mn hydroxide precursor with favorable spherical morphology is considered to be a good candidate. It can be obtained by a coprecipitation, sol–gel, or spray-pyrolysis process. However, for the sol–gel approach, a much more time-consuming technological process is necessary. As for the spray-pyrolysis route, it is difficult to realize the commercialization due to equipment limitation. Therefore, the coprecipitation method is widely considered the best choice for synthesizing a uniformly distributed, homogeneous, and phase-pure Ni-Co-Mn hydroxide precursor for LiNi1−x−y Co y Mn x O2 positive material. However, to the best of the authors’ knowledge, few theoretical studies on the thermodynamic analysis of the Ni-Co-Mn hydroxide coprecipitation process have been reported.

Xiao and Ye[14] and Su et al.[15] studied the Me2+-NH3-OH−-H2O (Me = Ni, Co, Mn) coprecipitation system by thermodynamic analysis, and the lg[M]-pH graphs at different ammonia concentrations were constructed. The lg[M]-pH graphs show that every lg[M]-pH curve had an optimum pH for precipitating Ni2+, Co2+, and Mn2+ at the greatest degree at a certain concentration. Hence, the process of the coprecipitation is greatly impacted by the pH and the ammonia concentration. However, it cannot reveal the exact composition of the precipitate. Though a large number of potential-pH diagrams for Ni-H2O,[16,17] Co-H2O,[18] and Mn-H2O systems[19,20] have been published, they are restricted to a single metal-H2O system or a specific activity value. So far, no reports on the potential-pH diagrams for Ni-Co-Mn-H2O complex systems have been found.

In this article, a series of potential-pH diagrams related to the coprecipitation of Ni-Co-Mn hydroxide were studied. The potential-pH diagrams for Ni-H2O, Co-H2O, and Mn-H2O simple systems at various ion activities at 323 K (50 °C), as well as Ni-Co-Mn-H2O complex systems at activity 1.00 at 298 K, 323 K, and 373 K (25 °C, 50 °C, and 100 °C) were constructed for predicting the formation of Ni-Co-Mn hydroxide. The influences of the ion activity and temperature were further discussed. Li(Ni0.5Co0.2Mn0.3)O2, which has excellent electrochemical properties, was considered as one of the most potential cathode materials. Therefore, the precursor (Ni0.5Co0.2Mn0.3)(OH)2 was synthesized under the guidance of the constructed potential-pH diagrams. Results from this are presented in Section IV.

Thermodynamic Calculation and Estimation

All reactions in Me-H2O systems were expressed in the following general form:

The relationship between the Gibbs free energy change of a reaction and the activities of the involved species is

where Δ r G T are \( \Delta_{\text{r}} G_{T}^{\varTheta } \) are the Gibbs free energy change of the reaction at temperature TK and the standard Gibbs free energy change of the reaction under standard condition, respectively, kJ mol−1; R represents the gas constant, J mol−1 K−1; T is the absolute temperature, K; and \( a_{{{\text{H}}_{ 2} {\text{O}}}} \), \( a_{\text{B}} \), \( a_{\text{A}} \), and\( a_{{\text{H}^{ + } }} \)are the activities of H2O, B, A, and H+, respectively. a, n, b, and c are the numbers of A, H+, B, and H2O participating in the reaction.

Based on \( \Delta_{r} G_{T}^{{}} \; = \;-zF\varphi_{T} = \;-2.303n{\text{R}}T\text{pH}_{T}^{{}} \), the potential and pH for the construction of the potential-pH diagrams can be calculated by Eqs. [3] and [4], respectively:

where φ T denotes the electrode potential of the reaction, V; z is the number of the electron participating in the reaction; and F refers to the Faraday constant.

The Gibbs free energy change of each reaction at elevated temperatures can be calculated from the following Equation:[21]

where \( \Delta G_{298}^{\varTheta } \) is the standard Gibbs free change at 298 K (25 °C), \( \Delta \overline{{S_{298}^{\varTheta } }} \) is the absolute entropy value of the species, \( \Delta \overline{{C_{P}^{\varTheta } }} \) is the average heat capacity when temperature changes from 298 K (25 °C) to TK, \( \Delta \overline{{S_{298}^{\varTheta } }} \text{ = }\Delta S_{298}^{\varTheta } + 5n \), and \( \Delta S_{298}^{\varTheta } \) is the relative entropy value of the species.

It has been reported[22] that ignoring the contribution of the heat capacity change has little effect on the Gibbs free energy change of the reactions. Therefore, the heat capacity change in the article was neglected, so Eq. [5] is simplified as

For a solid compound, Latimer[23] proposed an additive method for estimating the standard entropy, in which the element value was assigned to the cation, whereas the value of the anion was variable and dependent on the cation charge.

For the aqueous oxy-anions, Connick and Powell[24] put forward Eq. [7] to calculate the entropies:

where Z is the absolute value of ionic charge and n is the number of O atoms, excluding those included in the hydroxyl groups.

For a complex anion \( \mathop {\text{MX}}\nolimits_{n}^{m - n} \), the method[25] to estimate the entropies is

where \( S_{{\mathop {\text{M}}\nolimits^{m + } }}^{\varTheta } \) is the entropy of the metal cation, \( r_{x}^{ - } \) is the radius of the anion, and the radius of the hydroxyl ion is 1.4.

In order to obtain the standard potential and \( \text{pH}_{T}^{\varTheta } \), the standard Gibbs free energy and standard entropy values of all the elements participating in the reactions should be obtained. The standard Gibbs free energy and standard entropy of various species considered in the Me-H2O system at 298 K (25 °C) were calculated and are given in Appendix A.

\( \varphi_{T}^{\varTheta } \) and \( \text{pH}_{T}^{\varTheta } \)of all the reactions considered in the Me-H2O systems at activity 1.00 and temperatures 298 K, 323 K, and 373 K (25 °C, 50 °C, and 100 °C) were calculated using formulations [3], [4], and [6]. The results are shown in Appendices B and C.

Results and Discussion

The potential-pH diagrams were constructed based on the calculated data listed in Appendices B and C. The potential-pH diagrams in Me-H2O simple systems and the Ni-Co-Mn-H2O complex system are discussed in Sections III–A and III–B.

Potential-pH Diagrams in Me-H2O Simple System (Me = Ni, Co, or Mn)

Assuming the activities of the dissolved species were 0.01, 0.10, and 1.00, the potential-pH diagrams for Ni-H2O, Co-H2O, and Mn-H2O simple systems at different activities at 323 K (50 °C) were constructed, as shown in Figures 1 through 3, respectively.

As shown in Figure 1, nickel occurs in various forms under different conditions in the system. Ni2+ in aqueous solution can be converted into different solids in the form of Ni, Ni(OH)2, Ni3O4, Ni2O3, or NiO2 under different conditions. Especially, Ni2+ is converted into Ni(OH)2 with an increase in pH over 6.71 at activity 0.01, indicating that it is possible to synthesize Ni(OH)2 by adjusting the pH value. The pH range of the stable region of Ni(OH)2 ranges from 6.71 to 14.04, and the potential range is from –0.75 to 0.38 V at activity 0.01 at 323 K (50 °C). The equilibrium line between Ni2+ and Ni(OH)2 is located at pH 6.71 when the species activity is 0.01, which moves toward the negative direction to pH 5.71 at activity 1.00. However, the equilibrium line between Ni(OH)2 and HNiO2 – moves from 14.04 to 16.04 when the activity changes from 0.01 to 1.00, resulting in an expansion of the region of Ni(OH)2. This demonstrates that the precipitation of Ni(OH)2 is more easily conducted as the species activity increases.

The Co-H2O system is similar to Ni-H2O system. As can be seen from Figure 2, Co2+ is hydrolyzed to form Co(OH)2 at pH 5.76 at activity 1.00, which is close to the precipitation pH 5.71 of Ni(OH)2. The equilibrium line between Co2+ and Co(OH)2 is located at pH values 6.76 and 5.76 at activities 0.01 and 1.00, respectively. Therefore, the predominant area of Co2+ shrinks as activity increases, resulting in the larger stability regions of the species in adjacent areas, i.e., Co, Co(OH)2 and Co3O4. Compared with the Ni-H2O system, the potential range of Co(OH)2 is narrower than that of Ni(OH)2.

Comparatively, the Mn-H2O system is more complex. Mn2+ is transformed into Mn(OH)2 at pH 6.89, which is higher than the pH values at which Ni2+ and Co2+ precipitate. The pH range of the predominant region of Mn(OH)2 is from 6.89 to 15.28 at activity 1.00, which is smaller than both Ni(OH)2 and Co(OH)2. However, the potential range of Mn(OH)2 is greater than those of Ni(OH)2 and Co(OH)2. The activity has the same effect on the predominant region of the species in the Mn-H2O system. The predominant region of Mn2+ is minified and that of Mn(OH)2 is expanded at higher activity.

From the preceding discussion, it is clear that Ni2+, Co2+, and Mn2+ can be converted into Ni(OH)2, Co(OH)2, and Mn(OH)2, respectively, under certain conditions. The stable regions of Ni(OH)2, Co(OH)2, and Mn(OH)2 show a similar tendency as activity increases. This finding demonstrates that it is more favorable for the hydrolysis of Me2+ to form Me(OH)2 at a higher activity. However, the activity has no effect on the equilibrium lines of Me/Me(OH)2 and Me3O4/Me(OH)2.

Potential-pH Diagrams in Ni-Co-Mn-H2O Complex System

The potential-pH diagrams for the Ni-Co-Mn-H2O complex system at activity 1.00 at 298 K, 323 K, and 373 K (25 °C, 50 °C, and 100 °C) were constructed as shown in Figures 4, 5 and 6, respectively.

A coprecipitation region of Ni(OH)2, Co(OH)2, and Mn(OH)2 at 298 K (25 °C) was clearly observed in Figure 4, suggesting that the Ni-Co-Mn hydroxide can be synthesized by the coprecipitation method. The pH range of the coprecipitation region is mainly determined by Mn(OH)2, which ranges from 7.51 to 16.48 at 298 K (25 °C). It moves to a lower and more favorable pH range from 5.92 to 13.35 at 373 K (100 °C), suggesting a greater possibility to obtain the coprecipitates of Ni-Co-Mn hydroxide in a weak alkaline solution at elevated temperatures. As can be seen, the top and bottom potential lines of the coprecipitation region are determined by Mn(OH)2 and Ni(OH)2, respectively. The equilibrium potential for Mn(OH)2/Mn3O4 and Mn3O4/Mn2O3 shifts toward the negative direction with increasing temperature. Therefore, metal oxides are considered to be formed easily at a relatively high temperature. As reported in the literature,[26] the Ni-Co-Mn hydroxide precursor obtained at elevated temperature in the coprecipitation process shows a better crystallinity, but with impurity metal oxides such as Mn3O4 and MnO2. The potential-pH diagrams for the Ni-Co-Mn-H2O system provide a good interpretation for the occurrence of the metal oxides.

Experimental Confirmation

For verifying the reliability of the potential-pH diagrams, the experimental tests were conducted in two different aqueous systems: MeSO4-NaOH-H2O and MeSO4-NaOH-NH3-H2O. In the MeSO4-NaOH-H2O system, a mixed aqueous solution of NiSO4, CoSO4, and MnSO4 (all industry grade, from Changsha Deli Xitu Chemical Co., Ltd.) with Ni:Co:Mn = 5:2:3 in the molar ratio was pumped into a continuously stirred tank reactor under nitrogen atmosphere. At the same time, the NaOH solution (analytically pure, Xilong Chemical Co., Ltd.) as a precipitant was also fed into the reactor. The addition of the NaOH solution was carefully controlled to keep the pH values of the solution in the reactor constant at 9 and 10, respectively. The precipitated powders were filtered and washed with deionized water until they were without Cl– and were then dried at 393 K (120 °C).

The crystal structure of the powders was characterized by Rigaku D/max-2500 X-ray powder diffraction using K α radiation. Furthermore, the morphology and composition of the particles were examined by a scanning electron microscope (SEM JEOLFootnote 1 JSM-6360LV) at 20 kV and inductively coupled plasma (ICP IRIS Intrepid II.XSP), respectively.

In the MeSO4-NaOH-NH3-H2O system, the process for obtaining the Ni-Co-Mn hydroxide precursor was similar to that in the MeSO4-NaOH-H2O system. In addition, the ammonia solution (25 to 28 vol pct, Xilong Chemical Co., Ltd.) as a chelating agent was also pumped into the reactor during the precipitation process, and the pH values of the solution in the reactor were controlled at 11 and 12, respectively.

The details of the test conditions are given in Table I, and numerous experiments were performed for each sample set. Typical samples were taken for analysis. The powders, namely, A1 and A2, were prepared from the MeSO4-NaOH-H2O system at pH 10 at 323 K (50 °C) and at pH 9 at 348 K (75 °C), respectively. The powders labeled N1 and N2 were obtained from the MeSO4-NaOH-NH3-H2O system at pH 11 and pH 12 at 323 K (50 °C), respectively.

Figure 7 shows the XRD patterns of the powders synthesized in the MeSO4-NaOH-H2O system. The most intensive peak at around 2θ = 19 deg along with a few more characteristic peaks (100) and (101) were observed in each of the XRD patterns of these two samples. This is in good accordance with the typical M(OH)2 (M = Ni, Co, Mn) structure and can be indexed to hexagonal CdI2 structure. The intensity of sample A2 is stronger than that of A1, demonstrating that elevating temperature is favorable for obtaining precipitates with better crystallinity. No extra diffraction peaks related to secondary phases or impurities were detected in the patterns.

The XRD patterns of samples N1 and N2, as shown in Figure 8, can be indexed with the typical M(OH)2 (M = Ni, Co, Mn) structure, which is consistent with that of A1 and A2, as given in Figure 7. The XRD patterns of the powders obtained from the systems with ammonia were slightly different from those without ammonia. Compared to Figure 7, the diffraction peaks in Figure 8 are narrower and smoother, indicating the significant effect of ammonia as a chelating agent on the crystallinity of Ni-Co-Mn hydroxide precursor.

The obtained solid samples were taken for ICP analysis to identify the contents of the metals. The results are given in Table II. As shown in Table II, the Ni:Co:Mn molar ratios of the precipitates are close to the molar ratio of Ni:Co:Mn of the feed liquid, which equals 5:2:3. Comparatively, the Ni:Co:Mn molar ratios of the samples N1 and N2 obtained from the MeSO4-NaOH-NH3-H2O system are closer than those of A1 and A2. The deviation of the Ni:Co:Mn molar ratios may be related to the different precipitation rates of metals, which result from the nonuniform products. It is suggested that the MeSO4-NaOH-NH3-H2O system is more favorable for accurately controlling the molar ratio of the metals. On the other hand, the NH4 + ion as the chelating agent in the MeSO4-NaOH-NH3-H2O system plays an important role in promoting the formation of the dense and sphere like hydroxide. As is well known, the sphere like hydroxide powders have been considered as an idea precursor for the production of the LiNi1−x−y Co y Mn x O2 cathode materials for lithium ion batteries, and the MeSO4-NaOH-NH3-H2O system has been applied in industry. The contents of Ni, Co, and Mn in the mother liquid were measured, and the results show that high metal yields were obtained from both processes (MeSO4-NaOH-NH3-H2O and MeSO4-NaOH-H2O systems).

Sample N1 with a molar ratio of Ni:Co:Mn of 4.99:2.00:3.01 was selected as the typical sample for further characterization. The SEM images of the powders of N1 are presented in Figure 9. It is obvious that the powders show similar-sphere morphology in secondary particles and the estimated particle size is about 10 to 15 µm in diameter, while the primary particles are needlelike and densely agglomerated in secondary forms.

The preceding experimental results show that Ni-Co-Mn hydroxide powders with molar ratio 5:2:3 of Ni:Co:Mn were successfully synthesized using the coprecipitation method. This is in a good agreement with the presented potential-pH diagrams.

Conclusions

In our work, the potential-pH diagrams of Ni-H2O, Co-H2O, and Mn-H2O simple systems and the Ni-Co-Mn-H2O complex system were constructed. The existence of the costable area of Ni(OH)2, Co(OH)2, and Mn(OH)2 indicates that it is possible to synthesize Ni-Co-Mn hydroxide precursor by a coprecipitation method. It is concluded that the stable region of the Ni-Co-Mn hydroxide is greatly affected by the activities of the aqueous species and the temperature. In the potential-pH diagrams, the predominant region of metal hydroxide is reduced with a decrease in ion activity and an increase in temperature. Furthermore, the formation of the metal hydroxides is easier at elevated temperatures. The Ni-Co-Mn hydroxide precursors were obtained from the two processes (MeSO4-NaOH-NH3-H2O and MeSO4-NaOH-H2O systems) in the verified experiments under the guidance of the given potential-pH diagrams. The experimental results are good, consistent with the constructed potential-pH diagrams. It is indicated that the MeSO4-NaOH-NH3-H2O system is better for the production of the Ni-Co-Mn hydroxide with an accurate composition and a sphere like morphology.

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

References

M.S. Whittingham: Am. Chem. Soc., 2004, vol. 104, pp. 4271–4301.

Y.S. Jung, A.S. Cavanagh, A.C. Dillon, M.D. Groner, S.M George, and S.H Lee: Electrochem. Soc., 2010, vol. 157, pp. A75–A81.

Z.C Liu, H.H Zhen, Y. Kim, and C.D Liang: Power Sources, 2011, vol. 196, pp. 10201–20206.

T.F. Yi, Y.R. Zhu, X.D. Zhu, J. Shu, C.B. Yue, and A.N. Zhou: Ionics, 2009, vol. 15, pp. 779–84.

A. Kuwahara, S. Suzuki, and M. Miyayama: Electroceramics, 2010, vol. 24, pp. 69–75.

D.C Li, T. Muta, L.Q. Zhang, M. Yoshio, and H. Noguchi: Power Sources, 2004, vol. 132, pp. 150–55.

T. Ohzuku and Y. Makimura: Chem. Lett., 2001, vol. 7, pp. 642–43.

X.Y. Jiang, Y. Sha, R. Cai, and Z. Shao: Mater. Chem. A, 2015, vol. 3, pp. 10536–44.

M.H. Lee, Y.J. Kang, S.T. Myung, and Y.K. Sun: Electrochim. Acta, 2004, vol. 50, pp. 939–48.

C. Deng, L. Liu, W. Zhou, K. Sun, and D. Sun: Electrochim. Acta, 2008, vol. 53, pp. 2441–47.

C.H. Chen, C.J. Wang, and B.J. Hwang: Power Sources, 2005, vol. 14, pp. 626–29.

M. Shui, S. Gao, J. Shu, W.D. Zheng, D. Xu, L.L. Chen, L. Feng, and Y.L. Ren: Ionics, 2013, vol. 19, pp. 41–46.

S.H. Park, C.S. Yoon, S.G. Kang, H.S. Kim, S.I. Moon, and Y.K. Sun: Electrochim. Acta, 2004, vol. 49, pp. 557–63.

X.Y. Xiao and Y.Q. Ye: South China Univ. Technol., 2010, vol. 38, pp. 30–34.

J.T. Su, Y.C. Su, and Z.G. Lan: Chin. Batt. Industry, 2008, vol. 13, pp. 18–21.

B. Beverskog and I. Puigdomench: Corros. Sci., 1997, vol. 39, pp. 969–80.

P.A. Brook: Corros. Sci., 1972, vol. 12, pp. 297–306.

J. Chivot, L. Mendoza, C. Mansour, T. Pauporte, and M. Cassir: Corros. Sci., 2008, vol. 50, pp. 62–64.

B. Messaoudi, S. Joiret, M. Keddam, and H. Takenouti: Electrochim. Acta, 2001, vol. 46, pp. 88–90.

S.L. Zhang and Z.L. Liang: Nonferrous Met., 1982, vol. 34, pp. 65–67.

Z.Q. Zhong and G.G. Mei: Application of Diagrams of Chemical Potential in Hydrometallurgy and Purification of Waste Water, Central South University Press, Changsha, 1986, pp. 36–38.

O. Kubaschcwski and C.B. Alcock: Metallurgical Thermochemistry, 5th ed., Metallurgical Industry Press, Beijing, 1985, p. 222.

W.M. Latimer: The Oxidation States of the Elements and Their Potentials in Aqueous Solutions, 2nd ed., Prentice-Hall, New York, NY, 1952, pp. 359–65.

R.E. Connick and R.E. Powell: Chem. Phys., 1953, vol. 21, pp. 2006–07.

K.X. Tan, Q.L. Wang, and H.S. Wang: Rong Jin Cai Kuang Re Li Xue He Dong Li Xue, Central South University Press, ChangSha, 2003, pp. 35–36.

S. Zhang, C. Deng, B.L. Fu, S.Y. Yang, and L. Ma: Power. Technol., 2010, vol. 198, pp. 373–80.

J.G. Speight: Lange’s Handbook of Chemistry, 16th ed., McGraw-Hill, New York, NY, 2004, pp. 1246–59.

S.M. Wen, Z.W. Zhao, and G.S. Huo: Chin. Power Sources, 2005, vol. 29, pp. 423–25.

C.H. Guo, Z.W. Zhao, and G.S. Huo: Chin. J. Power Sources, 2005, vol. 29, pp. 376–78.

R.L. Cowan and R.W. Staehle: Electrochem. Soc., 1971, vol. 118, pp. 557–59.

C.X. Lin, Z.H. Bai, and Z.R. Zhang: Handbook of Minerals and Related Thermochemical Data, Science Press, Beijing, 1985, p. 36.

Z.W. Zhao and G.S. Huo: Chin. J. Nonferrous Met., 2004, vol. 14, pp. 1926–33.

Acknowledgments

The authors are grateful for the financial support from the Government of Guangxi Zhuang Autonomous Region (Glorious Laurel Scholar Program No. 2011A025).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 19, 2016.

Appendices

Appendix A

See Table AI.

Appendix B

See Table BI.

Appendix C

See Table CI.

Rights and permissions

About this article

Cite this article

Li, L., Li, Y., Li, L. et al. Thermodynamic Analysis on the Coprecipitation of Ni-Co-Mn Hydroxide. Metall Mater Trans B 48, 2743–2750 (2017). https://doi.org/10.1007/s11663-017-0985-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-0985-x